Press release

Cobalt Acetate Production Unit Setup: Feasibility & Profit Metrics

Setting up a cobalt acetate production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Cobalt Acetate Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a cobalt acetate production plant setup cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/cobalt-acetate-manufacturing-plant-project-report/requestsample

What is Cobalt Acetate?

The cost of setting up a cobalt acetate production plant depends on several critical factors, including plant capacity, production technology, raw material availability, location, utility requirements, and compliance with environmental standards. Establishing a medium- to large-scale cobalt acetate plant generally requires significant capital investment, often ranging in the tens of millions of dollars, due to the need for specialized reaction vessels, crystallization systems, and purification equipment. Major cost components include land acquisition, site development, reactor units, neutralization facilities, crystallization tanks, filtration and drying systems, storage infrastructure, utilities, wastewater treatment, and safety systems. Additionally, the procurement of feedstock such as cobalt oxide, cobalt carbonate, or cobalt hydroxide and acetic acid, along with advanced corrosion-resistant equipment and quality control systems, adds substantially to initial expenses. Operating costs further involve labor, energy, maintenance, and logistics. The setup cost also varies depending on whether the plant uses direct neutralization of cobalt compounds with acetic acid, cobalt salt metathesis reactions, or solvent crystallization methodologies. Compliance with strict international and regional regulatory frameworks, particularly regarding heavy metal handling standards, Occupational Safety and Health Administration (OSHA) requirements, Environmental Protection Agency (EPA) regulations, and hazardous material storage and disposal controls, can significantly increase both capital and operational costs. However, while initial investment is substantial, cobalt acetate production plants offer attractive long-term returns due to the product's wide applications in catalysts, paint driers, pigments, chemical synthesis, textile printing, electroplating, and battery material precursors, making them a strategic venture for specialized cobalt compound and industrial chemical investors.

What is Driving the Cobalt Acetate Market?

The cobalt acetate production plant cost market is primarily driven by rising demand for catalysts, paint driers, and specialty chemical applications across chemical manufacturing, coatings, and advanced materials sectors. With growing consumption of cobalt acetate as a catalyst in oxidation reactions, drying agent in alkyd resin coatings and oil-based paints, intermediate in cobalt-based pigment production, and precursor for battery material synthesis, the need for high-purity cobalt acetate has surged, influencing plant expansion and setup costs. Rapid advancement in catalyst technology and battery material manufacturing in regions such as North America, Europe, and Asia-Pacific has also increased investment in specialized cobalt salt production infrastructure, creating strong incentives for new plant developments. Additionally, volatility in raw material prices for cobalt sources and acetic acid directly impacts feedstock availability and cost structure, thereby shaping overall project economics. Regulatory compliance and the integration of advanced, environmentally controlled heavy metal processing systems further contribute to escalating capital investment requirements. Chemical manufacturers, coating producers, pigment manufacturers, and battery material suppliers are also demanding production facilities with enhanced purity levels, improved safety protocols, and higher output efficiency, driving up initial setup expenditures. Furthermore, supply chain optimization, specialized storage infrastructure for cobalt compounds, and dedicated handling systems for reactive chemicals add to the financial outlay. Despite the high cost, favorable return on investment, coupled with growing demand for industrial catalysts, paint additives, and battery precursor materials, continues to stimulate market interest in cobalt acetate production projects, making it a strategic sector for specialty cobalt chemical manufacturing development and industrial supply chain competitiveness.

Buy Now: https://www.imarcgroup.com/checkout?id=10591&method=2142

Key Steps Required to Set Up a Cobalt Acetate Plant

1. Market Analysis

The report provides insights into the landscape of the cobalt acetate industry at the global level. The report also provides a segment-wise and region-wise breakup of the global cobalt acetate industry. Additionally, it also provides the price analysis of feedstocks used in the production of cobalt acetate, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the cobalt acetate production plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for cobalt acetate production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for cobalt acetate production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Request for Customization: https://www.imarcgroup.com/request?type=report&id=10591&flag=E

4. Project Economics

A detailed analysis of the project economics for setting up a cobalt acetate production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

Browse More Related Report:

• https://www.imarcgroup.com/sodium-lignosulfonate-manufacturing-plant-project-report

• https://www.imarcgroup.com/sodium-metasilicate-pentahydrate-manufacturing-plant-project-report

• https://www.imarcgroup.com/sodium-tartrate-manufacturing-plant-project-report

• https://www.imarcgroup.com/sodium-thiocyanate-manufacturing-plant-project-report

• https://www.imarcgroup.com/sodium-xylene-sulfonate-manufacturing-plant-project-report

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cobalt Acetate Production Unit Setup: Feasibility & Profit Metrics here

News-ID: 4300111 • Views: …

More Releases from IMARC Group

India B2B Events Market: Industry Trends & Growth Forecast by 2034

The India B2B events market size was valued at USD 1,688.72 Million in 2025 and is expected to reach USD 2,750.10 Million by 2034, growing at a compound annual growth rate (CAGR) of 5.57% from 2026 to 2034. The market growth is driven by increasing corporate spending on marketing, networking initiatives, and brand-building across industries, supported by government development of world-class MICE infrastructure and adoption of digital and hybrid event…

India Cold Chain Logistics Market to Reach USD 27.00 Bn by 2033 at 8.90% CAGR Am …

Source: IMARC Group | Category: Transportation and Logistics

Report Introduction

According to IMARC Group's latest report titled "India Cold Chain Logistics Market Size, Share, Trends and Forecast by Type, Application, and Region, 2025-2033", this study offers a granular analysis of the country's developing temperature-controlled supply chain. The study offers a profound analysis of the industry, encompassing market share, size, growth factors, key trends, and regional insights. The report covers critical market dynamics,…

India Plastic Packaging Market is set to reach USD 17.3 Billion by 2034 | Indust …

The India plastic packaging market size reached USD 13.2 Billion in 2025. The market is expected to reach USD 17.3 Billion by 2034, growing at a CAGR of 3.10% from 2026-2034. The market is majorly driven by the advancements in plastic materials and technologies, development of lightweight packaging solutions, creation of flexible packaging options, and innovation in barrier-enhanced packaging that extends shelf life and improves product performance.

Key Highlights in India…

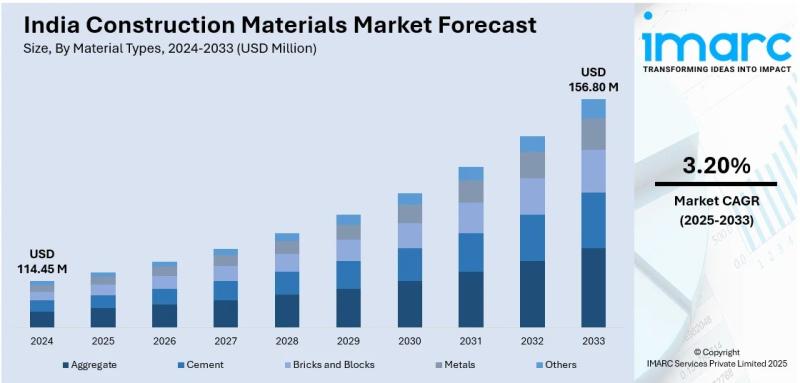

India Construction Materials Market to Hit USD 156.80 Mn by 2033 at 3.20% CAGR D …

Source: IMARC Group | Category: Chemical & Materials

Report Introduction

According to IMARC Group's latest report titled "India Construction Materials Market Size, Share, Trends and Forecast by Material Type, End User, and Region, 2025-2033", this study offers a granular analysis of the country's booming construction sector. The study offers a profound analysis of the industry, encompassing market share, size, growth factors, key trends, and regional insights. The report covers critical market…

More Releases for Cobalt

Cobalt Powder Market Growth Opportunities And Forecast to 2033 Hanrui Cobalt, Um …

Cobalt powder is a fine, metallic powder derived from the element cobalt, which is a transition metal. It is commonly used in various industrial applications, such as the production of high-performance alloys, magnets, and catalysts. Cobalt powder is known for its ability to withstand high temperatures and corrosion, making it crucial in aerospace, electronics, and battery technologies. It is also used in the manufacturing of rechargeable batteries, particularly in lithium-ion…

Global Cobalt Hydroxide Market 2024 Targets Impressive Growth of 8.97% CAGR (202 …

The global Cobalt Hydroxide Market size reached 163.84 USD Million in 2023. Looking forward, MarketsGlob expects the market to reach 325.74 USD Million by 2031, exhibiting a growth rate (CAGR) of 8.97% during 2024-2031.

The worldwide market research report for Cobalt Hydroxide presents a thorough examination of the market environment. This includes a detailed evaluation of prominent industry leaders, pricing patterns, as well as the broader factors influencing the market, both…

Cobalt Powder Market 2023 Leading Competitors - Umicore, Freeport Cobalt, Hanrui …

Global Cobalt Powder Market prepared by MarketsandResearch.biz features a detailed overview of different industry segments, including influential leading players and their visions, to assist readers in evaluating growth opportunities. The report provides many business organizations with the required information to proliferate their business' reach within the global Cobalt Powder market. The report is the collection of all the market-related details right from the finances, regional development to the future market…

Cobalt Powder Market Upcoming Trends, Top Company Analysis and Forecast by 2028 …

The Cobalt Powder global market is thoroughly researched in this report, noting important aspects like market competition, global and regional growth, market segmentation and market structure. The report author analysts have estimated the size of the global market in terms of value and volume using the latest research tools and techniques. The report also includes estimates for market share, revenue, production, consumption, gross profit margin, CAGR, and other key factors.…

Cobalt Hydroxide Oxide (CAS 12016-80-7) Market Actual Need Outlook, Supportive J …

Report Ocean releases a new report about Global Cobalt Hydroxide Oxide (CAS 12016-80-7) Market analysis and insights, which aims to provide deep insight into numerous factors that are vital to the growth of this industry.

The information presented in this report will chart trends in the market, analyst opinions and views, competitive landscapes, and key regions from a systematic perspective. A report on the Global Cobalt Hydroxide Oxide (CAS 12016-80-7) Market…

Cobalt Sulphate Market to see 1.8% CAGR till 2023 | Freeport Cobalt Oy, Ganzhou …

The research offers a detailed segmentation of the global sulphate market. Key segments analyzed in the research include type, process, shell material, application, end user and geography. Extensive analysis of sales, revenue, growth rate, and market share of each type, process, shell material, application and end user for the historic period and the forecast period is offered with the help of tables.

The market is analyzed based on regions and competitive…