Press release

The Global Thermal Interface Material (TIMs) Market is projected to reach a value of USD 6.6 Billion by 2030

According to the report published by Virtue Market Research in Global Thermal Interface Material (TIMs) Market was estimated to be worth USD 4.28 Billion in 2024 and is projected to reach a value of USD 6.6 Billion by 2030, growing at a steady CAGR of 7.5% during the forecast period 2025-2030.Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/global-thermal-interface-material-market/request-sample

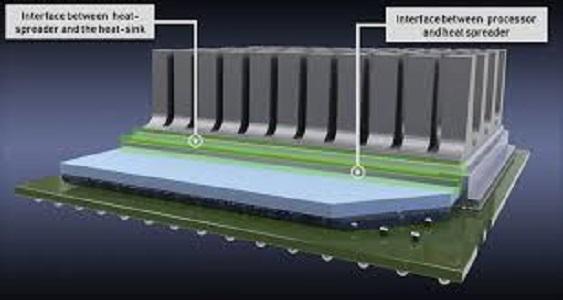

Thermal interface materials are essential components in modern electronics that help transfer heat from one surface to another, keeping devices cool and efficient. One long-term driver of the market is the rapid growth of the electronics and semiconductor sectors. As smartphones, laptops, data centers, and wearable devices become more powerful, the demand for effective heat management solutions increases. The COVID-19 pandemic temporarily disrupted supply chains and slowed production, but it also accelerated digital transformation and remote working, which increased demand for consumer electronics and cloud computing infrastructure. This dual effect shaped both short-term and long-term dynamics in the market.

In the short term, rising adoption of electric vehicles is driving demand for thermal interface materials. Batteries, power electronics, and charging systems in EVs generate heat that needs to be managed efficiently to ensure safety and performance. Companies are actively exploring innovative thermal solutions to handle higher voltages and compact designs, creating a surge in market demand. At the same time, an opportunity exists in the growing 5G infrastructure rollout. The increased data speeds and network density of 5G equipment produce higher thermal loads, prompting investments in advanced thermal interface solutions.

Manufacturers can leverage this growing need for efficient heat dissipation to expand their market presence.

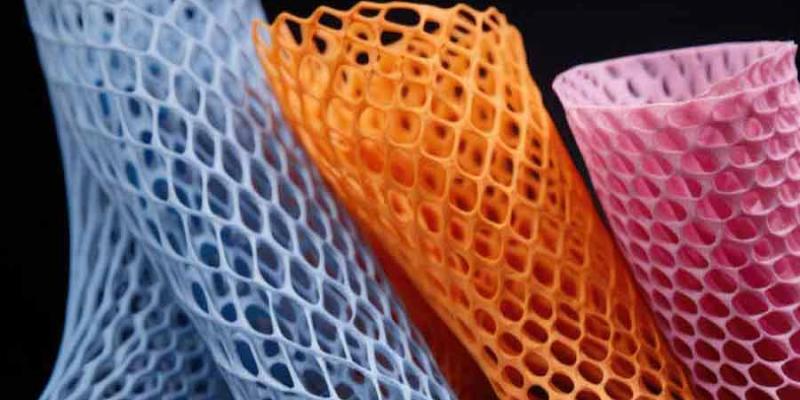

A notable trend in the industry is the shift toward materials that are both high-performance and eco-friendly. Traditional thermal interface materials often rely on synthetic compounds, but there is a growing preference for solutions with lower environmental impact without compromising conductivity. This trend is being reinforced by stricter regulations on chemical usage and rising awareness among electronics manufacturers about sustainability. Companies are experimenting with novel materials such as phase-change materials, thermally conductive pads, and gap fillers that not only offer improved thermal performance but are also recyclable or biodegradable, aligning with global sustainability goals.

Overall, the thermal interface material market is influenced by a combination of technological evolution and changing consumer needs. Long-term growth is tied to electronics and semiconductor expansion, while short-term drivers like electric vehicles and emerging 5G networks create immediate demand spikes. Opportunities in sustainable and high-performance materials are being actively pursued, with industry trends highlighting innovation and environmental responsibility. The market continues to adapt dynamically to new challenges, making it a crucial part of the electronics and energy sectors.

This interplay of innovation, demand, and sustainability ensures that thermal interface materials will remain critical in the next generation of devices and infrastructure. Market players are focusing on developing solutions that meet both technical and ecological requirements, fostering a balance between performance and responsibility. The continued evolution of devices, networks, and electric mobility will shape market growth, driving manufacturers to deliver materials that can efficiently manage heat while supporting broader environmental objectives. This combination of technical necessity and market opportunity positions the thermal interface material sector as a vital component of modern technology.

The market's trajectory also demonstrates how global events like COVID-19 can simultaneously challenge and accelerate demand. Supply chain disruptions highlighted vulnerabilities, but the surge in electronics consumption underscored the indispensable role of thermal interface materials. As devices become smaller, more powerful, and environmentally conscious, the need for innovative thermal solutions is expected to intensify. Companies that can combine efficiency, sustainability, and adaptability are likely to capture a larger share of the market, shaping the future of heat management across multiple industries.

The market, therefore, operates at the intersection of performance, innovation, and environmental consideration. Thermal interface materials are no longer just functional components; they are integral to device longevity, safety, and sustainability. Emerging trends suggest that the industry will continue to evolve rapidly, driven by increasing power densities, environmental regulations, and the proliferation of new technologies. This makes the thermal interface material market an exciting and strategically important segment in the global electronics and energy ecosystem.

Segmentation Analysis:

By Chemistry: Silicone, Epoxy, Polyimide, Others

Thermal Interface Material Market by chemistry is shaped by the different materials used to transfer heat efficiently. Silicone remains the largest subsegment in this category, as it provides excellent flexibility and thermal conductivity for electronics and industrial applications. Its reliability and long-term stability make it widely preferred in consumer devices, computer components, and telecom equipment. On the other hand, polyimide is the fastest-growing subsegment during the forecast period due to its ability to withstand higher temperatures and mechanical stress.

Polyimide-based materials are increasingly being adopted in advanced electronics, aerospace components, and electric vehicle systems where thermal and electrical performance are critical. Epoxy materials also continue to hold a significant share because of their adhesive properties and cost-effectiveness, particularly in industrial machinery and automotive electronics. Other chemistries, such as boron nitride composites or hybrid materials, are gaining attention in niche applications where specialized thermal management is needed. The growth in polyimide and other high-performance materials is driven by rising demand for miniaturized and high-power devices. Overall, this chemistry segmentation shows a mix of traditional, reliable materials and emerging high-performance compounds catering to evolving thermal management needs across multiple sectors.

By Product: Tapes and Films, Elastomeric Pads, Greases and Adhesives, Phase Change Material, Metal Based, Others

Thermal Interface Material Market by product includes several types designed for specific thermal applications. Elastomeric pads are the largest subsegment in this category, widely used due to their compressibility, ease of installation, and ability to fill gaps between components in computers, telecom devices, and automotive electronics. These pads provide reliable thermal conductivity and are suitable for repetitive assembly and disassembly, making them popular in industrial and consumer electronics.

Phase change materials (PCMs) are the fastest-growing subsegment during the forecast period because they adapt to temperature changes, improving heat transfer efficiency in high-performance electronics and EV battery systems. PCMs melt at a defined temperature and solidify upon cooling, providing dynamic thermal regulation. Greases and adhesives maintain a steady presence in applications where thin-layer thermal management is required, while tapes and films are favored for lightweight electronics and compact devices.

Metal-based thermal interface materials are also gaining traction in high-power applications like data centers and automotive power electronics. Other products, including hybrid gels and thermally conductive polymers, are emerging in specialized markets where performance requirements exceed conventional solutions. The diversity in product types reflects the need for tailored thermal management across a wide spectrum of applications.

By Application: Telecom, Computer, Medical Devices, Industrial Machinery, Consumer Durables, Automotive Electronics, Others

Thermal Interface Material Market by application is driven by the need to manage heat in various industries. The computer segment is the largest in this category because processors, GPUs, and data centers generate significant heat that requires reliable thermal interface solutions. Demand for cooling laptops, desktops, and servers continues to sustain the growth of this segment, especially in regions with high electronics adoption. Automotive electronics, however, is the fastest-growing subsegment during the forecast period.

The surge in electric vehicles, infotainment systems, and advanced driver-assistance systems has created an urgent need for thermal solutions that can handle compact, high-power modules. Telecom and industrial machinery applications also maintain steady growth, as base stations, networking equipment, and heavy machinery rely on efficient heat transfer for long-term stability. Medical devices and consumer durables continue to adopt thermal interface materials for electronics such as imaging equipment, wearable health monitors, and smart home appliances. Other specialized applications, including aerospace and defense electronics, further support niche growth. The variation across applications highlights how thermal interface materials adapt to both conventional cooling requirements and emerging high-performance demands in modern devices.

Read More @ https://virtuemarketresearch.com/report/global-thermal-interface-material-market

Regional Analysis:

Thermal Interface Material Market by region shows significant differences in adoption and growth trends. North America is the largest regional market due to the presence of leading semiconductor manufacturers, advanced data centers, and high consumer electronics demand. The region benefits from well-established manufacturing infrastructure, research capabilities, and rapid adoption of electric vehicles and 5G networks, which fuel steady demand for thermal solutions.

Asia-Pacific is the fastest-growing region during the forecast period as countries like China, Japan, South Korea, and India expand their electronics manufacturing base, telecom infrastructure, and automotive production. Rising disposable incomes, industrial automation, and government initiatives to promote electric mobility are driving the adoption of thermal interface materials in this region. Europe maintains moderate growth, supported by automotive electronics and industrial applications, while South America and the Middle East & Africa are gradually expanding due to emerging electronics markets and renewable energy projects. The regional trends show a combination of established high-demand areas and rapidly evolving markets, reflecting global shifts in technology, manufacturing, and energy transition initiatives.

Latest Industry Developments:

• Strategic Expansion into Emerging Markets: Companies in the thermal interface material market are increasingly focusing on expanding their presence in emerging markets, particularly in the Asia-Pacific region. This strategic move is driven by the rapid industrialization, growing electronics manufacturing, and rising demand for consumer electronics in countries like China, India, and Southeast Asia. By establishing local manufacturing facilities and forming partnerships with regional players, companies aim to enhance their supply chain efficiency and meet the specific thermal management needs of these markets. This approach allows them to capitalize on the region's growth potential and strengthen their competitive position.

• Development of Advanced Thermal Management Solutions: To stay ahead in the competitive landscape, companies are investing in the development of advanced thermal interface materials that offer superior performance. This includes the innovation of phase-change materials (PCMs) and metal-based solutions that provide efficient heat dissipation in high-power applications such as electric vehicles and data centers. By focusing on research and development, companies aim to offer products that not only meet the evolving thermal management requirements but also align with sustainability goals, thereby attracting environmentally conscious consumers and industries.

• Strategic Collaborations and Acquisitions: Companies are increasingly engaging in strategic collaborations and acquisitions to enhance their technological capabilities and market reach. By partnering with research institutions and acquiring companies with complementary technologies, firms can accelerate the development of innovative thermal interface materials and expand their product portfolios. These strategic moves enable companies to tap into new markets, leverage synergies, and strengthen their position in the thermal management industry.

customize the Full Report Based on Your Requirements @ https://virtuemarketresearch.com/report/global-thermal-interface-material-market/customization

contact Us:

Virtue Market Research

Kumar Plaza, #103, SRPF Rd, Ramtekadi, Pune, Maharashtra 411013, India

About Us:

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Global Thermal Interface Material (TIMs) Market is projected to reach a value of USD 6.6 Billion by 2030 here

News-ID: 4295977 • Views: …

More Releases from Virtue Market Research

The Global Vodka Seltzer Market is projected to reach a market size of USD 16.22 …

The Vodka Seltzer Market was valued at USD 9.4 billion in 2024 and is projected to reach a market size of USD 16.21 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.1%.

Request Sample @ https://virtuemarketresearch.com/report/vodka-seltzer-market/request-sample

The vodka seltzer market has grown from a niche beverage choice into a mainstream favorite, supported by shifting consumer lifestyles and evolving…

The Global Telehealth Services Market and is projected to reach a market size of …

The Global Telehealth Services Market was valued at USD 126.1 billion and is projected to reach a market size of USD 302.49 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.7%.

Request Sample @ https://virtuemarketresearch.com/report/telehealth-services-market/request-sample

The perennial shift towards patient-centric healthcare has been a pivotal long-term market driver for telehealth services. Over the years, the industry has witnessed…

The Subscription Box/Subscription E-Commerce Market is projected to reach a mark …

The Subscription Box/Subscription E-Commerce Market is valued at USD 47.19 billion in 2024 and is projected to reach a market size of USD 97.73 billion by the end of 2030. Over the outlook period of 2025-2030, the market is anticipated to grow at a CAGR of 12.9%.

Request Sample @ https://virtuemarketresearch.com/report/subscription-e-commerce-market/request-sample

The subscription e-commerce market has grown into one of the most dynamic parts of the digital economy. It began as a…

The Global Aramid Fibre Reinforced Polymer Composites Market is projected to rea …

According to the report published by Virtue Market Research in Aramid Fibre Reinforced Polymer Composites Market was valued at USD 5.55 billion and is projected to reach a market size of USD 8.57 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7.5%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/aramid-fibre-reinforced-polymer-composites-market/request-sample

The Aramid Fibre Reinforced Polymer Composites…

More Releases for Thermal

Thermal Weeder Market

Thermal Weeder Market Value is Anticipated to Increase at a Stable CAGR over the Forecast Period (2023 to 2029). It provides an in-depth analysis of the market segments which include products, applications, and competitor analysis.

Important changes in the business allow key players to attain larger profits. This Thermal WeederMarket study report is the best way to make changes with the help of entire market condition and metrics provided here. These…

Rising Demand for Thermal Analysis Techniques to Boost Differential thermal anal …

[San Francisco, USA] - Market research firm Trouve360Reports has added a latest report on the global differential thermal analysis market. The report offers a comprehensive analysis of the market, providing insights into key trends, growth drivers, and challenges that are shaping the industry.

The report presents a detailed market introduction, highlighting the definition of differential thermal analysis and its applications in various industries. The market overview section of the report offers…

Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market …

According to Market Study Report, Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market provides a comprehensive analysis of the Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC,…

What is the Difference Between Direct Thermal and Thermal Transfer Labels?

Northern Label Systems, specialists in supplying high quality labels explain the differences between Direct Thermal https://www.northern-label-systems.co.uk/labels-by-type/direct-thermal-labels and Thermal Transfer Labels https://www.northern-label-systems.co.uk/labels-by-type/thermal-transfer-labels

Thermal Transfer printing uses an ink ribbon to transfer the printed image from the heated printhead of the label printer onto the surface of the label while Direct Thermal printing transfers the image directly onto a heat sensitive material.

There are advantages and disadvantages to both methods. Direct Thermal label…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) …

Qyresearchreports include new market research report "Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Sales Market Report 2018" to its huge collection of research reports.

This report studies the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market status and forecast, categorizes the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market size (value & volume) by key players, type, application, and…