Press release

Diamond Powder Market Forecast to Reach US$1.27 Bn by 2030 Driven by Industrial Precision - Diamond Powder Market Analysis and Growth Trends

The global diamond powder market continues to demonstrate steady momentum, backed by expanding industrial applications and rising demand for precision machining. According to the latest study by Persistence Market Research, the market, valued at US$0.82 Bn in 2023, is projected to rise to US$1.27 Bn by 2030, reflecting a strong CAGR of 6.5%. Diamond powder has become an indispensable material across sectors such as industrial manufacturing, electronics, construction, and automotive due to its outstanding hardness, thermal conductivity, and abrasion properties. Increasing investments in micro-machining technologies and advanced polishing techniques are also pushing the market forward.Get Your FREE Sample Report Instantly - Click Now: https://www.persistencemarketresearch.com/samples/28939

Growing Role of Diamond Powder in Precision Manufacturing

Diamond powder has emerged as a preferred abrasive material for precision machining across a wide range of metals, alloys, ceramics, and composites. The ultra-fine abrasive property of diamond powder ensures surface finishing and ultra-smooth polishing, critical for industries that demand minimal tolerance levels and high product accuracy. Aerospace, tooling, and automotive production depend on diamond powder to enhance component durability and dimensional accuracy, driving the expansion of the market. The growing use of micro-machined parts is furthermore elevating product adoption across both established and emerging economies.

Simultaneously, industrial automation is enhancing the consumption rate of diamond-based abrasives. Computer Numerical Control (CNC) machines and advanced grinding systems operate with diamond powder to minimize wear-and-tear and increase efficiency during high-speed operations. With manufacturing shifting towards ultra-precision equipment globally, diamond powder is expected to continue playing a crucial role in enabling a superior end-product finish. As companies emphasize productivity with cost-effectiveness, diamond powder stands out as a highly viable solution for modern industrial requirements.

Diamond Powder Demand Driven by the Semiconductor and Electronics Sector

The semiconductor and electronics industry heavily relies on diamond powder to achieve precision polishing of silicon wafers and semiconductor components. Ultra-fine diamond particles are used in CMP (Chemical Mechanical Planarization) processes, enabling the smooth and even surfaces necessary for producing next-generation microchips. With the rapid rise of AI processors, EV battery management chips, and compact smart components, demand for high-performance polishing abrasives continues to grow. This makes the electronics sector one of the most influential demand engines for the diamond powder market.

Additionally, the miniaturization of consumer electronics amplifies the need for micro-fabrication components that demand exact tolerances during production. Smartphones, wearables, and computing devices incorporate highly sensitive materials that require diamond-based polishing and grinding. The ongoing shift toward nanotechnology further contributes to diamond powder adoption in laboratories and commercial R&D centers. As chip producers expand facilities across Asia, North America, and Europe, the semiconductor sector is set to drive sustained market consumption.

Diamond Powder Market Segmentation

By Product Type: Synthetic Diamond Powder - Natural Diamond Powder

By Particle Size: 0-10 μm - 10-45 μm - 45-75 μm - Above 75 μm

By Application: Polishing - Cutting - Grinding - Lapping - Others

By End Use: Electronics - Automotive - Aerospace - Construction - Machinery Manufacturing - Others

Increasing Adoption of Synthetic Diamond Powder for Industrial Efficiency

Synthetic diamond powder has become the dominant category owing to its uniform particle size and cost-efficiency. Unlike natural diamond powder, synthetic variants can be produced with controlled properties, making them suitable for high-precision and repeatable industrial applications. Manufacturers are increasingly shifting toward synthetic diamond powder to support large-volume production of tools, blades, and abrasive components. This material consistency has played a key role in boosting manufacturing reliability and minimizing material waste.

From a sustainability standpoint, synthetic diamond powder also provides an opportunity to conserve natural resources while simultaneously meeting rising industrial demands. Its engineered properties enable exceptional toughness and thermal stability, ensuring prolonged service life in high-temperature manufacturing settings. As a result, synthetic diamond powder is expected to retain the largest revenue share in the global market through 2030, supported by adoption in heavy-duty machining, construction equipment, and drilling applications.

Automotive Sector Emerging as a Major Consumer of Diamond Powder

The automotive manufacturing industry is another major adopter, utilizing diamond powder during the production of precision components such as bearings, fuel injector systems, valves, gears, and transmission parts. As automotive OEMs continue increasing focus on efficiency and long-term durability, the requirement for advanced abrasive materials has multiplied. Diamond powder plays a significant role in enhancing surface uniformity and minimizing friction-critical factors for engine performance.

Moreover, the rapid growth of electric vehicles (EVs) opens new pathways for diamond powder consumption. EV-specific parts such as battery housings, semiconductor modules, and lightweight alloys demand higher degrees of accuracy in fabrication. Diamond powder enables manufacturers to meet these needs with improved consistency and lower rejection rates. With global EV adoption accelerating across Europe, China, India, and North America, the automotive industry is expected to retain its role as a key market driver.

Get a Customized Market View in One Click: https://www.persistencemarketresearch.com/request-customization/28939

Rising Use of Diamond Powder in Construction and Infrastructure Projects

In the construction sector, diamond powder is widely integrated into cutting, drilling, and grinding equipment for concrete, stone, granite, and reinforced materials. The material's extreme hardness and thermal conductivity enable faster construction operations and reduced downtime for machinery. Infrastructure expansion across developing nations has significantly increased the need for industrial abrasives capable of handling high-durability substrates.

Additionally, diamond-enhanced construction tools require fewer replacements, reducing operational costs and improving productivity for commercial and residential project contractors. The growing global focus on smart cities, transportation upgrades, and residential developments directly enhances the demand trajectory for diamond powder. With urbanization at the core of government infrastructure budgets, the construction application segment is forecast to experience continued growth during the market assessment timeline.

Technological Advancements Strengthening Diamond Powder Production

Technological innovation has transformed the diamond powder industry with improved processing techniques such as HPHT (High Pressure High Temperature) and CVD (Chemical Vapor Deposition). These processes enable the creation of higher-purity synthetic diamond powder with enhanced particle uniformity, optimizing performance across industrial settings. New purification and micronization methods have also reduced impurities, further strengthening reliability and long-term stability.

Furthermore, digital manufacturing has enhanced customization capabilities, allowing manufacturers to tailor powder characteristics based on application requirements. This progress has resulted in premium diamond abrasives suitable for high-precision tasks such as turbine component resurfacing, ceramic machining, and optical equipment production. As technology continues advancing, diamond powder production will become increasingly sophisticated, widening its application spectrum and global market accessibility.

Expansion of Toolmaking and Abrasive Manufacturing Boosting Demand

Diamond powder is fundamental to the production of abrasive tools including grinding wheels, cutting discs, polishing pads, lapping compounds, and drilling bits. The booming demand for industrial equipment and heavy-duty tools has increased diamond powder consumption, particularly in Asia Pacific. The continuous expansion of manufacturing plants and investments in global supply chain upgrades further reinforce the industry's long-term growth.

Additionally, the aftermarket for tools has become equally strong, with industrial users replacing or upgrading equipment to support high-volume operations. Construction, automotive, aerospace, and mining industries all require durable abrasive tools powered by diamond powder. As industries focus on process optimization and quality assurance, the dependence on diamond-based abrasives will continue rising steadily.

Asia Pacific Dominating the Global Diamond Powder Landscape

Asia Pacific holds the largest share of global diamond powder consumption due to the region's powerful industrial base and rapid urbanization trends. China and India serve as major production hubs for construction materials, automobile components, and electronics-all key users of diamond powder. Furthermore, APAC offers competitive manufacturing costs, allowing companies to scale operations effectively.

Alongside industrial manufacturing, the region's expansion of mining and geological exploration also supports the use of diamond-based equipment. Growing government investments in highways, bridges, energy projects, and smart infrastructure are expected to keep APAC at the forefront of market revenue generation. With foreign companies continuing to establish production facilities in the region, Asia Pacific remains a powerhouse for market growth.

Market Challenges: Price Volatility and Technical Skill Requirements

Despite its high industrial value, the diamond powder market faces cost-related challenges that can impact small and medium-scale manufacturers. Fluctuating prices of raw materials and processing technology can influence profitability and widen the gap between large enterprises and small manufacturers. Cost-sensitive industries may also hesitate to adopt diamond powder-based tools compared to cheaper alternatives.

Another restraint arises from the skill and expertise required to properly integrate diamond powder equipment into industrial processes. Without trained operators or precision-based machine settings, diamond abrasives may not deliver optimal efficiency. Capacity-building programs and increased industry collaboration are key to minimizing these constraints and ensuring smooth usability across sectors.

For In-Depth Competitive Analysis, Buy Now: https://www.persistencemarketresearch.com/checkout/28939

Company Insights

✦ Element Six

✦ Tomei Diamond Co.

✦ ILJIN Diamond Co.

✦ Henan Huanghe Whirlwind Co.

✦ Saint-Gobain Abrasives

✦ Zhengzhou Sino-Crystal Diamond Co.

✦ Asahi Diamond Industrial Co.

✦ SF Diamond Co.

✦ Sandvik AB

✦ Engis Corporation

Future Outlook: Diamond Powder as a Backbone of Next-Gen Manufacturing

The growing adoption of automation, smart factories, and Industry 4.0 is expected to significantly enhance diamond powder consumption by 2030. Advanced machining techniques such as nano-polishing, laser cutting, and micro-engineering are increasingly dependent on ultra-fine abrasives to maintain quality consistency. As companies seek to improve turnaround times and minimize surface defects, diamond powder will remain an essential material to achieve next-level production outputs.

Furthermore, innovation in high-performance materials such as composite metals, ceramics, and heat-resistant alloys underscores the need for diamond-based machining tools. The global shift toward EV transportation, semiconductor fabrication, and precision aerospace engineering further strengthens the market outlook. With its high-value capabilities and unmatched performance advantages, diamond powder is positioned as a critical pillar of next-generation industrial engineering.

Explore the Latest Trending Research Reports:

• Latin America Industrial Explosives Market Research Report - https://www.persistencemarketresearch.com/market-research/latin-america-industrial-explosives-market.asp

• Dearomatic Solvents Market Research Report - https://www.persistencemarketresearch.com/market-research/dearomatic-solvents-market.asp

• Oxo Alcohol Market Research Report - https://www.persistencemarketresearch.com/market-research/oxo-alcohol-market.asp

Contact Us:

Persistence Market Research

Second Floor, 150 Fleet Street,

London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Diamond Powder Market Forecast to Reach US$1.27 Bn by 2030 Driven by Industrial Precision - Diamond Powder Market Analysis and Growth Trends here

News-ID: 4284802 • Views: …

More Releases from Persistence Market Research

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

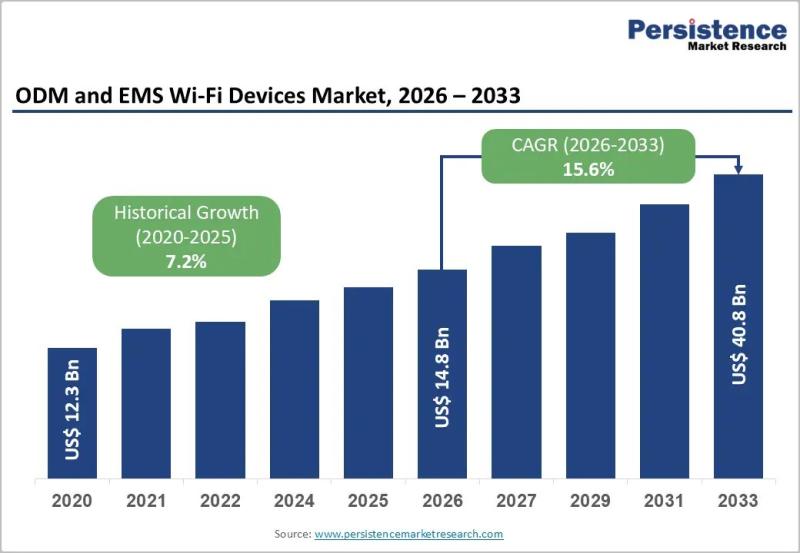

ODM and EMS Wi-Fi Devices Market to Reach US$ 40.8 Billion by 2033 at 15.6% CAGR

The global ODM and EMS Wi-Fi devices market is projected to be valued at US$ 14.8 billion in 2026 and is forecast to surge to US$ 40.8 billion by 2033, registering a robust CAGR of 15.6% between 2026 and 2033. This rapid growth reflects the accelerating demand for advanced wireless connectivity solutions across residential, enterprise, and industrial environments. The expansion of 5G infrastructure, enterprise digital transformation strategies, and large-scale IoT…

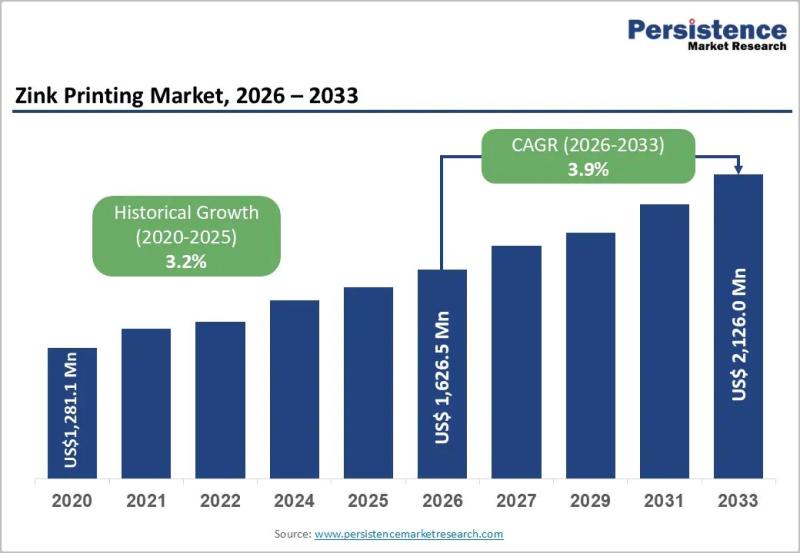

Zink Printing Market to Reach US$ 2,126.0 Million by 2033 at 3.9% CAGR

Zink Printing Market Size and Trends Analysis

The global Zink printing market is projected to be valued at US$ 1,626.5 million in 2026 and is expected to reach US$ 2,126.0 million by 2033, expanding at a CAGR of 3.9% between 2026 and 2033. Zink (Zero Ink) printing technology eliminates the need for ink cartridges by using heat-activated color crystals embedded within specialized paper. This innovation has positioned Zink printers as a…

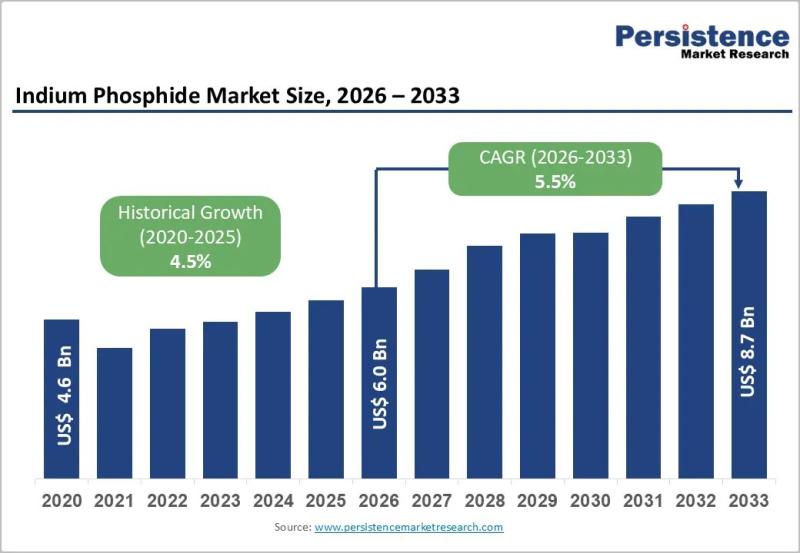

Indium Phosphide Market to Reach US$ 8.7 Billion by 2033 at 5.5% CAGR

The global Indium Phosphide (InP) market is poised for steady expansion, with its valuation expected to reach US$ 6.0 billion by 2026 and further grow to US$ 8.7 billion by 2033, registering a CAGR of 5.5% between 2026 and 2033. Indium phosphide, a high-performance compound semiconductor material, is widely used in optoelectronics, high-frequency electronics, and photonic integrated circuits (PICs). The market growth is largely fueled by the accelerating deployment of…

More Releases for Diamond

Industrial Diamond Market Hits New High | Major Giants Sandvik, Zhongnan Diamond …

HTF MI just released the Global Industrial Diamond Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

𝐌𝐚𝐣𝐨𝐫 Giants in Industrial Diamond Market are:

De Beers Group, Element Six,…

Diamond Wire Rope Market 2023: Companies Revenue Analysis- Diamond WireTec, Asah …

The Diamond Wire Rope market research report is proficient and top to bottom research by specialists on the current state of the industry. This statistical surveying report gives the most up to date industry information and industry future patterns, enabling you to distinguish the items and end clients driving income development and benefit. It centres around the real drivers and restrictions for the key players and present challenge status with…

Synthetic Diamond Market Seeking Excellent Growth | New Diamond Technology, Appl …

Advance Market Analytics published a new research publication on "Synthetic Diamond Market Insights, to 2027" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Synthetic Diamond market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample Copy of…

Jewelry Diamond Market is Booming Worldwide | Zhongnan Diamond, Jinqu Chaoying D …

Latest launched research document on Global Jewelry Diamond Market study of 115 Pages provides detailed analysis with presentable graphs, charts and tables. The Research Study presents a complete assessment of the Market and highlights future trend, growth factors & drivers, leaders opinions, facts, and primary validated market data. The research study provides estimates for Global Jewelry Diamond Forecast till 2026*.

How to reach that market place and its associated audience with…

Synthetic Diamond Market | Key Players - Include Element Six (E6), Applied Diamo …

As per the current market trends and the promising nature of the Global Synthetic Diamond Market, it can be estimated that the future holds positive outcomes. In order to provide a deep insight about the concerned market, Market Research Reports Search Engine would be publishing a resourceful analysis that will enclose knowledge about the regional market size, revenue and opportunity status. Readers will be offered the privilege to decode various…

Global Industrial Diamond Sales Market 2017 - Advanced Diamond Solutions, Applie …

The Industrial Diamond Sales market research report distils the most essential aspects of the market and presents them in the form of a comprehensive and cohesive document. The findings of this report have been obtained via a balanced mix of both primary and secondary research. Interviews of C-level executives in the Industrial Diamond Sales market form a chunk of the qualitative analysis contained in this report.

Download Sample Report @…