Press release

How to Start an CNC Machining Services Business in 2025: Investment, Revenue Model & ROI

IMARC Group's "CNC Machining Services Business Plan and Project Report 2025" offers a comprehensive framework for establishing a successful CNC machining services business. The critical areas, including market trends, investment opportunities, revenue models, and financial forecasts, are discussed in this in-depth report and are therefore useful resources to entrepreneurs, consultants and investors. Whether evaluating the viability of a new venture or streamlining an existing one, the report gives an in-depth analysis of all the ingredients that make it successful, starting with business formation and profitability over time.What is a CNC Machining Services Business?

A CNC Machining Services business is a specialized precision manufacturing firm designed to deliver comprehensive computer-controlled machining solutions. These organizations emphasize accurate fabrication using advanced machining technologies, material expertise frameworks, tolerance optimization strategies, quality control protocols, production efficiency programs, and evidence-based manufacturing methodologies, catering to aerospace companies, automotive manufacturers, medical device producers, electronics firms, defense contractors, and industrial equipment makers seeking reliable precision component production and custom manufacturing capabilities.

They offer a variety of services including CNC milling and turning, multi-axis machining, precision grinding, EDM (Electrical Discharge Machining), Swiss-type machining, prototype development, production runs, surface finishing and treatments, quality inspection and certification, design for manufacturability consultation, and reverse engineering support for businesses committed to producing high-precision components and reducing manufacturing lead times.

The category encompasses full-service CNC machine shops, specialized precision manufacturing facilities, contract machining providers, and integrated production partners, each prioritizing dimensional accuracy, material versatility, fast turnaround times, consistent quality, cost-effective solutions, technical expertise, application-specific manufacturing, and comprehensive client collaboration.

To achieve these goals, CNC Machining Services integrate state-of-the-art CNC mills, CNC lathes, multi-axis machining centers, Swiss-type machines, grinding equipment, EDM systems, CAD/CAM software platforms, CMM inspection equipment, and production management technologies.

Depending on their positioning, these establishments may operate as independent job shops, specialized high-precision manufacturers, high-volume production facilities, or integrated engineering and manufacturing partners, delivering complete machining services tailored to diverse industries, material requirements, and levels of precision complexity.

Request for a Sample Report: https://www.imarcgroup.com/cnc-machining-services-business-plan-project-report/requestsample

CNC Machining Services Business Market Trends and Growth Drivers

The trends and drivers of a CNC Machining Services business are shaped by the increasing demand for precision-engineered components, growing complexity of product designs, and the rising need for low-volume custom manufacturing and rapid prototyping. These factors, combined with a stronger focus on supply chain localization and just-in-time manufacturing practices, are fuelling demand for comprehensive CNC machining solutions. Contributing to this shift is the expanding interest in lightweighting initiatives, advanced material applications, tight tolerance requirements, complex geometries, along with the client preference for reduced lead times, quality certifications, and integrated engineering support within the evolving manufacturing ecosystem.

To meet these demands, operators are investing in advanced multi-axis machining centers, automated production systems, high-speed machining technologies, precision measurement equipment, and compliance with industry quality standards including ISO 9001, AS9100, and ISO 13485 certifications.

These investments not only enhance manufacturing capabilities but also strengthen business outcomes by aligning with broader trends in advanced manufacturing and Industry 4.0 integration.

Revenue diversification is another critical factor in building financial resilience. In addition to direct machining service fees, income streams may include engineering design support, prototype development services, material sourcing and supply, tooling and fixture fabrication, assembly and sub-assembly services, quality inspection and certification, finishing and coating services, and long-term contract manufacturing partnerships.

Location and infrastructure access play a vital role in success. Firms positioned in manufacturing regions with access to aerospace clusters, automotive suppliers, medical device hubs, and established industrial zones benefit from steady client acquisition and business growth. At the same time, sophisticated production scheduling systems, compliance with industry-specific quality standards, and adherence to material traceability protocols ensure operational excellence and client confidence.

However, the business also faces risk factors, such as rapidly evolving machining technology that can require significant equipment investments, intense competition from offshore manufacturers and other domestic machine shops, dependence on raw material costs and availability, and operational challenges related to skilled workforce shortages and equipment downtime.

A successful CNC Machining Services business model requires careful financial planning-including capital investment in CNC equipment and facility infrastructure, procurement of cutting tools and measuring instruments, and adoption of comprehensive quality management frameworks. It also demands experienced CNC machinists, manufacturing engineers, quality inspectors, and production planners, supported by effective marketing strategies to build client relationships, foster trust, and establish long-term partnerships with product developers, OEMs, tier-one suppliers, and innovation-driven manufacturers. By delivering high-quality components, on-time delivery, and exceptional technical expertise, these businesses can support client manufacturing needs while helping companies achieve cost savings and production efficiency.

Report Coverage

The CNC Machining Services Business Plan and Project Report includes the following areas of focus:

• Business Model & Operations Plan

• Technical Feasibility

• Financial Feasibility

• Market Analysis

• Marketing & Sales Strategy

• Risk Assessment & Mitigation

• Licensing & Certification Requirements

The comprehensive nature of this report ensures that all aspects of the business are covered, from market trends and risk mitigation to regulatory requirements and client-focused service delivery strategies.

Key Elements of CNC Machining Services Business Setup

Business Model & Operations Plan

A solid business model is crucial to a successful venture. The report covers:

• Service Overview: A breakdown of CNC milling services, CNC turning operations, multi-axis machining, Swiss-type machining, precision grinding, EDM services, prototype fabrication, production manufacturing, quality inspection, surface finishing, and design consultation services offered

• Service Workflow: How each quote request, design review, material procurement, machining operation setup, production execution, in-process inspection, finishing operations, final quality verification, and delivery process is managed

• Revenue Model: An exploration of the mechanisms driving revenue across multiple machining capabilities and industry sectors

• SOPs & Service Standards: Guidelines for consistent machining quality, tolerance compliance, safety protocols, and client satisfaction

This section ensures that all operational and service delivery aspects are clearly defined, making it easier to scale and maintain service excellence.

Buy Report Now: https://www.imarcgroup.com/checkout?id=44367&method=1911

Technical Feasibility

Setting up a successful business requires proper manufacturing infrastructure planning. The report includes:

• Location Selection Criteria: Key factors to consider when choosing facility locations and target market segments

• Space & Costs: Estimations for required production floor space, machine tool placement, material storage areas, quality inspection rooms, and associated costs

• Equipment & Systems: Identifying essential CNC mills, CNC lathes, multi-axis centers, grinding machines, EDM equipment, CAD/CAM software, CMM inspection systems, and production management platforms

• Facility & Technology Setup: Guidelines for creating professional manufacturing facilities and efficient production workflow infrastructure

• Utility Requirements & Costs: Understanding the electrical power, compressed air, coolant systems, and utilities necessary to run machining operations

• Human Resources & Wages: Estimating staffing needs, roles, and compensation for CNC machinists, setup technicians, manufacturing engineers, quality inspectors, production supervisors, and support personnel

This section provides practical, actionable insights into the business infrastructure needed for setting up your business, ensuring production efficiency and operational excellence.

Financial Feasibility

The CNC Machining Services Business Plan and Project Report provides a detailed analysis of the financial landscape, including:

• Capital Investments & Operating Costs: Breakdown of initial and ongoing investments

• Revenue & Expenditure Projections: Projected income and cost estimates for the first five years

• Profit & Loss Analysis: A clear picture of expected financial outcomes

• Taxation & Depreciation: Understanding tax obligations and equipment depreciation

• ROI, NPV & Sensitivity Analysis: Comprehensive financial evaluations to assess profitability

This in-depth financial analysis supports effective decision-making and helps secure funding, making it an essential tool for evaluating the business's potential.

Market Insights & Strategy

Market Analysis

A deep dive into the CNC machining services market, including:

• Industry Trends & Segmentation: Identifying emerging trends and key market segments across aerospace and defense, automotive manufacturing, medical devices, electronics and semiconductors, industrial machinery, and energy sectors

• Regional Demand & Cost Structure: Regional variations in manufacturing activity and cost factors affecting CNC machining operations

• Competitive Landscape: An analysis of the competitive environment including established machine shops, specialized precision manufacturers, offshore production facilities, and integrated OEM capabilities

Profiles of Key Players

The report provides detailed profiles of leading players in the industry, offering a valuable benchmark for new businesses. It highlights their strategies, machining capabilities, quality certifications, and market positioning, helping you identify strategic opportunities and areas for differentiation.

Capital & Operational Expenditure Breakdown

The report includes a comprehensive breakdown of both capital and operational costs, helping you plan for financial success. The detailed estimates for facility development, equipment acquisition, and operating costs ensure you're well-prepared for both initial investments and ongoing expenses.

• Capital Expenditure (CapEx): Focused on facility setup and layout design, CNC milling machines, CNC turning centers, multi-axis machining equipment, grinding and finishing systems, EDM machines, CAD/CAM software licenses, CMM inspection equipment, and material handling systems

• Operational Expenditure (OpEx): Covers ongoing costs like staff salaries and benefits, raw material procurement, cutting tools and consumables, equipment maintenance and repairs, facility utilities, quality certification renewals, marketing expenses, insurance, and training programs

Financial projections ensure you're prepared for cost fluctuations, including adjustments for equipment upgrade cycles, material price variations, competitive pricing pressures, and market demand changes over time.

Profitability Projections

The report outlines a detailed profitability analysis over the first five years of operations, including projections for:

• Total revenue from machining services, engineering support, material sales, finishing operations, and contract manufacturing programs, expenditure breakdown, gross profit, and net profit

• Profit margins for each service line and year of operation

• Revenue per machine hour projections and capacity utilization growth estimates

These projections offer a clear picture of the expected financial performance and profitability of the business, allowing for better planning and informed decision-making.

Request For Customization: https://www.imarcgroup.com/request?type=report&id=44367&flag=E

Our expertise includes:

• Market Entry and Expansion Strategy

• Feasibility Studies and Business Planning

• Company Incorporation and CNC Machining Services Setup Support

• Regulatory and Licensing Navigation

• Competitive Analysis and Benchmarking

• Industry Partnership Development

• Branding, Marketing, and Client-Focused Business Strategy

About Us

IMARC Group is a leading global market research and management consulting firm. We specialize in helping organizations identify opportunities, mitigate risks, and create impactful business strategies.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Start an CNC Machining Services Business in 2025: Investment, Revenue Model & ROI here

News-ID: 4291623 • Views: …

More Releases from IMARC Goup

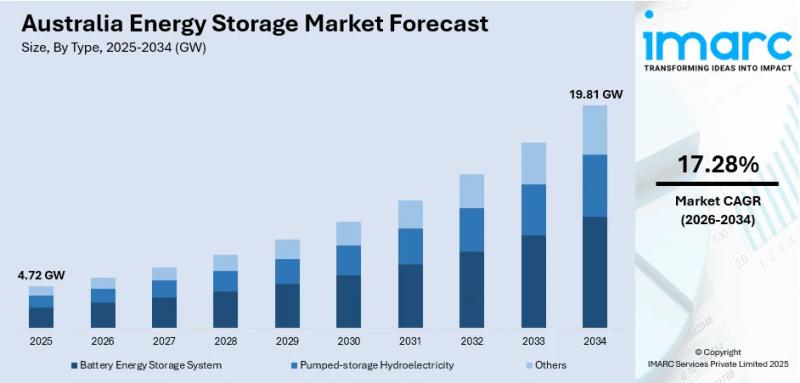

Australia Energy Storage Market Projected to Reach GW 19.81 by 2034

Market Overview

The Australia energy storage market size reached 4.72 GW in 2025 and is projected to reach 19.81 GW by 2034, growing at a compound annual growth rate (CAGR) of 17.28% during 2026-2034. The market expansion is driven by accelerated renewable energy integration, strong policy support for decarbonization, grid modernization initiatives, and increasing deployment of battery energy storage systems (BESS) across residential, commercial, and utility-scale applications. The rapid shift toward…

Southeast Asia E-commerce Market Size, Share, Growth, Trends, Outlook and Indust …

According to IMARC Group's report titled "Southeast Asia E-Commerce Market Size, Share, Trends and Forecast by Type, Transaction, and Country 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Southeast Asia E-commerce Market Outlook

The Southeast Asia e-commerce market size was valued at USD 269.63 Billion in 2025 and is projected to reach USD 1,480.47 Billion by 2034, growing at a compound annual…

India Generative AI Market: Emerging Trends, Growth Outlook and Industry Forecas …

According to IMARC Group's report titled "India Generative AI Market Size, Share, Trends and Forecast by Component, Technology, Application, Model, Customers, End Use, and Region, 2025-2033" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Generative AI Market Overview

The India generative AI market size reached USD 1.30 Billion in 2024 and is expected to grow to USD 5.40 Billion by 2033, exhibiting…

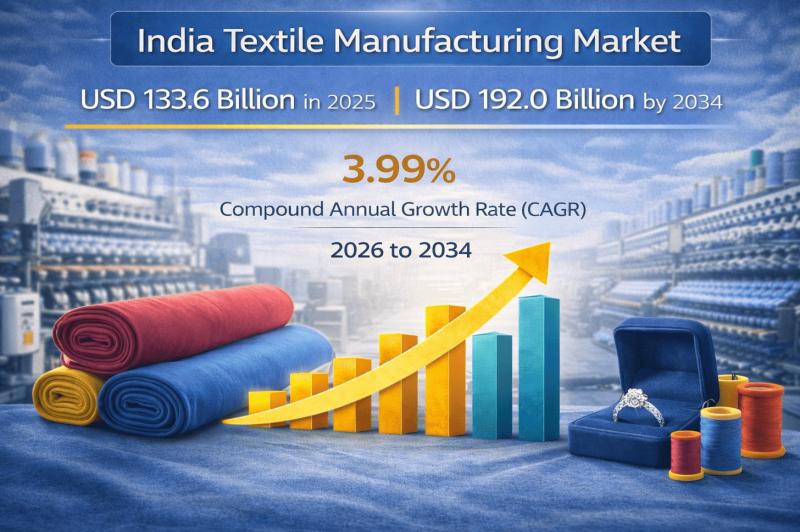

India Textile Manufacturing Market Report 2026-2034: Industry Size, Share, Growt …

According to IMARC Group's report titled "India Textile Manufacturing Market Size, Share, Trends and Forecast by Process Type, Textile Type, Equipment and Machinery, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Textile Manufacturing Market Outlook

The India textile manufacturing market size reached USD 133.6 Billion in 2025. The market is projected to grow at a compounded annual growth rate…

More Releases for CNC

XTJ CNC Elevates Custom CNC Machining for Highly Precise Industrial Applications

Carmel, IN 46032, United States, 28th Jan 2026 - XTJ CNC, a prominent provider of custom CNC machining servicesa prominent provider of custom CNC machining services, has announced significant advancements in its capabilities to better serve industries requiring high-precision components. With a focus on custom CNC machining, the company is reinforcing its reputation as a trusted partner in the aerospace, automotive, and electronics sectors. These advancements reflect XTJ CNC's commitment…

Benefits of CNC Machining for Custom Robotic Projects - Tuofa CNC Machining

Robotics is evolving quickly, and higher-performance robots demand stronger mechanical consistency. As DOF increases, joint stacks and mounting interfaces must align accurately to preserve smooth, repeatable motion. CNC machining delivers custom parts with controlled dimensions and reliable quality, reducing fit issues during assembly. It also shortens prototype cycles and supports small-batch production, helping robotics teams convert designs into dependable hardware.

Robotics is getting smarter and smarter. Better perception, smarter control loops,…

CNC Controller Market Report 2024 - CNC Controller Market Trends, Opportunities …

"The Business Research Company recently released a comprehensive report on the Global CNC Controller Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

CNC Controller Global Market to Generate $3.84 Billion By 2028, Registering at a …

"The new report published by The Business Research Company, titled CNC Controller Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the cnc controller market size has grown strongly in recent years. It will grow from $2.82 billion…

Silver CNC Now Offers CNC Rotary Tables for CNC Machining Centers

Silver CNC is now offering a new line of CNC rotary tables that are perfect for use with CNC machining centers. The rotary tables are available in three different sizes, and each one is made from high-quality cast iron to ensure durability and precision. With a built-in indexing system, the rotary tables make it easy to position your workpiece exactly where you need it. Plus, they're backed by a full…

Trending 2020: CNC Machine (CNC Machine Tools) Market Booming Worldwide

Prophecy Market Insights recently presented CNC Machine (CNC Machine Tools) market report which provides reliable and sincere insights related to the various segments and sub-segments of the market. The market study throws light on the various factors that are projected to impact the overall dynamics of the CNC Machine (CNC Machine Tools) market over the forecast period (2019-2029).

The CNC Machine (CNC Machine Tools) research study contains 100+ market data Tables,…