Press release

Centrifugal Compressor Market Set to Reach USD 5.7 Billion by 2034, Driven by Steady Industrial Demand

The Centrifugal Compressor Market highlights steady growth driven by rising industrial demand, energy efficiency needs, and expanding applications across oil & gas, power generation, chemical processing, and HVAC systems. The global market, valued at USD 3.5 Bn in 2023, is projected to reach USD 5.7 Bn by 2034, reflecting a CAGR of 4.6% from 2024 to 2034. This growth is supported by increasing adoption of advanced compression technologies, modernization of industrial infrastructure, and the push for cleaner, more reliable mechanical systems. As industries continue to prioritize operational efficiency and reduced emissions, centrifugal compressors are expected to remain essential components in large-scale processing and energy operations worldwide.The major factors driving the growth of the global industry is the growth of the oil and gas industry, metal and mining industry, and power industry. The demand for centrifugal compressor market in the oil & gas industry is majorly due to their exhaustive applications in high-pressure air, air separation, and fuel gas boosting. Centrifugal compressor industry trends include growing demand for natural gas, rising investments in petrochemical projects, and increasing focus on energy efficiency.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/checkout.php?rep_id=58767<ype=S

Global centrifugal compressor market is expected to grow over the forecast period due to the revival of stalled infrastructure projects, the demand for eco-friendly products, and technological innovations in centrifugal compressor technology. Manufacturers of centrifugal compressors in the industry are allocating a major portion of their revenue to R&D to differentiate them from the competition perspective.

Market Segmentation

By Service Type

The market is increasingly service-oriented as operators seek to extend the lifecycle of high-value assets.

New Equipment Sales: Dominated by large-scale capital projects (greenfield refineries, LNG terminals).

Aftermarket & Maintenance: The fastest-growing segment. This includes routine servicing, spare parts replacement, and remote monitoring subscriptions.

Overhaul & Retrofit: A critical segment for aging infrastructure in Europe and North America, where older compressors are being retrofitted for higher efficiency or to handle new gas mixes (e.g., hydrogen blending).

By Sourcing Type

Original Equipment Manufacturer (OEM): OEMs (e.g., Siemens Energy, Baker Hughes) retain the majority share, especially for critical, high-pressure applications where warranty and proprietary technology are paramount.

Aftermarket (Third-Party/Distributors): Gaining traction for non-critical components and standard maintenance, driven by cost-competitiveness and faster lead times.

By Application

Process Gas Compression: The largest revenue generator, critical for chemical reactions and refining.

Natural Gas Transport: High demand due to expanding pipeline networks and LNG value chains.

Air Separation: Vital for producing industrial gases (nitrogen, oxygen) for medical and manufacturing use.

Clean Energy (New): Rapidly expanding segment covering Hydrogen Compression and CCUS, where compressors must handle high pressures and supercritical CO2.

By Industry Vertical

Oil & Gas: Remains the dominant vertical (approx. 40% share) due to upstream extraction and downstream refining needs.

Power Generation: Driven by gas-fired power plants and the integration of turbines.

Chemicals & Petrochemicals: Steady growth fueled by demand for plastics, fertilizers, and synthetic materials.

Food & Beverage / Pharmaceuticals: Niche but high-value segment requiring Oil-Free centrifugal compressors to ensure product purity (Class 0 air).

By Region

Asia-Pacific (APAC): The fastest-growing region, led by China and India's massive industrial build-out and refining capacity additions.

North America: The largest mature market, driven by shale gas processing, LNG export terminals, and advanced technological retrofits.

Middle East & Africa: Significant growth due to mega-projects in Saudi Arabia and UAE aimed at diversifying energy exports.

Europe: Focus is almost entirely on efficiency upgrades, hydrogen pilot projects, and decarbonization compliance.

Regional Analysis

North America: In 2025, the U.S. continues to lead in technological adoption. The focus has shifted heavily toward updating existing infrastructure with digital twin capabilities to predict failures before they happen.

Asia-Pacific: Industrial hubs in China and Southeast Asia are driving volume. In 2024 alone, the region accounted for over 35% of global new unit orders, specifically for large-scale petrochemical complexes.

Market Drivers and Challenges

Drivers

LNG Infrastructure Boom: With natural gas serving as a "bridge fuel," massive investments in LNG liquefaction trains (which rely heavily on large centrifugal compressors) are a primary growth engine.

Decarbonization Mandates: Stricter emissions regulations are forcing industries to replace inefficient reciprocating units with high-efficiency centrifugal models, particularly those using magnetic bearings (MagLev) to reduce friction and energy loss.

Hydrogen Economy: The unique physics of hydrogen (low density) requires specialized, high-speed centrifugal compressors, creating a new, lucrative equipment category.

Challenges

High Capital Expenditure (CAPEX): Centrifugal compressors are expensive, complex assets. High interest rates in 2024/2025 have delayed some Final Investment Decisions (FIDs) for new plants.

Surge and Stall Issues: Technically, these compressors are sensitive to flow variations. Managing "surge" (flow reversal) requires complex control systems, adding to the cost and maintenance burden.

Raw Material Volatility: Fluctuating prices of steel, titanium, and specialized alloys impact manufacturing costs and delivery timelines.

Market Trends (2024-2025)

Magnetic Bearings: A move away from oil-lubricated bearings to active magnetic bearings (AMB) to eliminate oil systems, reduce maintenance, and lower environmental risk.

Digitalization & IIoT: Integration of platforms like GE Predix and Siemens' Xcelerator is now standard. Operators demand real-time vibration monitoring and predictive analytics to extend maintenance intervals.

Modular Design: Manufacturers are shifting toward "plug-and-play" skid-mounted designs that reduce on-site installation time by up to 30%.

Future Outlook

By 2034, the market will likely look vastly different. While Oil & Gas will still be a major player, the "Green Compressor" segment will be substantial. We anticipate:

Hybrid Compressors: Units designed to handle varying blends of natural gas and hydrogen as pipeline networks transition.

Service-as-a-Business: OEMs will increasingly sell "Compressed Air/Gas as a Service" rather than just the hardware, shifting CAPEX to OPEX for customers.

Key Market Study Points

Fastest Growing Segment: Hydrogen & CCUS applications.

Dominant Technology: Multi-stage centrifugal compressors (due to high pressure ratio requirements in energy sectors).

Key Metric: Efficiency improvements of 1-2% are now major selling points due to high energy costs.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=58767<ype=S

Competitive Landscape

The market is consolidated, with top players controlling a significant share of the high-spec market.

Major Players: Atlas Copco, Ingersoll Rand, Siemens Energy, Baker Hughes, Mitsubishi Heavy Industries (MHI), Elliott Group, MAN Energy Solutions.

Strategy: Market leaders are aggressively acquiring smaller firms specializing in AI/analytics and specialized gas handling (like CO2) to future-proof their portfolios.

Recent Developments (2024-2025)

Baker Hughes (Oct 2024): Secured a major contract with Saipem to provide Integrated Compressor Line (ICL) technology for the Kaminho FPSO project in Angola. These units use magnetic bearings and are hermetically sealed to eliminate emissions.

Danfoss (2025): Celebrated the 30th anniversary of its Turbocor® technology, launching a new range of high-capacity oil-free compressors optimized for low-GWP (Global Warming Potential) refrigerants, targeting the green HVAC market.

Siemens Energy (Late 2024): Announced the successful deployment of its IoT-enabled compressor fleet in a major European hydrogen pilot, achieving a 15% reduction in energy consumption through AI-driven operational adjustments.

M&A Activity: Industry giants have continued to consolidate, with several mid-sized acquisitions in 2025 focused on strengthening aftermarket service networks in the APAC region to support the growing install base.

Explore Latest Research Reports by Transparency Market Research:

Ground Protection Mat Market - https://www.transparencymarketresearch.com/ground-protection-mats-market.html

Industrial Floor Mats Market - https://www.transparencymarketresearch.com/industrial-floor-mats-market.html

Ultrasonic Cleaning Equipment Market - https://www.transparencymarketresearch.com/ultrasonic-cleaning-equipment-market-report.html

High Torque Stepper Motor Market - https://www.transparencymarketresearch.com/high-torque-stepper-motor-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Centrifugal Compressor Market Set to Reach USD 5.7 Billion by 2034, Driven by Steady Industrial Demand here

News-ID: 4280282 • Views: …

More Releases from transparencymarketresearch

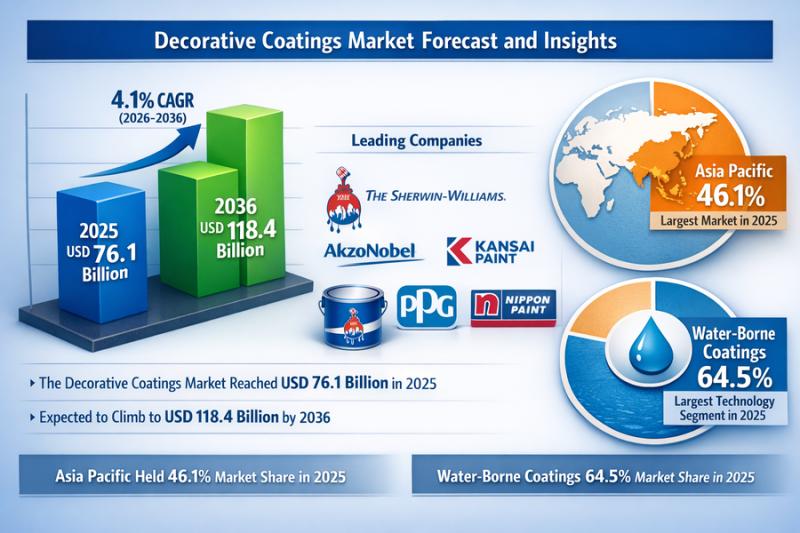

Decorative Coatings Market to Reach USD 118.4 Billion by 2036 at 4.1% CAGR

The decorative coatings market was valued at USD 76.1 billion in 2025 and is projected to reach USD 118.4 billion by 2036. The industry is expected to grow at a steady CAGR of 4.1% during the forecast period from 2026 to 2036, driven by rising construction activities, increasing demand for aesthetic building solutions, and ongoing product innovations.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1450

Market Overview

Decorative coatings are applied…

Europe and Asia Pacific Commercial Fuel Cards Market to Reach USD 1,042.2 Billio …

The Europe and Asia Pacific commercial fuel cards market was valued at USD 534.2 billion in 2025 and is projected to reach USD 1,042.2 billion by 2036, growing at a CAGR of 6.2% from 2026 to 2036. Market growth is driven by rising cross-border transportation demand across Europe and the rapid expansion of fuel retail networks in the Asia Pacific region.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85701

Market…

Air Fryer Market to Reach USD 2,343.9 Mn by 2036 Driven by Health-Focused Cookin …

The global air fryer market was valued at USD 1,103.4 Mn in 2025 and is projected to reach USD 2,343.9 Mn by 2036, expanding at a CAGR of 7.8% from 2026 to 2036. Market growth is primarily driven by rising health consciousness and increasing demand for low-oil cooking appliances among consumers. Busy urban lifestyles, compact kitchen trends, and the growing preference for convenient home-cooking solutions are further supporting adoption. Additionally,…

Global Yeast Market to Reach US$ 16.9 Bn by 2036 Driven by Bakery and Beverage D …

The global yeast market was valued at USD 9.7 Bn in 2025 and is projected to reach USD 16.9 Bn by 2036, expanding at a CAGR of 5.1% from 2026 to 2036. Market growth is primarily driven by increasing demand from the bakery and food processing industries, along with the steady expansion of alcoholic and non-alcoholic beverage production. Rising consumption of convenience foods and fermented products continues to support sustained…

More Releases for Compressor

Refrigeration Compressor Market Thriving Worldwide: Emerson, GMCC, Huayi Compres …

Latest Study on Industrial Growth of Global Refrigeration Compressor Market 2023-2029. A detailed study accumulated to offer the Latest insights about acute features of the Refrigeration Compressor market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends…

Refrigeration compressor purchase

Refrigeration compressor purchase Compressor selection is the first step in the establishment of a refrigeration system. Choosing a suitable refrigeration compressor can neither have excess power nor insufficient cooling capacity, which can lead to an increase in power consumption. It must be more suitable for the local environment. In this article, the editor will share with you the selection principles of refrigeration compressors.

First: Select the compressor according to the…

Oil Free Compressor Market (Oil-Free Compressor, Oil-Free Air Compressor) Key Pl …

Oil Free Compressor (Oil-Free Compressor, Oil-Free Air Compressor) Market Insights 2019, Global and Chinese Scenario is a professional and in-depth study on the current state of the global Oil Free Compressor (Oil-Free Compressor, Oil-Free Air Compressor) industry with a focus on the Chinese market. The report provides key statistics on the market status of the Oil Free Compressor (Oil-Free Compressor, Oil-Free Air Compressor) manufacturers and is a valuable source of…

Compressor Valves Market Trends, in-Depth Assessment, New Strategies, Price, Fut …

What is Compressor Valves?

Compressor Valves are the valves used in a compressor to control the flow of fluid in a cylinder. The compressor valves are circular with a series of plates that are placed between valve seat and cover. The compressor valves market is expected to grow due to the revival of stalled infrastructure projects, the demand for eco-friendly products, and technological innovations.

The reports cover key market developments in…

Business Overview: Global Oil Free Compressor (Oil-Free Compressor, Oil-Free Air …

An oil-free compressor is only one of several types of compressors available. It works the same way as a standard air compressor, and may even look very similar on the outside; internally, however, it contains special seals designed to keep the crucial lubricating oil away from the compressed air. The moving parts inside the compressor require lubrication to reduce the friction. Lubrication is essential in adequate amounts, regardless of the…

Compressor Valves Market| key manufacturers- Cook Compression, Burckhardt Compre …

There has been prevalence of compressor valves in the oil and gas industry for its exhaustive applications in upstream, midstream and downstream operations. Given oil and gas industry is the most sought after primary source of energy, demand for compressor valves has surged. In addition, a significant demand for better wastewater management facilities is anticipated to favorably influence the market for compressor valves.

Get free Sample Copy @ https://www.mrrse.com/sample/17813

Small and medium-sized…