Press release

How to Profit from Isoeugenol in 2025: Manufacturing Cost, Market Demand & ROI Guide

Setting Up Isoeugenol Manufacturing Plant offers a strong opportunity for entrepreneurs, investors, and MSMEs looking to enter the expanding aroma chemicals and specialty chemicals market. Isoeugenol is an important organic compound widely used in fragrances, flavors, perfumes, pharmaceuticals, and as an intermediate in various chemical syntheses. Due to the increasing demand from the personal care, cosmetics, and food industries, establishing an isoeugenol manufacturing unit provides significant commercial potential and sustainable long-term growth prospects.To build a successful production unit, it is crucial to clearly understand the Raw Material Requirements, Machinery Requirements, Setup Cost Analysis, and complete Cost Breakdown. This comprehensive guide explains each of these essential aspects to support informed investment decisions.

Understanding the Growing Demand for Isoeugenol

Isoeugenol is widely used in the production of:

• Perfumes and fragrance blends

• Soaps, detergents, and cosmetics

• Flavoring agents in food and beverages

• Pharmaceuticals and agrochemicals

• Fine chemicals and intermediates

Market growth is driven by:

• Rising demand for natural and synthetic aroma chemicals

• Expansion of the cosmetics and personal care industry

• Growth in food and beverage flavoring products

• Increasing use in specialty chemical applications

• Rapid development in emerging economies

By Setting Up Isoeugenol Manufacturing Plant, businesses can supply to fragrance manufacturers, FMCG companies, pharmaceutical firms, and export markets.

Request for a Sample Report: https://www.imarcgroup.com/isoeugenol-manufacturing-plant-project-report/requestsample

Key cost drivers in isoeugenol production

Raw materials: The expense of essential inputs such as eugenol (used in certain chemical synthesis routes) or biomass (for bioconversion processes) represents a significant portion of the total production cost.

Production technology:

Chemical synthesis: Costs are affected by reaction efficiency, catalyst and reagent usage, energy requirements, and the complexity of purification steps.

Bioconversion: Production via fermentation or other biological methods involves costs related to microbial strain development, culture media, fermentation systems, and downstream separation and purification.

Operational costs: These include expenditures on energy and utilities, workforce, equipment maintenance, waste management, and compliance with environmental and safety regulations.

Capital investment: Establishing a production facility requires substantial initial spending on land acquisition, plant construction, process equipment, and supporting infrastructure.

Market dynamics:

Competition: The scale, pricing strategies, and market presence of competitors influence profitability.

Regional variations: Production costs differ across regions due to variations in labor rates, energy costs, raw material availability, and regulatory conditions.

Raw Material Requirements for Isoeugenol Manufacturing Plant

High-quality raw materials are crucial for efficient synthesis and consistent product output.

Core Raw Materials

• Eugenol (primary raw material)

• Potassium hydroxide or sodium hydroxide

• Organic solvents (ethanol, methanol, toluene)

• Catalysts

• Distilled water

Packaging Materials

• Glass bottles

• HDPE drums

• Aluminum containers

• Labels, seals, and export cartons

Quality Considerations

• High purity input chemicals

• Controlled moisture content

• Stable chemical properties

• Compliance with industrial and export standards

• Safe storage conditions

Strong supplier relationships and proper storage are essential for quality consistency.

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=11140&flag=C

Machinery Requirements for Setting Up Isoeugenol Manufacturing Plant

Choosing suitable machinery ensures safe processing and accurate chemical conversion.

Core Manufacturing Machinery

• Reaction vessels with agitators

• Condensers and distillation units

• Heating and cooling systems

• Solvent recovery system

• Filtration equipment

• Pumps and pipeline fittings

• Storage tanks

Packaging & Filling Machinery

• Liquid filling machines

• Sealing and capping machines

• Labeling machines

• Batch coding equipment

Quality Control & Laboratory Equipment

• Gas chromatograph (GC)

• pH meters

• Spectrophotometers

• Density and viscosity measuring tools

Supporting Systems

• Water treatment plant

• Ventilation and fume extraction systems

• Air compressors

• Backup power generator

Automation and safety equipment directly impact productivity and setup cost efficiency.

Plant Infrastructure and Layout Essentials

A well-planned facility layout ensures safe and efficient operations.

Key Infrastructure Components

• Raw material storage area

• Reaction and distillation section

• Purification and filtration zone

• Packaging unit

• Finished goods warehouse

• Quality control laboratory

• Administrative office

• Worker amenities

Utilities and Support Systems

• Continuous power supply

• Water purification system

• Effluent treatment plant

• Fire safety installations

• Proper ventilation system

Buy Now:

https://www.imarcgroup.com/checkout?id=11140&method=1911

Setup Cost Analysis for Isoeugenol Manufacturing Plant

The setup cost depends on plant capacity, level of automation, and location.

Capital Expenditure (CAPEX)

• Land purchase/lease

• Construction and civil work

• Machinery procurement

• Installation and commissioning

• Storage and handling systems

• Laboratory setup

Operational Expenditure (OPEX)

• Raw material procurement

• Utilities (electricity, water, steam)

• Labor costs

• Equipment maintenance

• Packaging and logistics

• Regulatory compliance

Working Capital Requirements

• Raw material stock

• Packaging inventory

• Salary buffer

• Utility expenses

• Marketing and distribution costs

Cost Breakdown of Setting Up Isoeugenol Manufacturing Plant

Primary Cost Components

• Land and building development

• Production machinery

• Raw materials inventory

• Quality testing equipment

• Packaging systems

• Utilities and installations

• Workforce and training

Additional Cost Considerations

• Research and development

• Environmental clearances

• Export certifications

• Insurance and branding

• Transportation setup

Challenges to Consider

Before setting up an isoeugenol plant, investors should consider:

• Toxic and flammable chemical handling risks

• Raw material price fluctuations

• Strict environmental regulations

• Need for skilled technicians

• Quality consistency demands

• Competition in aroma chemical market

Partnering with technical experts and ensuring compliance with safety rules reduces operational risks.

Conclusion

Setting Up Isoeugenol Manufacturing Plant presents strong growth potential in the expanding fragrance and specialty chemical industry. With rising global demand for aroma compounds, manufacturers can achieve long-term profitability. By carefully analyzing Raw Material Requirements, Machinery Requirements, Setup Cost Analysis, and Cost Breakdown, entrepreneurs can develop a safe, scalable, and profitable operation with strong market positioning.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Profit from Isoeugenol in 2025: Manufacturing Cost, Market Demand & ROI Guide here

News-ID: 4290847 • Views: …

More Releases from IMARC Group

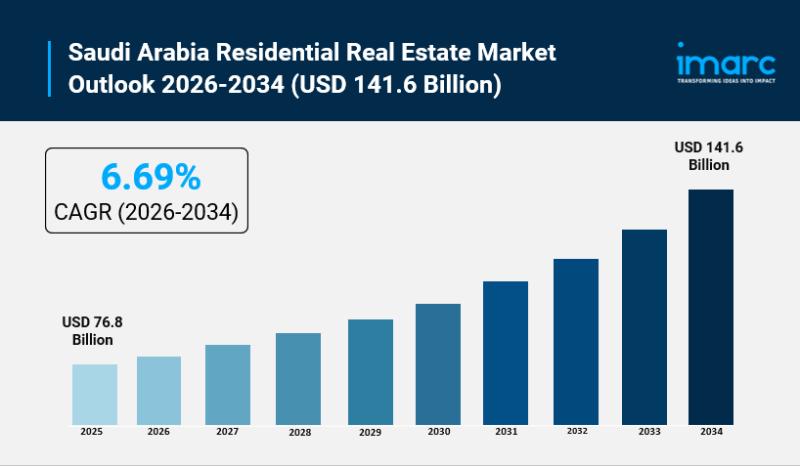

Saudi Arabia Residential Real Estate Market Size to Worth USD 141.6 Billion by 2 …

Saudi Arabia Residential Real Estate Market Overview

Market Size in 2025: USD 76.8 Billion

Market Forecast in 2034: USD 141.6 Billion

Market Growth Rate 2026-2034: 6.69%

According to IMARC Group's latest research publication, "Saudi Arabia Residential Real Estate Market Report by Type (Condominiums and Apartments, Villas and Landed Houses), and Region 2026-2034", the Saudi Arabia residential real estate market size reached USD 76.8 Billion in 2025. Looking forward, IMARC Group expects the market to…

Fuel Oil Prices See Strong Upside Momentum Across Key International Markets

Northeast Asia Fuel Oil Prices Movement January 2026:

Northeast Asia fuel oil prices in January 2026 were recorded at USD 0.84/kg, rising by 5.0% due to higher regional demand and limited supply. The fuel oil price trend showed upward momentum, while the fuel oil price index strengthened moderately. The fuel oil price chart reflected a clear price increase. The fuel oil price forecast suggests continued firmness in the short term.

Get the…

Citric Acid Production Plant (DPR) 2026: Industry Trends, CapEx/OpEx and Market …

The global citric acid manufacturing industry is experiencing steady growth driven by the rapidly expanding food and beverage sector and increasing demand for natural preservatives and acidulants. At the heart of this expansion lies a critical industrial ingredient-citric acid. As consumers worldwide increasingly seek clean-label products and manufacturers prioritize natural food additives over synthetic alternatives, establishing a citric acid production plant presents a strategically compelling business opportunity for entrepreneurs and…

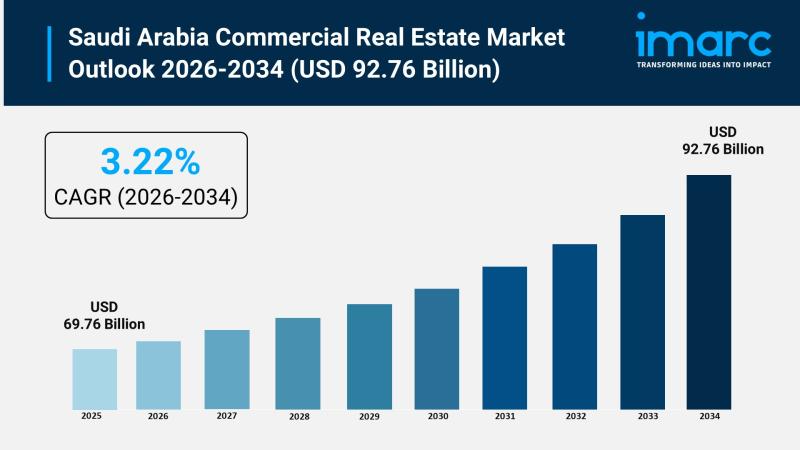

Saudi Arabia Commercial Real Estate Market is Booming with a CAGR of 3.22% by 20 …

Saudi Arabia Commercial Real Estate Market Overview

Market Size in 2025: USD 69.76 Billion

Market Size in 2034: USD 92.76 Billion

Market Growth Rate 2026-2034: 3.22%

According to IMARC Group's latest research publication, "Saudi Arabia Commercial Real Estate Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034", The Saudi Arabia commercial real estate market size was valued at USD 69.76 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD…

More Releases for Isoeugenol

Blockchain-in-security Market Segmentation Analysis by Application, Type, and Ke …

New Jersey, US State: "The global Blockchain-in-security market in the Information Technology and Telecom category is projected to reach USD 5.8 billion by 2031, growing at a CAGR of 20.5% from 2025 to 2031. With rising industrial adoption and continuous innovation in Information Technology and Telecom applications, the market is estimated to hit USD 1.2 billion in 2024, highlighting strong growth potential throughout the forecast period."

Request For Proposal RFP Software…

Telecom Testing Equipment Market Segmentation Analysis by Application, Type, and …

New Jersey, US State: "The global Telecom Testing Equipment market in the Information Technology and Telecom category is projected to reach USD 20.1 billion by 2031, growing at a CAGR of 7.2% from 2025 to 2031. With rising industrial adoption and continuous innovation in Information Technology and Telecom applications, the market is estimated to hit USD 12.5 billion in 2024, highlighting strong growth potential throughout the forecast period."

The telecom testing…

Project Portfolio Management Solutions Market Segmentation Analysis by Applicati …

New Jersey, US State: "The global Project Portfolio Management Solutions market in the Information Technology and Telecom category is projected to reach USD 12.22 billion by 2031, growing at a CAGR of 9.23% from 2025 to 2031. With rising industrial adoption and continuous innovation in Information Technology and Telecom applications, the market is estimated to hit USD 5.72 billion in 2024, highlighting strong growth potential throughout the forecast period."

Project Portfolio…

Methyl Cellulose Manufacturing Plant Revenue 2023: Industry Trends and Raw Mater …

IMARC Group's report, titled "Methyl Cellulose Manufacturing Plant Project Report 2023: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a methyl cellulose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more. In…

Global Guaiacol (CAS 90-05-1) Market - Revenue and Growth Rate 2027

Guaiacol is a yellowish aromatic oil that is commonly consequent from wood creosote. It is a biodegradable product that has low potential of the bioaumulation. Guaiacol is a slightly yellow colored liquid or a crystalline solid with a distinctive aromatic odor. Guaiacol performs as a precursor to several flavorants such as eugenol and vanillin. A predicted 85% of the vanillin is introduced from guaiacol. Guaiacol is industrially produced by…

Global Isoeugenol Market 2021 Report- Future Growth and Opportunities | Jiangxi …

The Global Isoeugenol Market research report also includes analyzing all the organizations operating in the market and leadership mapping. In addition, Global Isoeugenol Market provides a strategic standpoint of the industry, such as measures drivers and government rules and policies. Finally, Global Isoeugenol Market analyzes the efficacy of the government led-strategies and policies promoting the Global Isoeugenol Market and industry.

Get FREE PDF Sample of the Report @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5218971

The key market…