Press release

Industrial Hydraulic Equipment Market to Hit US$ 39.7 Billion by 2032 - Persistence Market Research

The global industrial hydraulic equipment market is entering a transformative period driven by expanding manufacturing sectors, rapid advancements in automation, and increasing demand for high-precision machinery. Industrial hydraulic systems-including pumps, valves, actuators, filters, cylinders, and power units-are vital to the operation of heavy machinery and industrial plants. They provide unmatched power density, efficiency, and control for applications such as material handling, metalworking, mining, agriculture, and construction. According to recent industry estimates, the market is valued at US$ 28.2 billion in 2025 and is projected to reach US$ 39.7 billion by 2032, rising at a CAGR of 5.0%. This growth trajectory reflects rising capital expenditure in critical sectors, the modernization of industrial infrastructure, and the adoption of intelligent hydraulic equipment capable of delivering better performance and reliability.Download Free Sample & Check the Latest Market Analysis: https://www.persistencemarketresearch.com/samples/34911

A combination of factors is contributing to the market's expansion, including the global shift toward automated manufacturing, increasing adoption of Industry 4.0 practices, and the rising need for robust, high-force machinery in industrial environments. Hydraulics remain the preferred technology where mechanical strength, precise motion control, and long-distance power transmission are critical. Among the various equipment categories, hydraulic pumps and cylinders represent the leading product segment due to their central role in fluid power systems and broad applicability across industrial domains. In terms of geographical distribution, Asia Pacific stands as the dominant regional market, largely due to its flourishing manufacturing ecosystem, massive infrastructure investments, and the continued expansion of industries such as automotive, construction, mining, and agriculture. Countries such as China, India, Japan, and South Korea are significantly strengthening the region's market leadership through industrialization and the adoption of advanced machinery.

Key Highlights from the Report

• Industrial hydraulic equipment market expected to reach US$39.7 billion by 2032.

• Asia Pacific remains the leading regional market with robust industrialization and infrastructure development.

• Hydraulic pumps and cylinders dominate the product segment due to widespread industrial application.

• Increasing adoption of automation and Industry 4.0 enhances demand for smart hydraulic systems.

• Construction and manufacturing industries continue to generate substantial equipment requirements.

• Technological advancements support development of energy-efficient and high-performance hydraulic equipment.

Market Segmentation

The industrial hydraulic equipment market is structured across multiple layers of segmentation that reflect the diverse needs of industries utilizing hydraulic systems. One of the primary segmentation categories is product type, which includes hydraulic pumps, motors, valves, cylinders, accumulators, filters, power units, and accessories. Each of these components plays a different functional role in industrial fluid power systems. Hydraulic pumps and motors convert mechanical power into fluid power and vice versa, enabling efficient movement and pressure generation in industrial machinery. Hydraulic cylinders are widely used across construction machinery, agricultural equipment, and material handling systems due to their ability to deliver high force and precise motion control. Hydraulic valves regulate fluid direction, pressure, and flow, making them indispensable for safety and efficiency in hydraulic circuits.

Another key segmentation involves end-user industries, which define the demand landscape for hydraulic equipment. Major sectors include construction, manufacturing, automotive, aerospace, mining, agriculture, marine, material handling, and energy. The construction industry continues to be the largest consumer due to its reliance on heavy-duty equipment such as excavators, loaders, cranes, and road-building machinery-all of which require sophisticated hydraulic systems. The manufacturing sector also plays a critical role, especially with the growing adoption of automated production lines, CNC machines, injection molding systems, and metal fabrication equipment. Increasing demand from the mining and energy sectors reflects the need for durable hydraulic systems capable of operating under extreme conditions, handling abrasive materials, and ensuring uninterrupted operations.

The market can also be segmented by technology trends, such as conventional hydraulic systems, electro-hydraulic systems, and smart hydraulic equipment. Electro-hydraulic systems, which combine the power of hydraulics with the precision of electronics, are rapidly gaining momentum in industries that demand improved accuracy and integration with digital monitoring systems. Smart hydraulic systems-with embedded sensors, IoT connectivity, and predictive maintenance capabilities-are growing in adoption due to their ability to reduce downtime and optimize energy consumption. These advancements are reshaping the competitive landscape and opening new growth avenues for manufacturers.

Get a Customized Market View in One Click : https://www.persistencemarketresearch.com/request-customization/34911

Regional Insights

Regional demand for industrial hydraulic equipment varies significantly based on industrial maturity, economic development, and investment patterns. Asia Pacific dominates the global landscape, accounting for a substantial share of the total market. The region's lead is driven by ongoing industrialization, massive investments in construction and infrastructure, and the proliferation of manufacturing facilities across China, India, Japan, and Southeast Asia. China, in particular, is a global manufacturing hub with large-scale production of construction machinery, automotive components, and industrial equipment-all requiring advanced hydraulic systems. India is witnessing notable growth as government initiatives in infrastructure and industrial development accelerate demand for hydraulic machinery.

North America is another prominent region, supported by technologically advanced industries and a high adoption rate of automated manufacturing systems. The U.S. market benefits from strong investments in oil & gas, aerospace, heavy machinery, and automotive production. Manufacturers in North America prioritize efficiency, precision engineering, and compliance with stringent safety regulations, encouraging the uptake of high-performance hydraulic components. Furthermore, modernization of industrial plants and the adoption of Industry 4.0 practices continue to stimulate demand for intelligent and energy-efficient hydraulic systems.

Europe maintains established demand, with countries such as Germany, Italy, Sweden, and the UK leading in the production of sophisticated industrial machinery. The region's engineering excellence and focus on sustainable manufacturing practices have led to a rising adoption of energy-efficient hydraulic solutions. The automotive and industrial automation sectors also significantly contribute to equipment demand. Meanwhile, Latin America and the Middle East & Africa represent emerging growth regions. In Latin America, construction activity, mining operations, and agricultural mechanization drive demand for hydraulic machinery. The Middle East & Africa region sees rising adoption due to infrastructure development, oil & gas exploration, and investments in industrial equipment modernization, offering long-term potential for hydraulic equipment suppliers.

Market Drivers

The industrial hydraulic equipment market is propelled by several strong growth drivers that align with the expanding needs of global industries. One of the most influential drivers is the increasing automation across manufacturing plants, where hydraulic systems are essential in operating automated machinery with high force and precision. As industries adopt robotics, CNC machines, and advanced manufacturing systems, the requirement for dependable hydraulic components intensifies. Another major driver is the rapid development of global infrastructure, particularly in Asia Pacific and the Middle East. Large-scale construction projects rely on hydraulic equipment to power heavy machinery, enhance efficiency, and reduce project timelines.

Technology also plays a pivotal role, with innovations in hydraulic pumps, valves, and cylinders improving system efficiency, reducing energy consumption, and extending service life. Industries are increasingly shifting toward electro-hydraulic systems, which offer enhanced control and integration with digital monitoring tools. Additionally, the global push for higher productivity and reduced downtime has encouraged industries to invest in high-quality hydraulic equipment capable of operating under harsh conditions. The mining, oil & gas, and marine sectors depend heavily on hydraulic systems for applications involving high pressure, heavy loads, and continuous operation, further strengthening market demand. Collectively, these drivers establish a strong foundation for sustained market growth.

Market Restraints

Although the market shows strong growth potential, several constraints may hinder faster adoption of hydraulic equipment. A significant restraint is the high initial cost associated with purchasing and installing industrial hydraulic systems. The complexity of hydraulic equipment, along with the need for specialized components and skilled installation, often results in considerable capital investment-posing challenges for small and medium-sized enterprises. Another concern is the maintenance requirement of hydraulic systems. Regular inspections, fluid changes, leak detection, and component replacement are essential to ensure operational safety and efficiency; however, these maintenance needs can be costly and time-intensive.

Environmental concerns also serve as a restraint, particularly related to the use of hydraulic fluids that can pose contamination risks if leakage occurs. Industries must adhere to strict environmental regulations and safety standards, increasing compliance costs. Additionally, fluctuations in raw material prices-especially steel, aluminum, and specialty alloys-affect manufacturing costs and create pricing uncertainties. The emergence of alternative technologies, particularly electric actuation systems, may also challenge the growth of traditional hydraulic solutions in certain applications that demand cleaner and quieter operation. These factors collectively present challenges that manufacturers and industries must navigate as they plan their hydraulic equipment investments.

Click to Purchase the Full Report & Start Exploring : https://www.persistencemarketresearch.com/checkout/34911

Market Opportunities

Despite existing challenges, the industrial hydraulic equipment market presents significant opportunities for innovation, expansion, and competitive differentiation. A major opportunity lies in the growing adoption of smart hydraulic systems equipped with advanced sensors, IoT connectivity, and predictive maintenance algorithms. These systems allow real-time monitoring of pressure, flow, temperature, and wear conditions, helping industries prevent downtime and enhance operational efficiency. As digitalization spreads across manufacturing plants, demand for intelligent hydraulic solutions is expected to rise sharply.

Another promising opportunity arises from the global shift toward energy-efficient systems. Manufacturers are intensifying efforts to design hydraulic pumps, valves, and actuators that reduce energy consumption while maintaining performance. Electro-hydraulic hybrid systems and variable-speed pump solutions are gaining traction as industries aim to meet energy efficiency targets. Additionally, expanding industrialization in emerging economies-particularly in Southeast Asia, Africa, and Latin America-offers untapped potential for hydraulic equipment companies. Infrastructure growth, mechanization of agriculture, mining expansion, and construction of smart cities present avenues for sustained market penetration.

Sustainability initiatives are also creating new possibilities. Manufacturers increasingly focus on biodegradable hydraulic fluids, low-leak components, and environmentally safe materials to meet global standards. Companies that invest in research and development for eco-friendly hydraulic technologies stand to benefit from long-term industry shifts toward sustainable operations.

Company Insights

Key players operating in the global industrial hydraulic equipment market include:

• Bosch Rexroth AG

• Eaton Corporation

• Parker Hannifin Corporation

• Danfoss A/S

• Kawasaki Heavy Industries Ltd

• Nachi-Fujikoshi Corp

• KYB Corporation

• HAWE Hydraulik SE

• Hydac International GmbH

• Wipro Infrastructure Engineering

• Bucher Hydraulics

• Komatsu Ltd

Recent Developments:

Leading manufacturers have introduced advanced electro-hydraulic systems with integrated digital monitoring features designed to support Industry 4.0 objectives.

Major hydraulic equipment companies have expanded production capacities in Asia Pacific to meet the surge in demand from construction and manufacturing industries.

Related Reports:

https://www.persistencemarketresearch.com/market-research/carbon-brush-market.asp

https://www.persistencemarketresearch.com/market-research/construction-aggregates-market.asp

https://www.persistencemarketresearch.com/market-research/drilling-machines-market.asp

https://www.persistencemarketresearch.com/market-research/thermostatic-mixing-valves-market.asp

https://www.persistencemarketresearch.com/market-research/foamer-pump-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial Hydraulic Equipment Market to Hit US$ 39.7 Billion by 2032 - Persistence Market Research here

News-ID: 4300935 • Views: …

More Releases from Persistence Market Research

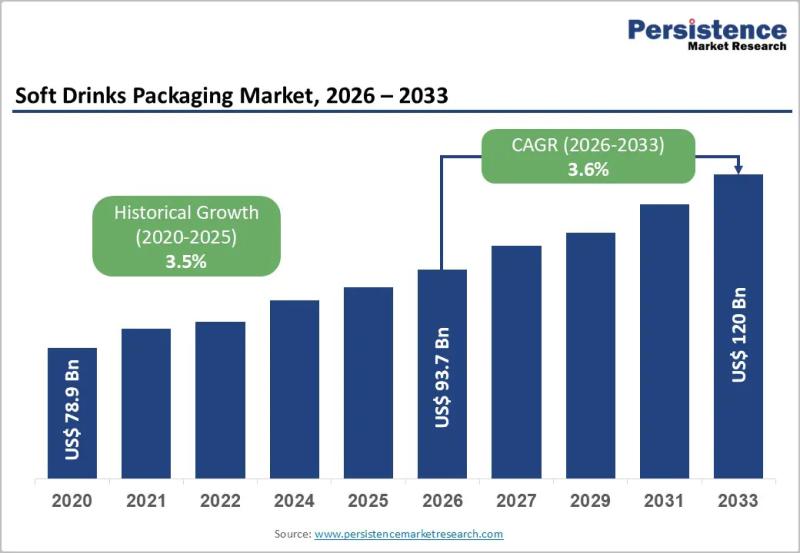

Soft Drinks Packaging Market to Reach US$120.0 Billion by 2033 - Persistence Mar …

The soft drinks packaging market plays a central role in the global beverage industry, serving carbonated drinks, juices, flavored water, energy drinks, and ready to drink teas and coffees. Packaging is no longer limited to containment and transportation; it has evolved into a critical component of branding, sustainability strategy, consumer convenience, and supply chain efficiency. Manufacturers are increasingly focusing on lightweight materials, recyclable packaging formats, and innovative designs that improve…

Christmas Tree Valves Market Size to Reach US$8.1 Billion by 2033 - Persistence …

The Christmas Tree Valves Market plays a critical role in the upstream oil and gas industry, serving as a central component in wellhead equipment systems. Christmas tree valves are installed on oil and gas wells to control pressure, regulate flow, and ensure safe extraction of hydrocarbons. These assemblies, commonly referred to as "Christmas trees," consist of multiple valves, spools, and fittings arranged in a structure that resembles a decorated tree.…

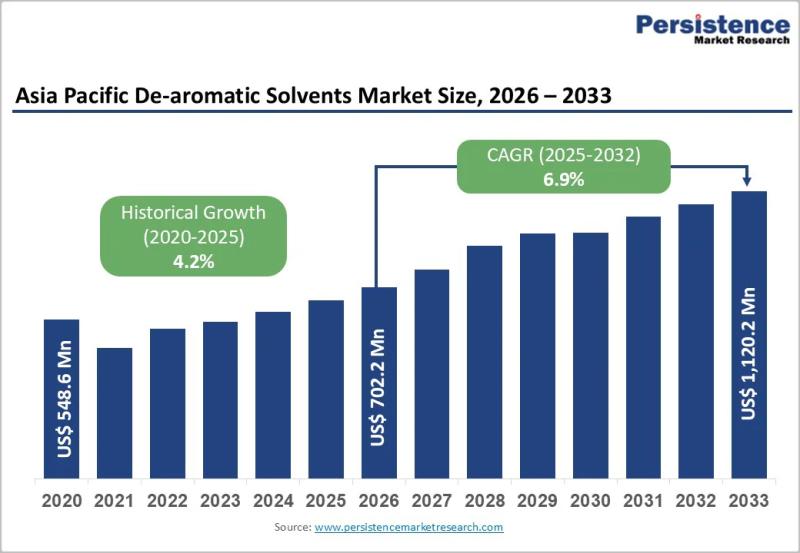

Asia Pacific De-aromatic Solvents Market to Reach US$1,120.2 Million by 2033 - P …

The Asia Pacific De-aromatic Solvents Market is gaining steady momentum as industries across the region increasingly shift toward low aromatic, high purity solvent formulations. De-aromatic solvents are hydrocarbon solvents that have significantly reduced aromatic content, making them suitable for applications requiring low odor, lower toxicity, and improved environmental performance. These solvents are widely used in paints and coatings, adhesives, inks, metalworking fluids, agrochemicals, and cleaning formulations. As regulatory scrutiny around…

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

More Releases for Hydraulic

Hydraulic Cylinders: Powering Growth in the Hydraulic Tools Market

The hydraulic tools market is a critical sector, providing essential equipment for construction, manufacturing, and heavy industry. Within this dynamic market, the hydraulic cylinder segment stands out as a high-opportunity area, serving as the core component that drives the power and functionality of countless hydraulic tools.

Market Dynamics and Growth Drivers

Hydraulic cylinders convert fluid pressure into linear force, enabling the operation of a wide range of hydraulic tools, from jacks and…

Sealing Components and Hydraulic Hose Suppliers for Shielded Hydraulic Supports

Shaanxi Kelong New Materials Co., Ltd. [https://www.snkelong-sealhose.com/about-us/] is an enterprise focusing on the research and development and production of new materials. It is committed to providing high-quality sealing series products and hydraulic hose series products for coal, mining, chemical industry and other fields.

In a cooperation project with Shandong Mining Machinery Huaneng Equipment Manufacturing Co., Ltd., Shaanxi Kelong New Materials Co., Ltd. successfully developed a shielded hydraulic support. This stand uses…

Ningbo Vicks Hydraulic: Hydraulic System Features And Applications

Hydraulic System [https://www.vickshydraulic.com/products/servo-system/] and Servo System for Machine: A Powerful Combination

In the world of industrial machinery, the combination of a hydraulic system and a servo system has proven to be a powerful and efficient solution for various applications. The hydraulic system utilizes fluid power to generate force and motion, while the servo system uses feedback control to precisely regulate the movement of the machine. When these two systems are integrated,…

Compared With Ordinary Hydraulic Systems, Servo Hydraulic Systems Have Many Adva …

The servo system is an energy-saving and efficient hydraulic control method that uses a servo motor to drive the main transmission oil pump, reduce the control valve circuit, and control the hydraulic system slide. It is suitable for stamping, die forging, press fitting, die casting, injection molding, straightening, and other processes.

Compared with ordinary hydraulic presses, servo hydraulic presses [https://www.zx-hydraulic.com/news/what-is-a-servo-hydraulic-press/] have the advantages of energy saving, low noise, high efficiency, good…

Global Hydraulic Piston Pumps Market Forecast 2018-2025 Eaton, Oilgear, Kamat, H …

Recently added detailed market study "Global Hydraulic Piston Pumps Market" examines the performance of the Hydraulic Piston Pumps market 2018. It encloses an in-depth Research of the Hydraulic Piston Pumps market state and the competitive landscape globally. This report analyzes the potential of Hydraulic Piston Pumps market in the present and the future prospects from various angles in detail.

The Global Hydraulic Piston Pumps Market 2018 report includes Hydraulic Piston Pumps…

Global Umbilical Market: By Type- Hydraulic, Electro Hydraulic, Electro-Fiber Op …

Latest industry research report on: Global Umbilical Market | Industry Size, Share, Research, Reviews, Analysis, Strategies, Demand, Growth, Segmentation, Parameters, Forecasts

Increasing concern towards declining crude oil prices coupled with the restoration of mature fields and exploring deep sea oil and gas reservoirs drive the growth of Umbilical Market.

Request For Sample Report @ http://www.marketresearchreports.biz/sample/sample/717439

The Global Umbilical Market in Oil and Gas Industry has been growing at a positive rate, on account…