Press release

High-Performance Tungsten Heating Elements and Tungsten Twisted Wire: Ideal Choices for Industrial Applications

In industrial and high-tech fields, selecting the right materials is crucial to ensuring the long-term stable operation of equipment. Especially in high-temperature environments, conventional materials often cannot meet the rigorous performance requirements. Both tungsten heating elements and tungsten twisted wire, with their outstanding high-temperature resistance, strength, and electrical conductivity, have become the preferred materials for various critical applications. Whether as heating elements or resistance wires, tungsten's unique advantages offer long-lasting and durable solutions for customers.Why Choose Tungsten Heating Elements?

Tungsten heating elements(https://www.forgedmoly.com/wolfram-filament-tungsten-wire-for-heating-wire-elements.html), as a high-temperature heating material, are widely used across various industries, particularly in equipment that requires high-temperature environments. Tungsten itself has the highest melting point (up to 3422°C), making it an ideal material for high-temperature heating, and its high-temperature resistance ensures that tungsten heating elements can operate stably in many extreme temperature conditions without degradation.

The advantages of tungsten heating elements include:

Exceptional High-Temperature Endurance: Tungsten maintains its structural integrity at high temperatures, preventing material degradation and making it ideal for applications such as furnaces and heat treatment equipment.

Long-Term Durability: With high strength and hardness, tungsten heating elements can remain reliable even after long-term use in high-temperature environments, reducing replacement and maintenance costs.

Excellent Electrical Conductivity: Tungsten heating elements effectively conduct electricity, making the heating process more efficient and ensuring even temperature distribution, which enhances production efficiency.

Energy Efficiency: Due to tungsten's high electrical conductivity, it can more efficiently convert electrical energy into heat, helping reduce energy consumption and meeting modern industry's energy-saving requirements.

Tungsten heating elements are widely used in furnaces, heating tubes, gas heaters, and electronic equipment heating elements, providing efficient, stable, and long-lasting heating solutions.

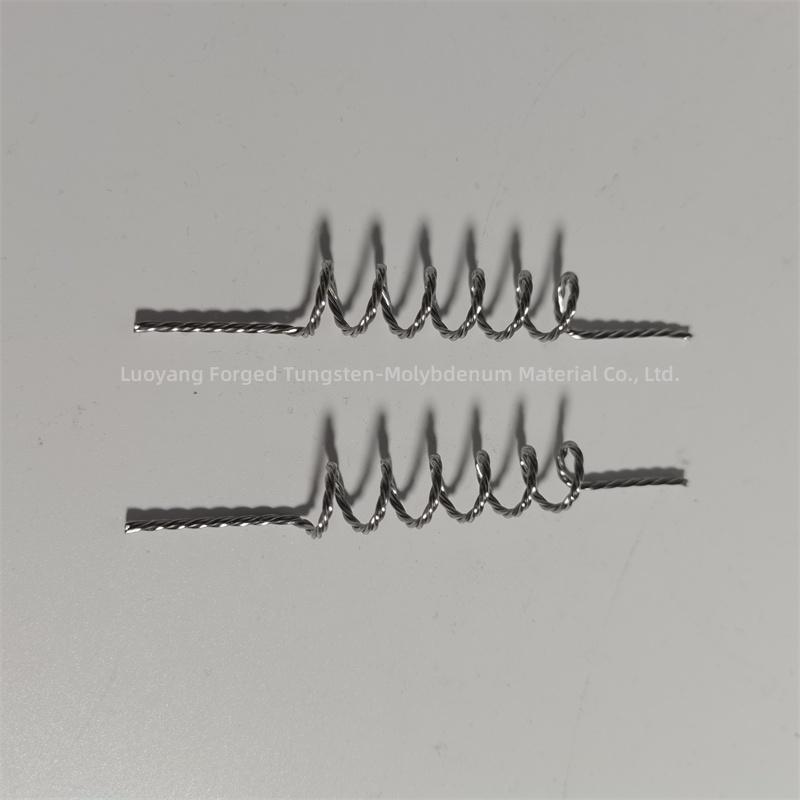

Tungsten Twisted Wire: A Versatile High-Temperature Material

Similar to tungsten heating elements, tungsten twisted wire is also widely used in high-temperature and corrosion-resistant environments due to its exceptional strength and high-temperature stability. Tungsten twisted wire is made by twisting multiple tungsten filaments together, which enhances strength and tensile resistance, making it suitable for applications requiring high mechanical and electrical performance.

Applications of tungsten twisted wire include:

High-Temperature Resistance Heating: Tungsten twisted wire, with its excellent conductivity and high melting point, is commonly used in various resistance heating elements, such as electric heaters and heating wires.

Electron Beam Welding: Tungsten twisted wire plays a vital role in electron beam welding, functioning at extremely high temperatures while providing strong electrical current and heat.

Aerospace: With its high strength and stability at high temperatures, tungsten twisted wire is widely used in high-performance components in the aerospace industry, especially in engine parts and high-temperature environments.

Metallurgy: Tungsten twisted wire is used in high-temperature furnaces in the metallurgy industry, withstanding the extreme heat of the smelting process and supporting equipment and machinery operations effectively.

Comparing Tungsten Heating Elements and Tungsten Twisted Wire

Although tungsten heating elements and tungsten twisted wire differ in their applications, they share similar core advantages-high temperature resistance, strength, and good electrical conductivity. The choice of which product to use depends on your specific needs and application scenario.

Tungsten heating elements are typically used in applications where uniform heating is required, such as furnaces and heating elements. Their primary advantage lies in their excellent current conduction and heating efficiency.

Tungsten twisted wire, on the other hand, is better suited for applications that require higher mechanical strength, temperature stability, and corrosion resistance, such as electron beam welding, aerospace applications, and high-temperature resistance heating.

Why Choose Us?

When choosing tungsten heating elements or tungsten twisted wire(https://www.forgedmoly.com/), quality and reliability are the most important considerations. As a professional tungsten product manufacturer, we are committed to providing customers with high-quality, high-performance tungsten heating elements and tungsten twisted wire to ensure long-term, stable performance in extreme environments.

Our tungsten heating elements and tungsten twisted wire feature:

High-Temperature Stability: Every piece of tungsten wire is designed to perform reliably in extreme temperatures, ensuring your equipment operates smoothly for years.

Customization Services: Whether you need specific lengths, diameters, or twisting patterns, we offer tailored solutions to perfectly match your applications.

Excellence in Customer Support: We have a dedicated technical team ready to assist you throughout the customization process, from product selection to installation, ensuring optimal performance of your equipment.

Luoyang Forged Tungsten-Molybdenum Material Co., Ltd.

jiajia@forgedmoly.com

No. 102, Building 33, Phase II of Zhongde Industrial Park, Yibin District, Luoyang City, Henan Province

Luoyang Forged Tungsten-Molybdenum Material Co., Ltd. is an well-know manufacturer for refractory metals in China. With 20 years' experience and more than 100 product developments, we perfectly understand the behavior and capabilities of molybdenum, tungsten, tantalum, and niobium. We supply you with top-quality products that are specifically adapted for use in your applications. We ensure the safety and health of our employees. We protect the environment and are careful in the way we use raw materials and energy.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release High-Performance Tungsten Heating Elements and Tungsten Twisted Wire: Ideal Choices for Industrial Applications here

News-ID: 4284659 • Views: …

More Releases for Tungsten

Tungsten Market to Explosive Growth by 2028: Key Players Xiamen Tungsten, Chongy …

Market Study Report presents latest report on global Tungsten Market, which evaluates the growth trends of the industry through historical study and estimates future prospects based on comprehensive research. The report extensively provides the market share, growth, trends and forecasts for the period 2022-2028.

Tungsten Market Size was estimated at USD 1050.7 million in 2021 and is projected to reach USD 1665.2 million by 2028, exhibiting a CAGR of 6.8% during…

Tungsten Trioxide Powder Market by Top Manufacturers - Xiamen Tungsten, Guangdon …

The Tungsten Trioxide Powder Market research report looks at the examples in the parent market, close by the standard factors and piece of the pie in different portions and sub-sections. The Tungsten Trioxide Powder Market report furthermore predicts the effect of different industry viewpoints accessible in market portions and geologies. The exploration report also distinguishes the market circumstance and impending difficulties of the overall market. It then analyzed competitive landscapes,…

Tungsten Metal Powder Market 2022 Global Outlook- Tungsten, Chongyi ZhangYuan Tu …

Global "Tungsten Metal Powder" Research Report presents a complete overview and comprehensive explanation of the industry. It is an analytical study that focuses on target groups of customers covering historical, current, and future market revenue and growth rate for both the demand and supply side. The research analyst details the value chain and its distributor analysis. The report provides conclusions and recommendations for a large range of industries and commercial…

Tungsten Metal Powder Market COVID 19 Overview: Demand Analysis & Growth Opportu …

The Market For Tungsten Metal Powder Market Is Expected to Reach Rise At A CAGR Of 5% During The Forecast Period.

The Tungsten Metal Powder Market 2022-2026 report presents the opportunities for the players. It also offers business models and market forecasts for the participants. This market analysis allows industry manufacturers with future market trends. The Study reports provides the information about the technological advancement, new product launches, new players and…

Tungsten Carbide Market Players Focus on Executing Business Expansion Activities …

Key advancements in the Tungsten Carbide Market, as well as organic and inorganic growth methods, are covered in the research. Acquisitions, as well as partnerships and engagements, were seen as inorganic growth tactics in the Tungsten Carbide market. These efforts have laid the groundwork for market participants to expand their business and client base. The research examines the variables influencing the Tungsten Carbide, as well as industry trends affecting the…

Global Blue Tungsten Oxide (BTO) Market 2019-2025 | Tejing Tungsten, H.C. Starck …

Researchmoz added Most up-to-date research on "Global Blue Tungsten Oxide (BTO) Market Insights,Forecast to 2025" to its huge collection of research reports.

Tungsten blue, as known as blue tungsten oxide, BTO, - tungsten oxide, hence the name as appearance of blue powder, with reducibility. Blue tungsten oxide refers to a class of dark blue compound with the mixed valence state of tungsten () and tungsten (V), it is the product of…