Press release

Fatty Alcohol Ethoxylates (FAE) Production Plant 2025: Market Growth, Machinery Cost, & Capital Investment

Setting up a fatty alcohol ethoxylates (FAE) production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Fatty Alcohol Ethoxylates (FAE) Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a fatty alcohol ethoxylates (FAE) production plant cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/fatty-alcohol-ethoxylates-manufacturing-plant-project-report/requestsample

What is Fatty Alcohol Ethoxylates (FAE)?

Fatty alcohol ethoxylates (FAE) are non-ionic surfactants generated out of natural or synthetic fatty alcohols via ethoxylation. These surface-active substances are good surfactants with outstanding capability that both reduces the surface and interfaces. As a result of their high detergency and wetting properties, excellent solubility and emulsification characteristics, FAEs are among the most widely used surfactants in detergents, personal care products, textile treatment, agrochemicals and industrial cleaning products. FAEs are multifunctional, as the degree of ethoxylation can be adjusted to make them suitable for a wide variety of applications. As they are biodegradable and compatible with other surfactants, they can be used in a wide range of applications.

What is Driving the Fatty Alcohol Ethoxylates (FAE) Market?

The global fatty alcohol ethoxylates market is driven by the increasing demand of biodegradable and natural surfactants for home care, personal care, and industrial applications. People want ecological and lasting goods that do less damage to the earth. Manufacturers are shifting their investments towards bio-based fatty alcohols from vegetable oils such as palm, coconut, and rapeseed to improve the environmental profile of FAEs. Legislators legislate the use of less hazardous biodegradable chemicals corporations commit to clean production and parties reduce carbon emissions these actions drive the growth of such products. The move to more concentrated and high-efficiency cleaning detergents is driving demand for FAEs due to their wetting and emulsifying properties.

Some of the factors driving growth in the industry are an increase in industrial end-use applications and production in Asia-Pacific countries, increasing per capita disposable income, increasing manufacturing facilities, as well as more efficient ethoxylation processes, catalyst systems, and supply chain integration, which together reduce costs and enable product customizations. The agricultural sector, in turn, is also increasing demand for FAEs, which are in use in pesticide and herbicide formulations to improve separability and efficacy. In addition, volatile petrochemical prices and increasing pressure for sustainable palm-oil certification are other drivers for more diversified, sustainable feedstock procurement.

Buy now: https://www.imarcgroup.com/checkout?id=9034&method=2142

Key Steps Required to Set Up a Fatty Alcohol Ethoxylates (FAE) Plant

1. Market Analysis

The report provides insights into the landscape of the fatty alcohol ethoxylates (FAE) industry at the global level. The report also provides a segment-wise and region-wise breakup of the global fatty alcohol ethoxylates (FAE) industry. Additionally, it also provides the price analysis of feedstocks used in the production of fatty alcohol ethoxylates (FAE), along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the fatty alcohol ethoxylates (FAE) production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for fatty alcohol ethoxylates (FAE) production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for fatty alcohol ethoxylates (FAE) production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=9034&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a fatty alcohol ethoxylates (FAE) production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

Browse Related Reports:

• Micanite Production Plant Cost: https://www.imarcgroup.com/micanite-manufacturing-plant-project-report

• Monoisopropylamine Production Plant Cost: https://www.imarcgroup.com/monoisopropylamine-manufacturing-plant-project-report

• N-Butylaniline Production Plant Cost: https://www.imarcgroup.com/n-butylaniline-manufacturing-plant-project-report

• Octene Production Plant Cost: https://www.imarcgroup.com/octene-manufacturing-plant-project-report

• Para Dichlorobenzene Production Plant Cost: https://www.imarcgroup.com/para-dichlorobenzene-manufacturing-plant-project-report

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fatty Alcohol Ethoxylates (FAE) Production Plant 2025: Market Growth, Machinery Cost, & Capital Investment here

News-ID: 4302073 • Views: …

More Releases from IMARC Group

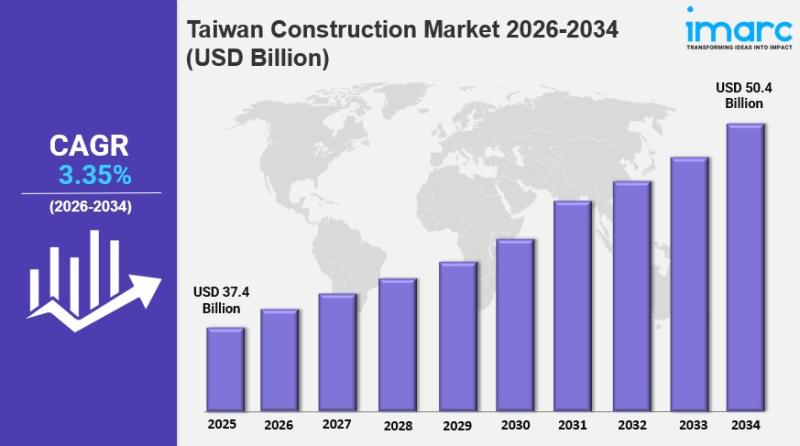

Taiwan Construction Market Size, Share, In-Depth Insights, Trends and Forecast 2 …

IMARC Group has recently released a new research study titled "Taiwan Construction Market Report by Sector (Residential, Commercial, Industrial, Infrastructure (Transportation), Energy and Utilities Construction), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Taiwan construction market size reached USD 37.4 Billion in 2025 and is projected to grow to USD 50.4…

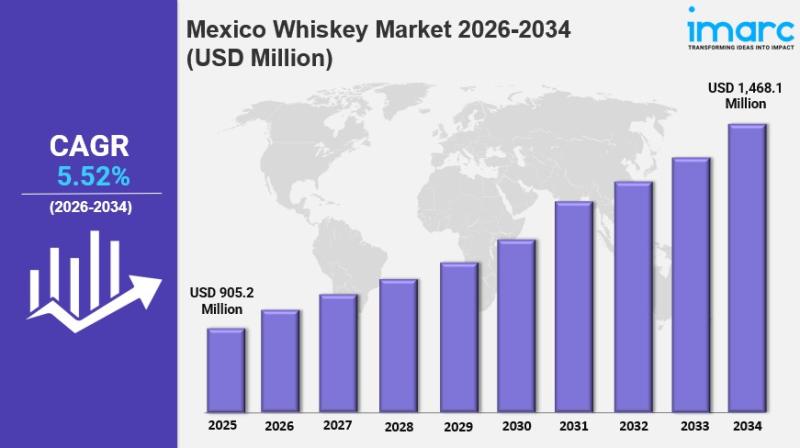

Mexico Whiskey Market Size to Hit USD 1,468.1 Million by 2034: Trends & Forecast

IMARC Group has recently released a new research study titled "Mexico Whiskey Market Size, Share, Trends and Forecast by Product Type, Quality, Distribution Channel, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico whiskey market size reached USD 905.2 Million in 2025. It is projected to grow to USD 1,468.1 Million…

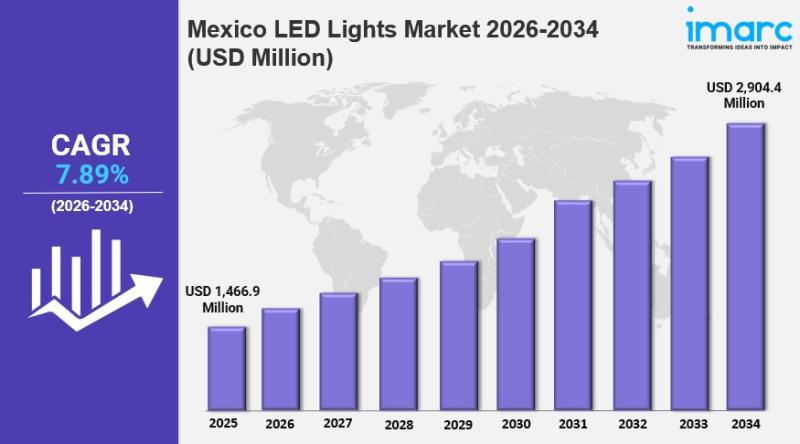

Mexico LED Lights Market 2026 : Industry Size to Reach USD 2,904.4 Million by 20 …

IMARC Group has recently released a new research study titled "Mexico LED Lights Market Size, Share, Trends and Forecast by Product Type, Application, Import and Domestic Manufacturing, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico LED lights market was valued at USD 1,466.9 million in 2025 and is projected to…

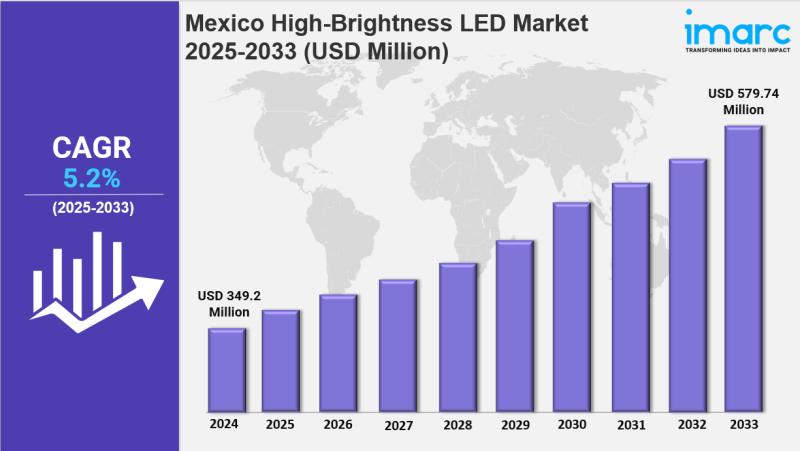

Mexico High-Brightness LED Market Size, Share, Latest Insights and Forecast 2025 …

IMARC Group has recently released a new research study titled "Mexico High-Brightness LED Market Size, Share, Trends and Forecast by Application, Distribution Channel, Indoor and Outdoor Application, End-Use Sector, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico high-brightness LED market size reached USD 349.2 Million in 2024 and is…

More Releases for FAE

TenXer Labs Hosts Free Webinar on Digital Transformation in Field Applications E …

TenXer Labs is hosting a free live webinar on the digital transformation in Field Applications Engineering (FAE) on August 29, 2024, at 8:00 AM PST.

TenXer Labs, a pioneer in empowering semiconductor companies with solutions for streamlined IC exploration and evaluation, is excited to announce an exclusive webinar titled "Embrace the Future: Digital Transformation in Field Applications Engineering (FAE)." This virtual roundtable will take place on August 29, 2024, from…

Wood Recycling Market May See a Big Move | Austin Wood Recycling, Fae Western, R …

Advance Market Analytics published a new research publication on "Wood Recycling Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Wood Recycling market was mainly driven by the increasing R&D spending across the world.

Get inside Scoop of the report, request…

Fatty Alcohol Ethoxylates (FAE) Manufacturing Plant Report | Project Details, Ma …

IMARC Group's report, titled "Fatty Alcohol Ethoxylates (FAE) Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for setting up a fatty alcohol ethoxylates (FAE) manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation…

Wood Recycling Market Is Booming Worldwide | Fae Western, Recycling Hub, Wood Re …

Advance Market Analytics published a new research publication on "Wood Recycling Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Wood Recycling market was mainly driven by the increasing R&D spending across the world. Some of the key players profiled…

Excavator Tillers Market 2018 Size, FAE, Cat, Paladin Attachments

Global Excavator Tillers market 2018 by ReportsQuest presents a professional and complete analysis of on the current Industry situation. The Global report includes Excavator Tillers Revenue, market Share, industry volume, Trends, Growth aspects. It analyses the important factors of the based on present industry situations, demands, business strategies utilized by Excavator Tillers market players and the future prospects from various angles in detail. Industry analysis is a assessment tool used…

Global Soil Stabilizer Market 2018 - BOMAG, FAE GROUP S.p.A, CMI, Roadtec

Apex Market Research, recently published a detailed market research study focused on the “Soil Stabilizer Market” across the global, regional and country level. The report provides 360° analysis of “Soil Stabilizer Market” from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global PP Pipe industry, and estimates the future trend of Soil Stabilizer on…