Press release

Cutting Equipment Market Set to Reach US$7.6 Billion by 2032, Says Persistence Market Research

The global cutting equipment market is entering a phase of steady expansion, driven by rapid industrialization, advanced manufacturing practices, and the growing integration of automation across various sectors. Cutting equipment comprises a wide array of tools and machinery designed to cut, shape, and process materials ranging from metals and alloys to plastics, composites, and wood. These systems play a critical role in industries such as automotive, aerospace, construction, shipbuilding, heavy machinery, metal fabrication, and manufacturing. As industries evolve toward higher levels of precision, reliability, and productivity, the demand for technologically advanced cutting equipment continues to surge.Get a Sample PDF Brochure of the Report: https://www.persistencemarketresearch.com/samples/13255

In 2025, the global cutting equipment market is projected to be valued at US$ 5.3 billion, and by 2032, the industry is expected to grow to US$ 7.6 billion, reflecting a CAGR of 5.2% over the forecast period from 2025 to 2032. This growth is primarily driven by the increasing adoption of laser cutting machines, plasma cutters, and waterjet cutting systems, all of which offer enhanced accuracy, speed, and operational efficiency. The leading segment in the global market is laser cutting equipment, consistently chosen by industries that demand high precision and minimal material waste. Geographically, Asia Pacific dominates the market, supported by its strong manufacturing ecosystem, rising infrastructural investments, and the presence of major metal fabrication and automotive production centers across China, India, Japan, and South Korea.

Key Highlights from the Report

• The cutting equipment market is expected to reach US$ 7.6 billion by 2032.

• Laser cutting equipment remains the leading segment due to its precision and versatility.

• Asia Pacific continues to dominate global demand, driven by advanced manufacturing activities.

• Increasing industrial automation fuels the adoption of high-performance cutting systems.

• Demand for lightweight materials in automotive and aerospace sectors boosts equipment upgrades.

• Investments in infrastructure and metal fabrication industries strengthen global market growth.

Market Segmentation

The cutting equipment market is segmented across several dimensions, including equipment type, technology, application, and end-use industry. Each segment offers unique insights into consumer preferences, technological advancements, and market demand patterns.

Based on equipment type, the market encompasses laser cutting machines, plasma cutters, waterjet cutting systems, oxy-fuel cutting equipment, and mechanical cutting tools. Among these, laser cutting machines hold the largest share due to their unmatched precision, speed, and capability to cut a wide range of materials. Their application in industries requiring intricate designs, thin material cutting, and advanced processing has positioned them as a preferred choice. Plasma cutting systems are widely used for thicker metal sections and remain popular in shipbuilding, construction, and heavy machinery sectors. Waterjet machines are favored in applications requiring cold cutting and high edge quality, such as aerospace component manufacturing.

The market is also segmented by technology, including CNC (Computer Numerical Control), manual cutting, and semi-automatic systems. CNC-operated cutting equipment leads the market, driven by its superior accuracy, automation benefits, and compatibility with Industry 4.0 technologies. Automated cutting systems reduce labor costs, minimize human error, and significantly increase production speed, making them a top choice for large-scale manufacturing operations.

From an application perspective, cutting equipment is used across welding and fabrication, construction, automotive component production, aerospace part manufacturing, electronics, and metalworking. The metal fabrication segment remains the largest market, due to its integral role in manufacturing structural components, industrial equipment parts, and consumer goods. The automotive and aerospace industries are also major contributors, as they increasingly rely on precision cutting technologies to process lightweight materials such as aluminum, titanium, composites, and high-strength alloys.

In terms of end-use industries, the market serves automotive, aerospace & defense, construction & infrastructure, shipbuilding, industrial machinery manufacturing, electronics, and energy. Automotive manufacturing is one of the fastest-growing end-use industries due to the expanding adoption of electric vehicles (EVs), which require high-precision component manufacturing. The construction sector, driven by rising investments in urban development and industrial infrastructure, also remains a key contributor to equipment demand.

Read More In Detail: https://www.persistencemarketresearch.com/market-research/cutting-equipment-market.asp

Regional Insights

The regional dynamics of the cutting equipment market highlight the strong influence of manufacturing activity, technological adoption, and industrial investments across different parts of the world. Asia Pacific (APAC) leads the global market, accounting for the largest share and expected to maintain its dominance throughout the forecast period. Nations like China, Japan, South Korea, and India have robust industrial sectors requiring continuous upgrades in metal fabrication, automotive production, and heavy engineering. The region's strong infrastructural development, increased government spending on industrial automation, and expansion of manufacturing export capabilities reinforce APAC's top position.

North America represents another highly lucrative region, driven by technological innovation, strong adoption of CNC cutting equipment, and high demand from the aerospace, automotive, and defense sectors. The United States leads the market within the region, fueled by its advanced manufacturing base and sustained investments in industrial modernization. The push toward reshoring manufacturing activities and the adoption of advanced materials further strengthen regional growth.

Europe remains a critical market for cutting equipment, supported by world-class automotive manufacturing, aerospace engineering hubs, and stringent quality standards in industrial production. Germany, Italy, and France remain the major contributors, with a strong presence of high-end manufacturing equipment suppliers and technology innovators. The region's focus on energy-efficient and environmentally sustainable manufacturing practices further drives the adoption of advanced cutting systems.

Latin America and Middle East & Africa (MEA) are emerging growth regions, with increasing industrial investments in Brazil, Mexico, South Africa, and the UAE. These regions benefit from expanding construction and infrastructure projects, mining activities, and growing adoption of modern manufacturing techniques. Government initiatives supporting industrialization and technology adoption create attractive opportunities for cutting equipment manufacturers.

Market Drivers

The cutting equipment market is witnessing robust growth due to several key drivers shaping the global industrial landscape. One of the primary drivers is the rapid growth of industrial automation. As manufacturing facilities transition toward smart factories, they integrate advanced cutting technologies that offer higher efficiency, accuracy, and operational flexibility. Precision cutting machines, particularly laser and CNC systems, support fast production cycles and tighter tolerances, making them essential for modern manufacturing.

Another significant driver is the rising demand for lightweight materials in automotive and aerospace industries. With the global shift toward fuel-efficient vehicles, electric mobility, and high-performance aircraft, manufacturers require cutting equipment capable of processing aluminum, carbon fiber, titanium, and other advanced materials. Additionally, the global increase in construction projects, metal fabrication activities, and infrastructural development boosts demand for durable and versatile cutting machinery.

Investment in renewable energy infrastructure, including wind turbines and solar mounting structures, also positively influences the market, as these components require precision cutting for enhanced performance. Moreover, technological innovations-such as AI-driven cutting optimization, cloud-based monitoring, and automated diagnostics-offer significant advantages to manufacturing units, pushing demand for advanced machinery.

Market Restraints

Despite its promising growth outlook, the cutting equipment market faces several restraints. One of the most prominent challenges is the high upfront cost of advanced cutting systems, especially laser and waterjet cutting machines. Small and medium-sized enterprises (SMEs) often struggle to invest in these high-value systems, which can limit adoption in emerging markets.

Another restraint is the shortage of skilled technicians who can operate and maintain sophisticated cutting equipment, particularly CNC and automated systems. As machinery becomes more advanced, the gap between required technical skills and available workforce continues to widen.

The market also faces challenges related to maintenance costs and operational downtime, as cutting equipment requires regular upkeep to ensure precision and safety. Additionally, fluctuations in raw material prices, especially metals, and slowdowns in industrial sectors such as automotive or construction can temporarily reduce demand for cutting machinery. Regulatory compliance, especially regarding emissions generated from certain cutting processes, may also create barriers for traditional systems like oxy-fuel cutting.

Do You Have Any Query Or Specific Requirement? Request Customization of Report: https://www.persistencemarketresearch.com/request-customization/13255

Market Opportunities

The future of the cutting equipment market presents abundant opportunities for growth and innovation. One of the biggest opportunities lies in the expansion of smart cutting technologies, including AI-powered cutting path optimization, IoT-enabled predictive maintenance, and cloud-based monitoring platforms. These advancements significantly improve efficiency, reduce waste, and support energy-efficient manufacturing.

There is also immense opportunity in emerging markets across Asia, Africa, and Latin America, where industrialization is accelerating rapidly. Manufacturers in these regions are increasingly investing in modern fabrication technologies to improve output quality and compete globally.

The growing electric vehicle (EV) sector represents another major opportunity. EV manufacturing requires high-precision cutting for battery enclosures, lightweight frames, and intricate components, boosting demand for advanced laser and plasma cutting equipment.

Sustainable manufacturing trends are pushing companies toward energy-efficient and eco-friendly cutting technologies, such as fiber lasers and cold cutting systems. As industries adopt greener processes, equipment manufacturers have the opportunity to introduce next-generation cutting systems with reduced energy consumption and lower carbon footprints.

Company Insights

• Colfax Corporation

• Lincoln Electric Holdings, Inc.

• ESAB

• Hypertherm Inc.

• Koike Aronson, Inc.

• Messer Cutting Systems

• Bystronic Laser AG

• Amada Co., Ltd.

• TRUMPF Group

• The Linde Group

Recent Developments:

Several global manufacturers have introduced next-generation fiber laser cutters with enhanced AI-driven automation systems designed to reduce waste and optimize operational speed.

Leading companies have expanded their product lines by integrating advanced CNC control technologies and digital monitoring tools to support remote diagnostics and maintenance.

Related Reports:

https://www.persistencemarketresearch.com/market-research/jaw-crusher-market.asp

https://www.persistencemarketresearch.com/market-research/metal-sanding-machines-market.asp

https://www.persistencemarketresearch.com/market-research/offset-printing-press-market.asp

https://www.persistencemarketresearch.com/market-research/pneumatic-valves-and-accessories-market.asp

https://www.persistencemarketresearch.com/market-research/ride-on-power-trowel-market.asp

https://www.persistencemarketresearch.com/market-research/ride-on-aerator-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cutting Equipment Market Set to Reach US$7.6 Billion by 2032, Says Persistence Market Research here

News-ID: 4272581 • Views: …

More Releases from Persistence Market Research

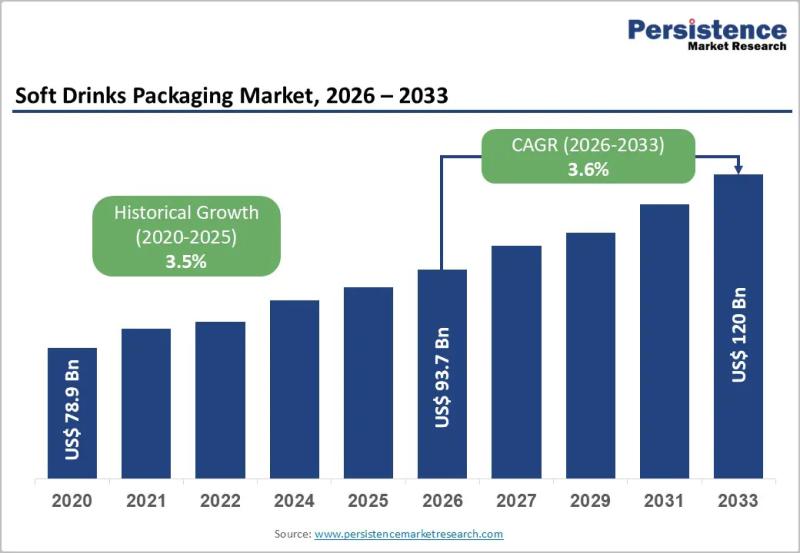

Soft Drinks Packaging Market to Reach US$120.0 Billion by 2033 - Persistence Mar …

The soft drinks packaging market plays a central role in the global beverage industry, serving carbonated drinks, juices, flavored water, energy drinks, and ready to drink teas and coffees. Packaging is no longer limited to containment and transportation; it has evolved into a critical component of branding, sustainability strategy, consumer convenience, and supply chain efficiency. Manufacturers are increasingly focusing on lightweight materials, recyclable packaging formats, and innovative designs that improve…

Christmas Tree Valves Market Size to Reach US$8.1 Billion by 2033 - Persistence …

The Christmas Tree Valves Market plays a critical role in the upstream oil and gas industry, serving as a central component in wellhead equipment systems. Christmas tree valves are installed on oil and gas wells to control pressure, regulate flow, and ensure safe extraction of hydrocarbons. These assemblies, commonly referred to as "Christmas trees," consist of multiple valves, spools, and fittings arranged in a structure that resembles a decorated tree.…

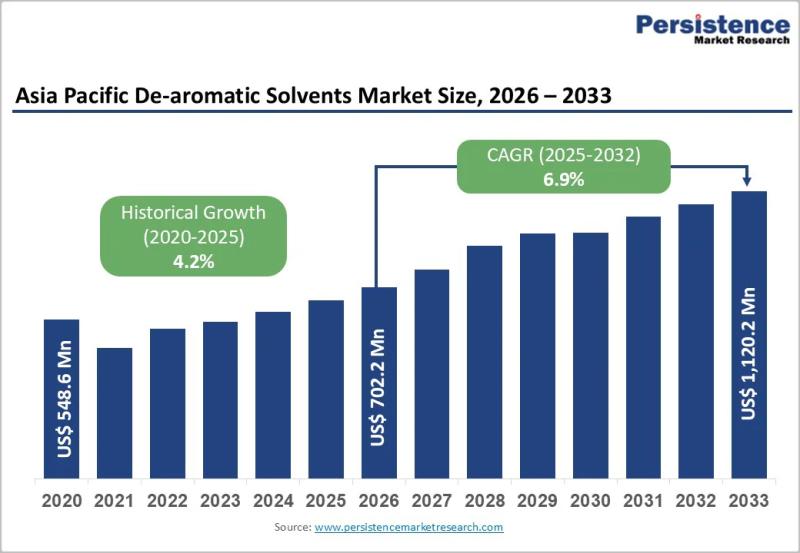

Asia Pacific De-aromatic Solvents Market to Reach US$1,120.2 Million by 2033 - P …

The Asia Pacific De-aromatic Solvents Market is gaining steady momentum as industries across the region increasingly shift toward low aromatic, high purity solvent formulations. De-aromatic solvents are hydrocarbon solvents that have significantly reduced aromatic content, making them suitable for applications requiring low odor, lower toxicity, and improved environmental performance. These solvents are widely used in paints and coatings, adhesives, inks, metalworking fluids, agrochemicals, and cleaning formulations. As regulatory scrutiny around…

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

More Releases for Cutting

Comparing CO2 Laser Cutting to Other Fabric Cutting Methods

Choosing the Right Tool for Precision and Efficiency

Choosing the correct focal length for your CO2 laser is crucial for achieving precise cuts, especially when working with laser cutting fabric. The focal length determines the laser beam's spot size and depth of focus, directly impacting cutting quality. Shorter focal lengths (e.g., 1.5" to 2") are ideal for fine details on thin materials, while longer focal lengths (e.g., 4" to 5") suit…

Cutting Edge Solutions: Analyzing the Booming Cutting Fluid Market

The global cutting fluid industry is poised for significant growth, with projections indicating a Compound Annual Growth Rate (CAGR) of 4.1% from 2023 to 2033. By 2033, the market is expected to achieve a valuation of USD 16.3 billion, underscoring its critical role in industrial manufacturing and machining processes.

Cutting fluids, often referred to as coolants or lubricants, play a pivotal role in industrial metalworking. These fluids are designed to reduce…

Is Die Cutting The Same As Cricut? What Is The Difference Between Die Cutting An …

Die cutting and Cricut are related but not exactly the same. Die cutting is a general term for the process of using a die to cut out shapes from various materials, such as paper, fabric, or metal. This can be done manually with a die cutting machine or press, or with the help of electronic die cutting machines like the Cricut.

Cricut is a brand of electronic die cutting machines that…

Profboard launches cutting-edge cutting board on Kickstarter

Image: https://www.getnews.info/wp-content/uploads/2024/06/1718783865.png

Revolutionizing Kitchen Safety and Convenience for Home Chefs

Profboard, the premier manufacturer of innovative cutting board systems, is proud to announce the launch of the Profboard Private edition. Since 2006, Profboard has been a trusted name among chefs and culinary enthusiasts worldwide. Now, the same professional-grade quality and innovation can be experienced in home kitchens.

Profboard sets a new standard with its cutting-edge cutting board system designed to revolutionize your kitchen.…

Fiber Laser Metal Cutting Machines Market Cutting-Edge Technology for Efficient …

Global Fiber Laser Metal Cutting Machines Market Overview:

The Fiber Laser Metal Cutting Machines market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Fiber Laser Metal Cutting Machines market has experienced significant growth, driven by factors such as increasing consumer demand,…

Metal Cutting Fluids Market Report 2018: Segmentation by Type (Emulsion Metal Cu …

Global Metal Cutting Fluids market research report provides company profile for Blaser, Idemitsu Kosan, Daido Chemical Industry, COSMO Oil, Master, Exxon Mobil Corporation, Houghton (Gulf Oil), BP, Fuchs, Yushiro Chemical, Quaker and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…