Press release

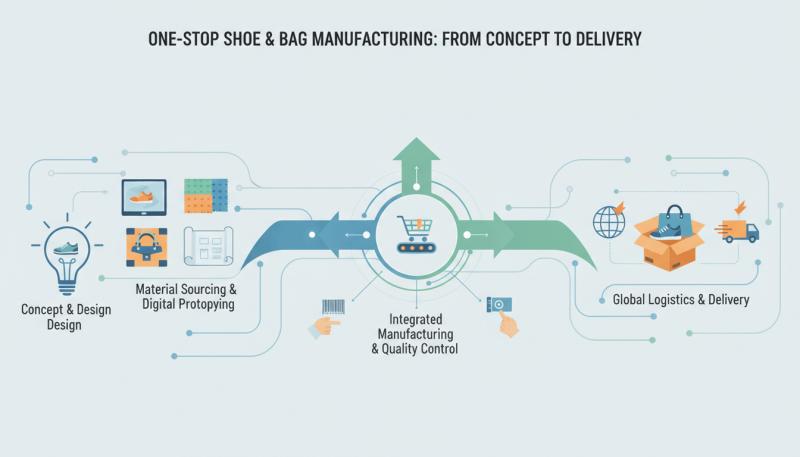

Complete Guide to One-Stop Shoe & Bag Manufacturing: From Concept to Delivery

Image: https://www.lishangzishoes.com/uploads/Complete-Guide-to-One-Stop-Shoe-and-Bag-Manufacturing-From-Concept-to-Delivery.png1. Complete Guide to One-Stop Shoe & Bag Manufacturing: From Concept to Delivery

: "Our designs always get distorted during sampling": "Material suppliers delay deliveries, disrupting our entire production schedule": "Quality issues get bounced between factory and inspection companies": "Logistics surprises make us miss crucial launch windows"

Do these challenges sound familiar? In traditional fragmented manufacturing models, brands face the nightmare of managing multiple vendors. Communication barriers, inconsistent quality standards, and mismatched timelines across different stages constantly drain your energy, time, and profits.

As a one-stop shoe and bag manufacturer with 25 years of specialized experience, Lishangzi deeply understands these pain points. This article will take you behind the scenes to explore how true one-stop manufacturing systematically solves these issues, delivering not just products, but complete solutions from concept to delivery.

2. Why Traditional Multi-Supplier Models Are Failing Your Brand

Before diving into solutions, let's diagnose the root problems of traditional models:

The Communication Cost Black Hole

- Disconnect between design and production: Designs that can't be executed in real manufacturing

- Multiple information handoffs: Each stage requires reinterpreting requirements

- Cultural and technical terminology gaps: Misunderstandings between different suppliers

The Quality Control Dilemma

- Inconsistent standards: Each supplier operates with their own quality metrics

- Difficult traceability: Finger-pointing when problems arise

- Inefficient corrections: Issues require coordination across multiple vendors

Hidden Time and Cost Drain

- Difficult progress coordination: One delayed link affects the entire project

- Repeated sampling and modifications: Redundant work across different suppliers

- High emergency costs: Premium payments for rush orders

3. The One-Stop Solution: Redefining Shoe & Bag Manufacturing

True one-stop manufacturing isn't just about putting all processes under one roof-it's about building a fully coordinated system centered around your brand. This system addresses traditional pain points through four core advantages:

Unified Communication Channel Dedicated project management from start to finish ensures consistent and accurate information flow

End-to-End Quality Traceability Complete quality documentation from raw materials to finished goods enables quick problem identification and resolution

Integrated Progress Management Real-time monitoring of each stage through advanced ERP systems allows for proactive alerts and adjustments

Transparent Costing Clear cost breakdowns at every stage eliminate hidden fees and duplicate charges

4. Deep Dive: Six Key Stages of One-Stop ManufacturingStage 1: Strategic Planning & Design Development

This phase transforms your market insights into executable product plans.

How We Solve Traditional Design Phase Pain Points:

- Market adaptability analysis: Leveraging 25 years of experience to provide expert advice on design feasibility, cost structure, and market competitiveness

- Tech pack optimization: Transforming creative designs into technical documents including material specifications, process requirements, and quality standards

- Upfront cost assessment: Estimating production costs during the design phase to prevent budget overruns

Image: https://www.lishangzishoes.com/uploads/shoe-bag-design-team-working-on-technical-pack.png

Stage 2: Material Strategy & Sourcing

Quality materials are the foundation of quality products. We ensure both quality and delivery through systematic material management.

Innovative Material Management Practices:

- Supply chain visibility: Mapping supply chains for key materials with real-time inventory and delivery monitoring

- Pre-shipment quality inspection: Sampling and testing materials before they arrive at the factory

- Alternative solution reserves: Maintaining backup suppliers for critical materials to ensure supply security

Stage 3: Engineering Development & Sampling

This critical phase transforms drawings into physical products through precise engineering.

Precision Control in Sampling:

- Three-stage sampling system:

- Proto sample: Validates design concept and basic structure

- Engineering sample: Tests functionality and durability

- Pre-production sample: Confirms mass production feasibility

- Cross-departmental review: Production, quality, and engineering teams jointly evaluate samples

- Data-driven improvements: Using 3D scanning and measurement equipment to ensure sample accuracy

Image: https://www.lishangzishoes.com/uploads/shoe-prototype-evolution-three-sampling-stages.png

Stage 4: Production Execution & Embedded Quality

Replicating sample standards across every product requires strict processes and embedded quality management.

Our Production Quality Assurance System:

- Standardized operating procedures: Clear operation standards and inspection requirements for each process

- In-line quality monitoring: Quality checkpoints at 13 critical process stages

- Real-time data dashboards: Live displays showing quality status and progress

Stage 5: Brand Integration & Packaging

Products must reach consumers with perfect brand presentation.

Brand Consistency Assurance:

- Brand standard management: Detailed manuals for brand application standards

- Packaging testing: Simulating transport environments to test packaging protection

- Visual quality inspection: 100% check of brand marking application quality

Stage 6: Smart Logistics & Delivery

The final step is equally crucial-we ensure products arrive on time and in perfect condition.

Specific Logistics Optimization Measures:

- Multiple logistics options: Various choices based on urgency and cost requirements

- End-to-end visibility management: Complete logistics tracking from factory to warehouse

- Emergency response mechanisms: Rapid response processes for unexpected situations

Image: https://www.lishangzishoes.com/uploads/warehouse-management-logistics-optimization.png

5. Quantifiable Benefits: Specific Value One-Stop Manufacturing Brings

Through our systematic approach, clients typically achieve:

Time Efficiency Improvements

- 30-40% reduction in product development cycles

- 60% fewer sample confirmation rounds

- 98% on-time delivery rate

Cost Optimization

- 40% reduction in communication and time costs

- 15% improvement in material utilization

- 20-25% decrease in overall manufacturing costs

Quality Enhancement

- Over 95% first-time inspection pass rate

- 70% reduction in customer complaints

- Significant improvement in product consistency

6. Success Story: Transformation Journey of an Emerging Footwear Brand

Before partnering with us, an online footwear brand faced these challenges:

- 6-month product development cycles

- Average 5 sample revisions for confirmation

- 65% consistency between mass production and samples

After implementing our one-stop solution:

- Development cycle shortened to 3.5 months

- Sample confirmations reduced to 2 rounds

- 95% consistency between mass production and samples

- 300% sales growth in the first year

7. Your Next Steps: How to Start One-Stop Partnership

We understand each brand has unique needs and starting points. We offer three partnership paths:

Initial Consultation Ideal for brands still defining requirements-we'll arrange senior consultants to analyze your situation and optimization direction

Pilot Project Test the one-stop advantage with 1-2 products to experience the benefits firsthand

Strategic Partnership Establish long-term deep cooperation with dedicated production lines and priority resource allocation

Image: https://www.lishangzishoes.com/uploads/one-stop-manufacturing-partnership-pathways.png

8.Conclusion: Choosing Your Manufacturing Method is Choosing Your Growth Path

In today's competitive market environment, manufacturing method selection is no longer just about cost-it's a strategic decision affecting brand survival and development. One-stop manufacturing represents not just a production method, but a new business logic centered on efficiency and quality.

At Lishangzi, through 25 years of accumulation and iteration, we've built one-stop manufacturing into a powerful tool helping brands break through growth bottlenecks. From design concepts to product delivery, we're not just executors-we're your trusted manufacturing partner.

Start Your Efficient Manufacturing Journey Today:

- See [One-Stop Manufacturing Solution Brochure [https://www.lishangzishoes.com/how-to-start-a-shoe-bag-line/]]

- Schedule [Dedicated Manufacturing Consultant Consultation [https://www.lishangzishoes.com/contact-us/]]

- Check [Our Factory [https://www.lishangzishoes.com/factory/]]

Media Contact

Company Name: XINZIRAIN

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=complete-guide-to-onestop-shoe-bag-manufacturing-from-concept-to-delivery]

Country: China

Website: https://www.lishangzishoes.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Complete Guide to One-Stop Shoe & Bag Manufacturing: From Concept to Delivery here

News-ID: 4283015 • Views: …

More Releases from ABNewswire

CostaRicaFSBO.com Launches Special Pricing Offer for Costa Rica Property Sellers

Leading For-Sale-By-Owner Platform Helps Sellers and Buyers Connect Without High Agent Commissions

CostaRicaFSBO.com, the premier online marketplace dedicated exclusively to Costa Rica real estate listings, is helping property owners across the country sell their homes, land, hotels, villas, and farms without the burden of costly real estate agent commissions. To celebrate the platform's growing community of sellers and buyers, CostaRicaFSBO.com is offering an exclusive limited-time listing rate of just $99 USD…

Toy Fair New York 2026: Trends in the toy industry on Messe.TV

Messe.TV provides comprehensive coverage of the Toy Fair in New York, sending a clear signal for independent trade journalism in the international toy industry. In a phase of structural change within the trade fair landscape, we are placing greater emphasis on independent research and editorial classification.

The decision to focus our presence consistently on New York this year is the result of this development - with the aim of continuing to…

Olson Hypnosis Method: Orlando's Most Trusted Path to Lasting Change for Over 30 …

Olson hypnosis method offers a research-backed, personalized approach to lasting change by working with the subconscious. Orlando Hypnosis Center founder Daniel Olson has helped clients for 30+ years in-person and online. Free consultation available.

ORLANDO, FL - February 23, 2026 - Olson Hypnosis Method, the proprietary subconscious-based approach developed by Daniel Olson of the Orlando Hypnosis Center, has quietly become one of the most sought-after hypnotherapy programs in the country -…

Austin Bankruptcy Lawyers Guide Texans Through Chapter 7 Bankruptcy Filings

Austin Bankruptcy Lawyers helps Texans file Chapter 7 through structured legal guidance. The firm's bankruptcy attorney supports individuals throughout the filing process and helps them understand their legal options under federal and Texas law.

Austin, TX - Austin Bankruptcy Lawyers [https://www.austinbankruptcylawyers.com/] is guiding Texas residents through Chapter 7 bankruptcy filings to help them achieve financial fresh starts. The firm's Austin bankruptcy lawyer offers straightforward advice on qualifying for Chapter 7, helping…

More Releases for Manufacturing

Manufacturing the Future: Exploring the In-Space Manufacturing Market

Rapid improvements in space technology have created new opportunities for in-space production, transforming the space sector. The in-space manufacturing sector is expanding rapidly as space agencies and private companies investigate ways to manufacture products and structures in space. According to MarketsandMarkets' thorough market research analysis, the worldwide in-space manufacturing market is predicted to expand significantly in the next years. In this blog article, we will evaluate the recent trends and…

Global Miscellaneous Market by Types (Gasket, Packing, and Sealing Device Manufa …

The global Miscellaneous market was valued at xx million in 2020 and is projected to reach US$ xx million by 2027, at a CAGR of xx% during the forecast period.

Global Miscellaneous Market overview

Miscellaneous Market research report offers great insights into the market and consumer data and their interpretation through various figures and graphs.

Miscellaneous markets have experienced significant growth in recent years. The main reason for this is the increasing…

Smart Factory Transforming from “Manufacturing” to “Intelligent Manufactur …

The concept of “Industry 4.0” was officially announced by the German government in 2013 at the Hannover Messe. Since then, its influence has taken the world by storm. From steam mechanization to power automation to data informatization, the Industry 4.0, driven by “intelligentization”, will completely subvert the expectations, changing perceptions of productivity and production relations in the traditional manufacturing industry by way of qualitative change – an immortal monument, perhaps,…

Additive & Conventional Manufacturing – Hybrid Manufacturing Techniques From C …

Croft Filters, based in Warrington, England, have been supplying custom filtration and separation solutions for over 31 years. Over this time, Croft has developed a reputation for their quality, bespoke service through manufacturing a variety of products for specific requirements. These products have included Filtration Cones, Baskets & Screens, Disc Filters and Filtration Housings amongst others, and they are made with Wire Mesh, Wedge Wire and Perforated Plate, depending on…

Digital Meter Market 2017 - Al-Jon Manufacturing, Environmental Manufacturing, H …

The Global Digital Meter Market 2017 Industry Research Report focused on global and regional market, major manufacturers, as well as the current state of the Digital Meter industry. First, "Global Digital Meter Industry 2017" report analyzed the basic scope of this industry like definition, specification, classification, application, industry policy, news analysis and Digital Meter industry chain structure.

Major Companies Covered in this report:-

Al-Jon Manufacturing

Heitman Laboratories

Kws Manufacturing Company

Kmb Systems

Obvius Holdingd Llc

Lubecorp Manufacturing

Quadlogic…

Competitive Segmentation of Global Mixed-mode Manufacturing Market 2016 Industry …

The market research report titled Mixed-mode Manufacturing Market Research Report 2016 provides a detailed overview of the global Mixed-mode Manufacturing market, in terms of crucial market factors such as the demand drivers, challenges, market segments, key companies, and the recent market trends. The quantitative and the qualitative information presented in this research study is based on primary and secondary sources of information. Moreover, much of the information contained in this…