Press release

Strategic Insights into Ginger Processing 2025 : Plant Cost & Setup

The ginger industry has become one of the fastest-growing segments in the spice processing sector, supported by increasing consumer demand across global markets. Setting up a ginger processing plant requires more than just infrastructure; it involves strategic planning, investment, efficient equipment, and strong market awareness. This article presents an overview of ginger processing plants, covering setup, processing stages, market trends, investment considerations, and operational requirements.What About Ginger?

Ginger holds a significant position in the global spice market due to its distinctive flavor, aromatic properties, and extensive medicinal applications across traditional and modern healthcare systems. It is rich in bioactive compounds, particularly gingerol, and offers anti-inflammatory, digestive, and antioxidant benefits while being a versatile ingredient in culinary, pharmaceutical, and nutraceutical applications. The growing popularity of ginger in both household kitchens and health-conscious consumer segments has driven demand for processed and value-added products such as dried ginger, ginger powder, ginger oil, ginger paste, pickled ginger, and ginger extracts. Sustainable cultivation practices, organic certification, and quality assurance are becoming increasingly important, as consumers and regulators emphasize pesticide-free production, traceability, and authenticity in this widely consumed functional spice.

Request a Sample Report: https://www.imarcgroup.com/ginger-processing-plant-project-report/requestsample

What is Driving the Ginger Market?

The ginger market is primarily driven by rising consumer demand for natural health supplements and functional foods, alongside increasing awareness of ginger's therapeutic properties in preventing and managing various health conditions. Global production advancements, particularly in mechanized harvesting, post-harvest handling, and processing technologies, have improved yield quality and reduced losses, ensuring consistent supply to meet growing consumption. Expanding international trade, improved supply chain infrastructure, and the proliferation of health food stores have further facilitated wider accessibility across regions. Moreover, the popularity of ginger in beverages, dietary supplements, cosmetics, and ethnic cuisines is fueling demand in retail, foodservice, and pharmaceutical sectors. Population growth, urbanization, rising disposable incomes, and the wellness trend in emerging and developed economies also support market expansion. Organic certification, fair trade practices, and quality standardization programs are influencing consumer choices, aligning the industry with evolving preferences for authentic, high-quality, and responsibly sourced ginger products.

Understanding Ginger Processing

• Ginger processing refers to converting freshly harvested ginger rhizomes into safe, high-quality, and market-ready products for various applications.

• Processing activities include cleaning, washing, peeling, slicing, drying, grinding, oil extraction, quality testing, standardization, and packaging.

• Fresh ginger is perishable and prone to microbial contamination; therefore, strict hygiene standards, moisture control, and quality monitoring are vital.

• Efficiency in the process ensures consistent quality, compliance with food safety regulations, preservation of bioactive compounds, and appropriate shelf life for domestic and export markets.

Key Components of a Business Plan

• Executive Summary: Outlines vision, mission, and business objectives for the ginger processing enterprise.

• Market Research: Identifies demand patterns, consumer preferences, application segments, export opportunities, and competitive players in the spice processing industry.

• Operational Strategy: Includes plant design, processing capacity, product portfolio (dried, powdered, oil, paste), workflow optimization, and quality assurance measures.

• Marketing and Sales Plan: Defines distribution channels, branding strategies, B2B partnerships, and positioning in domestic retail, foodservice, pharmaceutical, and international spice markets.

• Financial Planning: Covers projected investments, cost structures, revenue expectations, working capital needs, and profitability analysis.

• Risk Assessment: Evaluates potential challenges such as raw material seasonality, price fluctuations, quality variations, regulatory compliance, and market competition.

Capital Investment Overview

CapEx (Capital Expenditure):

• Land acquisition, plant construction, drying facilities, storage warehouses, and specialized equipment purchase.

• One-time costs associated with establishing infrastructure, processing lines, quality control laboratories, and ensuring operational efficiency.

• Defines long-term production capacity, product quality standards, and market competitiveness.

Buy Report Now: https://www.imarcgroup.com/checkout?id=7618&method=1911

OpEx (Operating Expenditure):

• Recurring costs including labor, utilities, fuel for drying, packaging materials, storage, and transportation.

• Raw ginger procurement from farmers or aggregators and regular equipment maintenance.

• Compliance with food safety regulations, organic certifications, export standards, hygiene practices, and quality control programs.

Machinery and Equipment Requirements

Primary Equipment:

• Washing and cleaning systems for removing soil and impurities.

• Peeling machines (mechanical or abrasive peelers) for skin removal.

• Slicing and cutting equipment for uniform thickness.

• Drying systems including solar dryers, hot air dryers, or cabinet dryers with temperature control.

• Grinding and pulverizing mills for producing ginger powder.

• Oil extraction equipment using steam distillation or solvent extraction methods.

• Sieving and grading machines for particle size classification.

• Mixing and blending equipment for standardized products.

• Automated packaging machines including pouching, bottling, and sealing systems.

• Temperature and humidity-controlled storage facilities.

Supporting Equipment:

• Material handling conveyors and elevators.

• Boilers or heat generation systems for drying operations.

• Quality testing instruments for moisture analysis, microbial testing, and chemical composition.

• Water treatment and wastewater management systems.

• Dust collection and ventilation systems for powder processing areas.

Operating Costs

• Procurement of fresh ginger rhizomes from contract farmers, cooperatives, or open market sources.

• Labor salaries including processing workers, quality control staff, and supervisory personnel.

• Utilities such as electricity, water, fuel (diesel, LPG, or biomass) for drying and heating operations.

• Maintenance and servicing of dryers, grinding mills, extraction equipment, and processing machinery.

• Packaging materials including food-grade bags, pouches, bottles, containers, labels, and cartons.

• Transportation, warehousing, and distribution logistics for domestic and international markets.

• Certification costs (organic, HACCP, ISO), compliance activities, testing fees, and quality assurance programs.

Raw Materials

• Main Raw Material: Fresh ginger rhizomes sourced from contract farmers, agricultural cooperatives, or wholesale markets, selected based on variety, maturity, and quality grade.

• Additional Inputs: Packaging materials including food-grade plastic bags, paper pouches, glass or PET bottles, aluminum foil, and export-quality cartons.

• Auxiliary Materials: Processing aids for peeling, food-grade solvents for oil extraction (if applicable), preservatives for paste products, and desiccants for moisture control.

• Supply Considerations: Consistency of ginger quality and pungency levels, reliable sourcing partnerships with farmer groups, seasonal harvest management, adherence to organic cultivation practices (if targeting organic segment), and storage of raw material to ensure year-round processing capability.

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7618&flag=C

Frequently Asked Questions (FAQs)

1. What is the first step in setting up a ginger processing plant?

The process begins with developing a comprehensive business plan, identifying target product categories (dried, powder, oil, paste), securing suitable land preferably near ginger-growing regions, obtaining necessary food safety licenses and certifications, and establishing relationships with reliable ginger suppliers or farmer cooperatives.

2. Why is controlled drying considered critical in ginger processing?

Controlled drying prevents moisture-related spoilage and mold growth, preserves the bioactive compounds (gingerol and shogaol), maintains flavor and aroma characteristics, ensures product stability and extended shelf life, and helps meet domestic and international quality standards for dried spices.

3. Can ginger processing plants focus only on domestic markets?

Yes, though many plants also target exports, as international markets-particularly in Europe, North America, Middle East, and East Asia-show strong demand for high-quality dried ginger, ginger powder, and ginger oil, often offering premium pricing for certified organic and pesticide-free products.

4. How does automation benefit ginger processing?

Automation improves processing efficiency and throughput, reduces labor dependency and manual handling, ensures consistent product quality and particle size uniformity, minimizes contamination risks, enhances hygiene standards, and increases overall productivity while reducing processing costs per unit.

5. Is backward integration into ginger farming necessary?

Not mandatory; many processors rely on contract farming arrangements, procurement from farmer producer organizations, or spot market purchases for raw material supply. However, contract farming or direct farmer relationships can ensure consistent quality, reliable supply during peak processing seasons, better price stability, and the ability to implement specific cultivation practices aligned with processing requirements or organic certification needs.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excels in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Strategic Insights into Ginger Processing 2025 : Plant Cost & Setup here

News-ID: 4271098 • Views: …

More Releases from IMARC Group

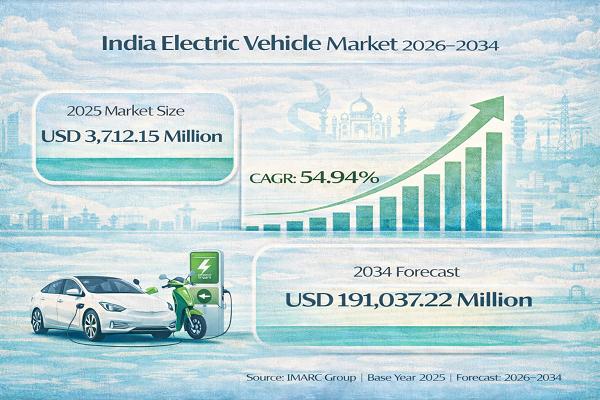

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Ginger

Ginger Beer Market

The "Ginger Beer Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Ginger Beer Market, 2024-2031

Verified Market Research's most recent report, "Ginger Beer Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth examination…

Ginger Beer Market Report Analysis, Research Studies | Crabbie"s Alcoholic Ginge …

DataM Intelligence has published a new research report on "Ginger Beer Market Size 2024". The report explores comprehensive and insightful Information about various key factors like Regional Growth, Segmentation, CAGR, Business Revenue Status of Top Key Players and Drivers. The purpose of this report is to provide a telescopic view of the current market size by value and volume, opportunities, and development status.

Get a Free Sample Research PDF -…

Ginger Oil Market Growing Demand for Ginger Oil in Food & Beverages across the G …

According to Precision Business Insights (PBI), the latest report, ginger oil market was valued at USD 11,654.9 million in 2022 and is poised to grow at CAGR of 3.8% during the forecast period 2023 to 2029. Increasing demand for ginger oil in the pharmaceutical industry and food and beverages industry. In addition, rising awareness associated with health benefits of ginger oil are the major key driving factors expected to grow…

Ginger Beer Market to Witness Astonishing Growth by 2029 | Barritt's Ginger Beer …

Ginger Beer may suggest that this beverage doesn't necessarily have alcohol content in it, Ginger Beer is actually a non-alcoholic drink. Originally, this firey drink was actually an alcoholic beverage made by fermenting water, sugar and ginger together.

The Ginger Beer Market research report is an expert's thorough research on the industry's current state. This statistical surveying report provides the most recent industry information and future trends, allowing you to identify…

Global Ginger Market: Increasing Awareness about Medicinal Properties of Ginger …

The global reach and acceptance for spices, especially for ginger have been increasing in recent years, presenting promising growth opportunities for large-scale manufacturers and processors of the spice that also promises vast health benefits, observes Transparency Market Research in a recent report. The global ginger market has multiple players, owing to which the vendor landscape is fragmented and is competitive in nature. The dominant players in the global ginger market…

Global Ginger Powder Ginger Extract Industry Market Analysis, Trends & Forecast …

Ginger Powder Ginger Extract Industry entails the qualitative and quantitative analysis of current and future market estimations. It also divulges details about the mode of research methodology used for the study. It includes data from primary as well as secondary resources.

The report is a useful resource for industry players, new entrants in the marketplace, and investors as it helps them plan their business to gain fruitful and meaningful outcomes.…