Press release

Solar Power Manufacturing Plant Setup Cost 2025: Feasibility Study and Profit Analysis

Solar power is the energy generated from sunlight using technologies such as photovoltaic (PV) panels, solar cells, and concentrated solar power systems. It is one of the fastest-growing renewable energy sources due to its abundance, sustainability, and ability to significantly reduce carbon emissions. Solar power is widely used for residential rooftops, commercial buildings, utility-scale solar farms, off-grid applications, and various industrial processes. As countries focus on clean energy transitions, solar power has become a key component in achieving energy security, reducing dependence on fossil fuels, and promoting long-term environmental protection.Setting up a solar power manufacturing plant involves establishing facilities for producing PV modules, solar cells, inverters, or related components. The process requires securing high-quality raw materials such as silicon wafers, EVA sheets, glass, back sheets, and aluminum frames. A modern plant must include automated soldering lines, laminators, stringers, and advanced testing equipment to ensure efficiency and durability. Investors must ensure compliance with environmental and energy standards, conduct a feasibility study, and design an optimized production layout. Additionally, strong supply chain networks, skilled labor, and quality certification (such as IEC standards) are essential for commercial success. With rising demand for renewable energy solutions, a solar manufacturing unit offers strong growth potential and long-term profitability.

IMARC Group's report, titled "Solar Power Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a solar power plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/solar-power-plant-manufacturing-plant-project-report/requestsample

Solar Power Industry Outlook 2025

The solar power manufacturing industry experiences explosive growth by 2025, driven by aggressive renewable energy targets, dramatic cost reductions making solar the cheapest electricity source in most markets, and climate commitments accelerating global energy transition. Global solar installations exceed 400-450 GW annually with cumulative capacity surpassing 1,800 GW, while the manufacturing sector consolidates around highly efficient technologies including PERC (Passivated Emitter and Rear Cell), TOPCon (Tunnel Oxide Passivated Contact), and emerging HJT (Heterojunction) and perovskite-silicon tandems achieving 25%+ efficiencies. China dominates with 80%+ global manufacturing capacity across the value chain, while supply chain diversification initiatives in US (Inflation Reduction Act incentives), EU (European Solar PV Industry Alliance), and India (Production Linked Incentive schemes) drive investments in localized manufacturing. Technological evolution toward larger wafer sizes (182mm, 210mm), bifacial modules, half-cut cell designs, and integrated storage solutions reshape product offerings. Sustainability concerns including polysilicon production energy intensity, end-of-life recycling, and carbon footprint transparency gain prominence, while module prices stabilize around $0.15-0.20/watt despite ongoing efficiency improvements creating exceptional value propositions for solar adoption.

Key Insights for setting up a Solar Power Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Buy now: https://www.imarcgroup.com/checkout?id=7835&method=1911

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Solar Power Manufacturing Plant

• Land acquisition and facility construction for cleanrooms (cell production), manufacturing halls (module assembly), warehousing for raw materials and finished goods, quality testing laboratories, and administrative buildings

• Raw material procurement systems varying by segment: polysilicon for ingot/wafer production; wafers for cell manufacturing; cells, glass, encapsulants (EVA/POE), backsheets, aluminum frames, junction boxes, and connectors for module assembly

• Crystal growing equipment including Czochralski pullers for monocrystalline ingots or directional solidification furnaces for multicrystalline, requiring precise temperature control and inert atmospheres

• Wafer processing equipment including multi-wire saws for ingot slicing, chemical etching systems, texturing equipment, cleaning stations, and automated handling systems

• Cell manufacturing cleanroom infrastructure with ISO Class 5-7 environments, HEPA filtration, temperature/humidity control, and contamination monitoring systems

• Solar cell processing equipment including diffusion furnaces for p-n junction formation, PECVD (Plasma Enhanced Chemical Vapor Deposition) for anti-reflective coatings and passivation layers, screen printing lines for metallization (front and back contacts), co-firing furnaces, edge isolation systems, and cell testing/sorting equipment.

Economic Trends Influencing Solar Power Plant Setup Costs 2025

• Polysilicon and silver price volatility significantly impacting cell manufacturing costs with silver paste representing 8-12% of cell costs and polysilicon determining wafer economics

• Massive capacity expansion globally creating equipment supply constraints and potential delivery delays from major suppliers (Meyer Burger, SCHMID, Centrotherm, Chinese equipment manufacturers)

• Government incentives and production subsidies including US IRA advanced manufacturing credits ($0.07/W modules domestically produced), India PLI schemes, and EU support driving investment economics

• Technology transition costs toward TOPCon, HJT, and perovskite requiring new equipment generations and process expertise beyond conventional PERC technology

• Supply chain localization mandates in US, EU, India creating opportunities for regional manufacturing despite higher costs versus Chinese competition

• Automation and Industry 4.0 adoption reducing labor costs, improving yields, and enabling data-driven process optimization but requiring upfront capital

• Energy costs for polysilicon and ingot production (highly energy-intensive) driving facility location toward cheap renewable electricity sources.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7835&flag=C

Challenges and Considerations for Investors

• Extreme capital intensity requiring $50-100 million for module assembly to $2+ billion for fully integrated facilities with extended payback periods

• Intense competition from Chinese manufacturers with massive scale advantages, vertical integration, and government support achieving industry-leading costs

• Rapid technological obsolescence with new cell architectures and efficiency improvements potentially stranding investments in equipment within 5-7 years

• Commodity-like market dynamics with module pricing highly competitive and margins compressed despite technological sophistication

• Polysilicon supply dependencies with production concentrated in China (80%+ global capacity) creating geopolitical and supply security concerns

• Scale requirements for competitiveness typically demanding multi-GW annual capacity to achieve acceptable unit economics.

Conclusion

Solar power is rapidly transforming the global energy landscape, emerging as a key driver of sustainable growth and energy independence. Supported by declining technology costs, strong government incentives, and increasing environmental awareness, the sector offers immense opportunities for investors and entrepreneurs. However, successful plant setup requires careful consideration of capital intensity, technology selection, and supply chain integration. With continuous innovation in high-efficiency solar cells and expanding renewable targets worldwide, solar power manufacturing remains a promising and future-ready investment avenue.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Solar Power Manufacturing Plant Setup Cost 2025: Feasibility Study and Profit Analysis here

News-ID: 4291564 • Views: …

More Releases from IMARC Group

Cost of Setting Up a Dicalcium Phosphate Production Plant & DPR 2026

Setting up a dicalcium phosphate production plant positions investors within a strategically important segment of the global animal nutrition and food additives industry, driven by increasing demand for feed-grade phosphates, mineral supplements, and pharmaceutical excipients. As modern livestock farming practices advance, animal nutrition requirements become more sophisticated, and the need for high-quality calcium and phosphorus supplementation grows, dicalcium phosphate continues to gain traction across animal feed manufacturing, pharmaceutical formulations, and…

India Online Insurance Market Report 2026-2034: Size, Share, Growth, Trends, Ins …

According to IMARC Group's report titled "India Online Insurance Market Size, Share, Trends and Forecast by Insurance Type, Enterprise Size, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Online Insurance Market Overview

The India online insurance market size reached USD 10.4 Billion in 2025 and is expected to grow to USD 20.8 Billion by 2034, exhibiting a CAGR of…

India Bed Linen Industry Report: Market Size, Demand Surge & Future Forecast 202 …

Introduction:

According to IMARC Group's report titled "India Bed Linen Market Size, Share, Trends and Forecast by Type, Application, Distribution Channel, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

How Big is the India Bed Linen Market?

The India bed linen market size was valued at USD 18.50 Billion in 2025 and is projected to reach USD 34.81 Billion by 2034,…

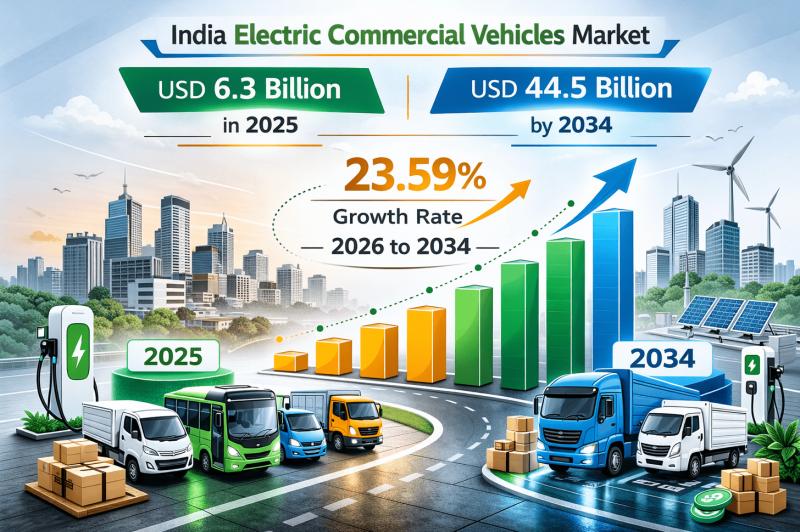

India Electric Commercial Vehicles Market Report 2026-2034: Size, Growth, Trends …

According to IMARC Group's report titled "India Electric Commercial Vehicles Market Size, Share, Trends and Forecast by Vehicle Type, Propulsion Type, Battery Capacity, End User, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Electric Commercial Vehicles Market Analysis

The India electric commercial vehicles market size reached USD 6.3 Billion in 2025 and is expected to grow to USD 44.5…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…