Press release

PEM Electrolyzer Manufacturing Plant: Costs, Setup, and Market Opportunities Explained

Introduction - Overview of a Proton Exchange Membrane (PEM) Electrolyzer Manufacturing Plant:Setting up a Proton Exchange Membrane (PEM) electrolyzer manufacturing plant presents a high-growth opportunity in the clean hydrogen sector. PEM electrolyzers are advanced hydrogen-generation systems that split water into hydrogen and oxygen using a solid polymer membrane as the electrolyte. They are valued for their high energy efficiency, rapid response times, compact design, and compatibility with renewable energy sources such as solar and wind.

With rising global demand for green hydrogen in industries such as power generation, mobility, chemicals, and refining, this article provides a project-report-style overview of the PEM electrolyzer production process, plant setup requirements, economic feasibility, and strategic opportunities.

Market Overview & Trends - Surging Demand for Green Hydrogen Technology:

The PEM electrolyzer market is rapidly expanding due to increasing global emphasis on carbon-neutral energy. Governments and industries are investing heavily in green hydrogen infrastructure, driving demand for scalable and efficient electrolyzer technologies. Key market trends include the development of multi-megawatt electrolyzer systems, integration with renewable power grids, modular electrolyzer designs, advancements in catalyst technology (platinum/iridium), and the shift toward mass manufacturing to reduce cost per kW.

Growth opportunities lie in hydrogen refueling stations, ammonia production, steel decarbonization, synthetic fuels, and large-scale renewable hydrogen hubs.

See the Data First: Download Your Sample: https://www.imarcgroup.com/proton-exchange-membrane-electrolyzer-manufacturing-plant-project-report/requestsample

Technical Aspects / Manufacturing Process - How PEM Electrolyzers Are Produced:

Manufacturing PEM electrolyzers involves precision engineering and advanced materials. The process begins with preparing the Membrane Electrode Assemblies (MEA), where catalysts are deposited onto a proton-conductive polymer membrane. Bipolar plates (made of titanium-coated or graphite-based materials) are machined and coated to ensure conductivity and corrosion resistance.

The electrolyzer stack is assembled by combining MEAs, gaskets, bipolar plates, and end plates under controlled pressure. The assembled stack undergoes leak testing, performance testing, and durability validation.

Key raw materials include proton exchange membranes, iridium/platinum catalysts, titanium components, graphite plates, seals and gaskets, power electronics, sensors, and enclosure materials.

Quality control focuses on catalyst loading, membrane integrity, conductivity, efficiency rating, hydrogen purity, pressure resistance, and long-term durability metrics.

Plant Setup Requirements - Machinery, Layout & Infrastructure:

A Proton Exchange Membrane (PEM) electrolyzer manufacturing plant requires a highly controlled environment with specialized machinery and cleanroom facilities. The plant layout typically includes:

• MEA fabrication section

• Catalyst coating area

• Bipolar plate machining and coating line

• Stack assembly section

• Testing and diagnostics laboratory

• Power electronics integration zone

• Packaging and warehousing

Essential machinery includes membrane coating machines, catalyst deposition systems, CNC machining tools, coating chambers, precision assembly stations, hydrogen leak detectors, pressure testing units, electrical testing benches, and automated quality-inspection equipment.

Infrastructure requirements include stable power supply, ventilation, cleanrooms (ISO standards), gas handling systems, ESD-safe assembly zones, water purification units, and hydrogen safety systems such as detectors and emergency controls.

Project Economics - CapEx, OpEx & Profit Potential:

Establishing a PEM electrolyzer manufacturing plant involves significant capital expenditure due to the specialized nature of the materials and equipment. CapEx includes land development, cleanroom facilities, precision machinery, stack testing units, catalyst handling systems, and working capital. Operating expenses include catalysts (platinum/iridium), membranes, titanium components, energy consumption, skilled labor, maintenance, packaging, and quality testing.

Revenue is generated through sales of electrolyzer stacks, complete electrolyzer systems, service contracts, replacement parts, and integration solutions.

Profitability is influenced by production scale, material sourcing, automation levels, and long-term supply agreements with hydrogen developers. Rising investment in green hydrogen globally significantly enhances market potential.

Risk Factors & Success Strategies - Ensuring Reliability and Competitive Advantage:

Key risks include high raw material costs (especially catalysts), supply-chain constraints, rapid technological advancements, and stringent hydrogen safety standards. Additionally, competition from alkaline and solid oxide electrolyzer technologies may affect market share.

Success strategies include investing in R&D for catalyst loading optimization, adopting advanced membrane-coating techniques, securing long-term contracts with hydrogen project developers, forming technology partnerships, and implementing automation to reduce manufacturing costs. Certification compliance and robust safety protocols strengthen market competitiveness.

Request a Customized Project Report for Your Capacity: https://www.imarcgroup.com/request?type=report&id=28026&flag=C

Conclusion - Feasibility and Future Potential of PEM Electrolyzer Manufacturing:

A Proton Exchange Membrane (PEM) electrolyzer manufacturing plant is a highly promising and future-ready investment aligned with global energy transition goals. With advanced manufacturing capabilities, strong quality control, and strategic market positioning, investors can build a scalable and profitable facility supporting the worldwide expansion of green hydrogen production.

FAQs - PEM Electrolyzer Manufacturing Plant Setup:

1. What raw materials are required for PEM electrolyzer manufacturing?

A. Proton exchange membranes, platinum/iridium catalysts, titanium or graphite bipolar plates, gaskets, seals, and power electronics.

2. What machinery is essential for a PEM electrolyzer manufacturing facility?

A. Catalyst coating machines, membrane processing units, CNC machining tools, coating chambers, assembly stations, leak testers, and diagnostics instruments.

3. What factors influence the production cost of PEM electrolyzers?

A. Catalyst cost, membrane technology, titanium component pricing, energy usage, labor skill level, and quality testing systems.

4. Are PEM electrolyzers profitable to manufacture?

A. Yes-demand for green hydrogen is rising rapidly, and PEM electrolyzers offer premium margins due to high efficiency and strong industry adoption.

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release PEM Electrolyzer Manufacturing Plant: Costs, Setup, and Market Opportunities Explained here

News-ID: 4302283 • Views: …

More Releases from IMARC Group

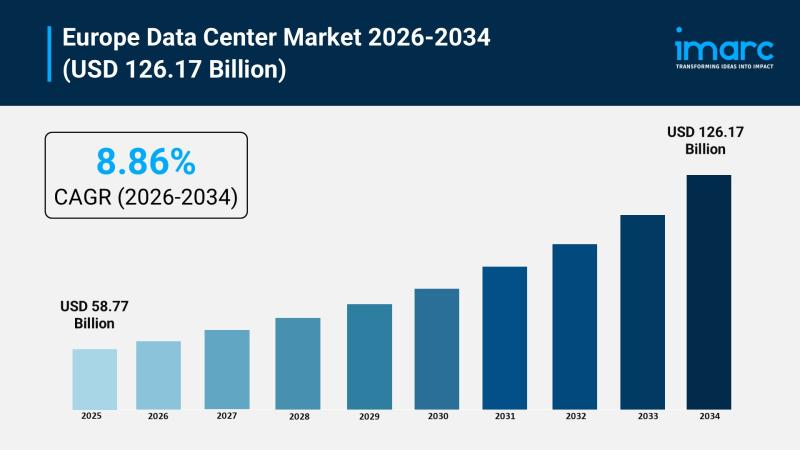

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

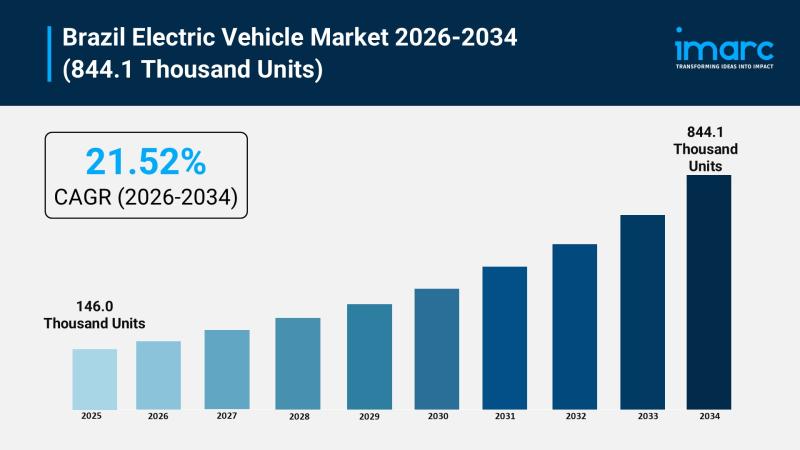

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for PEM

PEM Electrolyzer Market to Witness 30.42% CAGR Growth by 2034

According to Market Research Future analysis, the PEM Electrolyzer Market was valued at USD 0.66 Billion in 2024 and is projected to grow from USD 0.86 Billion in 2025 to USD 9.12 Billion by 2034, recording a CAGR of 30.42% during the forecast period.

The global focus on clean energy and decarbonization has accelerated the adoption of Proton Exchange Membrane (PEM) electrolyzers, a key technology for producing green hydrogen. PEM electrolyzers…

PEM Electrolyzer Market Trends, Key Players & Future Scope 2034

On April 10, 2025, Exactitude Consultancy., Ltd. announces the release of the report "Global PEM Electrolyzer Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2034". The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across…

Power Entry Module PEM Market Size 2024 to 2031.

Market Overview and Report Coverage

A Power Entry Module (PEM) is an electrical component that combines a power plug with circuit protection components, such as a fuse or circuit breaker, in a single unit. These modules are commonly used in electronic devices and equipment to provide a convenient and safe way to connect to power sources.

The Power Entry Module PEM Market is expected to experience significant growth in the…

PEM Electrolyzer Market - Know the Untapped Revenue Growth Opportunities

PEM Electrolyzer Market to reach over USD 2304.37 million by the year 2031 - Exclusive Report by InsightAce Analytic

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global PEM Electrolyzer Market Size, Share & Trends Analysis Report By End-User (refining industry, power & energy storage, ammonia production, methanol production, transportation) And Material Type (iridium, platinum)- Market Outlook And Industry Analysis 2031"

The global PEM electrolyzer market…

PEM Electrolyzer Market Current Scenario with Forecast to 2031

PEM Electrolyzer Market to reach over USD 2304.37 million by the year 2031 - Exclusive Report by InsightAce Analytic

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global PEM Electrolyzer Market Size, Share & Trends Analysis Report By End-User (refining industry, power & energy storage, ammonia production, methanol production, transportation) And Material Type (iridium, platinum)- Market Outlook And Industry Analysis 2031"

The global PEM electrolyzer market…

HT-PEM Membrane Electrode Assemblies (HT-PEM MEA) Market Research Report: Types, …

Global Info Research announces the release of the report "Global HT-PEM Membrane Electrode Assemblies (HT-PEM MEA) Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands…