Press release

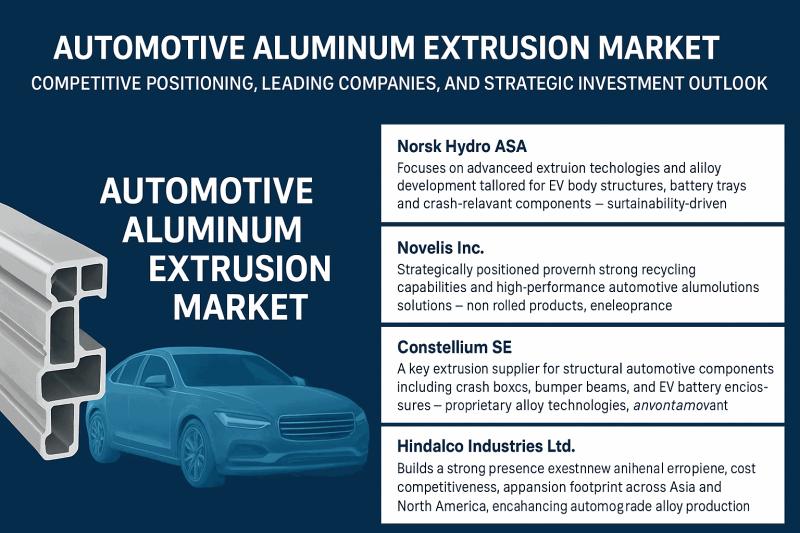

Automotive Aluminum Extrusion Market Players - Competitive Positioning, Strategic Strengths & Investor Outlook

The Automotive Aluminum Extrusion Market has become a central pillar of vehicle lightweighting initiatives, driven by automakers' growing focus on efficiency, structural strength, and sustainability. As global OEMs accelerate the transition toward electric mobility, demand for extruded aluminum components-spanning body structures, battery enclosures, chassis systems, crash management systems, and thermal solutions-continues to strengthen. The market's competitive landscape is shaped by a mix of global manufacturers, specialized extrusion companies, and vertically integrated aluminum giants, each adopting unique strategies to capture value across the automotive supply chain.➤ Request Free Sample PDF Report @ https://www.researchnester.com/sample-request-7202

Top Companies & Their Strategies

Norsk Hydro ASA

Norsk Hydro remains one of the most influential companies in the Automotive Aluminum Extrusion Market thanks to its extensive global presence, innovation leadership, and deep expertise in sustainable aluminum manufacturing. The company focuses on advanced extrusion technologies and alloy development tailored for EV body structures, battery trays, and crash-relevant components. Its sustainability-driven approach, including hydro-powered smelting and low-carbon aluminum solutions, strengthens its positioning with OEMs prioritizing ESG targets.

Novelis Inc.

Novelis, a subsidiary of Hindalco Industries, is strategically positioned through its strong recycling capabilities and high-performance automotive aluminum solutions. While known for rolled products, the company collaborates deeply with extrusion partners and offers integrated lightweighting solutions for body-in-white applications. Its strength lies in R&D, closed-loop recycling partnerships with global automakers, and its expansive North American and European footprint.

Constellium SE

Constellium is a key extrusion supplier for structural automotive components, including crash boxes, bumper beams, and EV battery enclosures. The company's proprietary alloy technologies, high-volume production capacity, and longstanding relationships with European automotive OEMs make it a preferred partner for next-generation mobility platforms. Constellium continues to invest in advanced extrusion presses and automated forming processes to support increasing demand for EV lightweighting.

Hindalco Industries Ltd.

Hindalco has built a strong presence in the Automotive Aluminum Extrusion Market through vertical integration, cost competitiveness, and its global subsidiary Novelis. The company's strategic focus includes expanding footprint across Asia and North America, enhancing automotive-grade alloy production, and scaling its extrusion plants to serve EV and commercial vehicle manufacturers. Its integrated value chain-from bauxite mining to finished components-provides a structural cost advantage in competitive markets.

➤ Explore detailed profiles of top players and new entrants in this space - access your free sample report → https://www.researchnester.com/sample-request-7202

Kaiser Aluminum Corporation

Kaiser Aluminum is recognized for its engineered aluminum products supporting aerospace and automotive markets. Its strategy in the automotive extrusion segment focuses on high-strength alloys, structural tube extrusions, and specialized applications for chassis and suspension systems. The company maintains competitive differentiation through its emphasis on product quality, material performance, and collaborative engineering with OEMs.

UACJ Corporation

UACJ is a prominent Asian supplier offering a wide range of aluminum extruded products for automotive frames, crash structures, and thermal management components. Its strategy revolves around expanding production capacity in Thailand, Japan, and North America while improving extrusion precision and product efficiency. UACJ's global expansion efforts support rising demand from international automakers producing EVs in Asia and the United States.

Bonnell Aluminum

Bonnell Aluminum is an emerging-force supplier focused on customized extrusions for automotive OEMs and Tier-1 suppliers. The company invests heavily in automation, machining centers, and post-extrusion fabrication to deliver value-added solutions. Its regional advantage in the U.S. positions it well for domestic EV platform production and nearshoring trends.

➤ View our Automotive Aluminum Extrusion Market Report Overview here: https://www.researchnester.com/reports/automotive-aluminum-extrusion-market/7202

SWOT Analysis

Strengths

Leading players in the Automotive Aluminum Extrusion Market benefit from strong global manufacturing footprints, long-term relationships with automotive OEMs, and steady investment in alloy innovation. Many companies possess vertically integrated supply chains, reducing exposure to raw material cost volatility and enabling quality control across production processes. Their ability to deliver lightweight, high-strength extrusions tailored for EV architectures gives them a critical competitive advantage, particularly as OEMs push for sustainable mobility.

Weaknesses

Despite their strengths, leading companies face operational complexities stemming from high capital requirements, energy-intensive smelting processes, and constraints in scaling specialized extrusion capabilities. High dependence on automotive demand cycles can create vulnerability during economic downturns or supply chain disruptions. Additionally, the transition to low-carbon or recycled aluminum requires significant investment in new technologies and infrastructure, which may strain smaller extrusion companies lacking access to large-scale capital.

Opportunities

Companies in the Automotive Aluminum Extrusion Market have substantial opportunities to expand into EV battery enclosures, structural components for electric SUVs and trucks, thermal management systems, and lightweight chassis modules. Government incentives promoting EV manufacturing and carbon-neutral production open pathways for new partnerships and plant expansions. Growing demand from emerging markets such as Southeast Asia, India, and Eastern Europe presents a chance for regional dominance. Increasing adoption of automation in extrusion and fabrication processes will further enhance productivity and meet rising OEM requirements for precision and speed.

Threats

The industry faces threats from fluctuating raw material prices, geopolitical uncertainties, and competitive pressure from composite materials and advanced high-strength steel. Shifts in government regulations, such as carbon taxation or recycling mandates, may increase costs for companies unable to implement low-carbon production at scale. Economic slowdowns may also reduce vehicle production volumes, directly affecting extrusion demand. Furthermore, reliance on global supply chains exposes companies to transportation delays, trade restrictions, and energy price volatility.

➤ Access a complete SWOT breakdown with company-specific scorecards: Claim your sample report → https://www.researchnester.com/sample-request-7202

Investment Opportunities & Trends

Increased M&A Activity

Mergers and acquisitions have become a defining trend as companies seek to expand production capabilities, diversify product lines, and strengthen regional presence. Acquisitions by global aluminum manufacturers often focus on extrusion companies with advanced facilities or close automotive OEM relationships. Private equity firms are increasingly investing in extrusion businesses due to predictable demand and strong long-term growth potential from EV platforms.

Funding Momentum in EV-Focused Aluminum Technologies

The surge in electric vehicle manufacturing has sparked significant investment into specialized aluminum extrusion technologies. Venture funding is supporting startups developing advanced thermal management extrusions, battery enclosure designs, and ultra-lightweight structural components. Many automakers have partnered with extrusion companies to co-develop next-generation battery tray architectures that prioritize thermal control and crash resistance.

Technology Integration Driving Capital Allocation

Automation, AI-driven quality control, and digital extrusion process monitoring are receiving heavy investment. Companies are upgrading extrusion presses, robotic machining centers, and automated fabrication lines to improve precision, reduce waste, and shorten lead times. Investments in low-carbon aluminum production-including recycling and renewable-energy-powered smelting-are becoming crucial differentiators.

Regional Expansion Trends

North America and Europe continue to attract capital due to steep EV adoption curves and supportive government policies such as manufacturing credits and carbon reduction mandates. Meanwhile, Asia-Pacific-especially India, China, and Thailand-is witnessing rapid expansion of extrusion facilities due to cost advantages, rising automotive production, and regional EV incentive programs. Companies are strategically adding capacity in these regions to localize supply chains and meet OEM demands for just-in-time manufacturing.

Notable Industry Developments in the Last 12 Months

Several global aluminum players expanded extrusion lines dedicated to EV battery tray profiles.

Multiple companies announced investments in recycling plants to supply low-carbon aluminum to automotive manufacturers.

Collaboration agreements were formed between extruders and EV OEMs to co-engineer crash-resistant structural components.

Governments in North America and Europe introduced new policies incentivizing domestic manufacturing of lightweight automotive materials.

Leading manufacturers launched new high-strength alloy families optimized for crash management systems and electric SUVs.

➤ Request Free Sample PDF Report @ https://www.researchnester.com/sample-request-7202

Related News -

https://www.linkedin.com/pulse/what-future-cutaneous-t-cell-lymphoma-treatment-market-ffcjf

https://www.linkedin.com/pulse/what-driving-rapid-growth-co2-heat-pump-water-heater-market-jvqhf

Contact Data

AJ Daniel

Corporate Sales, USA

Research Nester

77 Water Street 8th Floor, New York, 10005

Email: info@researchnester.com

USA Phone: +1 646 586 9123

Europe Phone: +44 203 608 5919

About Research Nester

Research Nester is a one-stop service provider with a client base in more than 50 countries, leading in strategic market research and consulting with an unbiased and unparalleled approach towards helping global industrial players, conglomerates and executives for their future investment while avoiding forthcoming uncertainties. With an out-of-the-box mindset to produce statistical and analytical market research reports, we provide strategic consulting so that our clients can make wise business decisions with clarity while strategizing and planning for their forthcoming needs and succeed in achieving their future endeavors. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automotive Aluminum Extrusion Market Players - Competitive Positioning, Strategic Strengths & Investor Outlook here

News-ID: 4280510 • Views: …

More Releases from Research Nester Pvt Ltd

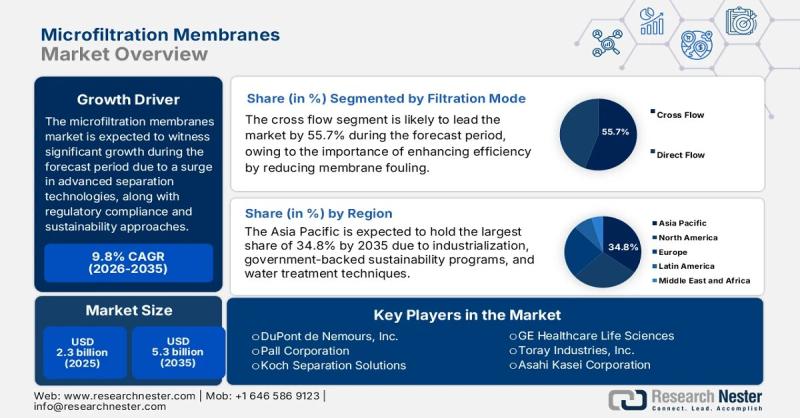

Microfiltration Membranes Market size to reach $5.3Billion by 2035 | Key players …

Market Outlook and Forecast

The microfiltration membranes market size reached USD 2.3 billion in 2025 and is projected to expand to USD 5.3 billion by 2035, reflecting strong industry fundamentals and sustained adoption across diverse end-use industries. The market is expected to grow at a compound annual growth rate (CAGR) of 9.8% between 2026 and 2035, driven by industrial modernization, environmental regulations, and technological innovation.

➤ Request Free Sample PDF Report @…

Top Companies in Food Grade Alcohol Market - Benchmarking Performance & Future V …

The food grade alcohol market is shaped by multinational ingredient producers, regional distillation leaders, and specialized ethanol processors. Competitive positioning is largely determined by feedstock access, regulatory compliance, supply chain resilience, and product customization for food and beverage applications.

➤ Request Free Sample PDF Report @ https://www.researchnester.com/sample-request-8307

Top Companies & Their Strategies

Archer Daniels Midland Company (ADM)

ADM remains one of the most influential players in the Food Grade Alcohol Market due to…

Energy Harvesting System Market Dominance: Top Companies Strengthening Share & I …

The energy harvesting system market is rapidly evolving as industries seek sustainable, maintenance-free power solutions for IoT devices, wireless sensor networks, industrial automation, healthcare wearables, and smart infrastructure. Energy harvesting systems convert ambient energy sources - including solar, thermal, vibration, and radio frequency (RF) - into usable electrical power.

As the global transition toward energy efficiency and decentralized power accelerates, the competitive landscape within the energy harvesting system market is intensifying.…

Luxury Hotel Market Players - Competitive Positioning, Strategic Strengths & Inv …

The Luxury Hotel Market is undergoing structural transformation as global travelers increasingly prioritize curated experiences, sustainability, and digital-first service models. No longer defined solely by opulence, the luxury hotel market now revolves around personalization, wellness integration, brand storytelling, and technological innovation. Leading hospitality companies are repositioning portfolios, expanding into high-growth destinations, and investing in asset-light models to strengthen competitive positioning.

This strategic analysis explores the top companies shaping the luxury hotel…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…