Press release

Mono-Material Fabric Shaping the Future of Sustainable Textiles | TEXNIC

TEXNIC is transforming the textile industry through advanced recycling and sustainable design. The company repurposes discarded battery separator films into lightweight, durable, and high-performance fabrics. With a strong focus on eco-friendly innovation, TEXNIC develops functional materials designed for long-term use in demanding fields, including automotive and technical textiles. MONOMAX, a fabric currently under development at TEXNIC, reflects this commitment by combining sustainability with advanced material engineering. Each creation embodies a balance between strength, efficiency, and environmental responsibility.MONOMAX Recyclable High-Performance Fabric

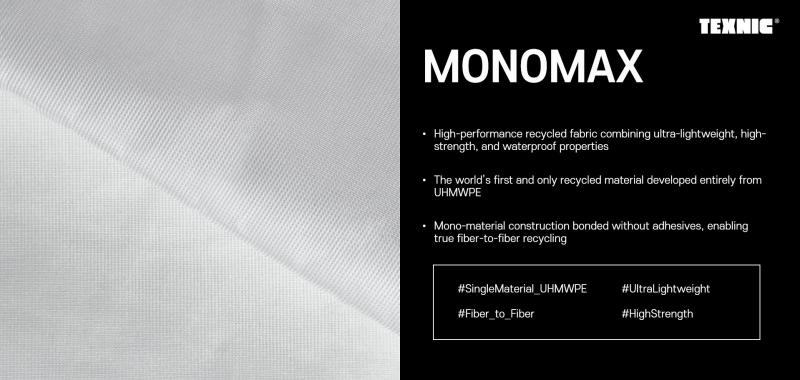

MONOMAX is a breakthrough in sustainable textile fabric technology, made entirely from 100 percent UHMWPE. Both the film layer and textile core share the same material type, forming a true mono-material construction that can be recycled repeatedly. Without the use of adhesives, this structure supports circular recycling while maintaining exceptional strength and lightweight flexibility. Designed for outdoor wear, sports gear, and automotive interiors, MONOMAX delivers high functionality with environmental consciousness.

Sustainability through Material Innovation

Conventional blended textiles are often difficult to recycle, but MONOMAX overcomes this challenge with its single-material structure that allows true fiber-to-fiber recycling. Its durability, weather resistance, and low weight make it ideal for applications that demand both mechanical performance and sustainability. This innovation demonstrates how advanced materials can contribute to reducing waste and extending product life cycles.

Key Highlights of MONOMAX Fabric

The mono-material UHMWPE design enables efficient recycling without separating layers or adhesives.

Lightweight at just 41 grams per square meter, it supports flexible and energy-efficient product design.

High tensile strength ensures lasting performance even in demanding environments.

Waterproof and windproof properties provide reliable protection in varied conditions.

As the first fabric developed fully from recycled UHMWPE, MONOMAX represents a new standard in sustainable, high-function textiles.

If you are looking for eco-friendly fabrics, you can find them at TEXNIC.

Click here if you are interested in TEXNIC eco-friendly fabrics.

View More: Mono-Material Fabric Shaping the Future of Sustainable Textiles

South Korea

TEXNIC is transforming the textile industry through advanced recycling and sustainable design. The company repurposes discarded battery separator films into lightweight, durable, and high-performance fabrics.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Mono-Material Fabric Shaping the Future of Sustainable Textiles | TEXNIC here

News-ID: 4291531 • Views: …

More Releases from TEXNIC

From Recycled Materials to Premium Fabrics Leading a Greener Textile Future | TE …

TEXNIC is transforming the textile industry through eco-friendly innovation. By repurposing discarded battery separators, the company creates lightweight, durable, and high-performance fabrics ideal for automotive interiors, outerwear, and activewear. With its sustainable apparel materials, TEXNIC demonstrates that eco-friendly innovation can deliver both quality and style.

Innovative Fabric Collection

TEXNIC's fabric collection combines advanced technology with sustainable design. Each material is crafted to deliver performance, comfort, and environmental responsibility.

HIGHFIVE R/S - Crafted from…

Pioneering Sustainable Textiles from Recycled Battery Waste | TEXNIC

TEXNIC, a sustainable textile manufacturing company, is revolutionizing the textile industry by transforming discarded electric vehicle (EV) battery separators into high-performance, eco-friendly fabrics. These separators, essential components in lithium-ion batteries, are typically discarded after use. TEXNIC's innovative process repurposes this waste into textiles that are waterproof, breathable, and durable, making them suitable for various applications, including fashion and industrial uses.

Sustainable Innovation at Its Core

The fabrics are crafted from recycled battery…

Turning Industrial Waste into Eco-Friendly High-Performance Fabrics | TEXNIC

TEXNIC is transforming discarded battery separators into eco-friendly fabrics. Its flagship material offers waterproofing, breathability, and durability similar to Gore-Tex, combining innovation with sustainability. By repurposing waste materials, the company not only addresses environmental concerns but also promotes a circular economy. This approach sets a leading example in the textile industry, demonstrating that environmental responsibility and high-performance materials can go hand in hand.

Key Features of TEXNIC Fabric

The fabric is made…

The Rise of Mono Material Fabric in Modern Textile Development | TEXNIC

TEXNIC is a material innovation company that turns discarded battery separator films into advanced functional fabrics through sustainable experimentation and recycling technology. The company focuses on creating durable, high-performance materials for long-term use in demanding fields such as automotive and technical textiles. MONOMAX fabric, under development at TEXNIC, delivers the qualities of ultra-lightweight and recycled high-function textile materials for applications like outdoor wear, sports gear, and automotive interiors.

Key Product…

More Releases for MONOMAX

From Recycled Materials to Premium Fabrics Leading a Greener Textile Future | TE …

TEXNIC is transforming the textile industry through eco-friendly innovation. By repurposing discarded battery separators, the company creates lightweight, durable, and high-performance fabrics ideal for automotive interiors, outerwear, and activewear. With its sustainable apparel materials, TEXNIC demonstrates that eco-friendly innovation can deliver both quality and style.

Innovative Fabric Collection

TEXNIC's fabric collection combines advanced technology with sustainable design. Each material is crafted to deliver performance, comfort, and environmental responsibility.

HIGHFIVE R/S - Crafted from…

Pioneering Sustainable Textiles from Recycled Battery Waste | TEXNIC

TEXNIC, a sustainable textile manufacturing company, is revolutionizing the textile industry by transforming discarded electric vehicle (EV) battery separators into high-performance, eco-friendly fabrics. These separators, essential components in lithium-ion batteries, are typically discarded after use. TEXNIC's innovative process repurposes this waste into textiles that are waterproof, breathable, and durable, making them suitable for various applications, including fashion and industrial uses.

Sustainable Innovation at Its Core

The fabrics are crafted from recycled battery…

The Rise of Mono Material Fabric in Modern Textile Development | TEXNIC

TEXNIC is a material innovation company that turns discarded battery separator films into advanced functional fabrics through sustainable experimentation and recycling technology. The company focuses on creating durable, high-performance materials for long-term use in demanding fields such as automotive and technical textiles. MONOMAX fabric, under development at TEXNIC, delivers the qualities of ultra-lightweight and recycled high-function textile materials for applications like outdoor wear, sports gear, and automotive interiors.

Key Product…

Transforming Industrial Waste into Advanced Functional Fabrics | TEXNIC

TEXNIC is transforming the textile industry through sustainable innovation. As the first company to develop high-performance fabrics from recycled secondary battery separator films, it leads the way in low-carbon textile technology. By turning industrial waste into durable, breathable, and eco-friendly materials, TEXNIC combines advanced performance with environmental care.

WINDCORE Pique - Reliable Comfort for Every Climate

WINDCORE Pique is designed to perform in all weather conditions, offering breathability, waterproofing, and wind…

Surgical Sutures Market to Generate CAGR of 6.50% by 2031, Owing to Rise in Dema …

Surgical Suture Market Size, Share, Growth Analysis, By Product (Suture Threads, Automated Suturing Devices), By Type (Multifilament Sutures, Monofilament Sutures), By Application (Cardiovascular Surgery, General Surgery), By End User (Hospitals, Ambulatory Surgical Centers), By Region - Industry Forecast 2024-2031

Surgical Sutures Market [https://www.skyquestt.com/report/surgical-suture-market] size was valued at USD 3.5 billion in 2022 and is poised to grow from USD 3.73 billion in 2023 to USD 6.17 billion by 2031, growing at…