Press release

Energy Bar Manufacturing Plant Cost 2025: Industry Trends, Machinery and Raw Materials

An energy bar is a nutrient-dense, ready-to-eat snack designed to provide quick energy, sustained fuel, and convenient nutrition. Typically made from ingredients like oats, nuts, seeds, dried fruits, sweeteners, and protein sources, energy bars are formulated to support active lifestyles, sports performance, and on-the-go consumption. They come in various types-protein bars, meal-replacement bars, and endurance bars-offering benefits such as improved satiety, muscle recovery, and balanced nutrient intake. With rising health consciousness and demand for portable functional foods, energy bars have become a popular choice among athletes, fitness enthusiasts, and busy professionals.Setting up an energy bar manufacturing plant involves selecting the right location, sourcing high-quality raw materials, and installing machinery for mixing, forming, baking (if required), cooling, and packaging. Investors must ensure compliance with FDA regulations, maintain strict hygiene standards, and adopt automated systems for consistent quality. Efficient supply chain planning, product innovation, and attractive packaging are essential for market competitiveness and long-term profitability.

IMARC Group's report, titled "Energy Bar Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up an energy bar manufacturing plant. It covers a comprehensive market overview to micro-level information, such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Energy Bar Industry Outlook 2025:

The energy bar industry demonstrates robust growth by 2025, driven by health and wellness trends, convenience-seeking lifestyles, sports nutrition market expansion, meal replacement adoption, clean-label ingredient preferences, and demographic shifts toward active aging and fitness consciousness. The global market exceeds $6-8 billion with North America representing the largest market showing sustained growth despite maturity, Europe exhibiting strong expansion particularly in protein and functional bars, while Asia-Pacific emerges as fastest-growing region with rising disposable incomes, westernization of snacking habits, and fitness culture adoption. Consumer preferences evolve toward higher protein content (15-20+ grams), cleaner ingredient lists with recognizable components, reduced sugar formulations using alternative sweeteners, plant-based proteins replacing dairy-derived ingredients, functional additives (probiotics, collagen, MCT oil, adaptogens), and premium positioning emphasizing quality over commodity pricing.

Request for Sample Report: https://www.imarcgroup.com/energy-bar-manufacturing-plant-project-report/requestsample

Key Insights for Energy Bar Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy Now: https://www.imarcgroup.com/checkout?id=9773&method=1911

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up an Energy Bar Plant:

• Land acquisition and facility construction for production areas with temperature/humidity control (18-22°C, 50-60% RH typical), ingredient storage areas (segregated for allergens), finished goods warehousing (climate-controlled preventing melting or hardening), quality control laboratories, and administrative offices

• Raw material procurement systems for diverse ingredients including:

• Carbohydrate sources: oats, rice crisps, quinoa, dried fruits, honey, syrups (brown rice, agave, date)

• Protein sources: whey protein isolate/concentrate, soy protein, pea protein, brown rice protein, nuts, seeds

• Fats: nut butters (almond, peanut, cashew), coconut oil, palm oil alternatives

• Binding agents: honey, syrups, glycerin, tapioca syrup

• Functional ingredients: vitamins, minerals, probiotics, fiber sources

• Flavoring: natural flavors, cocoa, vanilla, fruit extracts

• Coatings: chocolate (dark, milk), yogurt coating, carob

• Ingredient storage infrastructure including climate-controlled silos or bins for dry ingredients, refrigerated storage for nut butters and certain proteins, and allergen-segregated areas preventing cross-contamination

• Weighing and batching systems with industrial scales, automated dosing equipment for formula accuracy, and inventory management systems tracking ingredient usage

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9773&flag=C

Economic Trends Influencing Energy Bar Plant Setup Costs 2025:

• Protein ingredient costs with whey, pea, and alternative proteins subject to agricultural commodity cycles and demand from growing protein-fortified food sectors

• Clean-label premiums with consumers willing to pay more for recognizable ingredients, organic certification, non-GMO verification, and transparent sourcing

• Direct-to-consumer growth enabling premium pricing, customer data collection, and subscription models improving cash flow predictability

• Plant-based trend driving demand for vegan bars using pea, brown rice, hemp proteins and plant-based coatings replacing traditional dairy ingredients

• Sugar reduction initiatives with consumers seeking bars under 5g sugar requiring reformulation expertise and alternative sweetener costs

• Functional ingredients premiums with probiotics, collagen, MCT oil, adaptogens, and superfoods commanding higher retail prices supporting ingredient investments

• Packaging sustainability pressures driving investments in compostable films, recyclable materials, or reduced packaging despite higher costs

Challenges and Considerations for Investors in Energy Bar Plant Projects:

• Intense market competition with hundreds of brands competing for shelf space, consumer attention, and distribution relationships in mature markets

• Low barriers to entry enabling constant new entrants with minimal differentiation creating crowded category and price pressures

• Retailer power with major grocery chains demanding slotting fees, promotional allowances, and favorable terms particularly for new brands without track records

• Ingredient cost volatility with nuts, proteins, chocolate, and commodities subject to agricultural cycles affecting margin predictability

• Formulation complexity balancing taste, texture, nutrition, shelf-life, cost, and clean-label requirements often involving trade-offs

• Allergen management criticality with nuts, soy, dairy commonly used requiring stringent controls preventing cross-contamination and potential liability

• Shelf-life optimization requiring precise water activity control, preservative systems, and packaging barrier properties preventing spoilage or texture degradation

• Texture consistency challenges with bars potentially becoming too hard in cold or too soft in heat requiring formulation optimization and storage condition management.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Energy Bar Manufacturing Plant Cost 2025: Industry Trends, Machinery and Raw Materials here

News-ID: 4275890 • Views: …

More Releases from IMARC Group

Vegetable Oil Processing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/Op …

Setting up a vegetable oil processing plant positions investors in one of the most stable and essential segments of the food and agro-processing value chain, backed by sustained global growth driven by rising population, increasing consumption of edible oils, growth in packaged food demand, and expanding applications across food, personal care, and industrial sectors. As urbanization accelerates, consumer lifestyles shift toward convenience and packaged foods, and regulatory frameworks increasingly support…

Trinitrotoluene Production Plant DPR & Unit Setup 2026: Demand Analysis and Proj …

Setting up a trinitrotoluene production plant involves strategic planning, substantial capital investment, and a comprehensive understanding of production technologies. This critical explosive compound serves military and defense, mining and quarrying, construction and demolition, and industrial explosives manufacturing applications. Success requires careful site selection, efficient nitration processes, stringent safety protocols for handling hazardous materials, reliable raw material sourcing, and compliance with industrial safety regulations to ensure profitable and sustainable operations.

Market Overview…

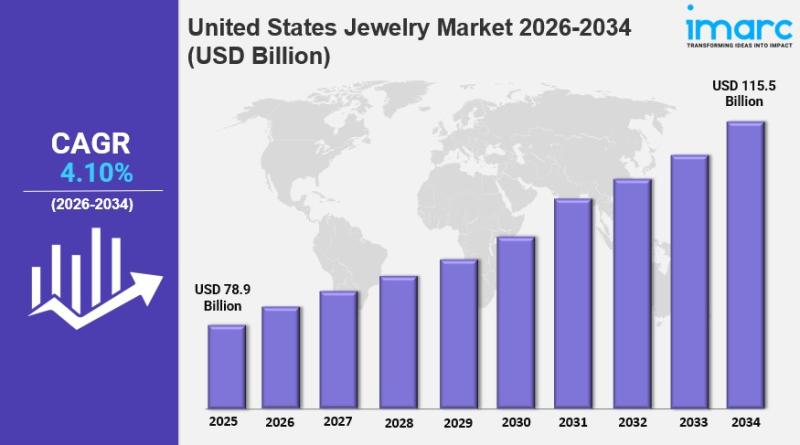

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…