Press release

Apricot Seed Oil Processing Plant Setup Guide 2025: Detailed Process Flow and Unit Operations

Apricot Seed Oil Processing Plant Report Overview:IMARC's new report titled "Apricot Seed Oil Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up an apricot seed oil processing plant. The study covers all the requisite aspects that one needs to know while entering the apricot seed oil industry. It provides a comprehensive breakdown of the apricot seed oil processing plant setup cost, offering detailed insights into initial capital requirements and infrastructure planning. This report is a must-read for entrepreneurs, investors, researchers, consultants, business strategists, and all those who have any kind of stake in the apricot seed oil industry. Additionally, the report analyzes the apricot seed oil processing plant cost, helping stakeholders evaluate the overall financial feasibility and long-term profitability.

Request for a Sample Report: https://www.imarcgroup.com/apricot-seed-oil-processing-plant-project-report/requestsample

Apricot Seed Oil Processing Plant

An apricot seed oil processing plant is a specialized facility designed to extract high-quality oil from apricot kernels through mechanical or solvent-based methods. The process typically involves cleaning, shelling, drying, cold pressing, filtration, and refining to achieve a pure and commercially viable product. Such plants incorporate advanced machinery to maintain nutrient integrity, ensure food-grade standards, and support large-scale production for cosmetic, pharmaceutical, and culinary applications. Efficient workflow systems and quality control protocols enable consistent output, making the facility a critical component in transforming raw apricot seeds into valuable oil used across multiple industries.

Market Analysis and Trends

The market for apricot seed oil processing is experiencing steady expansion, driven by rising demand for natural and plant-based ingredients in personal care, wellness, and specialty food sectors. Growth is supported by increasing consumer preference for cold-pressed oils rich in antioxidants, essential fatty acids, and skin-nourishing compounds. The cosmetic and skincare industries continue to be dominant end users, while pharmaceutical applications are gaining prominence due to the oil's functional properties. Market dynamics also reflect a shift toward sustainable sourcing and eco-friendly processing techniques, encouraging investment in modern extraction technologies and energy-efficient equipment. Emerging trends highlight the role of organic certification, traceability, and clean-label formulations in strengthening competitive positioning. Expanding production in apricot-growing regions, coupled with rising global trade activities, is expected to support long-term market growth for processing facilities.

Buy Full Report: https://www.imarcgroup.com/checkout?id=13749&method=2142

Processing Process and Technical Workflow

The processing process for apricot seed oil follows a structured workflow that begins with seed cleaning and controlled drying to ensure optimal quality. Mechanical shelling and kernel separation prepare the material for cold pressing or solvent extraction, depending on production requirements. Filtration and refining stages help achieve clarity, stability, and compliance with industry standards. Automated monitoring systems enhance efficiency, ensuring consistent output and adherence to technical specifications.

Aspects Covered

• Seed cleaning and preparation

• Kernel separation and handling

• Extraction through controlled methods

• Filtration for product refinement

• Quality assurance and monitoring

Key Aspects to Setup a Apricot Seed Oil Plant:

• Location to Setup Plant

• Market Research

• Plant Layout

• Construction and Infrastructure

• Equipment/Machinery Procurement

• Documentation and Licenses

• Cost Analysis

Types of Costs to Setup a Factory:

• Land, Location and Site Development Cost

• Plant Layout Cost

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask an Analyst for customization Report: https://www.imarcgroup.com/request?type=report&id=13749&flag=C

Key Considerations for Plant Design and Operations:

• Production Capacity: The plant layout and equipment selection should be tailored to the desired output level, ensuring efficient use of space, energy, and resources while supporting smooth operations across small, medium, or large-scale production environments.

• Automation Levels: The degree of automation should be planned according to budget, labor skill availability, and operational needs, enabling a balanced approach between manual control, semi-automation, or advanced fully automated systems.

• Location Adaptation: The facility's location should align with raw material availability, market accessibility, transportation infrastructure, and regulatory guidelines to enhance cost efficiency and operational reliability.

• Product Flexibility: The processing line should support multiple oil grades and variations, allowing adjustments in extraction methods, filtration stages, and packaging formats to meet shifting market and client requirements.

• Sustainability Features: The design should integrate energy-efficient equipment, waste reduction systems, and environmentally responsible practices to support long-term sustainability and compliance with global standards.

• Raw Material Sourcing: The sourcing framework should ensure a steady, cost-effective supply of apricot seeds through reliable procurement channels, seasonal planning, and strategic supplier relationships for consistent plant performance.

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

Plant Setup

Factoring Auditing

Regulatory Approvals, and Licensing

Company Incorporation

Incubation Services

Recruitment Services

Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Apricot Seed Oil Processing Plant Setup Guide 2025: Detailed Process Flow and Unit Operations here

News-ID: 4301719 • Views: …

More Releases from IMARC Group

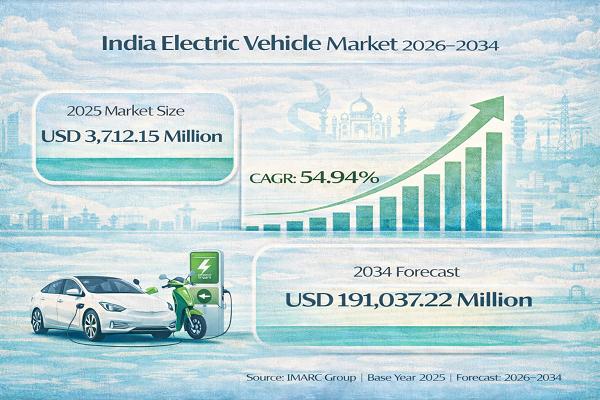

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…