Press release

Medical Tape Manufacturing Plant 2025: Complete Project Report on Setup, Machinery & Profitability

IntroductionMedical tape is an essential adhesive product used across healthcare settings to secure dressings, bandages, catheters, and medical devices to the skin. It is designed to offer strong adhesion while being gentle, breathable, and safe for prolonged skin contact. Unlike ordinary adhesive tapes, medical tape is manufactured using specialized materials such as non-woven fabrics, foam, paper, polyethylene, and silicone-based adhesives to reduce irritation and accommodate sensitive or fragile skin. These tapes are engineered for flexibility, moisture resistance, and ease of removal without damaging the skin. Their applications span hospitals, clinics, homecare, wound management, surgery, and sports medicine. With increasing focus on patient comfort, infection control, and advanced wound-care solutions, medical tape has become a critical component of modern healthcare systems.

Request for a Sample Report: https://www.imarcgroup.com/medical-tape-manufacturing-plant-project-report/requestsample

Market Drivers and Outlook

The global medical tape market is expanding due to the rising number of surgical procedures, growing prevalence of chronic wounds, and increasing emphasis on patient safety and proper wound care management. Hospitals and healthcare facilities are adopting skin-friendly and hypoallergenic tapes to minimize irritation, particularly for aging populations with delicate skin. Additionally, advancements such as silicone-based medical tapes, breathable waterproof materials, antimicrobial coatings, and stretchable designs are enhancing product performance and patient comfort.

The surge in home healthcare services, sports injury treatments, and demand for cost-effective wound management products further contribute to market growth. Government healthcare spending, rising awareness of infection prevention, and the growing adoption of single-use medical consumables are fueling demand, particularly across North America, Europe, and Asia-Pacific. Continuous innovation in adhesive technology and the shift toward biodegradable, latex-free, and skin-sensitive medical tapes are expected to propel the market in the coming years.

Medical Tape Manufacturing Plant Report Overview

IMARC Group's new report titled "Medical Tape Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a detailed roadmap for setting up a medical tape manufacturing facility. It covers every essential aspect of entering the medical tape market-from raw material sourcing to plant operations and financial planning.

The report includes an in-depth assessment of setup costs, capital investments, infrastructure requirements, machinery selection, and production workflows. It is an essential resource for entrepreneurs, investors, researchers, business strategists, and industry stakeholders seeking to evaluate feasibility and profitability in the medical tape manufacturing sector.

Medical Tape Manufacturing Plant Machinery Breakdown

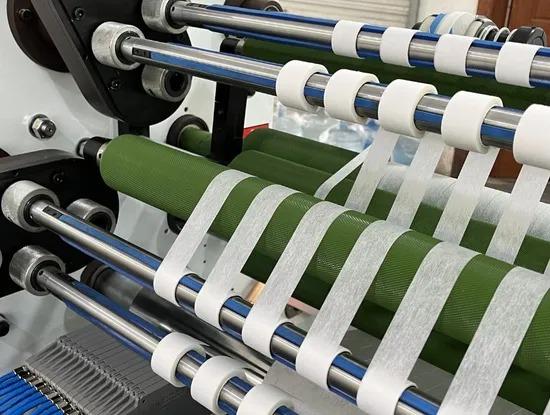

A medical tape manufacturing plant uses a series of specialized machines designed to coat, laminate, slit, and package adhesive materials efficiently while ensuring product quality and compliance with medical standards.

• Coating Machine: Applies adhesive uniformly onto the backing material to create the tape base.

• Laminating Machine: Bonds the adhesive-coated layer with release liners or protective films.

• Slitting Machine: Cuts large adhesive rolls into precise tape widths for various applications.

• Rewinding Machine: Rewinds slit tapes into consistent, smooth rolls ready for packaging.

• Packing Machine: Automatically seals, labels, and packs medical tape rolls for distribution.

Buy Full Report: https://www.imarcgroup.com/checkout?id=16269&method=2142

Benefits of Using a Medical Tape Manufacturing Unit

A medical tape manufacturing unit enhances production efficiency, ensures consistent product quality, and supports large-scale supply to meet the growing demand for medical consumables.

• Consistent Quality Control: Ensures uniform adhesion, durability, and safety standards across all tape batches.

• Cost-Effective Production: Reduces manufacturing costs through streamlined workflows and automated machinery.

• High Production Capacity: Enables large-volume output to meet hospital, clinic, and medical device industry demand.

• Customization Flexibility: Allows production of various tape types, including surgical, silicone, paper, and waterproof tapes.

• Improved Market Competitiveness: Supports faster delivery, better product variety, and higher profitability in the medical consumables sector.

Key Steps: Manufacturing Process and Technical Workflow

This section provides comprehensive insights into the technical processes involved in manufacturing medical tape, covering unit operations, production flow, and quality control standards. It includes detailed information on raw materials, mass balance, testing methods, and performance benchmarks that ensure product safety and compliance with medical standards.

Aspects Covered

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests (adhesion strength, biocompatibility, tensile strength, peel force, skin irritation tests)

Infrastructure and Setup Requirements

This section presents a full analysis of the infrastructure and planning considerations for establishing a medical tape manufacturing plant. It includes guidance on land selection, environmental compliance, plant layout, and critical cost factors. Additional insights are provided on machinery, utilities, packaging, transportation, and manpower.

Components Covered

• Land, Location and Site Development

• Plant Layout and Design Considerations

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Financial Projections and Economic Viability

This section analyzes the financial feasibility of setting up a medical tape manufacturing plant. It includes projections for capital expenditure (CapEx), operating expenditure (OpEx), taxation, depreciation, and profitability. Detailed financial models such as NPV, ROI, break-even analysis, and sensitivity analyses provide clarity on long-term profitability.

Aspects Covered

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis (NPV, IRR, Payback Period)

Frequently Asked Questions

• What are the raw material requirements for medical tape manufacturing?

• How much does it cost to set up a medical tape production plant?

• Which machinery is needed for medical tape production?

• Is medical tape manufacturing a profitable business in 2025?

Ask an Analyst for Customization Report: https://www.imarcgroup.com/request?type=report&id=16269&flag=C

Key Considerations for Plant Design and Operations

• Production Capacity: Align machinery selection and plant layout with the desired output-ranging from small-scale units to large industrial operations.

• Automation Levels: Options include semi-automatic and fully automated systems, depending on labor availability and capital budget.

• Location Adaptation: Choose a strategic site with access to raw materials, skilled labor, medical-grade packaging suppliers, and logistics hubs.

• Product Flexibility: Ensure the capability to produce various types of medical tapes such as surgical tape, silicone tape, paper tape, waterproof tape, and sports tape.

• Sustainability Features: Integrate renewable energy, manage waste efficiently, and implement eco-friendly raw material options (e.g., latex-free adhesives).

• Raw Material Sourcing: Secure reliable suppliers for adhesives, backing materials, release liners, and packaging to maintain consistent production quality.

About Us:

IMARC Group is a leading global market research and management consulting firm. We specialize in helping organizations identify opportunities, mitigate risks, and create impactful business strategies.

Our expertise includes:

• Market Entry and Expansion Strategy

• Feasibility Studies and Business Planning

• Company Incorporation and Factory Setup Support

• Regulatory and Licensing Navigation

• Competitive Analysis and Benchmarking

• Procurement and Supply Chain Research

• Branding, Marketing, and Sales Strategy

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Medical Tape Manufacturing Plant 2025: Complete Project Report on Setup, Machinery & Profitability here

News-ID: 4304656 • Views: …

More Releases from IMARC Group

Hydrogen Fluoride Manufacturing Plant DPR 2026: Investment Cost, Market Growth & …

Setting up a hydrogen fluoride manufacturing plant positions investors within a strategically important segment of the global specialty chemicals and fluorochemicals industry, driven by increasing demand for semiconductor manufacturing, refrigerant production, and pharmaceutical intermediates. As modern industrial processes advance, electronics manufacturing expands, and the need for high-purity fluorine compounds grows, hydrogen fluoride continues to gain traction across semiconductor fabrication, aluminum production, and petroleum refining worldwide. Rising demand from high-tech industries,…

Vinyl Acetate Ethylene Production Plant Cost 2026: Industry Overview and Profita …

Setting up a Vinyl Acetate Ethylene Production Plant positions investors in one of the most stable and essential segments of the specialty chemicals and polymer value chain, backed by sustained global growth driven by growing construction activity, rising demand for high-performance dry-mix mortars, increasing use in paints and coatings, and the dual-benefit advantages of delivering flexible, low-VOC polymer binder solutions that meet both industrial performance standards and evolving environmental compliance…

Fluff Pulp Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/Op …

Setting up a fluff pulp manufacturing plant positions investors within a strategically important segment of the global hygiene products and absorbent materials industry, driven by increasing demand for disposable hygiene products, absorbent personal care items, and medical applications. As consumer hygiene standards advance, disposable product adoption expands, and the need for high-quality absorbent materials grows, fluff pulp continues to gain traction across baby diapers, adult incontinence products, feminine hygiene items,…

Fire Alarms Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Pro …

Setting up a fire alarms manufacturing plant positions investors within a strategically important segment of the global safety and security equipment industry, driven by increasing demand for fire detection and safety systems, stringent building safety regulations, and growing awareness of fire protection measures. As modern construction practices advance, smart building integration expands, and the need for advanced fire safety infrastructure grows, fire alarms continue to gain traction across commercial buildings,…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…