Press release

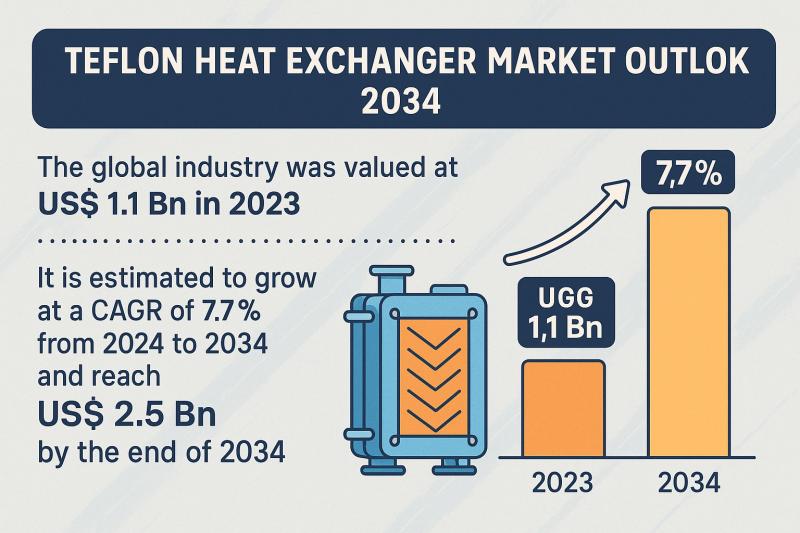

Teflon Heat Exchanger Market Poised to Reach USD 2.5 Billion by 2034 Amid Rising Demand for Energy Efficiency and Sustainable Thermal Management

The Teflon Heat Exchanger Market is entering a period of accelerated transformation, driven by the global shift toward energy-efficient industrial systems, sustainability mandates across power and waste management sectors, and continuous innovation in fluoropolymer-based thermal equipment. According to the latest industry analysis, the market-valued at US$ 1.1 Bn in 2023-is projected to grow at a CAGR of 7.7% from 2024 to 2034, reaching US$ 2.5 Bn by 2034.Examine key highlights and takeaways from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86276

With widespread adoption across chemical processing, metal treatment, pharmaceuticals, food & beverage, semiconductor manufacturing, petrochemical refining, and power generation, Teflon (PTFE) heat exchangers are becoming indispensable due to their unmatched corrosion resistance, high thermal stability, nonreactive surface properties, and ability to withstand extreme operating environments.

Market Overview

The Teflon Heat Exchanger Market has evolved into a cornerstone of high-performance industrial operations, particularly in sectors where corrosive fluids, volatile chemicals, and high-temperature processes are integral. Polytetrafluoroethylene (PTFE)-commercially known as Teflon-plays an essential role due to its hydrophobicity, nonreactivity, high temperature tolerance (-200°C to 260°C), low friction coefficient, and excellent insulating properties.

The market is witnessing robust adoption in industries such as:

Chemical processing and electrochemical industries

Semiconductor manufacturing

Pharmaceutical and drug production

Food & beverage sanitation and cooling

Metal processing and pickling operations

Power generation, including fossil-fueled and waste-to-energy plants

Oil & gas downstream systems

HVAC and environmental engineering

These sectors increasingly require heat exchangers that deliver corrosion resistance, high heat transfer efficiency, prolonged operational life, and reduced maintenance needs-attributes strongly aligned with PTFE-based systems.

Furthermore, industries facing rising energy prices and stricter emission regulations are shifting toward fluoropolymer heat exchangers to optimize energy usage, improve heat recovery, and comply with environmental directives.

Key Market Growth Drivers

1. Rising Focus on Energy Efficiency in End-use Industries

Growing awareness around energy conservation, combined with volatile energy costs, is driving industries to integrate heat exchangers that:

Improve heat transfer efficiency

Minimize operational energy losses

Reduce long-term utility expenses

Support sustainable manufacturing practices

Teflon heat exchangers are increasingly preferred due to their excellent corrosion resistance and capability to maintain high performance even under harsh conditions, enabling significant energy savings.

The global push to reduce carbon footprints is notable-especially as metal production alone contributes 40% of all industrial greenhouse gas emissions and 10% of global energy consumption. This has fueled the shift to PTFE heat exchangers, particularly in environments where metals fail due to corrosion or chemical degradation.

In the U.S., electricity prices rose 3.6% from 2023 to 2024, reinforcing a market-wide transition toward energy-efficient solutions.

2. Increased Focus on Sustainability in Power Generation & Waste Incineration

Global energy systems are undergoing rapid decarbonization. Governments and industries are adopting:

Low-emission technologies

High-efficiency heat recovery systems

Waste-to-energy operational frameworks

Flue gas desulfurization (FGD) technologies

Teflon heat exchangers significantly support these transitions by enabling:

Enhanced waste energy capture

Reduced geothermal fluid discharge

Lower water consumption in thermal systems

Improved exhaust gas purification

Fluoropolymer heat exchangers have become central to waste incineration units and fossil-fueled power plants, where high-temperature corrosion resistance is essential for maintaining long-term operational integrity.

3. Technological Advancements and Smart Heat Exchanger Development

Manufacturers are increasingly integrating smart technologies into heat exchanger design, prioritizing:

Remote monitoring

Thermal performance optimization

Predictive maintenance

Automated energy management

These innovations enhance efficiency, reduce downtime, and align with global sustainability targets. As vendors introduce more advanced PTFE systems, end-users are shifting from conventional metal designs to high-efficiency fluoropolymer alternatives.

Review our report to gain deeper insights and understanding -

https://www.transparencymarketresearch.com/teflon-heat-exchanger-market.html

Analysis of Key Players - Strategies and Industry Positioning

Major companies operating in the Teflon Heat Exchanger Market include:

Kansetsu International Co., Ltd.

FLUOROTHERM

Engiplas

Temtec Co., Ltd.

ShengLong Electric Heating Technology Co., Ltd.

Shenzhen Superb Heater Technology Co., Ltd.

API Heat Transfer

EVERSUPP Technology Corp.

Taiwan SRP Heat Exchanger Inc.

Jiangsu Rana Fluorine Material Technology Co., Ltd.

Wooam Super Polymer Co., Ltd.

Key Player Strategies Include:

1. Product Innovation & Advanced Design Integration

Companies are designing smart and energy-optimized heat exchangers with enhanced corrosion resistance, long operational life, and advanced tube configurations to outperform traditional systems.

2. Expansion of Production Capabilities

To meet increasing global demand, several players are restructuring and optimizing their production networks. For example:

API Heat Transfer consolidated production to facilities in Franklin, Iron Ridge, and Racine (Wisconsin) to enhance efficiency.

3. Strengthening Global Supply Chains

Manufacturers are deploying multi-region distribution networks to serve semiconductor, pharmaceutical, and chemical industries more effectively.

4. Strategic Customer-focused Manufacturing

Many players are adapting their manufacturing models based on customer feedback, aligning their product innovations with end-use industry performance requirements.

5. Sustainability-driven Portfolio Enhancement

Key firms are focusing on eco-friendly, high-efficiency PTFE heat exchangers to support customers' carbon reduction goals.

Market Challenges & Opportunities

Challenges

1. High Initial Capital Cost

Teflon heat exchangers, although cost-effective long-term, have higher upfront costs compared to traditional metal designs.

2. Limited Awareness in Emerging Markets

Industries in developing regions still rely heavily on low-cost metals due to lack of technical awareness regarding PTFE benefits.

3. Complex Manufacturing Processes

Production requires specialized fluoropolymer processing facilities, limiting market entry for small firms.

Opportunities

1. Rapid Industrialization in Asia Pacific

The region is expanding its metal processing, chemical, and semiconductor sectors, creating substantial opportunities for PTFE adoption.

2. Growing Sustainability Regulations

Stricter government mandates are pushing industries toward corrosion-resistant, energy-efficient systems.

3. Replacement of Aging Metal Heat Exchangers

A global surge in replacement demand-particularly in corrosive environments like pickling, anodizing, and flue gas treatment-creates a multi-billion-dollar opportunity.

4. Expansion into New End-use Sectors

Emerging growth areas include:

Waste-to-energy plants

Lithium-ion battery production

High-purity chemical handling

Renewable energy manufacturing lines

Key Player Strategies (Detailed Section)

Innovation-led R&D

Several companies are prioritizing research into:

Tube arrangements that minimize flow restrictions

Designs enabling long-term hydrostatic pressure performance

High-temperature & chemical-resistant configurations for power generation

Global Customer Acquisition

Players are targeting fast-industrializing regions through:

Direct sales channels

Distributor partnerships

Localization of product offerings

Capacity Expansion & Facility Optimization

API Heat Transfer's facility restructuring exemplifies a broader industry trend toward capacity optimization, improved logistics, and enhanced production efficiency.

Client-specific Customization

With industries requiring specialized heat transfer capabilities, manufacturers are increasingly offering tailored PTFE solutions, designed per application type, temperature range, and chemical exposure.

Recent Developments

Key recent milestones include:

2024 - Shenzhen Superb Heater Technology Co., Ltd.

Completed and dispatched 24 custom Teflon heaters for a Polish client, showcasing rising demand from European industries.

2023 - API Heat Transfer

Closed its Arcade, New York production facility and consolidated operations into more efficient sites across Wisconsin.

The strategy aimed to enhance capacity utilization, improve production efficiency, and align with customer requirements.

These developments highlight a shift toward global supply optimization, customized equipment production, and growing European demand for high-performance PTFE heat exchangers.

Investment Landscape and ROI Outlook

The Teflon Heat Exchanger Market presents a compelling investment opportunity due to:

1. Strong CAGR of 7.7% (2024-2034)

Driving demand from multiple high-growth industries.

2. Long Equipment Life & Low Maintenance Costs

PTFE systems offer significant ROI due to:

Reduced downtime

Lower corrosion-related failures

Prolonged operational lifespan

3. Alignment with Global Energy & Sustainability Mandates

Investors benefit from rising government-backed incentives across industries prioritizing energy optimization.

4. High Adoption Potential in Asia Pacific

The region dominates the market due to strong manufacturing ecosystems-particularly in China, India, Japan, and ASEAN.

5. Replacement Cycle Opportunity

Older metal heat exchangers are being replaced with PTFE models, ensuring steady long-term demand.

Market Segmentations (with Regional Insights)

By Type

Shell and Tube Heat Exchanger

Plate Heat Exchanger

Air-cooled Heat Exchanger

Others

By Size

Small-scale Heat Exchanger (Up to 15 kW)

Medium-scale Heat Exchanger (>15-150 kW)

Large-scale Heat Exchanger (>150 kW)

By End-use

Semiconductor

Chemical

Drug & Pharmaceutical

Food & Beverage

Pulp & Paper

Metal Processing

Petrochemical

HVAC Industry

Energy & Power

Others

Regions Covered

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Leading Region: Asia Pacific

Asia Pacific dominated the global market in 2023 due to:

Presence of major PTFE heat exchanger manufacturers

Expansion of metal processing and chemical industries

Increased semiconductor production

Strong industrialization across India, China, Japan, and ASEAN

India's metal sector is particularly strong, with 545 metallic mineral mines reported in FY22.

Why Buy This Report?

Comprehensive 2024-2034 market projections with segment-wise insights

Accurate assessment of drivers, restraints, and opportunities using verified data

Competitive landscape overview with profiling of leading manufacturers

Detailed regional breakdown capturing high-growth geographies

In-depth analysis of sustainability trends and energy-efficiency adoption

Recent developments, strategic moves, and investment patterns

Value chain analysis and Porter's Five Forces evaluation

Excel dataset + PDF for advanced business planning

This report delivers actionable insights for investors, manufacturers, suppliers, distributors, OEMs, and policymakers.

Buy this Premium Research Report for exclusive, in-depth insights -

https://www.transparencymarketresearch.com/checkout.php?rep_id=86276<ype=S

FAQs

1. What is the market size of the Teflon Heat Exchanger Market?

The market was valued at US$ 1.1 Bn in 2023 and is expected to reach US$ 2.5 Bn by 2034.

2. What is driving the demand for Teflon heat exchangers?

Rising energy costs, sustainability-focused policies, demand for corrosion-resistant equipment, and increased industrial process optimization.

3. Which region leads the global market?

Asia Pacific holds the largest market share due to its strong industrial growth and manufacturing ecosystem.

4. Who are the major players in the market?

Key companies include Kansetsu International, FLUOROTHERM, Engiplas, Shenzhen Superb Heater Technology, API Heat Transfer, Temtec, and others.

5. Which industries use Teflon heat exchangers?

Semiconductors, chemicals, pharmaceuticals, food & beverage, metal processing, petrochemicals, HVAC, and energy & power.

Explore Latest Research Reports by Transparency Market Research:

Ammonia Energy Market - https://www.transparencymarketresearch.com/ammonia-energy-market.html

LNG Engine Market - https://www.transparencymarketresearch.com/lng-engine-market.html

Solar-Powered EV Charging Stations Market - https://www.transparencymarketresearch.com/solar-powered-ev-charging-stations-market.html

Smart Energy Market - https://www.transparencymarketresearch.com/smart-energy-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Teflon Heat Exchanger Market Poised to Reach USD 2.5 Billion by 2034 Amid Rising Demand for Energy Efficiency and Sustainable Thermal Management here

News-ID: 4293173 • Views: …

More Releases from Transparency Market Research

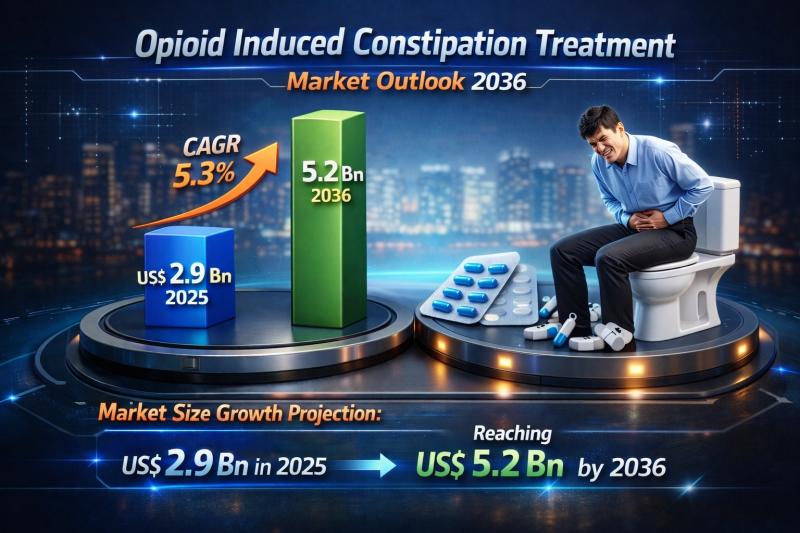

Global Opioid Induced Constipation Treatment Market Set to Reach USD 5.2 Billion …

The global opioid induced constipation (OIC) treatment market is witnessing steady and sustained growth as healthcare systems worldwide place increasing emphasis on comprehensive pain management and supportive care. Valued at US$ 2.9 billion in 2025, the market is projected to reach US$ 5.2 billion by 2036, expanding at a compound annual growth rate (CAGR) of 5.3% from 2026 to 2036. Growth is primarily fueled by the rising prevalence of chronic…

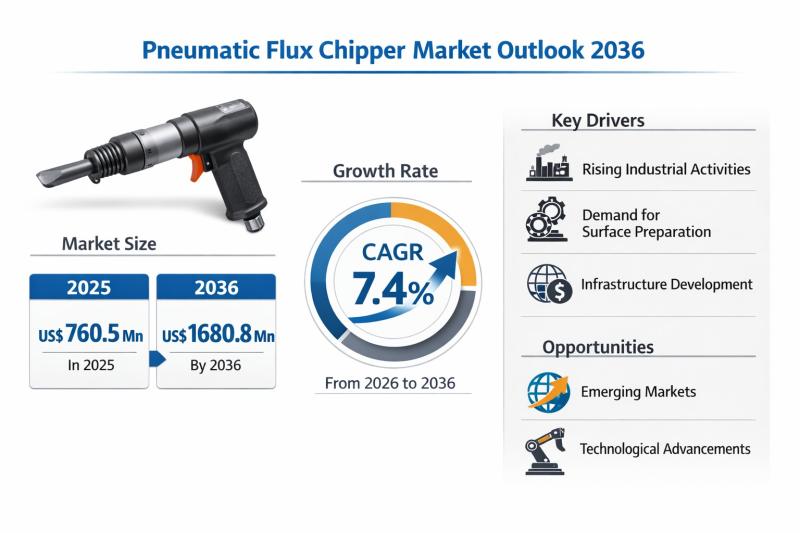

Pneumatic Flux Chipper Market Expanding at 7.4% CAGR Through 2036 - By Product T …

The global Pneumatic Flux Chipper Market is set to witness sustained and resilient growth over the next decade, underpinned by expanding heavy manufacturing activities, rising welding and fabrication demand, and continuous investments in industrial infrastructure across emerging and developed economies. According to the latest industry analysis, the market was valued at US$ 760.5 Mn in 2025 and is projected to reach US$ 1,680.8 Mn by 2036, expanding at a compound…

AI in Automotive Market Outlook 2036: Global Industry to Surge from US$ 19.8 Bil …

The AI in automotive market is entering a phase of exponential expansion, supported by rapid digitization of vehicles, growing safety mandates, and consumer demand for intelligent mobility. The global market was valued at US$ 19.8 Bn in 2025 and is projected to reach US$ 244.4 Bn by 2036, registering a remarkable CAGR of 27% from 2026 to 2036.

This growth trajectory reflects the transition of automobiles from mechanically driven products to…

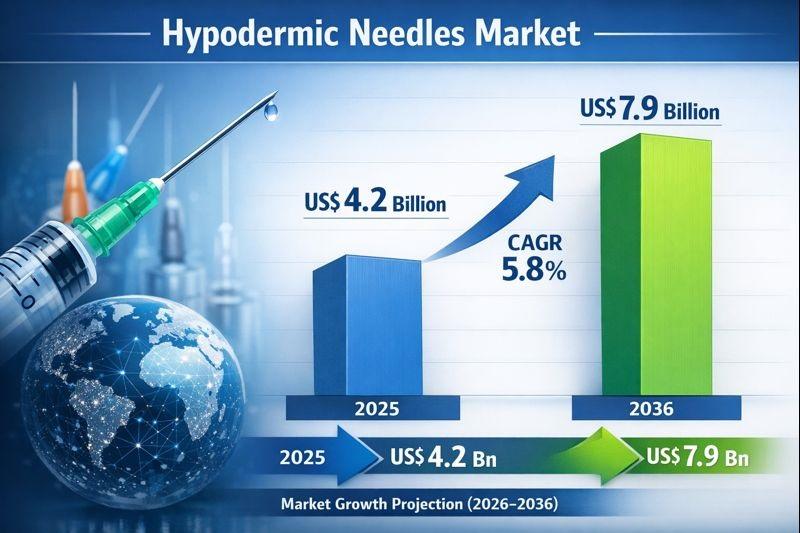

Hypodermic Needles Market to Reach US$ 7.9 Billion by 2036 on Rising Injectable …

The global hypodermic needles market was valued at approximately US$ 4.2 billion in 2025 and is projected to reach around US$ 7.9 billion by 2036, expanding at a CAGR of nearly 5.8% from 2026 to 2036, driven by the rising prevalence of diabetes, cancer, and chronic diseases, growing demand for injectable drugs and biologics, and the expansion of global vaccination and immunization programs; increasing adoption of safety-engineered and disposable needles,…

More Releases for Heat

Heat Meters Market, Transforming Heat Measurement with Intelligent Metering Solu …

The global heat meters market has become a critical component of modern energy infrastructure as governments, utility companies, and consumers strive for greater accuracy in heat consumption, improved energy efficiency, and transparent billing systems. Heat meters-devices that measure the thermal energy used in residential, commercial, and industrial heating systems-play an essential role in district heating networks, HVAC systems, and renewable heat integration. With rising global emphasis on energy conservation and…

Global Ceramic Heat Sink Heat Sink Market Drivers Analysis 2025

According to our (Global Info Research) latest study, the global Ceramic Heat Sink Heat Sink market size was valued at US$ million in 2024 and is forecast to a readjusted size of USD million by 2031 with a CAGR of %during review period.

This report is a detailed and comprehensive analysis for global Ceramic Heat Sink Heat Sink market. Both quantitative and qualitative analyses are presented by manufacturers, by region &…

Plate Fin Heat Sinks vs. Heat Pipe Heat Sinks: Which is Right for Consumers?

In the modern industrial landscape, heat sinks [https://www.coolerchina.com/] play a crucial role in ensuring the stable operation and longevity of equipment by effectively dissipating heat generated by devices into the surrounding environment. Among the numerous types of heat sinks available, plate fin heat sinks and heat pipe heat sinks are two of the most common. This article will compare these two types, helping you choose the right one for your…

Efficient Heat Transfer Solutions: Global Heat Pipe Heat Exchanger Market to Rea …

As per the study initiated by Evolve Business Intelligence, the global Heat Pipe Heat Exchanger market size accounted for USD 18.2 Billion in 2022, growing at a CAGR of 6.5% from 2023 to 2033. The Heat Pipe Heat Exchanger (HPHE) Market refers to the global market for heat exchangers that use heat pipes as a primary heat transfer element. Heat pipe heat exchangers are used in a wide range of…

India Heat Exchangers Market Size Set For Explosive Growth | Radiant Heat Exchan …

The India heat exchangers market accounted for $454.4 million in 2018, and is anticipated to reach $890.0 million by 2026, registering a CAGR of 8.6% from 2019 to 2026. Heat exchanger is a system designed to efficiently transfer energy between two or more fluids. The production of heat exchangers is a highly labor-intensive process, attributable to the long welding hours. Thus, heat exchangers are preferably manufactured in India, owing to…

Global Heat Pipe Heat Exchanger Market Research Report 2017

Summary

This report studies Heat Pipe Heat Exchanger in Global market, especially in North America, Europe, China, Japan, Southeast Asia and India, focuses on top manufacturers in global market, with capacity, production, price, revenue and market share for each manufacturer, covering

Mitsubishi Electric Corporation

Nortek Air Solutions

Munters Corporation

Greenheck

RenewAire

DRI Innovative Air Solutions

Reznor

Zehnder America

Ruskin Rooftop System

Market Segment by Regions, this report splits Global into several key Regions, with production, consumption, revenue, market share and growth…