Press release

Foundry Chemicals Market to Reach US$3.24 Billion by 2032 Driven by Rising Demand in Automotive and Industrial Casting

The global foundry chemicals market is undergoing a significant transformation, fueled by technological advancements, rising demand for high-quality castings, and expanding industrial activities. According to the latest study by Persistence Market Research, the market is valued at US$2.41 billion in 2025 and is projected to reach US$3.24 billion by 2032, registering a steady CAGR of 4.3%. Foundry chemicals play an essential role in improving casting efficiency, enhancing mold performance, and ensuring superior metallurgical properties, making them indispensable in industries such as automotive, machinery manufacturing, construction, and metal processing.Get Your FREE Sample Report Instantly - Click Now: https://www.persistencemarketresearch.com/samples/33543

Rising Demand for High-Precision Casting Components

The increasing requirement for high-precision metal casting components is one of the biggest catalysts propelling the foundry chemicals market. Foundry operations rely extensively on chemicals such as binders, coatings, additives, and release agents to ensure precision, reduce defects, and improve overall casting quality. With the growing complexity of metal components-particularly in the automotive and industrial machinery sectors-the need for chemical formulations that allow for high dimensional accuracy continues to rise. These chemicals help manufacturers eliminate casting flaws such as porosity, shrinkage, and surface roughness, ensuring superior performance in end-use applications.

In the years ahead, technological advancements such as 3D sand printing and automated molding systems are expected to further boost the adoption of specialized foundry chemicals. As manufacturers shift towards lightweight materials and intricate casting designs, the demand for innovative chemical solutions that enhance fluidity, strength, and mold stability will continue to grow. Foundries across emerging economies are also modernizing their processes, increasing their reliance on advanced chemical support solutions to reduce wastage and improve yield. As a result, the market is projected to maintain its upward trajectory throughout the forecast period.

Growing Automotive Production Driving Market Expansion

The automotive industry remains the dominant consumer of foundry chemicals, driven by increasing production of vehicles, electric mobility components, and lightweight structural parts. Casting is integral to automotive manufacturing, with components such as cylinder blocks, transmission cases, chassis parts, and braking systems relying heavily on high-quality molds and cores. Foundry chemicals ensure that these parts meet strict quality, durability, and performance standards. With global automobile production rebounding post-pandemic and electric vehicle (EV) manufacturing increasing, demand for precision castings and, consequently, foundry chemicals continues to surge.

Moreover, automotive manufacturers are aggressively exploring lightweight metals such as aluminum and magnesium to improve vehicle efficiency and meet global emission regulations. This shift is pushing foundries to adopt new chemical formulations that optimize metal flow, improve heat resistance, and enhance the stability of molds for non-ferrous casting. The increased adoption of automation in automotive foundries also requires chemical products that are compatible with high-speed production lines, ensuring consistency and minimizing downtime. These factors collectively fuel sustained growth in the foundry chemicals segment associated with the automotive industry.

Market Segmentation Overview

The foundry chemicals market is broadly segmented by product type, foundry type, industry, and region, each contributing distinct growth opportunities. The product type segment includes:

Market Segmentation

By Product Type

Binders

Coatings

Auxiliaries & Release Agents

Additives

Others

Each of these products plays a crucial role in casting. Binders, such as resin-based systems, are essential for holding sand grains together during mold and core-making. They offer stability, heat resistance, and improved structural strength. Coatings enhance surface finish, minimize defects, and provide thermal insulation, especially when used in high-temperature castings like steel. Auxiliaries and release agents ensure smooth mold separation, while additives improve mold permeability, thermal resistance, and casting consistency. Together, these chemicals enhance operational efficiency, reduce waste, and improve final product quality.

By Foundry Type

Iron

Steel and Alloy

Aluminum

Non-ferrous

In the foundry type segment, iron and steel foundries remain the largest consumers due to their dominance in heavy machinery and automotive component production. Meanwhile, aluminum foundries are growing rapidly, driven by the automotive industry's shift to lightweight materials. Non-ferrous foundries, producing copper, zinc, and magnesium components, are also witnessing increasing adoption of specialized chemicals to support advanced manufacturing practices.

Get a Customized Market View in One Click: https://www.persistencemarketresearch.com/request-customization/33543

Rapid Industrialization in Emerging Economies

Emerging markets such as India, China, Brazil, and Southeast Asia are playing an increasingly vital role in the growth of the foundry chemicals market. Rapid industrialization, infrastructure development, and the rising presence of automotive and machinery manufacturing plants have contributed significantly to the increased consumption of foundry chemicals. Many global foundry chemical manufacturers are expanding their footprint in these regions to capitalize on growing demand and competitive production costs.

The industrial machinery sector, in particular, is witnessing strong expansion in emerging economies due to growing construction, mining, and agriculture activities. Foundries supporting these industries rely heavily on chemical solutions to produce durable, high-strength components capable of withstanding harsh operational environments. As governments in Asia and Latin America invest heavily in industrial growth, the demand for advanced casting solutions-and therefore, foundry chemicals-is expected to remain robust.

Technological Advancements Improving Casting Efficiency

Modern foundries are increasingly embracing automation, digitalization, and advanced materials to improve casting output and minimize operational inefficiencies. Foundry chemicals are evolving to align with these advancements by offering improved formulations that support faster production, finer detail, and enhanced durability. For instance, developments in binder systems now focus on reducing emissions, controlling odor, and improving environmental compatibility. Such innovations align with global sustainability trends, making foundry chemicals more eco-friendly without compromising performance.

Additionally, advancements in coating materials now allow greater precision and improved surface finish in castings. These coatings can withstand higher temperatures and offer better anti-penetration properties, reducing defect rates. Automated mold-making and pouring systems also require chemicals that offer consistent performance, quick drying, and compatibility with digital molding equipment. As Industry 4.0 principles continue to revolutionize foundry operations, manufacturers of foundry chemicals are investing more in R&D to meet evolving industrial needs.

Increasing Focus on Sustainable and Eco-Friendly Solutions

Sustainability has become a major focus area for foundry chemical manufacturers as industries face stricter environmental regulations and rising awareness about ecological impacts. Traditional chemical formulations often involve emissions and volatile organic compounds (VOCs) during molding and casting. To address this challenge, companies are developing low-emission binder systems, water-based coatings, and biodegradable additives that reduce environmental footprint while maintaining casting quality.

Sustainable foundry chemicals not only help reduce pollution but also improve workplace safety for foundry workers. Technologies such as inorganic binders are gaining traction, providing high thermal stability with minimal emissions. The adoption of eco-friendly foundry chemicals is expected to accelerate further as industries prioritize cleaner production methods. Governments worldwide are also encouraging the transition through incentives and regulatory frameworks, ultimately supporting market growth in this segment.

Company Insights: Key Players Influencing Market Landscape

The competitive landscape of the foundry chemicals market is characterized by innovation, strategic partnerships, and global expansion. Several leading companies dominate the market by offering high-performance formulations and value-added technical support.

Company Insights

✦ ASK Chemicals

✦ Vesuvius

✦ Imerys

✦ Ferro

✦ Hexion

✦ Huttenes-Albertus

✦ Chemex Chemicals

✦ Wacker Chemie AG

✦ DOW

✦ Key Resins

These players invest significantly in research and development to create advanced formulations that cater to evolving industrial requirements. Many of them are also expanding their presence in Asia-Pacific and other emerging markets to tap into growing demand for advanced casting solutions.

Rising Use of Foundry Chemicals in Construction and Infrastructure

The construction industry is another major end-user of foundry products, significantly contributing to market growth. Foundry chemicals help create durable components used in construction machinery, structural frameworks, and architectural metal products. As large-scale urbanization projects and infrastructure upgrades continue worldwide, the demand for metal castings and foundry chemicals is expected to surge.

Furthermore, the increasing need for high-strength steel and aluminum components in modern construction practices drives the adoption of specialized chemical formulations. These chemicals enhance mold performance, provide better thermal insulation, and ensure consistent casting quality even in complex architectural designs. As construction activities increase across emerging economies, the foundry chemicals market is poised to benefit significantly, particularly in regions undergoing rapid urbanization and industrial expansion.

For In-Depth Competitive Analysis, Buy Now: https://www.persistencemarketresearch.com/checkout/33543

Market Outlook and Future Opportunities

Looking ahead, the foundry chemicals market is poised for steady expansion, driven by advancements in manufacturing technology, rising consumption of metal castings, and growing emphasis on sustainability. Innovation in binder systems, coatings, and additives will play a critical role in shaping future market trends. Additionally, the growth of the electric vehicle industry, renewable energy sector, and advanced machinery manufacturing will create new avenues for foundry chemical applications.

Manufacturers who invest in greener, more efficient formulations and digital solutions that enhance casting accuracy will remain competitive in the long run. As global industries evolve toward higher productivity and cleaner production standards, the demand for advanced foundry chemical solutions will continue to accelerate, positioning the market for sustained growth through 2032.

Contact Us:

Persistence Market Research

Second Floor, 150 Fleet Street,

London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Foundry Chemicals Market to Reach US$3.24 Billion by 2032 Driven by Rising Demand in Automotive and Industrial Casting here

News-ID: 4293123 • Views: …

More Releases from Persistence Market Research

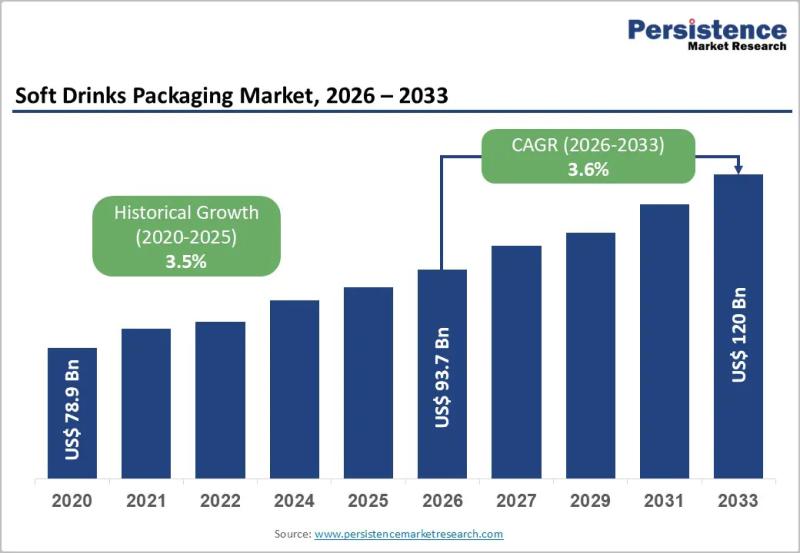

Soft Drinks Packaging Market to Reach US$120.0 Billion by 2033 - Persistence Mar …

The soft drinks packaging market plays a central role in the global beverage industry, serving carbonated drinks, juices, flavored water, energy drinks, and ready to drink teas and coffees. Packaging is no longer limited to containment and transportation; it has evolved into a critical component of branding, sustainability strategy, consumer convenience, and supply chain efficiency. Manufacturers are increasingly focusing on lightweight materials, recyclable packaging formats, and innovative designs that improve…

Christmas Tree Valves Market Size to Reach US$8.1 Billion by 2033 - Persistence …

The Christmas Tree Valves Market plays a critical role in the upstream oil and gas industry, serving as a central component in wellhead equipment systems. Christmas tree valves are installed on oil and gas wells to control pressure, regulate flow, and ensure safe extraction of hydrocarbons. These assemblies, commonly referred to as "Christmas trees," consist of multiple valves, spools, and fittings arranged in a structure that resembles a decorated tree.…

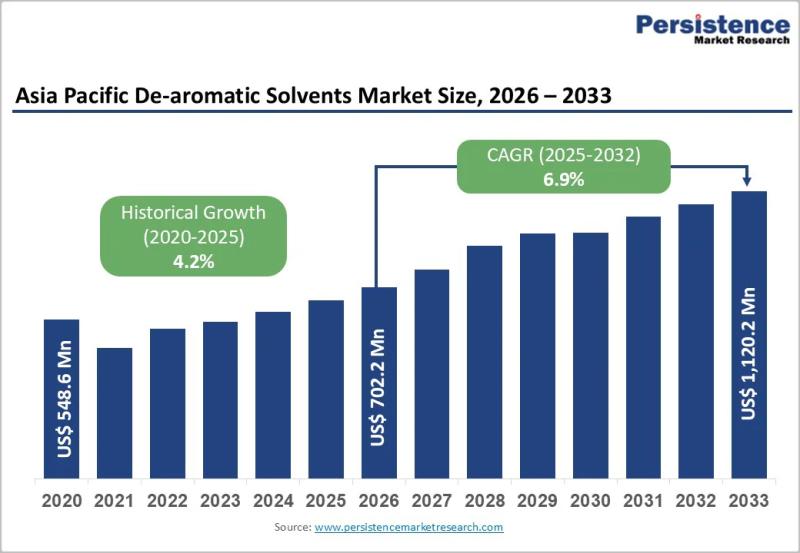

Asia Pacific De-aromatic Solvents Market to Reach US$1,120.2 Million by 2033 - P …

The Asia Pacific De-aromatic Solvents Market is gaining steady momentum as industries across the region increasingly shift toward low aromatic, high purity solvent formulations. De-aromatic solvents are hydrocarbon solvents that have significantly reduced aromatic content, making them suitable for applications requiring low odor, lower toxicity, and improved environmental performance. These solvents are widely used in paints and coatings, adhesives, inks, metalworking fluids, agrochemicals, and cleaning formulations. As regulatory scrutiny around…

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

More Releases for Foundry

Manhole Covers Market Size, Outlook 2033 by Key Companies-EJ Group, Neenah Found …

USA, New Jersey: According to Verified Market Revenue was valued at USD 4.5 billion in 2024 and is estimated to reach USD 6.9 billion by 2033, growing at a CAGR of 5.1% from 2026 to 2033.

How AI and Machine Learning Are Redefining the Future of Manhole Covers Market?

Artificial Intelligence (AI) and Machine Learning (ML) are rapidly transforming the manhole covers market by introducing smart solutions, predictive maintenance, and optimized manufacturing…

Foundry Tools Market Giants Spending Is Going To Boom | Artisan Foundry Shop, Ar …

The latest study released on the Global Foundry Tools Market by AMA Research evaluates market size, trend, and forecast to 2027. The Foundry Tools market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Key Players in…

Global Manhole Covers Market 2020 - EJ Group, Neenah Foundry, US Foundry, PAM, A …

A new statistical surveying study titled "Global Manhole Covers Market" investigates a few critical features identified with Manhole Covers Market covering industry condition, division examination, and focused scene. Down to earth ideas of the market are referenced in a straightforward and unassuming way in this report. A far-reaching and exhaustive essential investigation report features various actualities, for example, improvement factors, business upgrade systems, measurable development, monetary benefit or misfortune to…

2025 Analysis on Manhole Covers Market Report Forecast: By key players EJ Group, …

Up Market Research offers a latest published report on “Global Manhole Covers Market Research Report 2019” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 94 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Request Sample Copy Of this Report @ https://www.upmarketresearch.com/home/requested_sample/66757

Manhole Covers Market research report delivers a close watch…

Global Iron Casting [Ferrous Castings] Market 2018 Growth Rate by Players: Waupa …

Market Research Store Exposed a new deep Industry research report focuses on Iron Casting [Ferrous Castings] Market, delivers detailed analysis of market and future prospects of Iron Casting [Ferrous Castings] market. The critical and significant data in the study makes the research a very important tool for experts, analysts and managers to get ready-to-access analysis by the industry professionals. The Iron Casting [Ferrous Castings] Market report provides the complete analysis…

Ductile Iron Castings Market SWOT Analysis by Key Players: Durham Foundry, Penn- …

QY Research has lately published a new report on “Global Ductile Iron Castings Market: Industrial Chain Market Insights, Growth Trends and Competitive Analysis 2025,” for the forecasted period 8-years, i.e. between 2017 and 2025.

The Ductile Iron Castings market was valued at Million US$ in 2017 and is projected to reach Million US$ by 2025, at a CAGR of during the forecast period. In this study, 2017 has been considered…