Press release

Launch Your Fall Prevention Mat Plant in 2025: Detailed Cost Structure, Equipment List & Revenue Forecast

Fall Prevention Mat Manufacturing Plant CostA fall prevention mat manufacturing plant is a production facility used to manufacture high-quality impact-absorbing mats designed to reduce injuries caused by slips, trips, and falls. These mats are widely used in hospitals, senior care homes, schools, gyms, playgrounds, bathrooms, industrial facilities, and residential spaces. The manufacturing process involves material mixing, molding, compressing, curing, cutting, and finishing the mats into different sizes and thicknesses. A significant initial investment is required to establish a fall prevention mat manufacturing unit, which must be carefully planned to ensure product durability, safety compliance, and long-term profitability.

Unveiling the World of Fall Prevention Mats

Fall prevention mats are safety products made from materials such as rubber, foam, PVC, EVA, or gel-based compounds. These mats are engineered to absorb shock, reduce impact force, and provide a non-slip surface. They help minimize the risk of serious injuries, especially for elderly people, children, patients, and workers in high-risk environments. Growing awareness around workplace safety, aging populations, healthcare infrastructure development, and child safety is strongly driving demand for fall prevention mats at a global level.

Request a Sample Report:

https://www.imarcgroup.com/fall-prevention-mat-manufacturing-plant-project-report/requestsample

What are Fall Prevention Mats Used For?

Fall prevention mats are used in multiple sectors such as:

• Hospitals and nursing homes

• Elderly care facilities

• Children's play areas and daycare centers

• Gyms and sports facilities

• Schools and educational institutions

• Industrial and warehouse floors

• Bathrooms and wet areas

• Homes with senior citizens

The wide range of applications makes it essential to analyze the fall prevention mat manufacturing plant cost based on material type, thickness, and safety rating.

Key Factors for Fall Prevention Mat Plant Setup Requirements

Setting up a fall prevention mat manufacturing plant requires careful evaluation of raw materials, processing technology, certifications, and infrastructure.

Raw Materials and Supply Chain

The primary raw materials include rubber granules, foam sheets, EVA, PVC compounds, polyurethane, binding resins, and anti-slip coatings. The consistent availability of high-quality materials directly affects the durability and safety performance of the mats. Strong supplier relationships help in controlling the overall fall prevention mat production cost.

Processing Technology & Equipment

The plant requires rubber mixing machines, hydraulic compression molding machines, curing ovens, cutting machines, surface texturing machines, and finishing units. For advanced products, lamination and layering technology may also be required. These machines largely influence the overall fall prevention mat manufacturing plant cost.

Compliance and Certifications

Safety and quality standards such as ISO, OSHA, EN, and other regional safety certifications are essential. Compliance enhances market credibility and opens doors to institutional and international buyers.

Location & Infrastructure

The plant should ideally be located in an industrial area with good access to raw materials, logistics routes, power supply, water availability, and nearby consumer markets such as hospitals or educational institutions.

Ask An Analyst:

https://www.imarcgroup.com/request?type=report&id=15808&flag=C

Detailed Process Flow and Quality Control

Unit Operations Involved

1. Raw Material Mixing & Blending

2. Sheet Formation / Molding

3. Compression & Shaping

4. Heat Curing / Vulcanization

5. Cooling & Stabilization

6. Cutting & Trimming

7. Surface Texturing (Anti-slip)

8. Quality Inspection

9. Printing / Branding (If Required)

10. Packaging

11. Storage & Dispatch

Quality Assurance Criteria

• Impact absorption testing

• Slip resistance testing

• Thickness uniformity

• Load-bearing capacity

• Durability and wear testing

• Fire resistance (if applicable)

• Dimensional accuracy testing

These tests ensure the mats meet safety standards and provide reliable protection.

Factors Influencing Fall Prevention Mat Production Costs

CapEx and OpEx Analysis for Fall Prevention Mat Manufacturing Plant Cost

Raw Material Cost:

Rubber, EVA, PVC, and polyurethane are key cost contributors and may fluctuate based on market availability.

Capital Investment:

Includes land, building construction, molding machines, curing systems, cutting units, and quality testing laboratories.

Operational Cost:

Labor, electricity, heating systems, maintenance, packaging, and logistics expenses.

Thickness and Material Type:

High-density or multi-layer mats require more materials and processing time, increasing cost.

Market Demand & Application Type:

Medical and industrial-grade mats require higher specifications and thus greater investment.

Buy Now:

https://www.imarcgroup.com/checkout?id=15808&method=1911

Leading Fall Prevention Mat Manufacturers (Global/Regional)

• 3M Safety Solutions

• Honeywell Safety Products

• Notrax Global

• Wearwell LLC

• Mountville Mills

• Apache Mills

• Various OEM safety mat manufacturers

These companies lead the market with innovative designs and high safety standards.

Conclusion

A Fall Prevention Mat Manufacturing Plant presents a highly promising opportunity as global awareness of safety, injury prevention, and workplace compliance continues to grow. The rising elderly population, expansion of healthcare facilities, strict workplace safety regulations, and demand for child-safe environments are key growth drivers for this industry.

However, investors must carefully plan for raw material sourcing, machinery selection, quality compliance, and skilled manpower. With the right technology, location, and marketing strategy, a fall prevention mat manufacturing plant can offer strong ROI, long-term growth, and consistent market demand in the safety and wellness sector.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Launch Your Fall Prevention Mat Plant in 2025: Detailed Cost Structure, Equipment List & Revenue Forecast here

News-ID: 4286748 • Views: …

More Releases from IMARC Group

Brazil Hybrid Electric Vehicle Market: Growth Dynamics, Consumer Shifts, and Com …

The Brazil hybrid electric vehicle market size was 348.75 Thousand Units in 2025 and is forecasted to reach 2,551.74 Thousand Units by 2034, reflecting a CAGR of 24.75% during 2026-2034. This robust expansion is fueled by increasing environmental awareness, rising fuel costs, and government policies aimed at emission reduction. Advances in battery technology and flex-fuel hybrid variants leveraging Brazil's ethanol resources also contribute to market growth.

Sample Request Link: https://www.imarcgroup.com/brazil-hybrid-electric-vehicle-market/requestsample

Study Assumption…

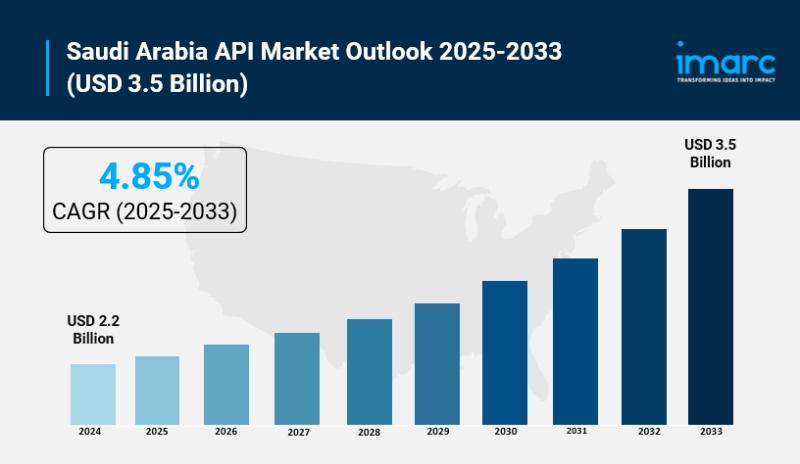

Saudi Arabia API Market Size to Expand USD 3.5 Billion by 2033 at a CAGR of 4.85 …

Saudi Arabia API Market Overview

Market Size in 2024: USD 2.2 Billion

Market Forecast in 2033: USD 3.5 Billion

Market Growth Rate 2025-2033: 4.85%

According to IMARC Group's latest research publication, "Saudi Arabia API Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Saudi Arabia API market size reached USD 2.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.5 Billion by 2033, exhibiting a growth rate…

France Real Estate Market to Reach USD 330.75 Billion by 2033 CAGR, 3.42% 2025-2 …

Market Overview

The France real estate market size reached USD 236.29 Billion in 2024 and is projected to reach USD 330.75 Billion by 2033, growing at a CAGR of 3.42% during the forecast period of 2025-2033. The market reflects cautious optimism influenced by evolving buyer expectations, government renovation schemes promoting energy efficiency, and an interest shift towards secondary cities and rural areas due to remote work trends. Improved mortgage conditions, sustainability,…

Hydrogen Price Index Q4 2025 Report - USA, Japan & Europe Drive Global Growth

The global Hydrogen Prices landscape is evolving rapidly as clean energy investments and decarbonization policies accelerate worldwide. This Hydrogen Price Trend Analysis highlights the latest shifts in the Hydrogen Price Index, regional benchmarks, and near-term forecasts. Businesses tracking the price of Hydrogen are closely monitoring cost movements driven by renewable energy expansion, industrial demand, and supply chain dynamics shaping the Hydrogen future price outlook.

Hydrogen Current Hydrogen Price Movements:

Recent Hydrogen Prices…

More Releases for Mat

Global Field Mat Sales Market Size by Application, Type, and Geography: Forecast …

USA, New Jersey- According to Market Research Intellect, the global Field Mat Sales market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

Due to rising demand from a variety of industries, including construction, oil & gas, agriculture, and military applications, the field mat sales market is…

Crane Mats Market Key Players - Matrax, Beasley Forest Products, Garnett Wood Pr …

United States, New Jersey: Crane Mats Market size was valued at USD 713.26 Million in 2021 and is projected to reach USD 1096.37 Million by 2030, growing at a CAGR of 4.89% from 2023 to 2030.

The Crane Mats Market has been experiencing significant growth over the past few years, driven by technological advancements, shifting consumer preferences, and increasing investment from both public and private sectors. This market encompasses a wide range…

Industrial Anti-static Mat Market to see Booming Business Sentiments | 3M. Co, A …

The Latest published market study on Industrial Anti-static Mat Market report provides an overview of the current market dynamics as well as what our survey respondents- all outsourcing decision-makers- predict the market will look like in 2031.The study breaks the market by revenue and volume and price history to estimate the size and trends analysis and identify gaps and opportunities.This report provides impactful insights for our clients including a vast…

BAZMAT ANTI-SLIP MAT REVIEW: IS THIS ANTI SLIP MAT LEGIT? ( USA AND CANADA REVIE …

Slippery surfaces can pose a significant risk, causing accidents and injuries in our daily lives. Whether it's in the kitchen, bathroom, or even at the office, a reliable solution to prevent slips and falls is crucial. This is where the Bazmat Anti-Slip Mat comes in. Engineered with advanced technology and superior materials, this anti-slip mat offers a practical and effective way to enhance safety and stability in any environment.

Designed to…

Glass Mat Market

The glass mat market size is expected to grow from USD 1.3 billion in 2022 to USD 2.2 billion by 2028 growing at a CAGR of 8.6% between 2023 to 2028.The glass mat market is mainly driven by increasing use of glass mat in the construction & infrastructure and industrial applications end-use industries. Automation in various industries is increasing preference for using glass fabrics, which is among the key restraints…

Plastic Protection Mat market: Complete Company Profiling of Dominant Players | …

"QY Research holds tons of experience in offering comprehensive and accurate analysis of global as well as regional markets. The report presented here is an industry-best compilation of detailed and quality research studies on the global Plastic Protection Mat market. It provides SWOT, PESTLE, and other important types of analysis to give a real and complete picture of the current and future scenarios of the global Plastic Protection Mat market.…