Press release

Energy Meter Manufacturing Plant Setup Report 2025: Machinery Cost and Technology Requirements

Setting up an energy meter manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Energy Meter Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing an energy meter manufacturing plant, covering everything from product overview and manufacturing processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/energy-meter-manufacturing-plant-project-report/requestsample

What is an Energy Meter?

An energy meter including electricity meter, electrical meter, energy meter, and electric meter measures the amount of electric energy a residence, business, or machine uses. In an electric circuit, energy equals current multiplied by voltage. Energy is measured in kilowatt-hours (kWh) in the United States. Energy meters have been an important aspect of the utility industry, providing a means for the utility company to bill the customer for actual power used. From older electromechanical energy meters, the energy meter has evolved to modern, digital, smart energy meters that can provide more frequent, real-time readings. A smart meter can help energy consumers to better understand their energy use and adjust their energy use accordingly, and it can help utilities better manage load, detect faults, and forecast demand. Some types of energy meters also measure the power factor, frequency, and maximum demand (maximum load for a period of time). With the growth of sustainability and energy efficiency applications, energy meters are becoming an increasingly important part of current power systems, which provide visibility, reduce energy waste, and help optimize power distribution networks.

What is Driving the Energy Meter Manufacturing Market?

The energy meter manufacturing market growth can be attributed to the technological developments and supportive government policies, and the global efforts towards energy efficiency and smart infrastructure. The growing deployment of smart grids across the globe to allow for data collection and real-time information about the power distribution is driving the growth of the energy meter manufacturing market. In order to reduce energy consumption, improving energy efficiency and the reliability of grid systems, governments are increasingly passing energy and building codes and smart metering programs. Increasing energy consumption due to rapid population growth and industrialization requires accurate and reliable monitoring and measurement of energy consumption. Another driver towards smart meters is the addition of Internet of Things (IoT) features, wireless communications and data analytics capabilities for energy meters which would provide value to the utility companies and consumers. Additionally, an increase in the integration of renewable energy sources such as photovoltaic systems and wind power also leads to the need for advanced meters. Furthermore, an increase in infrastructure requirements, digitalization, and the need for transparent billing systems are creating opportunities for the global energy meter manufacturing market to grow.

Buy Now: https://www.imarcgroup.com/checkout?id=11972&method=1911

Key Steps Required to Set Up an Energy Meter Manufacturing Plant

1. Market Analysis

The report provides insights into the landscape of the energy meter industry at the global level. The report also provides a segment-wise and region-wise breakup of the global energy meter industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of energy meter, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the energy meter manufacturing plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for energy meter manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for energy meter production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up an energy meter manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Request for Customized: https://www.imarcgroup.com/request?type=report&id=11972&flag=E

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

Latest News and Developments

The energy meter manufacturing industry has experienced substantial growth with major capacity expansions driven by global smart meter deployment programs and utility infrastructure modernization. Leading manufacturers including Landis+Gyr, Itron, and Schneider Electric have established advanced production facilities across multiple continents to meet surging demand for smart metering solutions. China remains the dominant manufacturing hub with companies like Wasion Group, Holley Technology, and Hexing Electrical expanding their automated production lines in Zhejiang and Hunan provinces, producing millions of meters annually for domestic electrification programs and international exports. India has emerged as a major production center with government-backed smart meter initiatives driving investments by companies like Genus Power and HPL Electric establishing state-of-the-art facilities.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Energy Meter Manufacturing Plant Setup Report 2025: Machinery Cost and Technology Requirements here

News-ID: 4292398 • Views: …

More Releases from IMARC Group

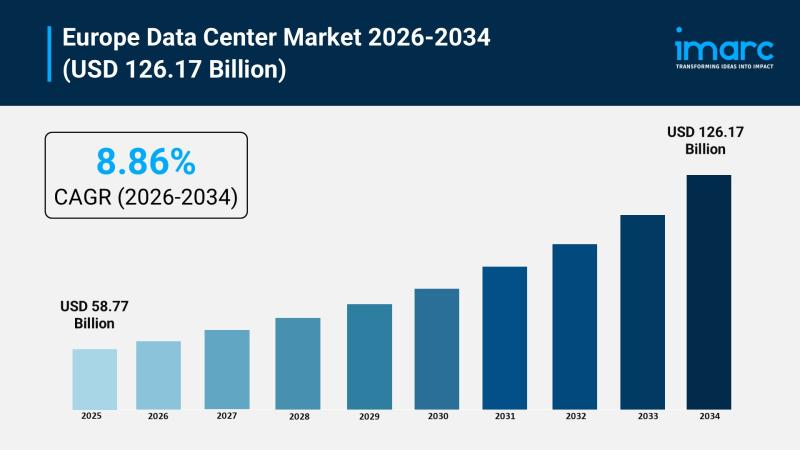

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

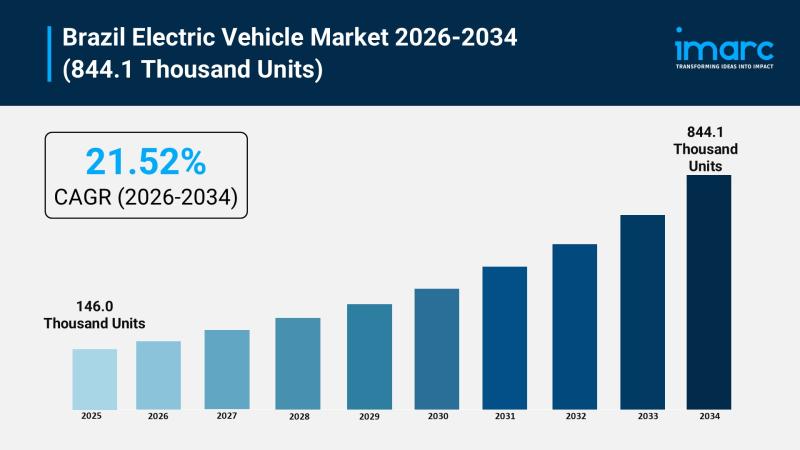

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Energy

Green Renewable Energy Market Next Big Thing: Enphase Energy, Bloom Energy, Clea …

Advance Market Analytics published a new research publication on "Green Renewable Energy Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Green Renewable Energy market was mainly driven by the increasing R&D spending across the world.

Get inside Scoop of the…

Business Energy Solution Market Size in 2023 To 2029 | SSE Energy Solutions, BES …

The large-scale Business Energy Solution market report provides valuable insights for clients looking to forecast investments in emerging markets, expand market share, or launch new products. The report presents multifaceted Business Energy Solution market insights that are simplified using established tools and techniques, making it a credible marketing report. Data is presented in a clear and easy-to-understand manner, with graphs and charts to aid comprehension. The report employs integrated approaches…

Decentralized Energy Storage Market Is Booming Worldwide | Fuelcell Energy, Enph …

A new business intelligence report released by AMA with title "Decentralized Energy Storage Market" has abilities to raise as the most significant market worldwide as it has remained playing a remarkable role in establishing progressive impacts on the universal economy. The Global Decentralized Energy Storage Market Report offers energetic visions to conclude and study market size, market hopes, and competitive surroundings. The research is derived through primary and secondary statistics…

Waste-To-Energy Technologies Market Top Growing Companies: Xcel Energy, Novo Ene …

Qurate Business Intelligence’s up-to-date research study on Waste-To-Energy Technologies was performed by highly qualified research professionals and industry experts. This is to provide an in-depth analysis on the Waste-To-Energy Technologies. The report is comprehensive and includes over 120 pages. The global energy market is witnessing a shift toward waste to energy technologies due to growing energy demands worldwide, the rapid depletion of conventional sources of energy, and concerns over…

Waste To Energy Market ||Novo Energy Ltd., Hitachi Zosen, Foster Wheeler A.G., S …

Zion Market Research published a new 110+ pages industry research "Global Waste to Energy Market Set For Rapid Growth, To Reach Value Around USD 42.74 Billion By 2024" is exhaustively researched and analyzed in the report to help market players to improve their business tactics and ensure long-term success. The authors of the report have used easy-to-understand language and uncomplicated statistical images but provided thorough information and detailed data on…

In-Pipe Hydro Systems Market | key player - Lucid Energy, Rentricity, Tecnoturbi …

Looking at the current market trends as well as the promising demand status of the “In-Pipe Hydro Systems Market” it can be projected that the future years will bring out positive outcomes. This research report added by MRRSE on its online portal delivers clear insight about the changing tendencies across the global market. Readers can gather prime facets connected to the target market which includes product, end-use and application; assisting…