Press release

Global Aluminum Castings Market Set to Reach USD 83.4 Billion by 2034 Amid Rising Demand for Lightweight Vehicles and Expanding Infrastructure Development

The global aluminum castings market is entering a new phase of accelerated growth as industries across automotive, construction, electronics, and heavy engineering embrace lightweight materials to enhance efficiency and sustainability. With expanding industrialization, rapid infrastructure upgrades, and stringent emission regulations influencing material choices, aluminum castings are gaining unprecedented traction worldwide. According to the latest market assessment, the aluminum castings industry, valued at USD 41.5 Bn in 2023, is projected to almost double and reach USD 83.4 Bn by 2034, advancing at a robust CAGR of 6.6% from 2024 to 2034.This press release offers a comprehensive 360-degree perspective on market drivers, opportunities, competitive dynamics, and future outlook positioning this sector as a key pillar of global manufacturing progress.

Explore core findings and critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=31241

Market Overview

Aluminum castings have become the preferred choice for manufacturers seeking lightweight, durable, and corrosion-resistant components. Their ability to withstand extreme environments, improve mechanical performance, and reduce operational costs makes them essential across multiple industries.

The market's upward trajectory is strongly tied to:

• The global transition toward fuel-efficient and electric vehicles

• Expansion of residential and commercial construction

• Increasing demand for high-performance electronic components

• Advancements in industrial machinery and automation

Asia Pacific emerged as the leading region in 2023, driven largely by automotive production growth in China, India, and South Korea. Meanwhile, North America and Europe continue to adopt aluminum solutions rapidly in response to evolving emission regulations and electric vehicle (EV) adoption.

Key Drivers of Market Growth

1. Rising Demand for Lightweight Vehicles

Lightweighting has become essential to improving fuel efficiency and reducing greenhouse gas emissions. Aluminum components now represent 30-40% of the total weight in modern lightweight vehicles.

Key supporting factors:

• Regulatory pressure globally to curb vehicular emissions

• Automakers shifting from steel and iron to aluminum composite components

• Aluminum's superior strength-to-weight ratio enabling safer, lighter, and more efficient vehicles

With countries accelerating EV adoption, demand for aluminum-based battery housings, thermal management components, and structural parts is projected to escalate rapidly.

2. Growth of the Building & Construction Sector

Aluminum is now the second most widely used metal in construction after steel. The sector relies on aluminum castings for:

• Curtain wall frames

• Door handles and knobs

• Window frames

• Roofing solutions

• Decorative structures

Urbanization, population growth, and infrastructure modernization in Asia, the Middle East, and Africa will continue to fuel market demand through 2034.

3. Expansion of Industrial and Agricultural Machinery Usage

Aluminum castings are increasingly deployed in:

• Mining equipment

• Agricultural harvesting machinery

• Industrial automation systems

Manufacturers are embracing aluminum materials that offer higher durability, improved efficiency, and superior corrosion resistance.

Latest Market Trends

1. Technological Innovations in Casting Processes

Innovative processes such as lost-foam casting, vacuum die casting, and additive manufacturing are improving accuracy, reducing material waste, and enabling the creation of complex geometries.

2. Rapid Adoption in Electric Vehicles

Aluminum plays a critical role in battery protection, energy regulation, and vehicle weight management. Aluminum's natural thermal capabilities help maintain optimal EV battery temperatures, enhancing lifespan and performance.

3. Strong Focus on Sustainability and Recycling

The global manufacturing ecosystem is shifting toward recyclable materials. Aluminum, with a recycling rate of nearly 90%, supports sustainability goals and aligns with regulatory initiatives aimed at circular economy adoption.

4. Industry Digitization and Automation

Smart manufacturing techniques-such as AI-enabled casting simulations and automated quality inspections-are becoming increasingly prevalent, enabling companies to reduce defects and improve production throughput.

Key Players and Industry Leaders

The aluminum castings market is highly fragmented yet competitive, with global and regional players focusing on R&D, collaborations, and capacity expansion.

Major companies include:

• Alcast Technologies Ltd.

• Arconic Inc.

• Consolidated Metco Inc.

• Dynacast International

• Gibbs Die Casting Corp.

• Ryobi Ltd.

• Bodine Aluminum Inc.

• Endurance Technologies Ltd.

• Eagle Aluminum Cast Products Inc.

• Oslan Aluminum Castings

• Nemak

• Alcoa Corporation

• Martinrea Honsel

These companies are consistently investing in advanced alloys and precision casting technologies to enhance performance for automotive, aerospace, and defense applications.

Recent Developments

• CSIR-NIIST & HAL Partnership (India, 2023)

Joint development of aerospace-grade aluminum alloy castings to support the aviation and defense manufacturing ecosystem.

• Sylatech's £3.4 Million DLMM Project (U.K., 2023)

Introduction of the MeltX innovation, enabling improved mechanical properties in post-consumer recycled aluminum-representing a major step toward greener manufacturing.

These developments underline growing global investment in next-generation casting technologies and sustainable alloy solutions.

Market Opportunities and Challenges

Opportunities

1. Surge in Electric Vehicle Manufacturing

With governments incentivizing EV adoption, demand for lightweight aluminum components will skyrocket across batteries, chassis, and motor housings.

2. Infrastructure Expansion in Developing Economies

Asia Pacific, Middle East, and Africa present strong opportunities for aluminum casting applications in construction, industrial machinery, and transport equipment.

3. Technological Advancements

Enhanced casting accuracy allows aluminum parts to penetrate new markets, including aerospace and medical equipment.

Challenges

1. High Production Costs

Aluminum casting requires substantial electricity, water, and resource investments, resulting in elevated operational costs.

2. Raw Material Price Volatility

Fluctuating aluminum prices can impact profit margins, affecting both large-scale and small-scale manufacturers.

3. Environmental Concerns

While aluminum is recyclable, its initial production remains energy-intensive, pushing manufacturers to adopt cleaner processes.

Buy this Premium Research Report to gain valuable industry intelligence - https://www.transparencymarketresearch.com/checkout.php?rep_id=31241<ype=S

Future Outlook

The aluminum castings market is on track for sustained expansion through 2034, supported by:

• Increasing electrification of transportation

• Urban development and smart city initiatives

• Advancements in high-strength aluminum alloys

• Global shift toward energy-efficient and lightweight materials

By 2034, aluminum castings will play a central role in modern mobility, energy systems, and next-generation industrial equipment. The integration of digital manufacturing technologies will further optimize production efficiency, reduce wastage, and enhance material performance.

Market Segmentation

By Source

• Primary Aluminum

• Secondary (Recycled) Aluminum

By Process

• Die Casting

• Permanent Mold Casting

• Sand Casting

By Application

Automotive

• Passenger Cars & LCVs

• Commercial Vehicles

• Motorbikes

Non-Automotive

• Infrastructure

• Industrial Machinery

• Consumer Products

• Aerospace & Defense

• Others

Regions Covered

• North America

• Europe

• Asia Pacific

• Latin America

• Middle East & Africa

Why Buy This Report?

Purchasing the Aluminum Castings Market Report provides strategic advantages, including:

• Comprehensive market forecasting to 2034

• In-depth competitive landscape analysis with profiles of leading global companies

• Detailed segmentation insights supporting targeted business decisions

• Evaluation of technological shifts reshaping the casting industry

• Regional analysis with growth hotspots and emerging opportunities

• Complete value chain and Porter's Five Forces analysis

• Access to PDF and Excel data formats for easy integration into strategic planning

Explore Latest Research Reports by Transparency Market Research:

Industrial Silica Market: https://www.transparencymarketresearch.com/industrial-silica-sands-market.html

Specialty Silica Market: https://www.transparencymarketresearch.com/specialty-silica-market.html

Braze Alloys Market: https://www.transparencymarketresearch.com/braze-alloys-market.html

Solar Panel Coatings Market: https://www.transparencymarketresearch.com/solar-panel-coatings-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact Us:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Aluminum Castings Market Set to Reach USD 83.4 Billion by 2034 Amid Rising Demand for Lightweight Vehicles and Expanding Infrastructure Development here

News-ID: 4274186 • Views: …

More Releases from Transparency Market Research

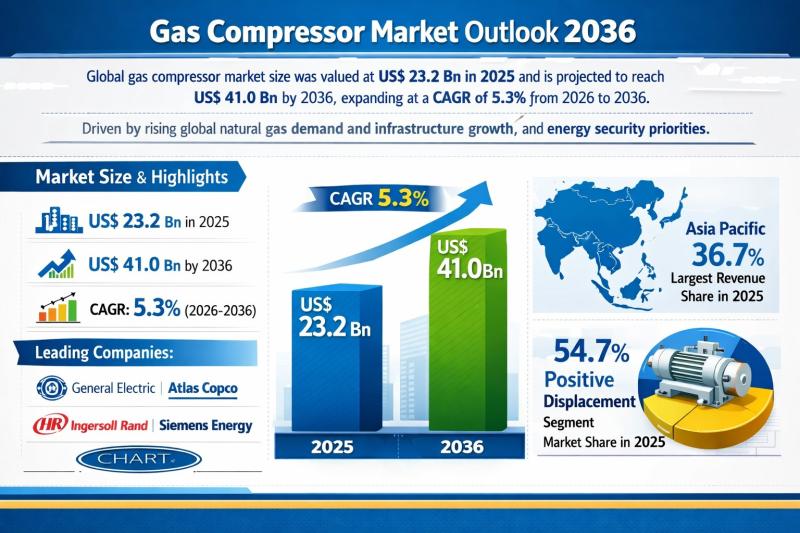

Gas Compressor Market Outlook 2036: Global Industry Expected to Reach US$ 41.0 B …

The global gas compressor market was valued at US$ 23.2 Bn in 2025 and is projected to reach US$ 41.0 Bn by 2036, expanding at a compound annual growth rate (CAGR) of 5.3% from 2026 to 2036. This steady growth trajectory reflects the structural importance of gas compression systems across upstream, midstream, and downstream gas value chains. Rising natural gas consumption, expansion of pipeline and LNG infrastructure, and national energy…

Anesthesia Drugs Market to be Worth USD 12.6 Bn by 2036 - By Drug / By Applicati …

The global anesthesia drugs market was valued at US$ 7.6 billion in 2025 and is projected to reach US$ 12.6 billion by 2036, expanding at a compound annual growth rate (CAGR) of 4.7% from 2026 to 2036. This steady growth trajectory reflects the essential and non-substitutable role of anesthesia drugs in modern healthcare systems. As surgical interventions continue to rise globally-across both elective and emergency procedures-the demand for safe, effective,…

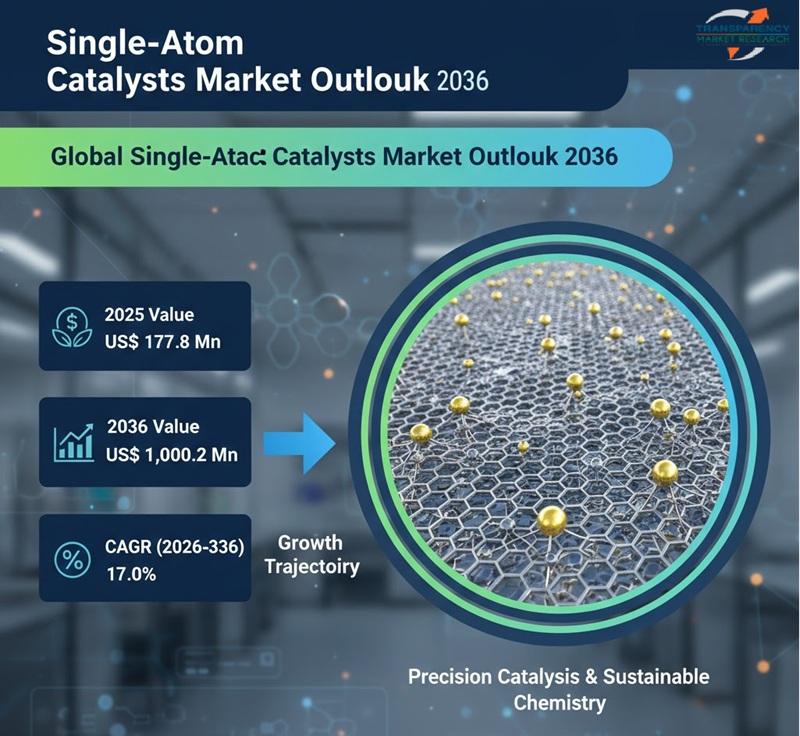

Single-Atom Catalysts Market Size is Expected to Expand from US$ 177.8 Million t …

The global single-atom catalysts (SACs) market is poised for remarkable growth as industries seek highly efficient, cost-effective, and sustainable catalytic solutions. Valued at US$ 177.8 million in 2025, the market is projected to reach US$ 1,000.2 million by 2036, expanding at a robust compound annual growth rate (CAGR) of 17.0% from 2026 to 2036. This rapid expansion reflects the growing importance of advanced catalysis in energy, chemicals, environmental protection, and…

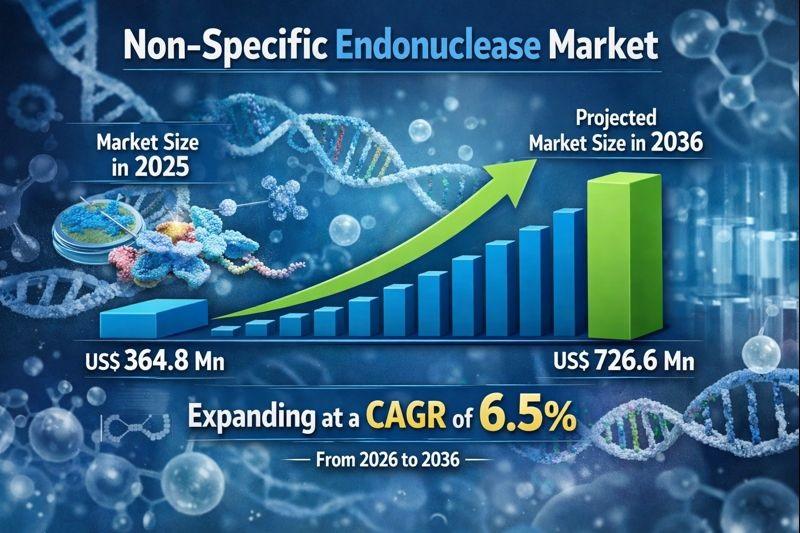

Non-specific Endonuclease Market to Reach USD 726.6 Million by 2036, Supported b …

The non-specific endonuclease market is witnessing steady growth, driven by the expanding use of molecular biology tools across biotechnology, pharmaceuticals, diagnostics, and academic research. Non-specific endonucleases are enzymes that cleave nucleic acids without requiring a specific recognition sequence, making them highly valuable for applications such as DNA/RNA degradation, sample preparation, viscosity reduction, and contamination control. Their broad activity profile differentiates them from restriction enzymes and enables versatile usage across multiple…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…