Press release

Automotive Aluminum Market | The USD 32.1B Lightweighting Engine Behind EV Range, SUV Design & Net-Zero Targets

Automotive Aluminum Market | The USD 32.1B Lightweighting Engine Behind EV Range, SUV Design & Net-Zero Targets

The Automotive Aluminum Market has moved from "alternative metal" to core architecture material for EVs, SUVs, and next-generation structural platforms.

From battery enclosures and body-in-white to crash structures and heat management, aluminum is now central to how OEMs engineer range, safety, and emission compliance.

The global Automotive Aluminum Market is valued at USD 19.2 billion in 2025 and is expected to reach USD 32.1 billion by 2035, growing at a 5.3% CAGR, as OEMs shift decisively toward aluminum-intensive platforms, closed-loop recycling, and low-carbon supply chains.

Get the Detailed Industry Analysis (including the Table of Contents, List of Figures, and List of Tables) - from the Automotive Aluminum Market Research Report: https://marketgenics.co/reports/automotive-aluminum-market-10030

Global Automotive Aluminum Market Outlook (2025-2035)

Three structural forces shape demand:

• Lightweighting for fuel efficiency and CO2 compliance

• EV platform electrification and battery safety architecture

• Circular aluminum supply chains and low-carbon smelting

Aluminum is no longer just a material choice; it is a strategic lever for regulation, range and resilience.

Market Snapshot - Key Numbers

• Market Size 2025: USD 19.2B

• Market Forecast 2035: USD 32.1B

• CAGR 2025-2035: 5.3%

• Largest Application Segment: Body-in-white (~36% share)

• Most Attractive Region: Asia Pacific

Total incremental opportunity: ~USD 12.9B in new value by 2035.

Why Automotive Aluminum Has Become Structurally Non-Negotiable

OEMs must simultaneously:

• Reduce vehicle weight to meet tightening fleet emission norms

• Extend EV range without oversizing batteries

• Achieve 5-star crash ratings with lighter architectures

• De-carbonize material inputs in line with net-zero roadmaps

Aluminum answers across:

• Body-in-white structures - high strength-to-weight with design flexibility

• Crash management systems - energy absorption in front/rear structures

• Battery housings - thermal conductivity + crash protection

• Chassis and suspension - stiffness with mass reduction

Automotive aluminum acts as the mechanical and thermal backbone of modern vehicle engineering.

To know more about the Automotive Aluminum Market - Download our Sample Report: https://marketgenics.co/download-report-sample/automotive-aluminum-market-10030

Lightweighting: From Fuel Economy to EV Range

Lightweighting is now a range strategy as much as a fuel-efficiency strategy.

Examples:

• Ford F-150 and F-150 Lightning use extensive aluminum in body panels and structural elements, cutting up to ~700 pounds in earlier redesigns and enabling better payload and efficiency.

• Tesla's platforms leverage aluminum-intensive architectures (Model S and Model 3) to balance crash performance, range, and acceleration.

• GM's Silverado EV has significantly increased aluminum content in body-in-white to remove hundreds of kilograms while maintaining structural rigidity.

As SUVs and pickups grow in global share, aluminum becomes essential to reconcile vehicle size with efficiency and emissions constraints.

EV Platforms: Battery Enclosures and Structural Integration

EV battery enclosures are emerging as one of the highest-value growth pockets for automotive aluminum.

Why aluminum dominates here:

• High thermal conductivity to help manage battery temperature

• High crash energy absorption with tailored extrusions and castings

• Corrosion resistance for underbody placement

• Compatibility with modular skateboard platforms

Examples:

• Magna International's aluminum structural battery enclosure facility in Ontario is dedicated to next-gen EV platforms, scaling lightweight, crashworthy enclosures for global OEMs.

• Constellium supplies aluminum crash management systems and battery enclosures for vehicles like the Hyundai IONIQ 6, balancing safety and mass.

• Hydro's partnership with Rivian targets custom extruded aluminum structures and enclosures for upcoming EV programs.

Battery housing is becoming a central profit and innovation zone for aluminum producers.

Buy Now: https://marketgenics.co/buy/automotive-aluminum-market-10030

Market Dynamics and Trends

Driver: SUV and Pickup Expansion Accelerating Aluminum Use

The ongoing global shift to larger vehicles - SUVs and pickups - is a structural driver. These vehicles are inherently heavier, so OEMs increasingly rely on aluminum for:

• Body panels and closures

• Frames and cross-members

• Suspension and control arms

• Crash and towing-relevant structures

Regulatory pressure amplifies this: Europe, North America and large Asia Pacific markets are closing in on stringent CO2 and fuel economy trajectories. Aluminum becomes a key design enabler of "large but efficient" vehicles.

Restraint: High Retooling and Integration Costs

Switching from steel-intensive to aluminum-intensive architectures is capital intensive.

• New forming, joining, and welding technologies are required.

• Plants must be retooled for different stamping, casting and assembly processes.

• Skilled labor and quality systems must be upgraded for material-specific characteristics.

Smaller OEMs and cost-constrained players can delay deep adoption. Mazda's cautious approach toward fully aluminum body frames and preference for mixed-material designs illustrates the capital and payback challenges.

Opportunity: Aluminum Battery Enclosures and e-Drive Components

Battery enclosures, e-motor housings, and structural integration for EV-specific platforms are defining the next growth wave.

Hydro-Rivian and Hydro-Nemak-type collaborations signal a clear direction:

• Tailored extrusions and castings for thermal and crash performance

• Modular, scalable aluminum architectures for global EV rollouts

• Design-optimized aluminum solutions enabling faster platform deployment

Battery and e-drive aluminum content is one of the most attractive multi-cycle revenue streams for producers.

Key Trend: Closed-Loop Recycling and Low-Carbon Aluminum

Closed-loop recycling is becoming a defining competitive feature.

• Shred generated from stamping and forming is captured, refined, and reintroduced as high-grade sheet and cast material.

• Circular flows cut reliance on primary aluminum and reduce carbon intensity.

• OEMs leverage closed-loop programs as proof-points for ESG commitments.

Stellantis-Novelis-style agreements are emblematic of a structural pivot to circular, lower-CO2 aluminum sourcing.

Segmental Focus: Body-in-White Leads

Body-in-white (BIW) holds around 36% share of the Automotive Aluminum Market.

Why BIW dominates:

• Frames, cross-members, pillars and panels are mass-critical components.

• Substituting steel with aluminum delivers large, measurable weight savings.

• Crashworthiness and design flexibility can be maintained or improved via tailored extrusions and high-strength alloys.

GM's use of increased aluminum in the BIW of the Chevrolet Silverado EV - cutting more than 400 kg while maintaining rigidity - is a clear indicator of OEM appetite for aluminum-intensive structures.

BIW leadership will continue as both ICE and EV platforms converge on lighter, stiffer, more modular architectures.

Asia Pacific - Highest Volume and Structural Growth

Asia Pacific is the most attractive region for the Automotive Aluminum Market.

Growth drivers:

• High vehicle production volume in China, India, Japan, and South Korea

• Strong EV and plug-in hybrid adoption in China and regional leaders

• Government policy support for lighter, more efficient vehicles and dual-carbon goals

Chinese OEMs like BYD are integrating high-strength aluminum frames and enclosures in hybrids and EVs (e.g., Seal U DM-i), embodying carbon and range objectives in material choices.

Asia Pacific will shape not just volume growth, but also future technical standards in automotive aluminum deployment.

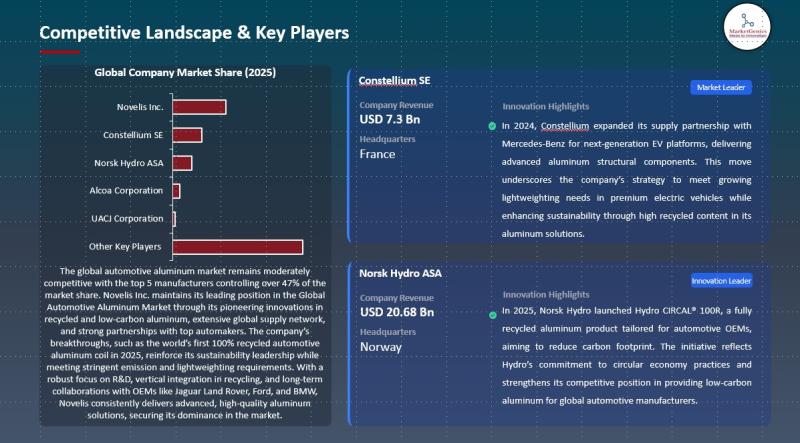

Ecosystem and Competitive Landscape

The Automotive Aluminum Market is moderately consolidated, with Tier 1 producers and integrated players shaping technology and price.

Key players include:

Novelis Inc.

Constellium SE

Norsk Hydro ASA

Alcoa Corporation

Hindalco Industries (via Novelis and regional operations)

Arconic Corporation

Kaiser Aluminum

Magna International (structural systems)

Nemak S.A.B. de C.V.

Rio Tinto Group

These companies leverage:

• Vertical integration across smelting, rolling, extrusions and components

• Automotive-grade R&D, including alloys, joining and forming techniques

• Closed-loop recycling and low-carbon production footprints

Strategic highlights:

• Novelis' 100% recycled EOL auto coil targeting body and structural applications with up to ~90% lower CO2 versus traditional primary production.

• Hydro-Nemak collaboration on low-carbon cast components for e-motor housings, battery trays and structural parts.

Competitive advantage is migrating toward low-carbon, recycled content leadership plus application-specific engineering.

Automotive Aluminum as the Structural Currency of Electrification

The Automotive Aluminum Market is not just along for the ride in automotive transformation - it is shaping it.

Growth is anchored in:

• EV platforms and battery safety

• SUV and pickup lightweighting

• Closed-loop, low-carbon supply chains

• Aluminum-intensive BIW and crash structures

From USD 19.2B in 2025 to USD 32.1B by 2035, this market grows because aluminum has become the structural currency of efficiency, range and sustainability.

Download the Full Automotive Aluminum Market Report (2025-2035)

415 Pages | EV & Lightweighting Opportunity Maps | OEM-Supplier Strategy Intelligence

About Us

MarketGenics is a global market research and management consulting company empowering decision makers across healthcare, technology, and policy domains. Our mission is to deliver granular market intelligence combined with strategic foresight to accelerate sustainable growth.

We support clients across strategy development, product innovation, healthcare infrastructure, and digital transformation.

Contact:

Mr. Debashish Roy

MarketGenics Research

800 N King Street, Suite 304 #4208, Wilmington, DE 19801, United States

USA: +1 (302) 303-2617

Email: sales@marketgenics.co

Website: https://marketgenics.co

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automotive Aluminum Market | The USD 32.1B Lightweighting Engine Behind EV Range, SUV Design & Net-Zero Targets here

News-ID: 4291835 • Views: …

More Releases from MarketGenics Research

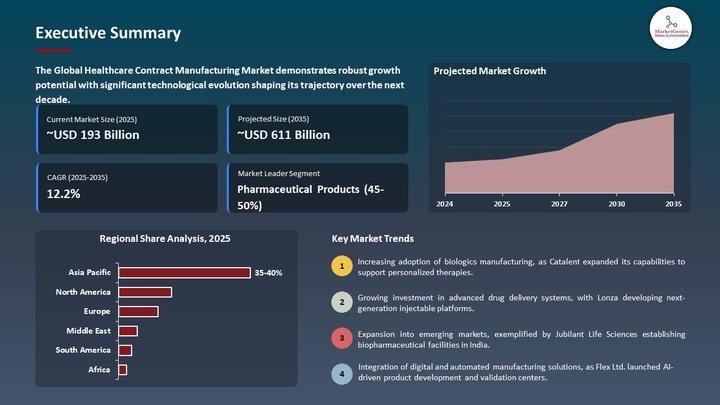

Healthcare Contract Manufacturing Market | Europe's Race for Quality-Centric Man …

Healthcare Contract Manufacturing Market | Europe's High-Precision Manufacturing Pivot Is Reshaping the Future of Therapeutics

The Healthcare Contract Manufacturing Market used to live in the operational shadows - a technical appendix to pharma strategy, an afterthought to medical device roadmaps.

That era is gone.

Europe's push for biologics scale-up, GMP modernization, sterile manufacturing compliance, and resilient supply chains has moved the Healthcare Contract Manufacturing Market from the backroom of operations into the center…

"Aerosol Cans Market in Europe: Sustainability, Aluminum Demand, and Regional Gr …

The world is moving fast on sustainability-biodegradable materials, reusable packaging, and recyclable metals are capturing headlines. Aerosol cans, often overlooked as simple packaging, have quietly evolved into a high-performance, environmentally-conscious solution across personal care, household, healthcare, and industrial sectors.

In 2025, the global Aerosol Cans Market reached USD 14.4 billion, and it is projected to expand to USD 24.0 billion by 2035, growing at a CAGR of 4.7%. For a sector…

Clinical Trial Supplies Market | Europe's New Era of Trial Logistics - Big Pharm …

Clinical Trial Supplies Market | Europe's Supply-Chain Transformation Reshaping the Future of Drug Development

The Clinical Trial Supplies Market used to live in the back rooms of pharma operations - cartons, kits, comparators, storage rooms and shipping labels.

That era is gone.

Europe's pivot toward precision medicine, biologics, decentralized studies, and multi-country regulatory complexity has pushed the Clinical Trial Supplies Market from a logistics afterthought into a strategic pillar of clinical success.

This shift…

Clinical Trial Supplies Market | Europe's Supply-Chain Reinvention - Cold-Chain …

The Clinical Trial Supplies Market used to be a logistics afterthought: labelled vials, dry ice shipments, and predictable pallet runs. That era is gone.

Europe's regulatory complexity, the explosion of biologics and cell & gene therapies, and the rise of decentralized clinical trials (DCTs) have moved the Clinical Trial Supplies Market from a vendor line-item into a strategic capability that determines trial speed, quality and cost. From cryogenic storage in Frankfurt…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…