Press release

What does an X-ray do to food? Industry Trends and Best Practices

In the modern food industry, safety and quality are not just expectations-they are essential. One of the most advanced technologies supporting these goals is X-ray inspection. But what exactly does an X-ray do to food, and why is it a trusted solution across the food production chain?Understanding X-ray Technology in Food Inspection

X-ray systems [https://www.techikgroup.com/x-ray-inspection-system/] work by emitting a controlled beam of X-rays through food products. These rays are absorbed at different levels depending on the density and composition of the materials they pass through. While food itself typically has a uniform density, foreign objects like metal, glass, stones, bone fragments, or dense plastic absorb X-rays differently. By analyzing the resulting image, the system can detect even small contaminants that may be invisible to the naked eye or hidden inside sealed packaging.

Importantly, X-ray inspection [https://www.techikgroup.com/x-ray-inspection-system/] does not alter, cook, or damage the food. The radiation dose used is extremely low and well within internationally recognized safety standards. This ensures that food remains completely safe for consumption after inspection.

Why X-ray is Preferred in Food Safety

Compared with traditional inspection methods such as metal detectors or visual checks, X-ray systems offer several advantages:

Broader detection range: X-rays can detect both metallic and non-metallic foreign objects.

Versatility: Suitable for a wide variety of food types-bulk, packaged, frozen, or irregularly shaped.

Quality assurance: Some systems can also check for weight deviations, missing components, or broken items.

Non-destructive testing: Maintains product integrity while improving overall safety.

Techik's X-ray Inspection Solutions [https://www.techikgroup.com/x-ray-inspection-system/]

At Techik, we are committed to enhancing food safety through innovation. Our X-ray inspection machines are designed with high-resolution imaging systems, intelligent algorithms, and user-friendly interfaces to meet the complex needs of modern food production.

Whether detecting bone fragments in meat, glass in sauces, or stones in dried fruits, Techik X-ray systems deliver high accuracy, high throughput, and stable performance. With flexible models for bulk products, pipeline inspection, or final packaging lines, Techik helps producers reduce recalls, meet regulatory compliance, and protect brand reputation.

From raw materials to finished goods, Techik ensures every product you deliver is safe, clean, and trustworthy.

Media Contact

Company Name: Techik Instrument (Shanghai) Co., Ltd.

Contact Person: Media Relations

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=what-does-an-xray-do-to-food]

Phone: 86-21-60671088-8860

Country: China

Website: https://www.techikgroup.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release What does an X-ray do to food? Industry Trends and Best Practices here

News-ID: 4285690 • Views: …

More Releases from ABNewswire

Infinite's B2B Lead Generation for Fintech Produces 163 Warm Leads for BridgerPa …

B2B lead generation agency Infinite generated 163 warm leads for fintech company BridgerPay in 6 months, achieving a 62% conversion rate to qualified opportunities and $62 cost per lead through targeted LinkedIn and email outreach to 4,676 payment decision-makers.

HERZLIYA, Israel - February 7, 2026 - Infinite, a B2B lead generation agency specializing in LinkedIn and email outreach, generated 163 warm leads for BridgerPay's Payment Operations Platform in a six-month campaign…

MT Dunn Plumbing Expands Emergency Services in Hillsboro & Across Portland, Oreg …

MT Dunn Plumbing LLC (CCB# 234243) expands 24/7 emergency services across Hillsboro, Beaverton, Portland & Washington County. The licensed, bonded, and insured contractor provides immediate response for burst pipes, water heater failures, sewer backups, and drain clogs. Operating from Hillsboro, owner Michael T Dunn serves residential and commercial properties region-wide. Emergency contact: 503-640-2458 or mtdunnplumbing.com.

Hillsboro, OR - MT Dunn Plumbing LLC, a licensed and established plumbing contractor serving the Portland…

Beyond the Prompt: How Mimic Motion Architecture is Redefining the 2026 Passive …

Image: https://www.abnewswire.com/upload/2026/02/ac57e1a7b6e53a95f52ea0f18fcb990c.jpg

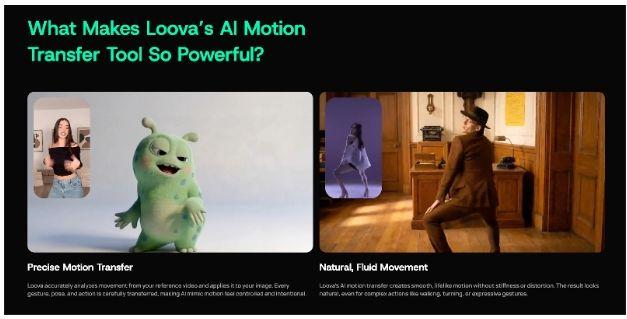

As we move through 2026, the digital economy is no longer just about "what" you show, but "how" it moves. Static content is losing ground to kinetic, motion-driven narratives that capture attention in seconds. At the center of this shift is Loova, whose proprietary Mimic Motion architecture has become the secret engine behind some of the most successful passive income streams this year.

This report breaks down the technical logic…

The Real Cost of Convenience: A Complete Guide to Vending Machine Startup Costs

Image: https://www.abnewswire.com/upload/2026/02/32ec9ac40420df59e70c21070d981def.jpg

The dream of earning passive income often leads aspiring entrepreneurs to the world of automated retail. It is a sector defined by low labor requirements and the ability to generate revenue around the clock. However, before you can stock your first row of snacks, you must understand the financial commitment required to get your equipment on-site. Many beginners find themselves asking how much do vending machines cost [https://dfyvending.com/vending-machine-startup-costs] as…

More Releases for Techik

Techik Showcases Whole Chain Seafood Inspection and Sorting Solutions at VIETFIS …

Techik will participate VIETFISH 2025, taking place on 27 June 2025 at the Saigon Exhibition and Convention Center, 799 Nguyen Van Linh, District 7, Ho Chi Minh City, Vietnam. Visitors are invited to explore Techik's latest innovations at booths B307-B308, where the company will present its comprehensive inspection and sorting solutions designed for the seafood industry.

As one of the leading providers of intelligent inspection [https://www.techikgroup.com/x-ray-inspection-system/] and sorting systems [https://www.techikgroup.com/optical-sorter-products/], Techik…

X-ray Food Inspection System Market Analysis By Top Keyplayers - LOMA, TDI Packs …

The "X-ray Food Inspection System Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global X-ray Food Inspection System Market, 2024-2031

Verified Market Research's most recent report, "X-ray Food Inspection System Market: Global Industry Trends, Share, Size, Growth, Opportunity and…

Who Can Benefit From Techik Coffee Color Sorter?

Coffee beans, the heart of every cup of coffee, undergo a meticulous journey from their initial form as cherries to the final brewed product. This process involves several stages of sorting and grading to ensure quality, flavor, and consistency.

The Journey of Coffee Beans

Coffee cherries are harvested from coffee plants, with each cherry containing two beans. These cherries must be carefully sorted to remove under-ripe or defective fruits before processing begins.…

What is the commonly used process of sorting coffee?

What is the process of sorting coffee [https://www.techik-colorsorter.com/application/coffee/]?

In the coffee industry, the pursuit of perfection begins with precision sorting and inspection. Techik, a pioneer in intelligent sorting solutions, offers state-of-the-art technology that ensures only the finest coffee beans make it through each stage of production. Our solutions are tailored to meet the diverse needs of coffee processors, from sorting fresh cherries to inspecting final packaged products.

Techik's sorting technology is equipped…

Booming Demand in the Multifunction Color Sorting Market Will Drive an Exponenti …

Multifunction Color Sorting Market 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭 𝟐𝟎𝟐𝟑 𝐢𝐬 𝐜𝐚𝐫𝐞𝐟𝐮𝐥𝐥𝐲 𝐜𝐨𝐧𝐝𝐮𝐜𝐭𝐞𝐝 𝐟𝐨𝐫 𝐭𝐡𝐞 𝐢𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐢𝐧 𝐚 𝐪𝐮𝐚𝐥𝐢𝐭𝐚𝐭𝐢𝐯𝐞 𝐚𝐧𝐝 𝐜𝐨𝐧𝐬𝐢𝐬𝐭𝐞𝐧𝐭 𝐰𝐚𝐲 𝐭𝐨 𝐞𝐧𝐬𝐮𝐫𝐞 𝐚 𝐬𝐮𝐜𝐜𝐞𝐬𝐬𝐟𝐮𝐥 𝐨𝐮𝐭𝐜𝐨𝐦𝐞 of Multifunction Color Sorting Market. In addition to identifying, analyzing, and estimating new trends, this research report also examines key industry drivers, challenges, and opportunities in addition to evaluating competitors, geographical areas, types, and applications. Understanding the competitive landscape is crucial for determining the product improvements…

Dangerous Liquid Detector Market Prediction, Strategies, Trends and SWOT Analysi …

LOS ANGELES, United States:

The global Dangerous Liquid Detector market has been garnering remarkable momentum in the recent years. The steadily escalating demand due to improving purchasing power is projected to bode well for the global market. QY Research’s latest publication, titled global Dangerous Liquid Detector market, offers an insightful take on the drivers and restraints present in the market. It assesses the historical data pertaining to the global Dangerous Liquid…