Press release

Polylactic Acid Production Plant Cost Analysis Report 2025: Machinery and Technology Requirements

The Polylactic Acid (PLA) Production Plant CostA polylactic acid (PLA) production plant is a facility that makes high purity PLA biopolymer from renewable plant derived raw materials for corn starch, sugarcane, glucose or other plant-derived feedstocks. A normal PLA production plant ferments the sugars in raw materials into lactic acid. Then the plant converts the lactic acid into the thermoplastic biodegradable polymer PLA by polycondensation. Because of high pre-investment capital costs involved in establishing such a facility, the site-specific design of a polylactic acid production cost facility requires careful planning.

Unveiling the World of Polylactic Acid (PLA)

Polylactic acid (PLA) is a biodegradable and bioactive thermoplastic aliphatic polyester made from renewable biomass feedstock, that can be found in numerous agricultural crops and used in a wide range of applications. Due to the common use of PLA, the polylactic acid production plant forms an important part of the global green chemistry and sustainable materials industry.

What is Polylactic Acid (PLA) Used For?

The packaging industry is another potential application for PLA, as a biodegradable alternative to petroleum-based resins for making food containers, plastic films, and bottles. In medicine it is used to make sutures, implants, drug delivery systems and other medical devices because of its biocompatibility and moderate degradation rates. Other uses include 3D printing filaments, textiles, agricultural films, and disposable cutlery. The sheer variety of applications led to interest in calculating the cost of production for polylactic acid (PLA).

Get the Sample Report: https://www.imarcgroup.com/polylactic-acid-manufacturing-plant-project-report/requestsample

Key Factors for PLA Plant Setup Requirements

Establishing a PLA plant requires careful consideration of several key factors that directly impact both the initial plant setup cost and long-term profitability.

• Raw Materials and Feedstock Supply: The cost and availability of primary raw materials like corn starch, sugarcane, or other fermentable carbohydrates are paramount. A secure and cost-effective supply chain is vital for managing the PLA production cost.

• Production Technology and Equipment: The choice between direct condensation polymerization or ring-opening polymerization (ROP) via lactide, as well as the selection of fermentation vessels, reactors, distillation columns, and extrusion equipment, directly influences efficiency and the final polylactic acid (PLA) production cost.

• Environmental Compliance and Approvals: Securing environmental clearances and adhering to local regulations for waste disposal, emissions, and sustainability standards is a non-negotiable step. This ensures sustainable operations and avoids costly penalties.

• Location and Infrastructure: Proximity to agricultural feedstock sources and end markets, along with access to a reliable power supply, water resources, and transportation networks, significantly impacts operational efficiency and overall polylactic acid production cost analysis.

Detailed Process Flow and Quality Control

The manufacturing process for PLA involves a series of meticulously controlled unit operations. Initially, the biomass feedstock is converted to fermentable sugars, which are then fermented by bacteria to produce lactic acid. The lactic acid is purified, converted to lactide through oligomerization and depolymerization, and finally polymerized via ring-opening polymerization to form high molecular weight PLA. A thorough polylactic acid (PLA) production plant report would detail each of these steps.

• Unit Operations Involved: The process includes key stages such as biomass pretreatment, fermentation, lactic acid purification, lactide formation, polymerization, devolatilization, and pelletization. Each step is carefully managed to ensure optimal conversion and product quality.

• Mass Balance and Raw Material Requirements: A precise mass balance calculation is essential for determining the exact quantity of feedstock, enzymes, catalysts, and other chemicals needed per unit of finished product. This directly influences the total polylactic acid (PLA) production cost.

• Quality Assurance Criteria: Quality is assessed based on molecular weight, optical purity, crystallinity, and thermal properties. Technical tests, including differential scanning calorimetry (DSC), gel permeation chromatography (GPC), and mechanical property analysis, are performed to meet stringent industry standards.

Factors Influencing PLA Production Costs

The overall polylactic acid (PLA) production cost is a complex interplay of various factors. A detailed PLA production cost analysis is essential for a profitable venture.

CapEx and OpEx Analysis for Polylactic Acid (PLA) Production Cost:

• Raw Material Costs: As the largest component of variable costs, the price of agricultural feedstocks and fermentation substrates is a major determinant of the final product's cost. Fluctuations in commodity prices can significantly impact profitability.

• Capital Investment: The initial plant setup cost for machinery, fermentation facilities, polymerization reactors, land, and construction constitutes a significant barrier to entry. This one-time expense is amortized over the life of the plant.

• Operational Costs: These include fixed costs like labor, maintenance, and insurance, as well as variable costs such as utilities (power, water, and steam), enzyme costs, and waste treatment.

• Grade and Purity: The final application of the PLA product dictates the required purity and grade. Higher grades, such as medical or food-contact grade, require more extensive purification and quality control, which increases the polylactic acid (PLA) production cost.

• Molecular Weight and Properties: The desired molecular weight and crystallinity of the final product impacts the polymerization conditions, processing time, and energy consumed during manufacturing, directly influencing the polylactic acid production cost.

• Location and Market Conditions: The geographical location influences transportation costs for raw materials and finished goods. Additionally, local market conditions, demand for sustainable materials, and regulatory incentives affect pricing and revenue.

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=8631&flag=C

Leading Polylactic Acid (PLA) Manufacturers

The market for PLA is dominated by several key global players who lead the industry in innovation and production capacity. These manufacturers set the benchmark for quality and scale.

• NatureWorks LLC

• TotalEnergies Corbion bv

• JIANGSU SUPLA BIOPLASTICS CO., LTD.

• COFCO

• Futerro

• Jiangxi Keyuan Biopharm Co.,Ltd.

Browse Related Reports:

Ethoxylates Production Plant Cost: https://www.imarcgroup.com/ethoxylates-manufacturing-plant-project-report

Ferric Oxide Production Plant Cost: https://www.imarcgroup.com/ferric-oxide-manufacturing-plant-project-report

Oxalic Acid Production Plant Cost: https://www.imarcgroup.com/oxalic-acid-manufacturing-plant-project-report

Polyester Films Production Plant Cost: https://www.imarcgroup.com/polyester-films-manufacturing-plant-project-report

Sodium Erythorbate Production Plant Cost: https://www.imarcgroup.com/sodium-erythorbate-manufacturing-plant-project-report

Threonine Production Plant Cost: https://www.imarcgroup.com/threonine-manufacturing-plant-project-report

Aluminum Bromide Production Plant Cost: https://www.imarcgroup.com/aluminum-bromide-manufacturing-plant-project-report

Ammonium Citrate Production Plant Cost: https://www.imarcgroup.com/ammonium-citrate-manufacturing-plant-project-report

Conclusion:

A successful Polylactic Acid (PLA) production plant requires a thorough understanding of the entire process, from initial plant setup and production cost analysis to market dynamics. The industry is continuously evolving, driven by growing demand for sustainable materials and advancements in biotechnology. By carefully managing feedstock sourcing, optimizing fermentation and polymerization processes, and adhering to strict quality standards, manufacturers can navigate the complexities of the market. Ultimately, a comprehensive polylactic acid (PLA) production plant report is essential for any company or investor aiming to thrive in this rapidly expanding bio-based materials sector.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polylactic Acid Production Plant Cost Analysis Report 2025: Machinery and Technology Requirements here

News-ID: 4304775 • Views: …

More Releases from IMARC Group

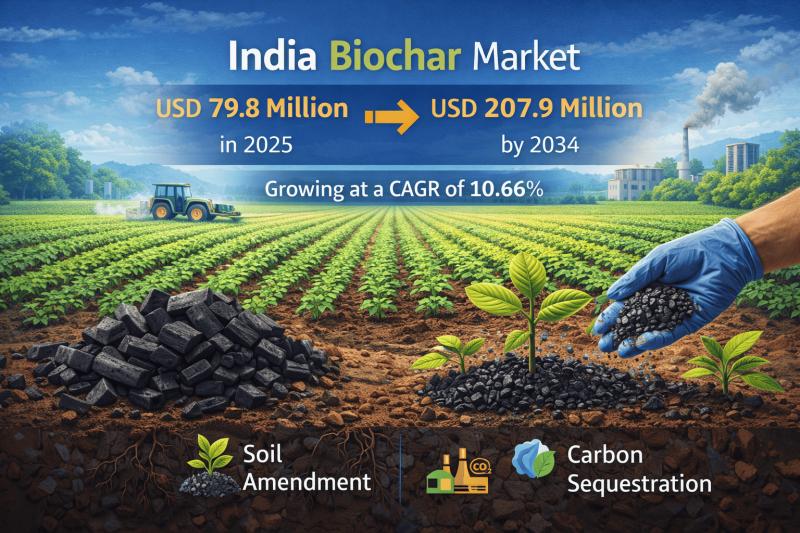

India Biochar Market Expected to Reach USD 207.9 Million by 2034, Industry Growi …

IMARC Group's latest research publication "India Biochar Market Size, Share, Trends and Forecast by Feedstock Type, Technology Type, Product Form, Application, and Region, 2026-2034" the India biochar market size reached USD 79.8 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 207.9 Million by 2034, exhibiting a growth rate (CAGR) of 10.66% during 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-biochar-market/requestsample

What is Biochar?

Biochar is a carbon-rich material produced through…

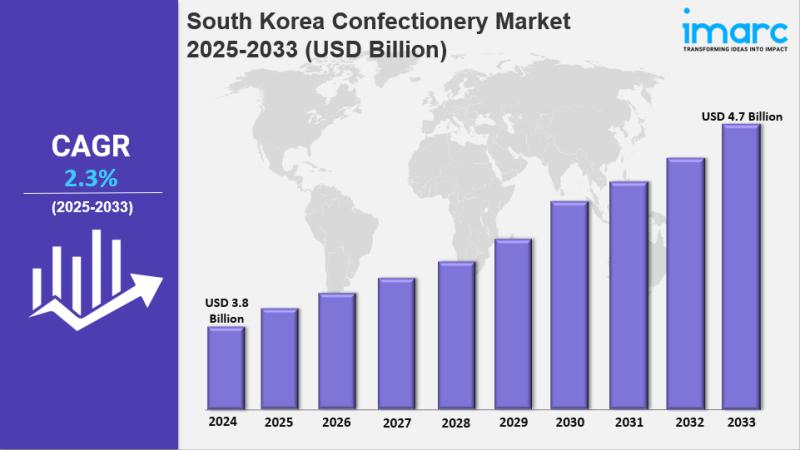

South Korea Confectionery Market Size, Growth, Latest Trends and Forecast To 203 …

IMARC Group has recently released a new research study titled "South Korea Confectionery Market Report by Product Type (Hard-Boiled Sweets, Mints, Gums and Jellies, Chocolate, Caramels and Toffees, Medicated Confectionery, Fine Bakery Wares, and Others), Age Group (Children, Adult, Geriatric), Price Point (Economy, Mid-Range, Luxury), Distribution Channel (Supermarkets and Hypermarkets, Convenience Stores, Pharmaceutical and Drug Stores, Online Stores, and Others), and Region 2025-2033", offers a detailed analysis of the market…

India Facility Management Market Expected to Reach USD 7.13 Billion by 2034, Ind …

IMARC Group's latest research publication "India Facility Management Market Size, Share, Trends and Forecast by Solution, Service, Deployment Type, Organization Size, Vertical, and Region, 2026-2034" The India facility management market size was valued at USD 2.86 Billion in 2025 and is projected to reach USD 7.13 Billion by 2034, growing at a compound annual growth rate of 10.66% from 2026-2034.

Request a Sample Report: https://www.imarcgroup.com/india-facility-management-market/requestsample

What is Facility Management?

Facility management refers to…

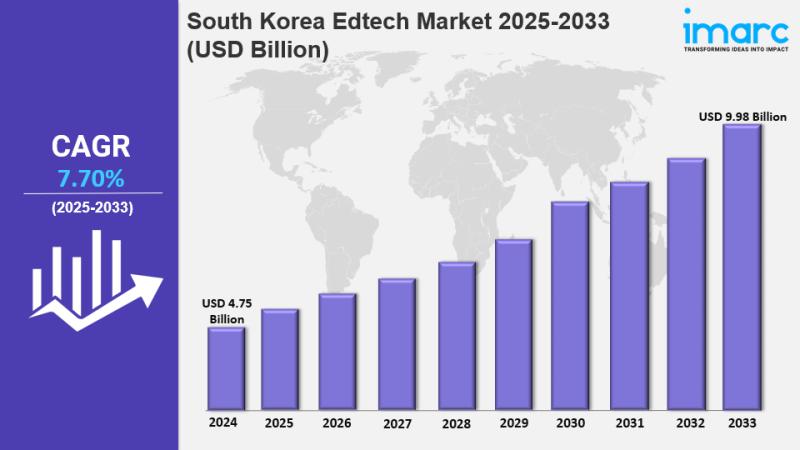

South Korea Edtech Market Share, Size, In-Depth Insights, Trends and Forecast To …

IMARC Group has recently released a new research study titled "South Korea Edtech Market Report by Sector (Preschool, K-12, Higher Education, and Others), Type (Hardware, Software, Content), Deployment Mode (Cloud-based, On-premises), End User (Individual Learners, Institutes, Enterprises), and Region 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview:

South Korea edtech market size reached USD…

More Releases for PLA

How Compostable PLA Straws Help the Environment

Compostable PLA straw [https://www.naturecutlery.com/qh-st-5-5-x-200-mm-biodegradable-pla-drinking-straw-in-bulk-package-2-product/]s are emerging as one of the key solutions to the global plastic crisis. Made from renewable materials like corn starch, these straws are an eco-friendly alternative to traditional plastic straws. Here's a closer look at how compostable PLA straws can have a positive impact on the environment and why they're a smart choice for businesses focused on sustainability.

1. Reduce Plastic Waste Accumulation

Traditional plastic straws are single-use…

Polylactic Acid (PLA) Market Growth Opportunities and Competitive Landscape Repo …

Polylactic acid (PLA) is a biodegradable thermoplastic polymer made from renewable resources such as corn starch or sugar cane. Unlike other thermoplastics, PLA can be degraded by microorganisms over time, making it an attractive material for sustainable and biodegradable products.

Key Trends

One of the major trends in PLA technology is the development of new and improved methods for PLA production. For example, catalysis of the conversion of lactic acid to PLA…

Polylactic Acid (PLA) Market Insights by 2031 & Covid-19 Analysis | Total Corbio …

Global Polylactic Acid (PLA) Market report from Global Insight Services is the single authoritative source of intelligence on Polylactic Acid (PLA) Market. The report will provide you with analysis of impact of latest market disruptions such as Russia-Ukraine war and Covid-19 on the market. Report provides qualitative analysis of the market using various frameworks such as Porters' and PESTLE analysis. Report includes in-depth segmentation and market size data by categories,…

Bio-polylactic Acid (PLA) Films Market Size, Status and Global Outlook During 20 …

MarketInsightsReports has published a report titled global Bio-polylactic Acid (PLA) Films Market research report 2020 that is a detailed observation of several aspects, including the rate of growth, technological advances, and different methodologies implemented by the primary current market players. The report is based on a collective analysis of data, which is obtained through primary and secondary research. It provides a systematic approach to the current and prospective scenario of…

Polylactic Acid (PLA) Market May See Exponential Growth in Future | BASF SE; Dan …

This Polylactic Acid (PLA) Market research report involves six major parameters namely market analysis, market definition, market segmentation, key developments in the market, competitive analysis, and research methodology. Competitive analysis is the major aspect of any market research report and by understanding this many points are covered in the report including strategic profiling of key players in the market, analyse their core competencies, and draw a competitive landscape for the…

Growth of Bio-polylactic Acid (PLA) Films Market | Top Vendors- NatureWorks, Fut …

Global Bio-PLA Films Market was valued at $354 million in 2016, and is anticipated to reach $910 million by 2023, growing at a CAGR of 14.5% from 2017 to 2023.

The key players profiled in the report are NatureWorks LLC, Futerro, Tale & Lyle, Total Corbion PLA, Hiusan Biosciences, Toray Industries, Inc., Taghleef Industries, Amcor Ltd. Toyobo, and Avery Dennison Corporation.

The other major players (not profiled in report) in the…