Press release

Invest in a Glass Dispenser Manufacturing Unit: 2025 Cost Modeling, Machinery & Market Returns

A glass dispenser is a storage and dispensing vessel crafted from food-grade glass, designed to hold liquids such as water, juices, syrups, oils, soaps, or sanitizers. Equipped with a tap, pump, or spigot, it allows safe, hygienic and controlled dispensing. Glass dispensers are valued for their non-reactive nature, durability, clarity, ease of cleaning, and reusable design. Commonly used in homes, restaurants, cafés, hotels, laboratories, and event settings, they combine functionality with aesthetic appeal for modern living and hospitality environments.Setting up a glass dispenser manufacturing plant

Establishing a glass dispenser manufacturing plant involves securing raw materials like silica sand, soda ash, limestone, and recycled glass, plus metal or plastic components for taps and lids. Key steps include melting the glass, molding or blowing to shape the dispenser, annealing, drilling for spout installation, surface finishing and tap assembly, followed by quality inspection and packaging. Essential equipment includes furnaces, molds, annealing ovens, polishing machines, drilling lines and automated assembly units. A dependable energy supply, skilled personnel, safety systems and efficient logistics are vital for consistent and profitable operations.

Request for a Sample Report: https://www.imarcgroup.com/glass-dispenser-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "Glass Dispenser Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a glass dispenser manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

This comprehensive business plan outlines every critical step involved in setting up a glass dispenser manufacturing plant successful unit - from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as glass dispenser manufacturing plant setup, cost breakdown, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Glass Dispenser industry outlook 2025:

By 2025, the glass dispenser industry is poised for steady growth, fueled by rising consumer preference for sustainable, reusable, and hygienic containers in the home and hospitality sectors. Increasing awareness of plastic pollution and a shift toward glass packaging are boosting demand. Trends such as premium drink service, wellness-centric beverage stations, and eco-conscious hotel chains further expand the market. Advances in design, surface finishing and customization will allow manufacturers to offer differentiated products. Overall, the outlook is strongly positive for manufacturers who invest in quality, design innovation and efficient production systems.

Key Insights for Glass Dispenser Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=17658&flag=C

Key Cost Components of Setting Up a Glass Dispenser Plant:

• Land & Site Development - Purchase or lease of land, site clearing, leveling, and internal road development

• Plant Construction - Production hall, raw material storage, finished goods warehouse, offices, and quality control laboratories

• Machinery & Equipment - Glass melting furnaces, molding/blowing machines, annealing ovens, drilling machines, polishing and finishing units

• Raw Materials - Silica sand, soda ash, limestone, recycled glass (cullet), metal/plastic taps, lids, and sealing components

• Utilities & Power Systems - High electricity and fuel requirements for furnaces, water supply, cooling systems, and backup power

• Environmental & Safety Systems - Dust control, ventilation, fire safety equipment, and waste glass management systems

• Quality Control & Laboratory Setup - Testing equipment for thickness, strength, and leak detection

• Installation & Commissioning - Machinery installation, calibration, trial runs, and process optimization

• Labor & Skilled Workforce - Glass technicians, machine operators, quality inspectors, supervisors, and support staff

• Packaging & Storage - Protective wrapping materials, cartons, pallets, and storage racks

• Transportation & Logistics - Raw material transport systems and finished product distribution setup

• Licensing & Regulatory Compliance - Industrial approvals, environmental clearances, and safety certifications

• Maintenance & Spares - Regular servicing, spare parts inventory, and repair tools

• Working Capital & Contingency - Funds for day-to-day operations, raw material stock, and unforeseen expenses

Economic Trends Influencing Glass Dispenser Plant Setup Costs 2025:

• Rising Raw Material Prices - Increasing costs of silica sand, soda ash, limestone, and recycled glass due to global supply chain disruptions and mining constraints.

• Energy & Utility Cost Escalation - Glass melting and annealing are highly energy-intensive processes; rising electricity and fuel tariffs significantly increase operating and setup costs.

• Machinery & Construction Inflation - Higher prices for furnaces, molding machines, annealing systems, and industrial construction materials raise overall capital expenditure.

• Packaging & Component Cost Increase - Higher costs of metal/plastic taps, lids, gaskets, cartons, and protective packaging materials affect total plant setup budgets.

• Environmental Compliance Investment - Stricter regulations on emissions, waste glass recycling, and pollution control require additional spending on eco-friendly systems.

• Logistics & Freight Volatility - Fluctuating transportation and import/export costs increase expenses for both raw material procurement and finished goods distribution.

• Labor & Skill Premium - Rising wages for skilled glass technicians, machine operators, and quality control experts add to long-term operating expenses.

• Growing Demand for Premium Designs - Increased demand for customized and designer glass dispensers requires advanced molds, finishing technology, and innovation, raising equipment and R&D costs.

• Regional Infrastructure Variations - Higher land prices, power tariffs, and weaker infrastructure in certain locations result in increased setup costs compared to industrial hubs.

Challenges and Considerations for Investors in Glass Dispenser Plant Projects:

• High Energy Consumption - Glass melting and annealing require continuous high temperatures, leading to heavy electricity and fuel usage.

• Large Initial Capital Investment - Furnaces, molds, shaping machines, and annealing systems demand significant upfront spending.

• Fragility & Breakage Risk - Glass products are prone to damage during production, handling, and transportation, increasing wastage costs.

• Skilled Workforce Requirement - Experienced glass technicians and machine operators are essential for maintaining product quality and consistency.

• Strict Quality Standards - Products must meet strength, thickness, hygiene, and leakage resistance requirements, which increases inspection and testing costs.

• Environmental Regulations - Emission control, waste handling, and recycling requirements add to capital and operational burdens.

• Competition from Alternatives - Plastic, stainless steel, and ceramic dispensers create pricing and market-entry challenges.

• Logistics & Storage Issues - Safe packaging, careful handling, and specialized storage are required to prevent damage.

• Demand Fluctuations - Market demand often changes based on trends in hospitality, home décor, and sustainability awareness.

• Long Break-Even Period - High setup and operating costs can extend the return-on-investment timeline for new plants.

Buy Now:

https://www.imarcgroup.com/checkout?id=17658&method=1911

Conclusion:

A glass dispenser manufacturing plant presents a strong and sustainable business opportunity in 2025, driven by rising demand for eco-friendly, reusable, and hygienic storage solutions across households, hospitality, wellness, and food service sectors. However, success in this industry depends on careful planning around high energy consumption, substantial machinery investment, strict quality control, and skilled manpower requirements. By selecting the right location, adopting energy-efficient technology, ensuring strong supplier partnerships, and maintaining high product standards, investors can achieve long-term profitability and build a competitive position in this growing, sustainability-focused market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Invest in a Glass Dispenser Manufacturing Unit: 2025 Cost Modeling, Machinery & Market Returns here

News-ID: 4286103 • Views: …

More Releases from IMARC Group

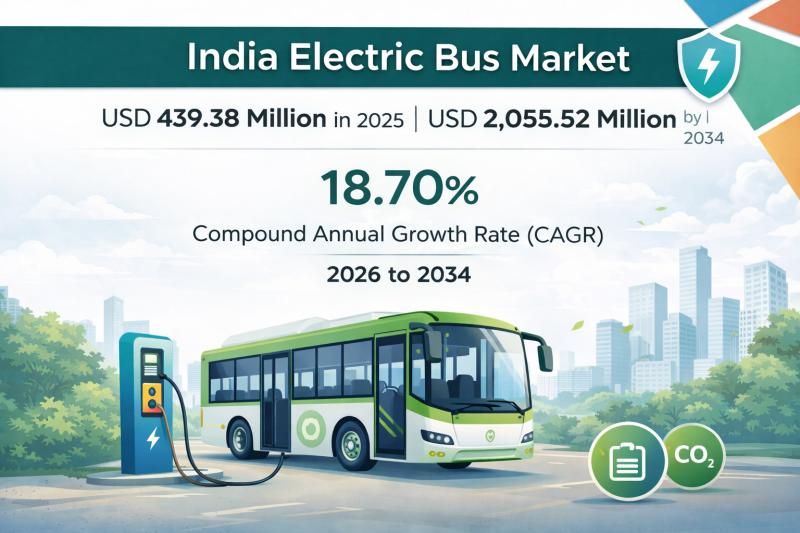

India Electric Bus Market 2026: Explosive Growth, Government Push & Investment O …

Introduction:

According to the latest research report titled "India Electric Bus Market Size, Share, Trends and Forecast by Propulsion Type, Battery Type, Length, Range, Battery Capacity, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

How Big is the India Electric Bus Market?

The electric bus market size in India was valued at USD 439.38 Million in 2025 and is projected to…

Glass Dispenser Manufacturing Plant Setup 2026: Process Flow, Machinery Cost and …

Setting up a glass dispenser manufacturing industry is witnessing robust growth driven by the increasing demand for hygienic, aesthetic, and reusable solutions for beverage dispensing in both commercial and residential sectors. At the heart of this expansion lies a versatile and sustainable product-the glass dispenser. As industries transition toward premium, eco-friendly dispensing solutions and the growing hospitality sector embraces reusable formats, establishing a glass dispenser manufacturing plant presents a strategically…

Electric Vehicle Component Manufacturing Plant DPR 2026: Cost Structure, Product …

Setting up an Electric Vehicle (EV) Component manufacturing plant positions investors in one of the most dynamic and rapidly expanding segments of the global automotive industry, backed by accelerating EV adoption, government-led electrification mandates, advancements in battery technologies, and expanding charging infrastructure investments. As countries worldwide implement stricter emission standards, offer manufacturing incentives, and pursue supply chain localization, the global EV component industry continues to present compelling opportunities for manufacturers…

Copper Prices February 2026 | Global Price Trend, Market Analysis & Forecast

Northeast Asia - Copper Prices February 2026

In Northeast Asia, copper prices surged to USD 15.88 per kg in February 2026, registering a significant 9.8% increase. The strong upward movement was driven by robust demand from electrical, electronics, and renewable energy sectors. Tight regional inventories and improved industrial activity further supported bullish market sentiment across the copper supply chain.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/copper-pricing-report/requestsample

Note: The analysis can be tailored to…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…