Press release

Automotive Air Filters Manufacturing Plant Cost Feasibility Report 2025: Capex/Opex Analysis with Profitability Forecasts

The automotive air filters industry has become one of the fastest-growing segments in the automotive components sector, supported by increasing vehicle production across global markets. Setting up an automotive air filters manufacturing plant requires more than just infrastructure; it involves strategic planning, investment, efficient equipment, and strong market awareness. This article presents an overview of automotive air filters manufacturing plants, covering setup, production stages, market trends, investment considerations, and operational requirements.What About Automotive Air Filters?

Automotive air filters hold a significant position in the global automotive aftermarket and OEM sectors due to their critical role in engine protection, performance optimization, and emission control. They are essential for preventing dust, debris, and contaminants from entering engine combustion chambers, thereby ensuring optimal fuel efficiency and engine longevity. The growing popularity of automotive air filters in both replacement markets and original equipment installations has driven demand for various types including paper filters, foam filters, cotton gauze filters, and cabin air filters with activated carbon. Performance standards and filtration efficiency are becoming increasingly important, as consumers and regulators emphasize vehicle maintenance, air quality, and environmentally responsible automotive components.

Request a Sample Report: https://www.imarcgroup.com/automotive-air-filters-manufacturing-plant-project-report/requestsample

What is Driving the Automotive Air Filters Market?

The automotive air filters market is primarily driven by rising vehicle population and increasing vehicle age, alongside growing awareness of regular maintenance that emphasizes engine health and performance optimization. Global expansion of the automotive industry, particularly in emerging markets, has boosted demand for both OEM and aftermarket filters, ensuring consistent supply to meet growing consumption. Expanding urbanization and deteriorating air quality in cities have further facilitated demand for high-efficiency cabin air filters across regions. Moreover, the popularity of performance aftermarket upgrades, premium filtration solutions, and eco-friendly filter materials is fueling demand in retail and automotive service sectors. Stricter emission regulations, growing vehicle ownership, and rising disposable incomes in developing economies also support market expansion. Sustainability initiatives, recyclable filter materials, and extended service life products are influencing purchasing decisions, aligning the industry with evolving preferences for cost-effective and environmentally responsible automotive maintenance solutions.

Understanding Automotive Air Filters Manufacturing

• Automotive air filters manufacturing refers to producing filtration components that protect vehicle engines and cabin environments from airborne contaminants.

• Manufacturing activities include filter media preparation, pleating, frame molding or fabrication, adhesive application, assembly, quality testing, and packaging.

• Filters must meet specific efficiency ratings and airflow requirements; therefore, strict quality control and performance testing are vital.

• Efficiency in the process ensures consistent quality, compliance with automotive industry standards, and reliable filtration performance for various vehicle applications.

Key Components of a Business Plan

• Executive Summary: Outlines vision, mission, and business objectives.

• Market Research: Identifies demand patterns, consumer behavior, and competitive players.

• Operational Strategy: Includes plant design, capacity, workflow, and quality assurance measures.

• Marketing and Sales Plan: Defines distribution channels, branding, and positioning in domestic and export markets.

• Financial Planning: Covers projected investments, cost structures, and revenue expectations.

• Risk Assessment: Evaluates potential challenges such as raw material supply, regulatory compliance, and market fluctuations.

Capital Investment Overview

CapEx (Capital Expenditure):

• Land acquisition, plant construction, utilities setup, and equipment purchase.

• One-time costs associated with establishing infrastructure and ensuring manufacturing efficiency.

• Defines long-term productivity and competitiveness.

OpEx (Operating Expenditure):

• Recurring costs including labor, utilities, packaging, storage, and transportation.

• Raw material procurement and regular equipment maintenance.

• Compliance with automotive quality certifications, industry standards, and environmental regulations.

Buy Report Now: https://www.imarcgroup.com/checkout?id=7788&method=1911

Machinery and Equipment Requirements

Primary Equipment:

• Filter media cutting and preparation machines.

• Pleating machines for accordion-fold formation.

• Injection molding machines for plastic end caps and frames.

• Metal frame fabrication equipment (stamping, bending, welding).

• Adhesive application systems (hot melt or polyurethane).

• Automated assembly lines for filter construction.

• Gasket and seal installation equipment.

• Quality testing apparatus (airflow resistance, filtration efficiency).

• Automated packaging machines for individual and bulk packaging.

• Material handling and storage systems.

Supporting Equipment:

• Compressors for pneumatic systems.

• Mold heating and cooling systems.

• Conveyors for component and finished product movement.

• Laboratory equipment for performance verification and quality control..

Operating Costs

• Procurement of filter media (cellulose paper, synthetic fibers, foam).

• Plastic resins for injection molding of frames and end caps.

• Metal components (wire mesh, expanded metal) for structural support.

• Labor salaries, training, and workforce management.

• Utilities such as electricity, compressed air, and water.

• Maintenance and servicing of machinery and equipment.

• Adhesives, sealants, gasket materials, and assembly consumables.

• Packaging materials including boxes, poly bags, and labeling.

• Transportation and distribution logistics.

• Certification, compliance, and quality assurance activities.

Raw Materials

• Main Raw Material: Filter media including cellulose paper, synthetic nonwoven fabrics, polyurethane foam, or cotton gauze materials.

• Structural Materials: Plastic resins (polypropylene, polyamide) for molded components, steel or aluminum for metal frames.

• Additional Inputs: Packaging materials including printed cartons, protective bags, and point-of-sale displays.

• Auxiliary Materials: Hot melt adhesives, polyurethane sealants, rubber gaskets, wire mesh, activated carbon granules (for cabin filters), and assembly hardware.

• Supply Considerations: Consistency of filter media quality and filtration ratings, reliable sourcing partnerships with material suppliers, adherence to automotive industry specifications (ISO standards), and quality certification requirements.

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7788&flag=C

Frequently Asked Questions (FAQs)

1. What is the first step in setting up an automotive air filters manufacturing plant? The process begins with developing a business plan, securing land in an industrial area, obtaining manufacturing licenses, and establishing partnerships with filter media suppliers and automotive distributors or OEM customers.

2. Why is filtration efficiency testing considered critical? Testing ensures filters meet industry standards (ISO 5011, SAE specifications) for particle capture, airflow resistance, and durability, which directly impacts engine performance, fuel efficiency, and customer satisfaction.

3. Can automotive air filters manufacturing plants focus only on domestic markets? Yes, though many plants also target exports, as international markets offer opportunities in both OEM supply chains and growing aftermarket demand across developing automotive markets.

4. How does automation benefit automotive air filters manufacturing? Automation improves production speed, ensures consistent pleating and assembly quality, reduces labor costs, minimizes defects, and enhances overall product uniformity and reliability.

5. Is backward integration into filter media production necessary? Not mandatory; most manufacturers source specialized filter media from established suppliers, focusing on filter design, assembly optimization, and market-specific product development for various vehicle segments.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automotive Air Filters Manufacturing Plant Cost Feasibility Report 2025: Capex/Opex Analysis with Profitability Forecasts here

News-ID: 4275522 • Views: …

More Releases from IMARC Group

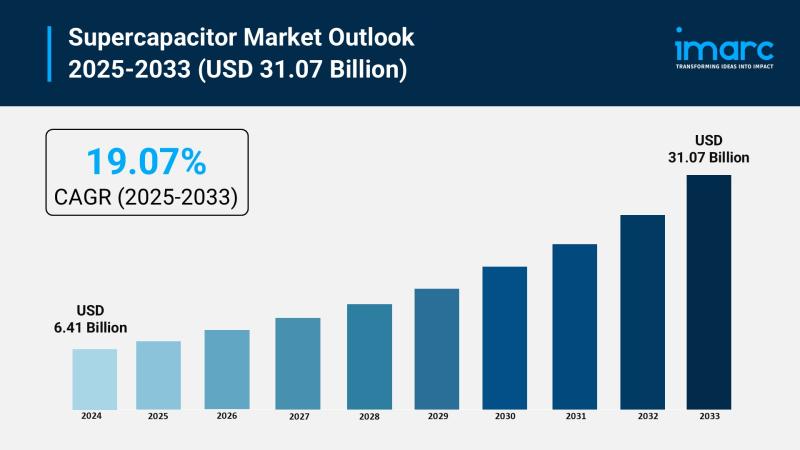

Supercapacitor Market Size to Reach $31.07B by 2033: Trends & Opportunities

Market Overview:

The supercapacitor market is experiencing rapid growth, driven by electrification of automotive systems, renewable energy and grid stabilization, and expansion of industrial automation and robotics. According to IMARC Group's latest research publication, "Supercapacitor Market Size, Share, Trends and Forecast by Product Type, Module Type, Material Type, End Use Industry, and Region, 2025-2033", the global supercapacitor market size was valued at USD 6.41 Billion in 2024. Looking forward, IMARC Group…

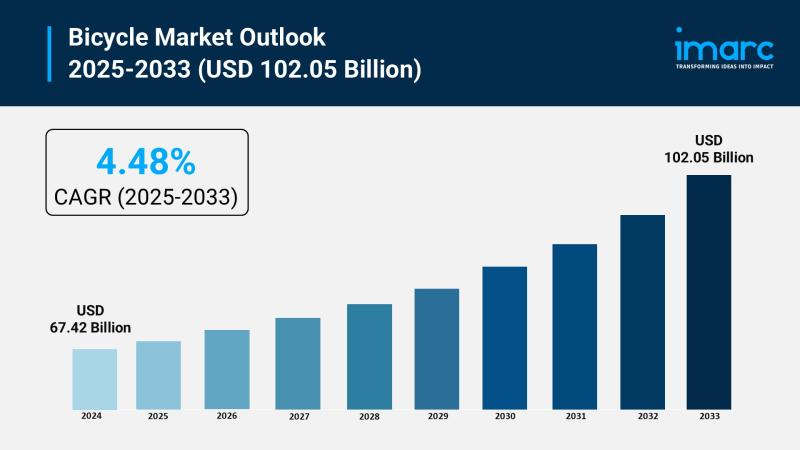

Bicycle Market Size to Surpass $102.05B by 2033: Growth & Insights

Market Overview:

The bicycle market is experiencing rapid growth, driven by global expansion of cycling infrastructure, rising health consciousness and preventative wellness, and technological advancements in e-bike propulsion. According to IMARC Group's latest research publication, "Bicycle Market Size, Share, Trends and Forecast by Type, Technology, Price, Distribution Channel, End User, and Region, 2025-2033", The global bicycle market size was valued at USD 67.42 Billion in 2024. Looking forward, IMARC Group estimates…

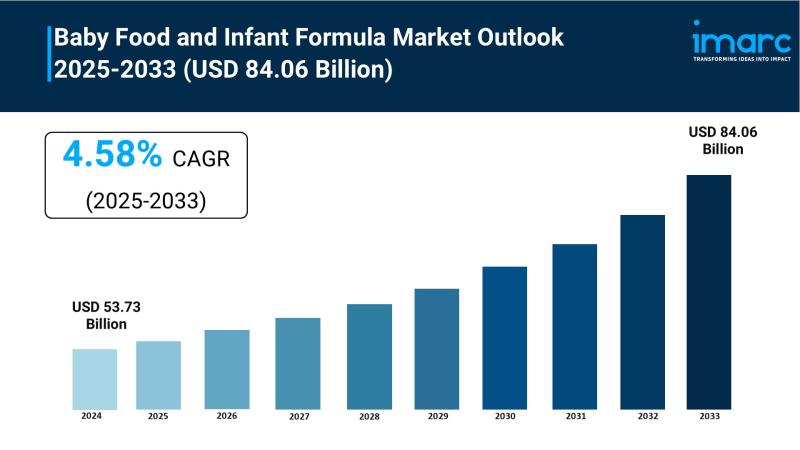

Baby Food and Infant Formula Market to Reach USD 84.06 Billion by 2033, Growing …

Market Overview:

The Baby Food and Infant Formula Market is experiencing steady expansion, driven by Increasing Awareness of Nutritional Needs for Infants, Rising Number of Working Women, and Technological Advancements and Product Innovation. According to IMARC Group's latest research publication, "Baby Food and Infant Formula Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global baby food and infant formula market size reached USD 53.73 Billion in 2024.…

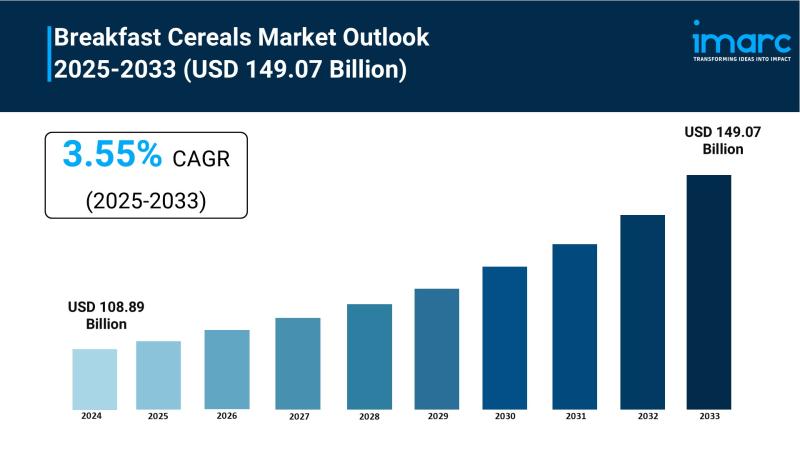

Breakfast Cereals Market to Reach USD 149.07 Billion by 2033, Growing at a CAGR …

Market Overview:

The Breakfast Cereals Market is experiencing rapid growth, driven by Health and Wellness Awareness, Busy Lifestyles and On-the-Go Demand and Rising Disposable Incomes and Global Market Expansion . According to IMARC Group's latest research publication, "Breakfast Cereals Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global breakfast cereals market size was valued at USD 108.89 Billion in 2024. Looking forward, IMARC Group estimates…

More Releases for Filter

Filter Aid Diatomaceous Earth For Gravity Filter

Technology data sheet

TYPE

Color

Grade

Permeability

Density

Screening%

PH

MIN darcy

TARGET darcy

MAX darcy

TARGET g/cm3

MAX g/cm3

+150mesh

MIN

TARGET

MAX

ZBS100

pink/white

Dissolve calcination

1.3

1.5

1.8

0.37

0.4

0

NA

4

8-11

ZBS150

pink/white

Dissolve calcination

1.5

1.9

2.3

0.35

0.4

0

NA

4

8-11

ZBS200

pink/white

Dissolve calcination

2.3

2.6

3

0.35

0.4

0

NA

4

8-11

ZBS300

white

Dissolve calcination

3

3.5

4

0.35

0.37

0

2

6

8-11

ZBS400

white

Dissolve calcination

4

4.5

5

0.35

0.37

2

4

10

8-11

ZBS500

white

Dissolve calcination

4.8

5.3

6

0.35

0.37

4

8

15

8-11

ZBS600

white

Dissolve calcination

6

7

8

0.35

0.37

6

10

20

8-11

ZBS800

white

Dissolve calcination

7

8

9

0.35

0.37

10

15

25

8-11

ZBS1000

white

Dissolve calcination

8

10

12

0.35

0.38

12

21

30

8-11

13

19

25

0.35

0.38

9

19

30

8-11

ZBS1200

white

Dissolve calcination

12

17

30

0.35

0.38

NA

NA

NA

8-11

Product Advantages

- complete range of permeability - complete certification: ISO, Halal, Kosher - suitable for all walks of life - Higher efficiency filtration - National Patent products

Application

In industrial applications, one or two kinds of diatomite filter aid are mixed and used according to the viscosity of the filtered liquid.To get the satisfactory…

Automotive Filters OE Market, By Filter Type (Air Filter, Fuel Filter, Oil Filte …

Automotive filters OE market is expected to grow at a compound annual growth rate of 4.95% over the forecast period of 2021 to 2028. Data Bridge Market Research report on automotive filters OE market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecasted period while providing their impacts on the market's growth.

View Detailed Report: https://www.databridgemarketresearch.com/reports/global-automotive-filters-oe-market

The automotive filters OE market has a huge potential to…

Automotive Filters Market to 2027 Global Analysis and Forecasts by Type (Fuel Fi …

The Automotive Filters is majorly used to remove the air pollutants, dust particles in order to improve the vehicle performance by reducing fuel consumption and resulting in high power output. These filters support in increasing the air flow and lessen the engine damage, which in turn increases the life span of the vehicle. Also, high gasoline prices are anticipated to shift manufacturer’s emphasis on reduced fuel consumption.

Get Free 20%…

Inferior Vena Cava Filter (IVC Filter) Market 2018-2025 Segmented by Types: Perp …

The Inferior Vena Cava Filter (IVC Filter) Market 2018 Research Report (Request Sample Report Here) is collected with several market features, for example, market overview, type, application, region, and players/suppliers. The valuation of Inferior Vena Cava Filter (IVC Filter) market report is set up to help strategists in understanding the production, revenue, price, market share and growth rate influence under the study period. This industry examination ensures that the reader…

Automotive Filter Market by Filter Type (Fuel Filter, Engine Oil Filter, Engine …

Automotive Filter Market by Filter Type (Fuel Filter, Engine Oil Filter, Engine Air Filter, Cabin Air Filters, Steering Filter, and Coolant Filter), Application (Passenger Cars and Commercial Vehicle), and Distribution Channel (OEM and Aftermarket): Global Opportunity Analysis and Industry Forecast, 2018-2024". The report offers in-depth analyses of the top investment pockets, drivers & opportunities, competitive landscape, and key strategic moves by key players. According to the report, the global automotive…

Automotive Filter Market by Filter Type (Fuel Filter, Engine Oil Filter, Engine …

Asia-Pacific is expected to dominate the global automotive filter market during the forecast period, owing to rise in demand for passenger cars. In 2017, China is projected to dominate the Asia-Pacific market. U.S. is anticipated to lead the market in North America, whereas the UK led the European market in 2017.

According to a recent report published by Allied Market Research, titled, Automotive Filter Market by Filter Type, Application, and Distribution…