Press release

Battery Charger Manufacturing Plant Setup Report 2025: Industry Trends, Machinery and Cost Breakdown

Battery charger manufacturing involves the design, engineering, and production of devices that restore energy to rechargeable batteries used in consumer electronics, electric vehicles, industrial equipment, and energy storage systems. These chargers vary by application, including smart chargers, fast chargers, wireless chargers, and high-capacity chargers for EVs. The process includes component sourcing, circuit design, assembly, testing, safety compliance, and quality assurance to ensure efficient, reliable, and safe charging performance. Modern battery chargers integrate intelligent control systems, thermal management, and automation to optimize charging cycles and extend battery life.The battery charger market is witnessing robust growth driven by the rising adoption of smartphones, laptops, wearables, and portable electronics, along with the global shift toward electric mobility. Increasing sales of electric vehicles and expansion of charging infrastructure are major growth drivers. The proliferation of renewable energy systems and home energy storage solutions further boosts demand for efficient chargers. Technological advancements such as fast charging, wireless charging, and adaptive charging algorithms are enhancing user convenience and performance. Additionally, government initiatives promoting clean energy, reduced carbon emissions, and digitalization are encouraging manufacturers to innovate and scale up production. Growing industrial automation and the need for uninterrupted power supply are also contributing to market expansion.

IMARC Group's report, titled "Battery Charger Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a battery charger manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Battery Charger Industry Outlook 2025

The battery charger manufacturing industry is expected to witness robust growth in 2025, driven by explosive electric vehicle adoption, expanding consumer electronics markets, renewable energy storage deployment, power tool proliferation, and increasing portable device usage globally. The transition to electric mobility creates massive demand for residential, workplace, and public EV chargers across power levels. Smartphone, laptop, tablet, and wearable device growth sustains consumer charger demand, while renewable energy integration requires sophisticated battery management systems. Fast charging technology evolution, wireless charging adoption, USB Power Delivery standardization, and GaN (gallium nitride) semiconductor integration drive innovation. Asia-Pacific dominates production, while global markets demand higher efficiency, compact designs, universal compatibility, and smart connectivity features. Manufacturers invest in miniaturization, thermal management, IoT integration, and sustainable materials.

Request for a Sample Report: https://www.imarcgroup.com/battery-charger-manufacturing-plant-project-report/requestsample

Key Insights for setting up a Battery Charger Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Battery Charger Manufacturing Plant

• Land acquisition and factory building construction with ESD-protected areas

• Electronic component procurement (transformers, switching power supply ICs, MOSFETs, diodes, capacitors, resistors, inductors)

• Printed circuit boards (PCBs) with SMT assembly capability

• Microcontrollers and charging management ICs

• Connectors, cables, and plugs (USB, DC barrel, EV charging standards)

• Enclosure materials (plastic housings via injection molding or metal cases)

• PCB assembly equipment (pick-and-place machines, reflow ovens, wave soldering, selective soldering)

• Injection molding machines for plastic enclosures (if in-house)

• Testing equipment (power analyzers, electronic loads, safety testers, EMI/EMC chambers, temperature cycling chambers)

• Quality control laboratory with functional and safety testing stations.

Economic Trends Influencing Battery Charger Plant Setup Costs 2025

• Semiconductor and integrated circuit price fluctuations affecting power management chips

• Rising copper prices impacting transformers, inductors, and PCB costs

• Electric vehicle boom driving massive EV charger market expansion

• Import duties on electronic components and finished chargers

• Currency exchange rates affecting component procurement costs

• Consumer electronics growth sustaining demand for mobile and laptop chargers

• Fast charging technology requiring advanced power electronics

• Competition driving miniaturization and efficiency improvements

• GaN and SiC semiconductor adoption requiring new design investments

• Energy efficiency regulations mandating higher performance standards.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=9176&flag=C

Challenges and Considerations for Investors

• High dependency on imported electronic components and semiconductors

• Intense global competition from Chinese manufacturers with cost advantages

• Rapid technology evolution requiring continuous product development

• Multiple product variants needed for different devices, voltages, and standards

• Strict safety and electromagnetic compatibility certification requirements

• Component obsolescence and supply chain disruptions affecting production

• Thin profit margins in commodity consumer charger segments

• Quality consistency critical for safety and brand reputation

• Counterfeit product competition damaging market and brand perception

• Working capital requirements for diverse component inventory.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Battery Charger Manufacturing Plant Setup Report 2025: Industry Trends, Machinery and Cost Breakdown here

News-ID: 4270609 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

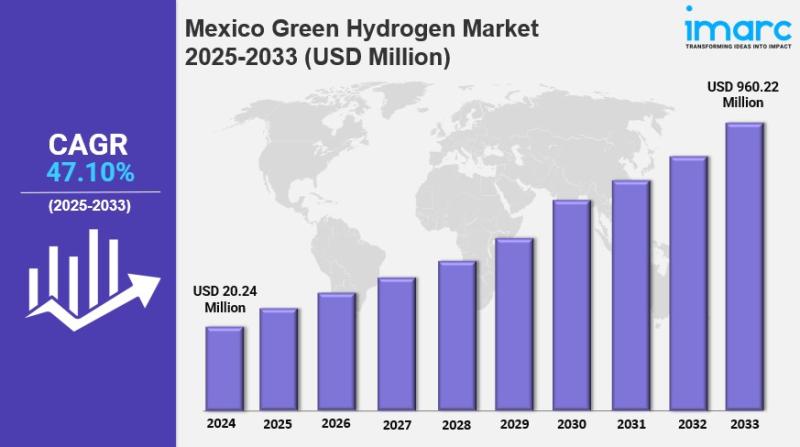

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…