Press release

Refrigerated Warehouse Automation Hardware Market Outlook 2035: Rising Cold Chain Complexity and High-Tech Infrastructure Driving Growth Toward US$ 16.0 Billion by 2035

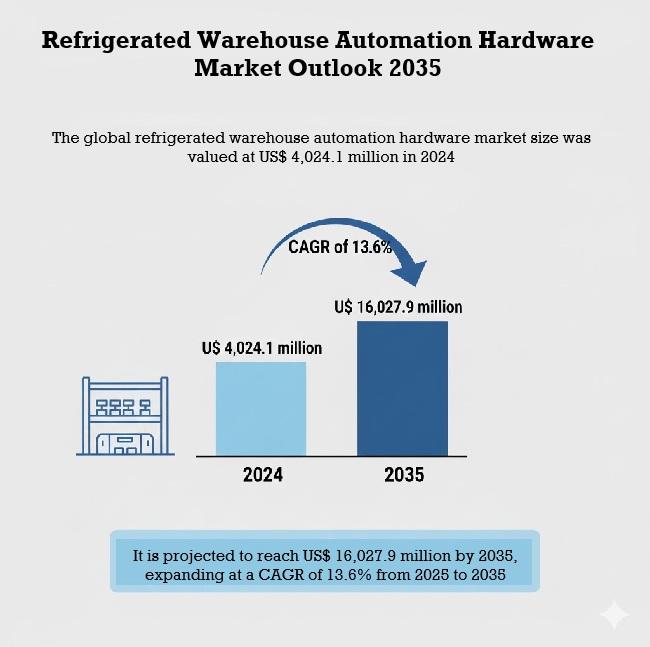

The global refrigerated warehouse automation hardware market is undergoing rapid expansion as industries increasingly rely on efficient, technologically advanced cold storage solutions. Valued at US$ 4,024.1 million in 2024, the market is expected to grow at a CAGR of 13.6% from 2025 to 2035, reaching US$ 16,027.9 million by 2035. The need to manage temperature-sensitive goods-ranging from pharmaceuticals and vaccines to fresh produce, meat, and frozen foods-is rising sharply worldwide. This demand is driving companies to embrace automation hardware that enhances storage efficiency, reduces labor dependency, minimizes spoilage, and ensures regulatory compliance. As global supply chains become more complex, automated refrigerated warehouses are evolving from optional upgrades to operational necessities.Dive Deeper into Data: Get Your In-Depth Sample Now!

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86819

Introduction

The refrigerated warehouse automation hardware market includes a broad array of automated systems such as palletizers, conveyors, automated storage and retrieval systems (AS/RS), robotic picking devices, shuttle systems, sensor-based monitoring solutions, and energy-efficient cooling technologies. These systems are designed to optimize temperature-controlled environments, reduce energy consumption, maintain consistent product integrity, and improve traceability across the cold supply chain.

In a world where e-commerce grocery platforms, pharmaceutical companies, and food producers face soaring demand and heightened expectations for product freshness and speed, the importance of automation hardware cannot be understated. Cold chain operators increasingly seek scalable, intelligent systems capable of supporting 24/7 operations. The push for digital transformation, coupled with labor shortages in warehouse operations, is further accelerating adoption of advanced automation hardware.

Key Market Drivers

One of the strongest market drivers is the expansion of the global cold chain logistics sector, propelled by shifting consumer preferences toward fresh and frozen food products. E-commerce grocery platforms and quick-commerce delivery services have raised expectations for rapid, accurate, and temperature-controlled deliveries. At the same time, pharmaceutical and biotech industries require precise storage and handling of vaccines, biologics, and temperature-sensitive drugs, intensifying the need for reliable automated cold storage hardware.

Labor challenges represent another major growth driver. Traditional refrigerated warehouses are labor-intensive environments with harsh working conditions, leading to high employee turnover and increasing operational inefficiencies. Automation hardware solves these challenges by reducing dependency on manual labor while improving accuracy and safety.

Energy efficiency is also driving adoption. Refrigerated warehouses are among the most energy-consuming industrial facilities. Automation hardware integrated with energy-optimizing components-such as high-efficiency compressors, smart cooling systems, and thermal-insulated automated storage units-helps operators significantly reduce costs. Additionally, stringent regulatory standards governing food safety and pharmaceutical integrity necessitate precise temperature control and traceability, which fully automated systems are uniquely capable of delivering.

Technology Landscape

The technology landscape of refrigerated warehouse automation hardware is experiencing rapid innovation. Automated Storage and Retrieval Systems (AS/RS) remain at the core, providing high-density storage and rapid movement of goods while minimizing human exposure to sub-zero environments. Modern shuttle-based AS/RS technologies allow multi-deep storage, improving capacity utilization and throughput.

Robotic material handling systems-including robotic palletizers, automated guided vehicles (AGVs), and autonomous mobile robots (AMRs)-are increasingly integrated into refrigerated settings. These robots are designed to function efficiently in low-temperature, high-humidity environments using advanced sensors and ruggedized hardware. Vision-guided robotic picking systems are becoming more common, enabling precise item retrieval even in dimly lit, cold conditions.

The integration of real-time monitoring hardware, including IoT sensors, RFID technologies, and digital temperature tracking systems, is reshaping warehouse operations. These devices enable predictive maintenance, remote diagnostics, and real-time temperature alerts, reducing product loss and downtime.

Recent advancements also include energy-efficient refrigeration technologies, insulated conveyor systems, high-speed automated doors, and smart lighting solutions designed for cold environments. Advanced warehouse management systems (WMS) and digital twins support hardware optimization by simulating workflows and improving resource allocation.

Market Challenges

Despite significant opportunity, several challenges could influence the growth trajectory of the refrigerated warehouse automation hardware market. One of the primary obstacles is the high capital investment required for installation, integration, and maintenance of automated cold storage systems. Many small and medium-sized cold chain operators struggle to absorb these costs, particularly in emerging economies.

Another challenge is the complexity of system integration. Automated systems need seamless interoperability among robotics, AS/RS, refrigeration units, sensors, and software. Poor integration can lead to downtime and operational inefficiencies. Additionally, maintaining hardware in low-temperature environments requires specialized engineering expertise.

Space constraints represent another limitation, especially in urban settings where e-grocery fulfillment centers and micro-warehouses operate. Retrofitting older cold storage facilities with heavy automation hardware can be costly and complicated.

Data security and cyberrisk also pose increasing challenges, as automated warehouses rely heavily on networked systems and IoT-enabled hardware. Any disruption or breach could hinder operations, particularly for pharmaceutical cold chains requiring continuous monitoring.

Buy Now: https://www.transparencymarketresearch.com/checkout.php?rep_id=86819<ype=S

Regional Insights

The refrigerated warehouse automation hardware market displays strong regional variation depending on industrialization, cold chain maturity, and investment capacity.

North America holds a leading share due to robust demand for frozen and fresh food, advanced pharmaceutical supply chains, and strong e-commerce penetration. The U.S. continues to invest heavily in automation to address labor shortages, improve food safety, and enhance logistics efficiency.

Europe shows strong adoption driven by strict food safety regulations, sustainability targets, and the need for high-efficiency refrigeration systems. Countries such as Germany, the Netherlands, and the U.K. are at the forefront of automated cold chain technology deployment.

Asia Pacific is the fastest-growing regional market. Expanding middle-class populations, rising consumption of processed and frozen foods, and rapid growth in pharmaceutical manufacturing are fueling demand. China, Japan, South Korea, and India are emerging hotspots for new refrigerated warehouse projects. Government investments in cold chain logistics across India and Southeast Asia are accelerating automation adoption.

Latin America and Middle East & Africa represent emerging markets where modernization of the cold chain is gaining momentum. Increased agricultural exports, rising food imports, and growing retail supermarket chains are creating the need for automated refrigerated infrastructure, though cost constraints remain a barrier.

Competitive Landscape

The competitive landscape of the refrigerated warehouse automation hardware market is defined by intense innovation, strategic partnerships, and a focus on system customization. Leading players are investing in ruggedized robotics, advanced AS/RS systems, and IoT-enabled monitoring hardware designed specifically for extreme temperature environments. Companies are also expanding their portfolios with energy-efficient compressor systems, high-performance conveyors, and automated pallet-handling technologies.

AutoStore AS

Daifuku Co., Ltd.

Geekplus Technology Co., Ltd.

Honeywell International Inc.

IHI Corporation

Kardex Holding AG

KION GROUP AG

KNAPP AG

Krones

KUKA SE & Co. KGaA

Mecalux S.A

Murata Machinery

Prime Robotics

SSI SCHÄFER GMBH & CO KG

TGW Logistics Group GmbH

Vanderlande Industries B.V.

Others

Collaborations between hardware manufacturers, cold chain logistics providers, food companies, and pharmaceutical distributors are becoming increasingly common as end users demand highly tailored systems. Many major vendors are pursuing geographic expansion, particularly in Asia Pacific, to capture rising demand from the region's booming refrigerated storage sector.

Future Outlook

Looking ahead, the refrigerated warehouse automation hardware market is poised for substantial growth as cold chain complexity intensifies worldwide. Technological advancements will continue to drive adoption, with robotics, AI-driven optimization, digital twins, and predictive maintenance tools becoming standard features in next-generation cold storage facilities. Energy efficiency will remain a priority, pushing companies to adopt greener refrigeration technologies and automation hardware that lowers operating costs.

Growing global dependence on temperature-sensitive pharmaceuticals, biologics, and food products will ensure sustained investment in automated cold infrastructure. By 2035, fully autonomous refrigerated warehouses-with robots handling every stage of product movement-will become increasingly common. As the market approaches US$ 16.0 billion, automation hardware will serve as the backbone of the global cold supply chain, supporting reliability, efficiency, and product integrity across industries.

Explore Latest Research Reports by Transparency Market Research:

Metal Powder Market: https://www.transparencymarketresearch.com/metal-powder-market.html

Carrier Screening Market: https://www.transparencymarketresearch.com/carrier-screening-market-report.html

Oncology Information System (OIS) Market: https://www.transparencymarketresearch.com/oncology-information-system-market.html

Dermatoscope Market: https://www.transparencymarketresearch.com/dermatoscope-market-report.html

Brain Computer Interface Market: https://www.transparencymarketresearch.com/brain-computer-interface-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact Us:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Refrigerated Warehouse Automation Hardware Market Outlook 2035: Rising Cold Chain Complexity and High-Tech Infrastructure Driving Growth Toward US$ 16.0 Billion by 2035 here

News-ID: 4305439 • Views: …

More Releases from Transparency Market Research

Power Lawn and Garden Equipment Market Size Forecast to USD 188.4 Billion by 203 …

Power Lawn and Garden Equipment Market Outlook 2036

The global power lawn and garden equipment market was valued at US$ 93.9 Billion in 2025 and is projected to reach US$ 188.4 Billion by 2036, expanding at a steady CAGR of 6.6% from 2026 to 2036. Market growth is driven by increasing residential landscaping activities, rising demand for battery-powered equipment, expanding commercial landscaping services, and growing consumer interest in outdoor aesthetics.

👉 Get…

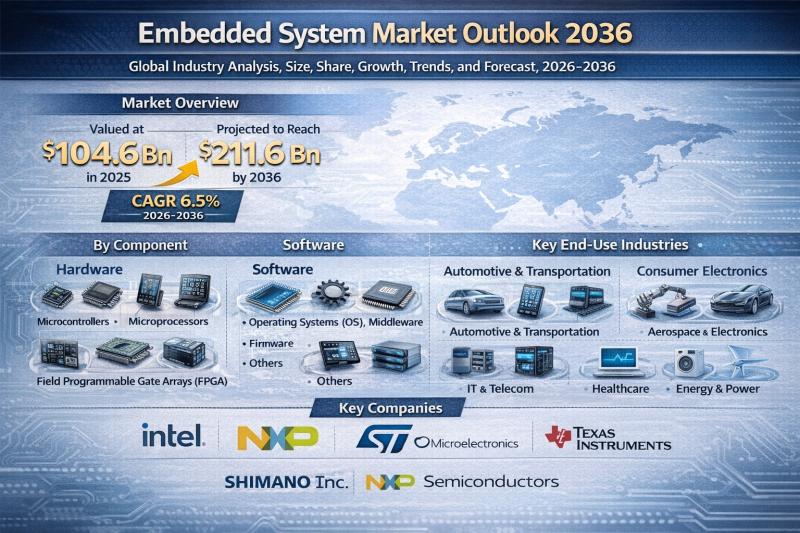

Global Embedded System Market to Reach USD 211.6 Bn by 2036, Expanding at 6.5% C …

The global embedded system market is poised for steady and sustained growth over the next decade, driven by rapid digital transformation across industries. Valued at US$ 104.6 Bn in 2025, the market is projected to reach US$ 211.6 Bn by 2036, expanding at a CAGR of 6.5% from 2026 to 2036. The increasing integration of embedded systems in automotive electronics, industrial automation, and IoT-enabled devices is positioning the industry as…

Industrial Fasteners Market Outlook 2036: Global Industry to Reach US$ 146.5 Bil …

The global industrial fasteners market was valued at US$ 104.6 Bn in 2025 and is projected to reach US$ 146.5 Bn by 2036, expanding at a steady CAGR of 3.1% from 2026 to 2036. The industry reflects consistent, volume-driven growth supported by expanding construction activities, infrastructure modernization, automotive production, and aerospace engineering advancements.

Between 2021 and 2024, the market demonstrated stable recovery post-pandemic, driven by revived industrial production and capital investments…

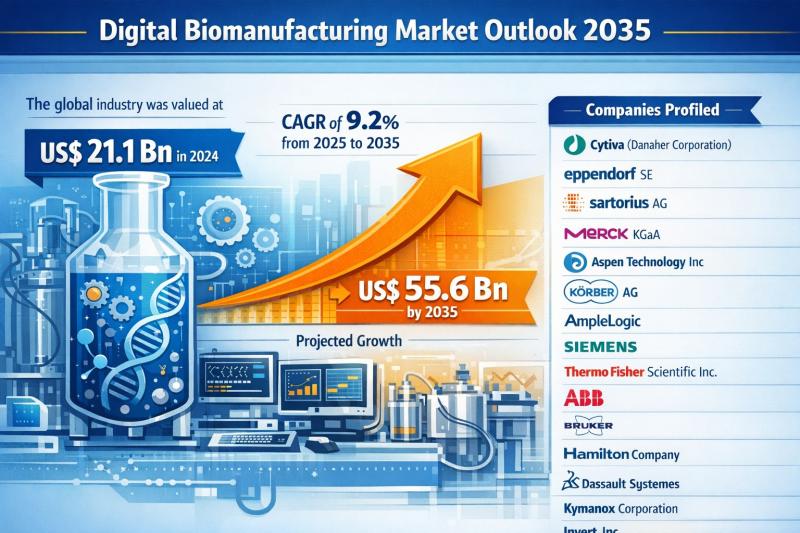

Digital Biomanufacturing Market Outlook 2035: AI-Driven MES, PAT, and Digital Tw …

The global digital biomanufacturing market was valued at US$ 21.1 Bn in 2024 and is projected to expand at a robust CAGR of 9.2% from 2025 to 2035, crossing US$ 55.6 Bn by the end of 2035. The strong double-digit expansion trajectory underscores the accelerating adoption of digital tools across biologics production facilities worldwide.

Between 2020 and 2024, the market witnessed steady adoption, supported by rapid digitalization efforts following pandemic-driven supply…

More Releases for Automation

Amvel Automation: Revolutionizing Industrial Processes through Automation

Amvel Automation, a leading automatic gates manufacturer in India, is transforming the industrial landscape with its cutting-edge automation solutions. With a strong focus on innovation and excellence, Amvel Automation is empowering industries to increase efficiency, productivity, and safety.

Comprehensive Automation Solutions

Amvel Automation offers a wide range of automation products and services, including:

Automatic Gates: Sliding gates, swinging gates, and rolling shutters for secure and convenient access control.

Industrial Automation: PLC-based automation solutions for…

Linear Transfer Systems Market to Witness Huge Growth by 2028 | ATS Automation, …

Linear Transfer Systems Market research report provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets. It also offers an in-depth examination of new product launches, recent developments, untapped geographies, and recent developments. Moreover, the report also provides intelligent insights on future technologies, R&D activities, and breakthrough product developments.

Click Here For Free Sample + Related Graphs of the Report at: https://www.reportsnreports.com/contacts/requestsample.aspx?name=6210965

This research report…

Linear Transfer Systems Market Top Key Players Focused - ATS Automation, Rockwel …

“Linear Transfer Systems Market” report explores manufacturer’s competitive scenario and provides market share for all major players of this market based on production capacity, sales, revenue, geographical presence and other major factors. The report also covers import/export data across all major regions covered in this report.

Download Sample PDF copy of this report @ https://www.upmarketresearch.com/home/requested_sample/65246

The key players covered in this study

ATS Automation

Rockwell Automation

Beckhoff Automation

Preh IMA Automation

Ruhlamat

Afag

Motion Index Drives

Pematech

TAKTOMAT

Haberkorn

Innovative Automation

Mecsmart Systems

Meto-Fer

This…

Linear Transfer Automation Market Size 2018 by Top Key Players and Application w …

The Linear Transfer Automation report offers a comprehensive evaluation of the market. It does so via in-depth insights, understanding market evolution by tracking historical developments, and analyzing the present scenario and future projections based on optimistic and likely scenarios. Each research report serves as a repository of analysis and information for every facet of the market

This report studies the global Linear Transfer Automation market status and forecast, categorizes…

Home Automation and Control Market Report 2018: Segmentation by Type (Home Autom …

Global Home Automation and Control market research report provides company profile for Schneider Electric SA, Vantage Controls, Crestron Electronics, Inc., iControl Networks Inc., Control4 Corporation, Honeywell International Inc., AMX LLC, Johnson Controls, ADT Corporation, Siemens AG, 2GIG Technologies and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume,…

Digital Process Automation Market Report 2018: Segmentation by Component, Busine …

Global Digital Process Automation market research report provides company profile for IBM (US), Appian (US), DST Systems (US), OpenText (Canada), K2 (US), Bizagi (England), DXC (US), Infosys (India), Oracle (US), Pegasystems (US), Tibco (US) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY…