Press release

Polyphenylene Oxide (PPO) Production Plant Cost: Feasibility Study and Profit Analysis

Setting up a polyphenylene oxide production plant involves selecting a suitable manufacturing method such as oxidative coupling polymerization of 2,6-dimethylphenol using copper-amine complex catalysts, securing raw material supply of phenolic monomers and catalyst systems, installing polymerization reactors, precipitation and washing units, compounding and pelletizing equipment, and solvent recovery systems, and ensuring compliance with environmental regulations and polymer quality standards.IMARC Group's report, titled "Polyphenylene Oxide (PPO) Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a polyphenylene oxide production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/polyphenylene-oxide-manufacturing-plant-project-report/requestsample

What is Polyphenylene Oxide?

Polyphenylene Oxide (PPO), also known as Polyphenylene Ether (PPE), is a high-performance engineering thermoplastic recognized for its exceptional dimensional stability, mechanical strength, and resistance to heat and chemicals. It is produced through the oxidative polymerization of 2,6-dimethylphenol using a copper-based catalyst system. PPO has a low moisture absorption rate, excellent dielectric properties, and retains structural integrity even under elevated temperatures, making it an ideal material for electrical and electronic applications. Pure PPO can be difficult to process due to its high melting point and lack of solubility in common solvents. Therefore, it is often blended with other polymers, most commonly polystyrene, to form NorylTM resin, which improves processability while maintaining high performance. PPO is widely used in automotive components, household appliances, fluid handling systems, and electronic parts where precision, durability, and long-term reliability are essential.

Key Insights for setting up a Polyphenylene Oxide Production Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Buy Now: https://www.imarcgroup.com/checkout?id=24268&method=2142

Key Cost Components

• Land and Site Development: Cost of land acquisition, site preparation, infrastructure development, and utility connections for chemical polymerization facility.

• Machinery and Equipment: Polymerization reactors with oxygen injection systems, copper-amine catalyst preparation units, precipitation tanks, centrifuges, washing and drying equipment, twin-screw compounding extruders, pelletizing systems, solvent recovery distillation columns, and quality control instrumentation.

• Raw Materials: 2,6-dimethylphenol (primary monomer), copper salts (catalyst), amine ligands (catalyst system), organic solvents (toluene, methanol), polymer additives, flame retardants, stabilizers, and blending polymers (polystyrene, polyamide).

• Environmental Compliance: Solvent vapor recovery systems, wastewater treatment plant for catalyst removal, air emission control equipment, hazardous waste management systems, and regulatory permits.

• Technology Licensing or R&D: Cost of patented oxidative coupling polymerization processes, proprietary catalyst systems, polymer blend formulations, or in-house material development programs.

Economic Trends Influencing Polyphenylene Oxide Plant Setup Costs 2025

• Phenolic Monomer Availability: Limited global production of 2,6-dimethylphenol-primarily from cumene or cresol derivatives-creates supply constraints and price volatility affecting raw material costs.

• Copper and Specialty Chemical Costs: Fluctuations in copper catalyst prices and specialty amine ligand costs impact polymerization economics and operating expenses.

• Engineering Plastics Demand Growth: Expanding electric vehicle production, 5G infrastructure deployment, and miniaturization of electronics drive demand for high-performance materials like PPO.

• Environmental Regulations: Stricter VOC emission limits, solvent recovery requirements, and catalyst waste disposal regulations necessitate investment in advanced recovery systems and closed-loop processes.

• Competition from Alternative Materials: Pressure from high-temperature polyamides (PA66, PPA), polyphthalamide (PPA), and liquid crystal polymers (LCP) affects market positioning and pricing strategies.

• Blending and Compounding Trends: Growing preference for PPO/polyamide blends (offering better impact resistance and processability) requires integrated compounding capabilities and increases capital requirements.

• Asia-Pacific Manufacturing Shift: Concentration of electronics and automotive production in China, Japan, and South Korea influences optimal plant location decisions and logistics planning.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=24268&flag=C

Challenges and Considerations for Investors

• High Capital Investment: Establishing a PPO plant requires substantial investment in specialized polymerization reactors, oxygen handling systems, solvent recovery infrastructure, and compounding facilities.

• Raw Material Supply Constraints: Limited global availability of 2,6-dimethylphenol creates dependency on few suppliers and potential supply chain vulnerabilities.

• Complex Polymerization Chemistry: Oxidative coupling polymerization requires precise control of oxygen levels, catalyst concentrations, temperature, and pressure to achieve consistent molecular weight and properties.

• Solvent Recovery Economics: Significant solvent usage (toluene, methanol) demands efficient recovery systems to maintain profitability and environmental compliance.

• Market Concentration: Dominance by major producers (SABIC, Asahi Kasei, Mitsubishi Chemical) with established technologies and customer relationships creates competitive barriers.

• Application-Specific Customization: Different end-uses require tailored formulations-flame-retardant grades for electronics, impact-modified blends for automotive, glass-fiber reinforced for structural applications-necessitating flexible production capabilities.

• Regulatory Compliance: Chemical handling regulations, polymer food contact approvals (for water applications), and UL flammability certifications require ongoing testing and documentation.

• Technology Evolution: Continuous development of competing high-temperature thermoplastics and advanced polymer blends requires ongoing R&D investment to maintain market relevance.

Conclusion

Investing in a polyphenylene oxide production plant presents opportunities in the high-performance engineering thermoplastics market serving electrical/electronics, automotive, and industrial applications. With growing demand from electric vehicle components, 5G telecommunications infrastructure, and water management systems, the market offers solid prospects-particularly for facilities incorporating efficient oxidative coupling processes, advanced blending technologies, and comprehensive solvent recovery systems. However, investors must carefully navigate challenges including limited phenolic monomer availability, complex polymerization chemistry requiring specialized expertise, significant solvent handling requirements, and competition from established global producers with proprietary technologies. Success in this sector demands robust process control systems, strategic partnerships with 2,6-dimethylphenol suppliers, expertise in polymer blending and compounding, commitment to environmental stewardship through solvent recovery, and ability to develop application-specific formulations meeting stringent electrical, thermal, and mechanical performance requirements, ensuring profitable operations in the premium segment of the global engineering plastics industry.

Browse More Related Report:

• Dibutyl Sulfide Production Plant: https://www.imarcgroup.com/dibutyl-sulfide-manufacturing-plant-project-report

• Dioxane Production Plant: https://www.imarcgroup.com/dioxane-manufacturing-plant-project-report

• Enamel Paint Production Plant: https://www.imarcgroup.com/enamel-paint-manufacturing-plant-project-report

• Ethylaniline Production Plant: https://www.imarcgroup.com/ethylaniline-manufacturing-plant-project-report

• Ethyl Lactate Production Plant: https://www.imarcgroup.com/ethyl-lactate-manufacturing-plant-project-report

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polyphenylene Oxide (PPO) Production Plant Cost: Feasibility Study and Profit Analysis here

News-ID: 4300754 • Views: …

More Releases from IMARC Group

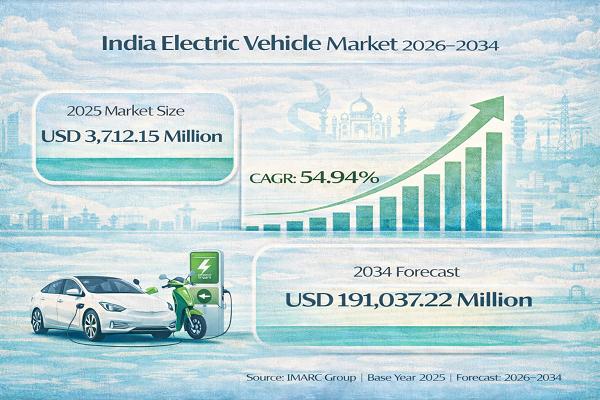

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…