Press release

Vacuum Casting Machine Sector Strengthens as Lightweight Manufacturing Trends Drive USD 5.3 Billion Forecast by 2034

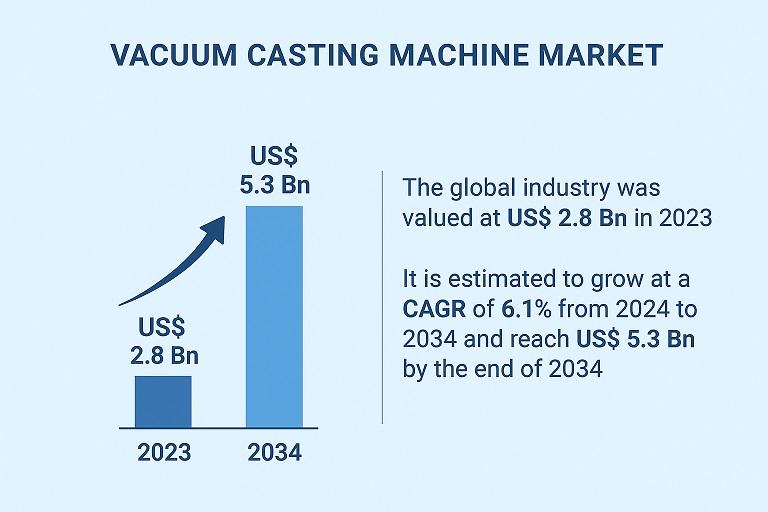

The global Vacuum Casting Machine Market is experiencing steady growth due to rising demand for rapid prototyping, customized manufacturing, and small-batch production across industries such as automotive, aerospace, medical devices, consumer electronics, and industrial equipment. Vacuum casting machines play a crucial role in producing high-precision components with excellent surface quality by removing trapped air during molding, ensuring accuracy and minimizing defects. Their growing acceptance as a cost-efficient alternative to injection molding is driving market expansion.In 2023, the global Vacuum Casting Machine Market was estimated to be valued at USD 2.8 billion, and it is projected to reach approximately USD 5.3 billion by 2035, registering a CAGR of around 6.1% during the forecast period. This growth is influenced by increasing need for flexible manufacturing systems, the rise of customized product development, and the integration of automated and digital production technologies.

Download Your Complimentary Report - Unlock Detailed Analysis: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86179

Key Players:

• Stratasys

• 3D Systems, Inc.

• ENVISIONTEC US LLC

• Proto Labs

• Renishaw plc.

• EOS GmbH

• Materialise

• Formlabs

• DWS - VAT

• Prodways Group

Key Market Drivers

Rising Demand for Rapid Prototyping and Small-Volume Production

Manufacturers in automotive, medical, and electronics sectors increasingly rely on vacuum casting for short-run production and prototype development. Vacuum casting significantly reduces development time and tooling costs, enabling faster product iterations and supporting innovation cycles. The ability to deliver highly accurate and aesthetic prototype models enhances adoption among R&D centers and design studios.

Technological Advancement and Automation

Modern vacuum casting systems are being enhanced with automation capabilities such as automated resin mixing, digital vacuum controls, and intelligent process monitoring. Automation reduces labor dependency, increases consistency, and improves productivity. These developments align with Industry 4.0 strategies, which emphasize efficiency, precision, and smart factory operations.

Growing Use of Complex and Precision-Engineered Components

Industries requiring intricate geometries, smooth surfaces, and defect-free finishing increasingly prefer vacuum casting machines. Medical devices, electronic enclosures, prosthetics, aerospace interiors, and specialty machinery components benefit from the dimensional accuracy and material flexibility offered by vacuum casting processes.

Sustainability and Material Efficiency

Vacuum casting is comparatively resource-efficient, producing minimal waste and enabling multiple mold reuse. As industries adopt cleaner and greener manufacturing practices, vacuum casting aligns with sustainability goals, strengthening its global demand.

Get this premium report for strategic insights: https://www.transparencymarketresearch.com/checkout.php?rep_id=86179<ype=S

By Region

• North America

• Europe

• Asia Pacific

• Latin America

• Middle East & Africa

• Regional Analysis

Asia Pacific

Asia Pacific dominates the vacuum casting machine market due to strong manufacturing bases in China, Japan, South Korea, and India. Expanding automotive, electronics, and industrial sectors drive demand. Increased adoption of automation strengthens growth prospects.

North America

North America is a leader in technologically advanced vacuum casting systems, supported by strong aerospace, medical, and automotive prototyping activities. High investment in R&D supports market penetration for precision-engineered parts.

Europe

Europe's demand is fueled by prototyping, electrified automotive systems, industrial robotics, research institutes, and advanced engineering applications. Sustainability regulations encourage low-waste manufacturing methods like vacuum casting.

Rest of the World

Growing industrialization and infrastructure upgrades open opportunities in Latin America and Middle East industrial sectors.

Market Trends

Integration of vacuum casting with 3D printing workflows

Adoption of high-performance casting resins for enhanced strength and durability

Shift toward customized production and limited-edition product manufacturing

Rising focus on energy-efficient and environmentally responsible processes

Increased market participation from SMEs and start-ups due to lower tooling investment

Challenges

Limited feasibility for large-volume manufacturing compared to injection molding

High initial investment for advanced fully-automatic casting systems

Skilled workforce requirement for mold preparation and precision handling

Competitive pressure from alternative advanced manufacturing technologies like additive manufacturing and CNC machining

Smart manufacturing and Industry 4.0 implementation

Lightweight component development for electric vehicles and aerospace

Medical device customization and prosthetic applications

R&D-driven premium engineering segments

As global manufacturers shift toward flexible, accurate, low-waste and customer-centric production methods, vacuum casting machines will continue to play a vital role in supporting short-run and prototype-focused manufacturing models. The market is likely to see significant innovation in automation, materials science, and digitally connected equipment, enabling improved productivity and sharper competitive positioning.

More Trending Reports by Transparency Market Research -

Ethyl Acetate Market - https://www.transparencymarketresearch.com/ethyl-acetate-market.html

HPLC Column Market - https://www.transparencymarketresearch.com/hplc-column-market.html

Plastic Compounding Market - https://www.transparencymarketresearch.com/plastic-compounding-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vacuum Casting Machine Sector Strengthens as Lightweight Manufacturing Trends Drive USD 5.3 Billion Forecast by 2034 here

News-ID: 4291317 • Views: …

More Releases from Transparency Market Research

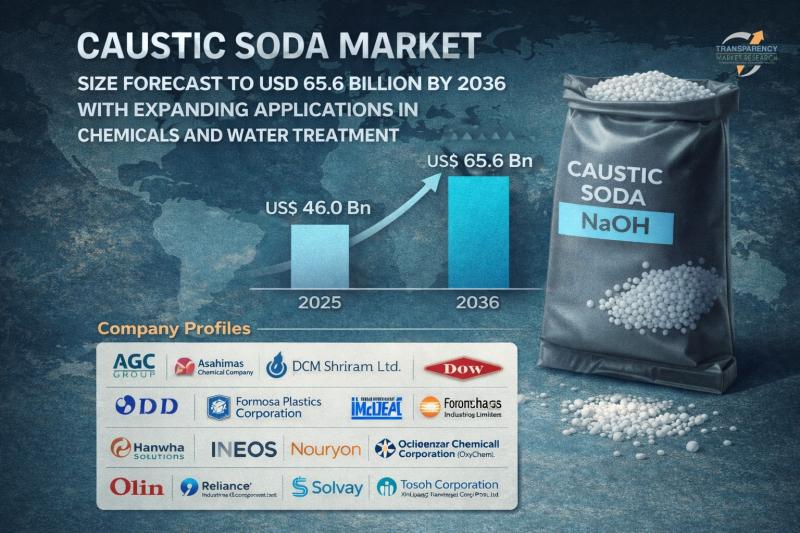

Caustic Soda Market Size Forecast to USD 65.6 Billion by 2036 with Expanding App …

Caustic Soda Market Outlook 2036

The global caustic soda market was valued at US$ 46.0 Billion in 2025 and is projected to reach US$ 65.6 Billion by 2036, expanding at a steady CAGR of 3.2% from 2026 to 2036. Market growth is driven by increasing demand from the pulp & paper industry, rising alumina production, expanding chemical manufacturing activities, and growing applications in water treatment and textiles.

👉 Get your sample market…

Global Baby Diaper Market Outlook 2036: Industry to Reach US$ 75.1 Billion by 20 …

The global baby diaper market was valued at US$ 44.5 Bn in 2025 and is projected to reach US$ 75.1 Bn by 2036, expanding at a steady CAGR of 4.9% from 2026 to 2036. This consistent upward trajectory reflects the essential nature of diapers in infant hygiene and the growing consumer preference for high-performance and convenient baby care products.

In 2025, North America accounted for 42.1% of the global revenue share,…

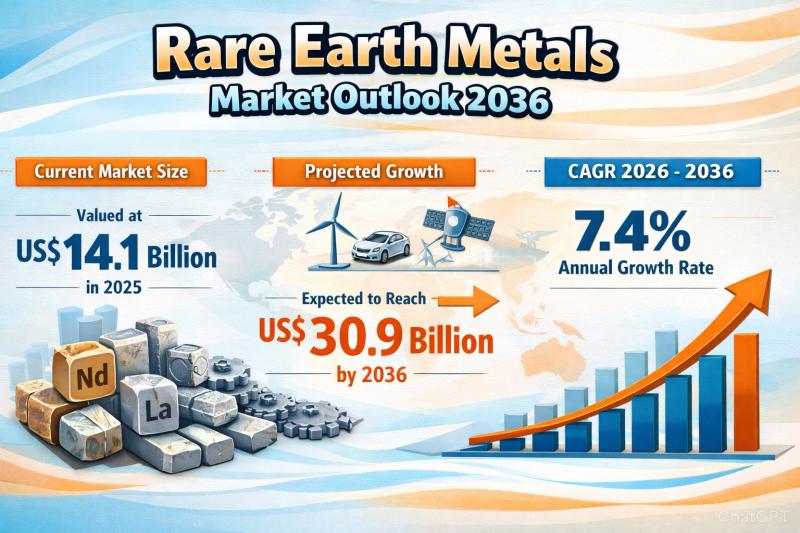

Rare Earth Metals Market to be Worth USD 30.9 Bn by 2036 - By Metal Type / By Ap …

The rare earth metals market has evolved from a niche industrial segment into a strategically critical global industry. In 2025, the market stood at US$ 14.1 Billion, driven primarily by increasing deployment of electric vehicles (EVs), renewable energy systems, defense electronics, and advanced industrial machinery.

Review critical insights and findings from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=823

By 2036, the market is expected to nearly double to US$ 30.9 Billion, supported by…

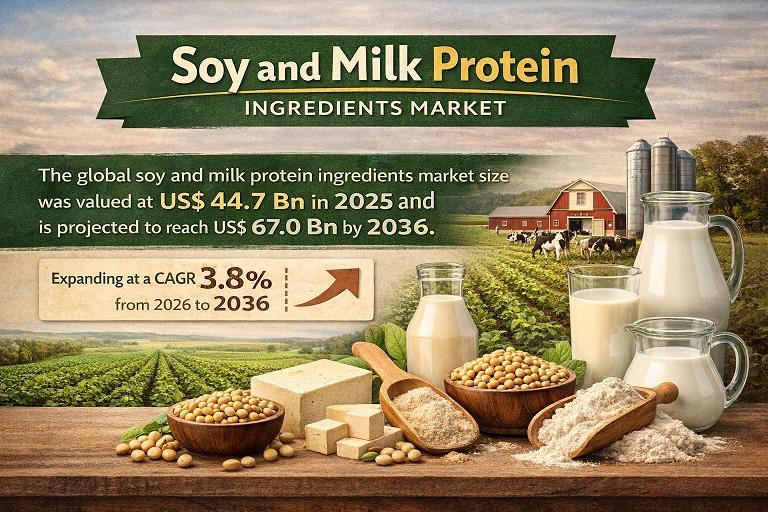

Soy and Milk Protein Ingredients Market to Reach USD 67.0 Billion by 2036 Amid R …

The global Soy and Milk Protein Ingredients Market is witnessing significant momentum as consumers increasingly prioritize high-protein diets, functional nutrition, and clean-label ingredients. With the surge in plant-based alternatives, sports nutrition products, and fortified food offerings, soy and milk protein ingredients have become critical components across multiple industries including food & beverages, pharmaceuticals, animal nutrition, and personal care.

The global Soy and Milk Protein Ingredients Market is projected to reach US$…

More Releases for Vacuum

Semiconductor Screw Vacuum Pump Market Industry Trends - Atlas Copco (Edwards Va …

MarketQuest.biz proclaims the addition of another new report titled Global Semiconductor Screw Vacuum Pump Market which is a well-synchronized synopsis of the market. The report offers broad insights extracted by thoroughly analyzing historical and current developments in the market. The report outlines the distinguishable players in the global Semiconductor Screw Vacuum Pump market with a clear-cut end goal to give an intelligent standpoint of the forces of the market, while…

Roots Vacuum Pumps Market SWOT Analysis by Key Players: Pfeiffer, Leybold, ANLET …

Roots vacuum pumps, or vacuum boosters, are dry vacuum pumps that are used together with backing pumps in a wide range of applications where large pumping speeds are required. Vacuum boosters operate completely contact-free and without sealing fluids such as oil or water in the working chamber, although with most models the two gearwheels of the synchromesh gearing and the bearings for the impeller shafts are lubricated with oil. Some…

Vacuum Coating Machines Market 2018 Global Key Country Analysis: Denton Vacuum, …

Vendor Landscape

Tetra Technologies, Inc., (U.S.), BP P.L.C. (U.K.), Statoil ASA (Norway), DNV GL (Norway), TechnipFMC PLC (U.K.), AF Gruppen ASA (Norway), Ramboll Group A/S (Denmark), and Aker Solutions ASA (Norway) are some of the key companies operating in the market. Amec Foster Wheeler (U.K.), John Wood Group Plc. (Scotland), Claxton Engineering Services (U.K.), Allseas group SA (Switzerland), and DeepOcean Group (Netherlands) among others.

Market Research Future’s (MRFR) latest study reveals that…

Global Rotary Vane Vacuum Pumps Market- Pfeiffer Vacuum, Tuthill, Osaka Vacuum, …

Global Rotary Vane Vacuum Pumps Market report 2017 is an in-depth research on the current situation of the Rotary Vane Vacuum Pumps industry.

The Scope of the Rotary Vane Vacuum Pumps research report:

The Global Rotary Vane Vacuum Pumps Market primarily includes a basic overview of the Rotary Vane Vacuum Pumps industry. It also includes Rotary Vane Vacuum Pumps definitions, classifications and applications. It segments the market by applications, types, regions, competitive…

Metallurgical High Vacuum Announces High Vacuum Newsletter

Fennville, MI---Metallurgical High Vacuum has created a new “High Vacuum News” to provide heat treat industry professionals with tips and hints to keep their vacuum pumps running strong.

As Geoff Humberstone, MHV President, comments: “This year marks 30 years for us as Metallurgical High Vacuum. Back in 1981, I saw the need for vacuum design and consulting and started the company. Within four years we added pump remanufacturing because we…

Metallurgical High Vacuum Ships Vacuum Chambers (Corrected)

Special Designs are Built to Customer Specifications

Fennville, MI--- Metallurgical High Vacuum recently shipped two chambers for customer-specific applications. One vacuum chamber is over 72” high and will be used in P E. Chemical Vapor Deposition. The other chamber is a 12-inch square design that will be used to weld silicon sticks, complete with a two-stage booster vacuum pumping system. Both chambers are built of type 304 stainless steel for…