Press release

Fluoropolymers (PTFE) Production Plant 2025: Process Details, Market Outlook, and Profitability Analysis

Setting up a fluoropolymers (ptfe) production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Fluoropolymers (PTFE) Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a fluoropolymers (ptfe) production plant cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/fluoropolymers-manufacturing-plant-project-report/requestsample

What are Fluoropolymers (PTFE)?

Fluoropolymers (PTFE) are polymerized forms from the monomer tetrafluoroethylene (TFE), used as a high-performance plastic. PTFE resists extreme chemicals and heat and does not stick prominently. To polymerize TFE, people commonly use suspension polymerization or emulsion polymerization. The PTFE resin dries, mills, and processes into sheets, films, rods, and coatings by methods such as paste extruding and compression molding. Because it has a low coefficient of friction, it melts at a high point, and it resists corrosive chemicals in an outstanding way, people use it in automotive applications, aerospace applications, electrical insulation, cookware coatings, and as seals for industrial, chemical, and electrical applications.

What is Driving the Fluoropolymers (PTFE) Market?

Increased need for high-performance polymer in automotive, electronics, aerospace, and chemical processing end-user industries drives fluoropolymers (PTFE) industry growth. PTFE sees wide use for high-performance polymer applications because it has unique properties of chemical inertness, heat resistance, electrical insulation, and extremely low friction. The use of PTFE in wire and cable systems, electronics, renewable energy systems, and high temperature applications continues to grow due to the increased use of electric vehicles and miniaturized electronics, along with the need for new medical devices and filtration systems. Industrial modernization, increased safety standards, and demand for durable, corrosion-resistant materials continue to drive global demand for PTFE products.

Buy now: https://www.imarcgroup.com/checkout?id=9216&method=2142

Key Steps Required to Set Up a Fluoropolymers (PTFE) Plant

1. Market Analysis

The report provides insights into the landscape of the fluoropolymers (ptfe) industry at the global level. The report also provides a segment-wise and region-wise breakup of the global fluoropolymers (ptfe) industry. Additionally, it also provides the price analysis of feedstocks used in the production of fluoropolymers (ptfe), along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the fluoropolymers (ptfe) production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for fluoropolymers (ptfe) production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for fluoropolymers (ptfe) production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=9216&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a fluoropolymers (ptfe) production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

Browse Related Reports:

• Lead (iv) Oxide Production Plant Cost: https://www.imarcgroup.com/lead-iv-oxide-manufacturing-plant-project-report

• Liquid Nitrogen Production Plant Cost: https://www.imarcgroup.com/liquid-nitrogen-manufacturing-plant-project-report

• Pentachlorophenol Production Plant Cost: https://www.imarcgroup.com/pentachlorophenol-manufacturing-plant-project-report

• Phenol Acetone Production Plant Cost: https://www.imarcgroup.com/phenol-acetone-manufacturing-plant-project-report

• Potassium Hexafluorophosphate Production Plant Cost: https://www.imarcgroup.com/potassium-hexafluorophosphate-manufacturing-plant-project-report

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fluoropolymers (PTFE) Production Plant 2025: Process Details, Market Outlook, and Profitability Analysis here

News-ID: 4300738 • Views: …

More Releases from IMARC Group

India In Vitro Diagnostics Market Set for Explosive Growth: Trends, Forecast & O …

India In Vitro Diagnostics Market Overview 2026-2034:

According to IMARC Group's report titled "India In Vitro Diagnostics Market Size, Share, Trends and Forecast by Test Type, Product, Usability, Application, End User, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

How Big is the In Vitro Diagnostics Industry in India?

The India in vitro diagnostics market size reached USD 5.6 Billion in…

Dairy Industry in Maharashtra: Market Size, Investment Opportunities & Growth Fo …

Introduction

According to IMARC Group's report titled "Dairy Industry in Maharashtra 2025-2033: Market Size, Growth, Prices, Segments, Cooperatives, Private Dairies, Procurement and Distribution" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

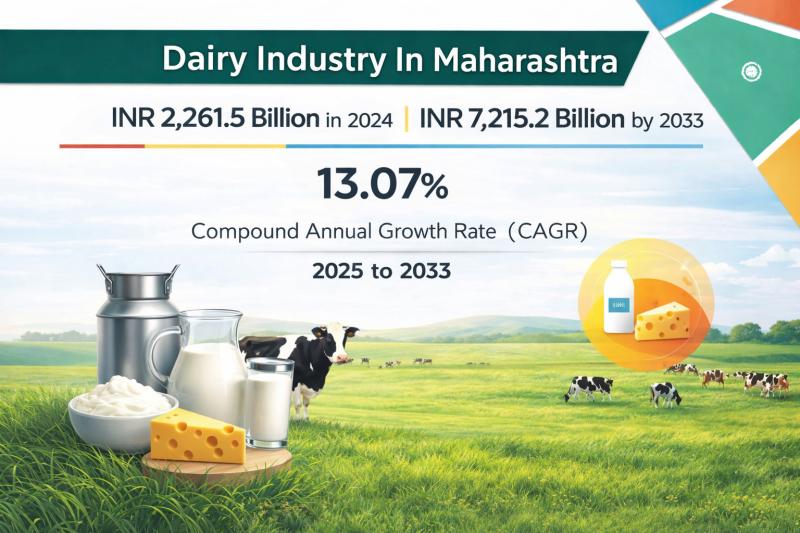

How Big is the Dairy Industry In Maharashtra?

The Maharashtra dairy market size reached INR 2,261.5 Billion in 2024. It is expected to grow at a CAGR of 13.07% during the forecast period…

Cost of Setting Up a Dicalcium Phosphate Production Plant & DPR 2026

Setting up a dicalcium phosphate production plant positions investors within a strategically important segment of the global animal nutrition and food additives industry, driven by increasing demand for feed-grade phosphates, mineral supplements, and pharmaceutical excipients. As modern livestock farming practices advance, animal nutrition requirements become more sophisticated, and the need for high-quality calcium and phosphorus supplementation grows, dicalcium phosphate continues to gain traction across animal feed manufacturing, pharmaceutical formulations, and…

India Online Insurance Market Report 2026-2034: Size, Share, Growth, Trends, Ins …

According to IMARC Group's report titled "India Online Insurance Market Size, Share, Trends and Forecast by Insurance Type, Enterprise Size, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Online Insurance Market Overview

The India online insurance market size reached USD 10.4 Billion in 2025 and is expected to grow to USD 20.8 Billion by 2034, exhibiting a CAGR of…

More Releases for TFE

Thin-Film Encapsulation (TFE) Market

Thin-Film Encapsulation (TFE) Market Overview

Thin film encapsulation (TFE) is an enabling technology for Organic Light Emitting diodes (OLED).

This report provides a deep insight into the global Thin-Film Encapsulation (TFE) market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

In a word,…

Thin-Film Encapsulation (TFE) Market, Size, Trends, Business Strategies 2025-203 …

Thin-Film Encapsulation (TFE) Market Overview

Thin film encapsulation (TFE) is an enabling technology for Organic Light Emitting diodes (OLED).

This report provides a deep insight into the global Thin-Film Encapsulation (TFE) market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps…

Thin-Film Encapsulation (TFE) Market to Witness the Highest Growth in Asia Speci …

The thin-film encapsulation (TFE) market is estimated to grow from USD 92 million in 2022 to reach USD 223 million by 2027; it is expected to grow at a CAGR of 19.4% from 2022 to 2027. The growth of the thin-film encapsulation (TFE) market can be attributed to the rising trend of TFE using inkjet printing technology and increased application of OLED displays in AR/VR headsets.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=255749417

The…

Thin-Film Encapsulation (TFE) Market | Size | Share | Trends | Growth | Scope | …

New Jersey, United States - Thin-Film Encapsulation (TFE) market was valued at USD 45.02 Million in 2019 and is projected to reach USD 210.59 Million by 2027, growing at a CAGR of 25.9% from 2020 to 2027.

The Global Thin-Film Encapsulation (TFE) Market research includes an in-depth analysis of key geographical trends, market dynamics, and global size estimates for the market industry. Product description, product classification, industry structure, and numerous participants in the Global…

Thin-Film Encapsulation (TFE) Market Overview and Regional Outlook Study 2018 - …

Thin-Film Encapsulation (TFE) Market - Snapshot

The technique utilized in Organic Light Emitting Diodes (OLED) is thin-film encapsulation (TFE). With a thin-film barrier, TFE can replace front glass in OLED devices. OLEDs are being hailed as the next-generation display technology as the number of wearable gadgets grows. Thin-Film Encapsulation (TFE) has appeared as the most promising method for protecting these flexible electronics and thus the global thin-film encapsulation (TFE) market is…

Thin-Film Encapsulation (TFE) Market Share 2020: Global Trends, Key Players, Ind …

The Thin-Film Encapsulation (TFE) market was valued at $45.2 million in 2019 and is expected to reach $2159 million by 2027 and is expected to grow at a CAGR of 25% from 2021 to 2027. The trend of thin film encapsulation using inkjet printing, the rapid adoption of flexible OLED displays for smart phones and smart wearables greatly drives the market growth, while the development of flexible glass plays a…