Press release

How to Check the "Cutting Edge" After a Tungsten Carbide Blades are Made

How to Check the "Cutting Edge" After a Tungsten Carbide blades are Made? We can think of it as :giving a final inspection to the armor and weapons of a general about to go into battle.I. What Tools or equipment Are Used for Inspection?

1. "Extension of the Eyes" - Optical Magnifiers:

Tools: Bench magnifiers, illuminated magnifiers, stereomicroscopes.

What they're for: This is the most common, first-step inspection. Just like using a magnifying glass to examine an antique, it magnifies the cutting edge several times to several dozen times to check for obvious "wounds" on a macro level.

2."Precision Ruler" - Profilometer/Surface Roughness Tester:

Tools: Specialized tool profilometers (with a precision probe).

What they're for: This one is impressive. It doesn't rely on sight. Instead, an ultra-fine probe gently traces along the cutting edge, mapping it out like drawing a map, and generates a precise computer image of the edge's exact shape and smoothness. Whether the rake angle, clearance angle, and edge radius meet the design specifications is revealed instantly.

3. "Super Microscope" - Electron Microscope:

Tools: Scanning Electron Microscope (SEM).

What they're for: Used when you need to "solve a mystery," to find extremely tiny (nanoscale) defects or coating issues. It sees in extreme detail, revealing the microscopic world invisible to ordinary microscopes.

II. What Possible Flaws We should pay attention to?During inspection, just like looking for smudges on a face, focus mainly on these types of "flaws":

1. Chips/Edge Breaks:

They look like: Small, irregular notches on the cutting edge, as if chipped off by a tiny stone. This is the most obvious defect.

Why it is not good: They will leave raised marks or scratches on the workpiece surface during machining and cause the tool itself to degrade rapidly.

2. Micro-chipping/Serrated Edge:

What they are: Under the microscope, the edge appears uneven, like tiny serrations. Less obvious than large chips, but very common.

Why they're bad: Affects cutting sharpness and finish quality, accelerating tool wear.

3. Coating Defects:

They shows: Tools usually have a super-hard coating (like non-stick pan coating). Defects may include peeling, bubbling, uneven color, or incomplete coverage (exposing the yellowish tungsten carbide underneath).

Why they sucks: The coating is the "protective suit." Areas with defects will wear out first, causing the tool to fail prematurely.

4. Uneven Edge/ Burrs:

What they look like: The edge radius or chamfer is uneven-wider in some spots, narrower in others; or there are tiny material overhangs (burrs).

Why it bad: Affects the stability of cutting forces and chip evacuation, reducing machining precision.

5. Cracks:

What they look like: Hairline lines appearing on or near the cutting edge. This is a very dangerous defect.

Why they're bad: Under cutting forces, cracks can easily propagate, leading to sudden tool breakage, which is very hazardous.

About Huaxin: Tungsten Carbide Cemented Slitting Knives Manufacturer

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD are a professional supplier and manufacturer of tungsten carbide products, such as carbide insert knives for woodworking, carbide circular knives for tobacco&cigarette filter rods slitting, round knives for corugatted cardboard slitting ,three hole razor blades/slotted blades for packaging, tape, thin film cutting, fiber cutter blades for textile industry etc.

With over 25 years development, our products have been exported to U. S. A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia etc. With excellent quality and competitive prices, Our hard working attitude and responsiveness are approved by our customers. And we would like to establish new business relationships with new customers. Contact us today and you will enjoy benefits of good quality and services from our products!

The high performance tungsten carbide industrial blades products

Image: https://www.huaxincarbide.com/uploads/fiber-cutting-blades.png

Staple fiber cutter blade

Image: https://www.huaxincarbide.com/uploads/Circular-knives-for-cigarette-filter-slitting.png

Circular knives for cigarette filter slitting

Image: https://www.huaxincarbide.com/uploads/%CF%86260X%CF%86158X1.5-8-holes1.png

Circular knives for corrugated packaging industry [https://www.huaxincarbide.com/circular-knives-for-corrugated-packaging-industry-product/]

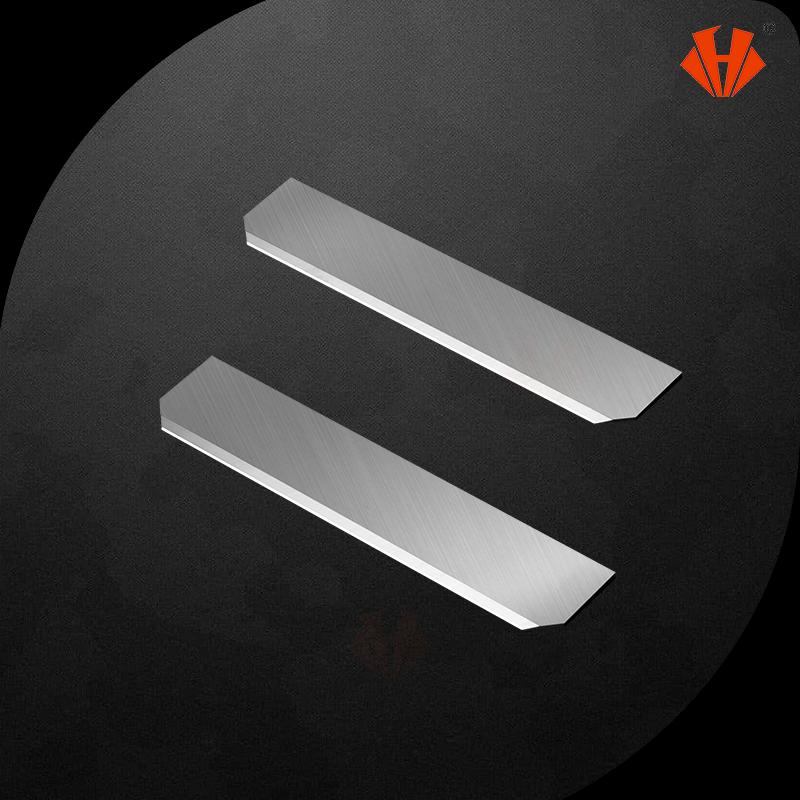

Image: https://www.huaxincarbide.com/uploads/huaxin-woodworking-carbide-blades.png

Carbide blades for woodworking [https://www.huaxincarbide.com/tungsten-carbide-knives-for-planers/]

Image: https://www.huaxincarbide.com/uploads/3-hole-slotted-double-edege-blades.png

Carbide blades for tape, thin film industry [https://www.huaxincarbide.com/carbide-blades-for-tapethin-film-industry/]

Image: https://www.huaxincarbide.com/uploads/Utility-Knife-Blades.png

utility knife

Custom Service

Huaxin Cemented Carbide manufactures custom tungsten carbide blades, altered standard and standard blanks and preforms, starting from powder through finished ground blanks. Our comprehensive selection of grades and our manufacturing process consistently delivers high-performance, reliable near-net shaped tools that address specialized customer application challenges across diverse industries.

Tailored Solutions for Every Industrycustom-engineered bladesLeading manufacturer of industrial blades

Click to contact for custom industrial knives [https://www.huaxincarbide.com/contact-us/]

Follow us: to get Huaxin's industrial blades products releases

Customer common questions and Huaxin answersWhat is the delivery time?

What is the delivery time for custom-made knives?

What payment methods do you accept?

About custom sizes or specialized blade shapes?

Sample or test blade to ensure compatibilityStorage and Maintenance

Media Contact

Company Name: Chengdu HUAXIN cemented carbide Co., Ltd

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=how-to-check-the-cutting-edge-after-a-tungsten-carbide-blades-are-made]

Country: China

Website: https://www.huaxincarbide.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Check the "Cutting Edge" After a Tungsten Carbide Blades are Made here

News-ID: 4305949 • Views: …

More Releases from ABNewswire

Garage Door Installation Resource for Beltsville MD Homeowners Established by Ne …

Neighborhood Garage Door Repair Of Laurel provides consistent garage door installation for Beltsville, MD. Through regional familiarity, the firm supports residential, emergency garage door installation, and commercial garage door installation needs. This steady presence ensures the community has access to essential services and professional support without reliance on external providers, reinforcing long-term property safety and operational standards.

Introduction: garage door Installation in Beltsville MD

Garage door Installation [https://www.neighborhood-gds.com/service-areas/laurel-md/#/media-room:~:text=appeal%20with%20professional-,garage%20door%20installation,-.%20Our%20experts%20ensure] services are now widely…

Emergency Garage Door Repair at Neighborhood Garage Door Repair Of Laurel Focuse …

Neighborhood Garage Door Repair Of Laurel continues to provide emergency repair services for properties across Beltsville MD, supporting access reliability and mechanical system balance. Through consistent service availability and region-specific operational knowledge, Neighborhood Garage Door Repair Of Laurel remains positioned within the local repair ecosystem as a dependable option for residents and businesses requiring timely garage door support.

Introduction: Emergency garage door repair in Beltsville MD

Emergency garage door repair [https://www.google.com/search?Emergency+garage+door+repair&kgmid=/g/11kjq4v8ft] services…

Garage Door Installation Solutions for Columbia MD Now Feature Enhanced Support …

Neighborhood Garage Door Repair Of Columbia is a vital resource for Columbia, MD, offering dependable garage door repair. With a focus on responsiveness, the company provides consistent support for residential and commercial clients, including emergency garage door repair and commercial garage door repair. Local residents can rely on their professional, timely solutions for long-term regional engagement and secure, reliable property maintenance.

Garage Door Repair in Columbia MD

Neighborhood Garage Door Repair Of…

Gother Targets Top 3 Travel Platform in Thailand

Image: https://www.abnewswire.com/upload/2026/02/63983da43450dd663ec390c6080abc6d.jpg

Thai-built platform Gother accelerates growth with AI, lifestyle services, and major banking app integration to redefine travel for the next-gen market.

Gother, a rising star in Thailand's digital travel landscape, is setting its sights on becoming one of the country's top three travel platforms by 2026. Operated by Search Engine Optimization Co., Ltd.-a joint venture between Beacon Venture Capital (Kasikornbank) and Krungthai Ventures (Krungthai Bank)-Gother has seen rapid adoption since…

More Releases for Carbide

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…