Press release

What is UV DTF Printer? Industry Trends and Best Practices

Uv Dtf [https://www.boranprinters.com/uv-dtf/] printer, which stands for UV Direct-to-Film printer, is a cutting-edge digital printing machine that creates durable, high-quality, and full-color decals. It combines two powerful technologies: UV (Ultraviolet) printing and the DTF (Direct-to-Film) transfer process. Unlike traditional UV printers that print directly onto a flat, rigid surface, a UV DTF printer prints a design onto a special film. This film is then easily transferred and applied to a wide range of surfaces, including those that are curved, irregular, or difficult to print on directly.This technology has rapidly grown in popularity because it offers a simple, no-heat, and highly versatile solution for customizing almost any hard, non-porous object.

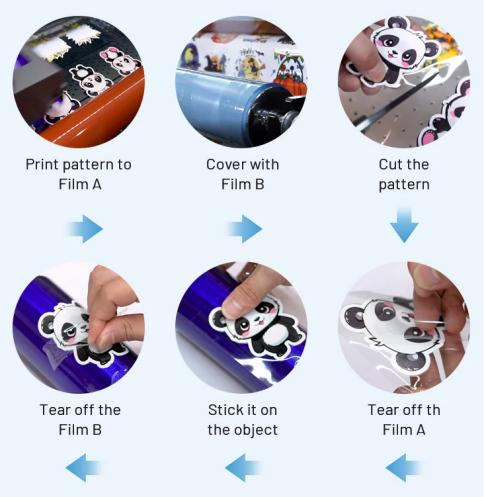

How a UV DTF Printer [https://www.boranprinters.com/dtf-printer-uv-dtf-printer/] Works: A Step-by-Step Breakdown

The process of creating and applying a UV DTF decal is a two-part system: printing the film and transferring the design.

1. The Printing Process (Printing onto the A-Film)

This is the "Direct-to-Film" part of the process. The printer uses specialized UV-curable inks and prints in a reverse order onto a release film, often called the "A-film." The layers are applied as follows:

Color Layer (CMYK): The printer first lays down the full-color design using CMYK (Cyan, Magenta, Yellow, Black) inks.

White Ink Layer: A layer of white ink is then printed directly on top of the color layer. This white background ensures that the colors of the design remain vibrant and opaque, regardless of whether the final object is dark or transparent.

Varnish/Gloss Layer: The final layer is a transparent varnish or gloss coat. This provides a protective barrier for the design, adding durability, scratch resistance, and a shiny, often tactile, raised texture.

As each layer of ink is applied, the built-in UV lamps inside the printer instantly cure and harden the ink. This immediate curing process creates a solid, durable, and slightly embossed design on the surface of the A-film.

2. The Transfer Process (Laminating and Applying with B-Film)

Once the design is fully printed and cured on the A-film, it's ready for the transfer stage.

Lamination: A second adhesive film, known as the "B-film," is laminated onto the printed A-film. The B-film is coated with a strong, permanent adhesive.

Peeling: The two films are pressed together, and the A-film is then peeled away. The printed design, with all its layers, now adheres perfectly to the sticky side of the B-film. This B-film can now be thought of as a ready-to-use sticker or transfer.

Application: The user simply places the B-film onto the desired object (e.g., a tumbler, phone case, or metal sign). Using their fingers or a squeegee, they apply firm, even pressure over the entire design.

Final Peel: After a few moments, the B-film is carefully peeled back, leaving the permanent, durable, and professional-looking UV DTF decal securely bonded to the object. No heat press is required, which is a major advantage

Image: https://ecdn6-nc.globalso.com/upload/p/2966/image_other/2025-09/how-uv-dtf-printer-works.png

Key Advantages of UV DTF Printing [https://www.boranprinters.com/dtf-printer-uv-dtf-printer/]

UV DTF technology offers significant benefits that set it apart from other printing methods.

1. Versatility and Wide Application Range: This is the most compelling advantage. Because the design is printed on a flexible film first, you can apply it to objects with irregular shapes, curves, or even textures. It works on almost any hard, non-porous material, including:

Glass and ceramics: Mugs, bottles, vases

Metals: Tumblers, keychains, industrial parts

Plastics: Phone cases, pens, custom packaging

Wood and acrylic: Signs, plaques, decorative items

Leather and PVC: Notebook covers, bags

2. Exceptional Durability and Quality: The UV-cured ink is highly resistant to water, scratches, abrasion, and fading from UV light. The printed image is sharp, vibrant, and has a tactile, raised effect that feels premium and professional.

3. No Heat Required: The transfer process is entirely cold. This means you can decorate heat-sensitive materials that would be damaged by a heat press. It also simplifies the process and reduces the need for additional equipment, making it a more accessible and efficient solution.

4. High Efficiency for Batch Production: You can print a full sheet of multiple UV DTF decals and then cut and store them for later use. This is perfect for fulfilling small-batch, on-demand, or personalized orders without a time-consuming setup for each item.

UV DTF vs. Other Printing Methods

It's helpful to understand how UV DTF compares to similar technologies.

UV DTF vs. Traditional UV Printing: Traditional UV printing requires a flatbed printer to print directly onto a flat object. While excellent for signs and flat surfaces, it can't handle a curved tumbler or a bottle with an irregular shape. UV DTF overcomes this limitation by transferring the design via a flexible film.

UV DTF vs. Regular DTF (Direct-to-Film) for Textiles: The key difference lies in the materials and application. Regular DTF uses water-based inks and a powdered adhesive to create transfers for fabrics and garments. The transfer is applied with a heat press. In contrast, UV DTF uses UV-curable inks and is for hard surfaces, with a simple, no-heat transfer process.

Conclusion

The UV DTF printer is a game-changer for the world of personalization and product branding. By liberating digital printing from the constraints of flat surfaces, it empowers businesses and creators to produce stunning, durable, and highly customized products with unparalleled ease and versatility. Whether for small-scale hobbyists or large-scale commercial operations, UV DTF technology offers a fast, efficient, and high-quality solution that is rapidly defining the future of product decoration.

We BORAN supply you 30cm and 60cm UV DTF printer with laminating as below, more details, Please whatsApp us: 008613621817141

Image: https://ecdn6-nc.globalso.com/upload/p/2966/image_other/2025-09/uv-direct-to-film-printer.jpg

Media Contact

Company Name: JIAXING BORAN DIGITAL TECHNOLOGY CO.,LTD

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=what-is-uv-dtf-printer]

Country: China

Website: https://www.boranprinters.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release What is UV DTF Printer? Industry Trends and Best Practices here

News-ID: 4269664 • Views: …

More Releases from ABNewswire

Otter Public Relations Awarded in the Excellence in Workplace Culture Award for …

ST. PETERSBURG, Fla. - Feb 23, 2026 - Otter Public Relations [https://otterpr.com/]was proudly awarded Excellence in Workplace Culture for Small Businesses for 2025.

Otter PR, founded by Scott Bartnick and Jay Feldman, is one of the nation's most highly rated and awarded PR firms. With over 300 years of combined experience, Otter PR is known for results-driven campaigns and securing valuable media coverage. Otter PR's team of publicists, writers, marketers, and…

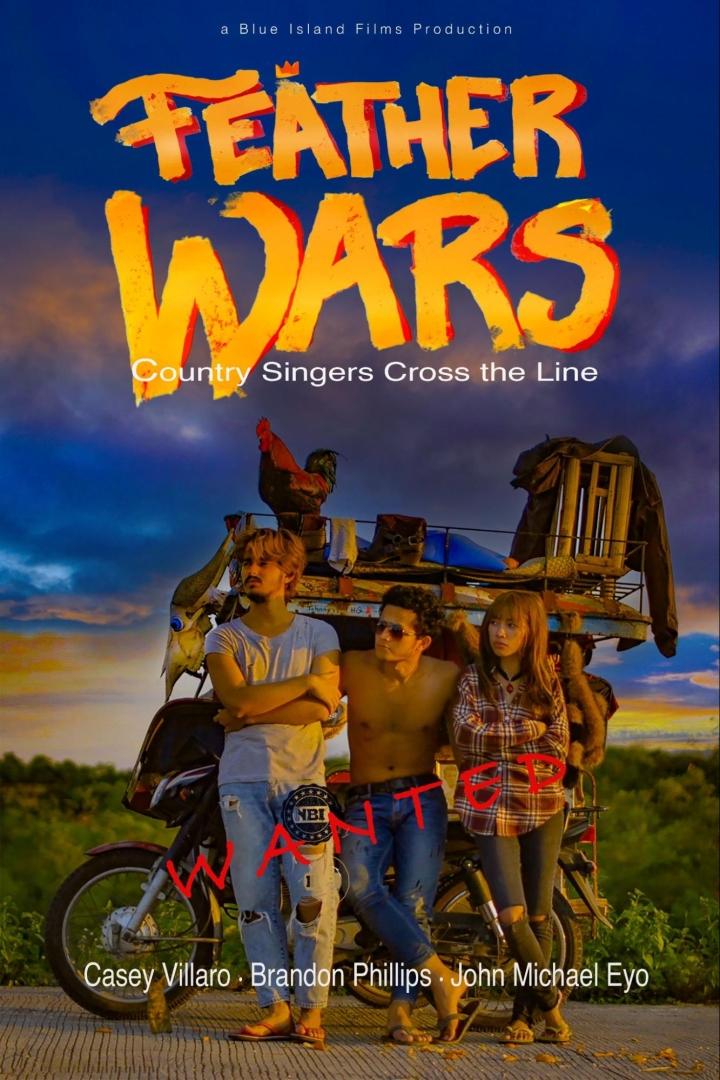

Philippine Coming-of-Age Film "Feather Wars" (2025) Wraps Production in Bohol, S …

Feather Wars is a 140-minute Filipino coming-of-age adventure comedy filmed in Bohol. Directed by Tim Fitzharris and produced by Jesse Fitzharris, it follows two teen musicians fleeing their abusive stepfather, funding their escape through underground cockfighting scams. Blending dark comedy, music, and family drama, the film highlights Filipino culture and earned international screenplay recognition before completing production in 2025.

BOHOL, PHILIPPINES - The Philippine independent film Feather Wars, a 140-minute coming-of-age…

BPOSeats Launches Flexible, Fully-Managed Office Solutions to Help BPOs and Star …

BPOSeats.com introduces plug-and-play office spaces designed for BPO companies, startups, and remote teams seeking cost-efficient, scalable, and fully managed workspace solutions across the Philippines.

Philippines - February 23, 2026 - BPOSeats.com, a leading provider of fully-managed office and seat leasing solutions, announces its continued expansion in supporting BPO companies, startups, and remote teams with flexible, scalable office infrastructure across the Philippines.

As businesses increasingly prioritize agility and cost efficiency, traditional long-term office…

Great Yarmouth Serviced Accommodation: QF Living Signs Pavilion Sands Apartment …

Two-bedroom coastal apartment near the seafront and River Yare, designed for leisure and business stays.

Image: https://www.abnewswire.com/upload/2026/02/d6ed430595914579b21c5f71bc16191e.jpg

Great Yarmouth, Norfolk - QF Living, a locally operated Great Yarmouth serviced accommodation provider, has expanded its portfolio with the signing of Pavilion Sands Apartment in Gorleston-on-Sea [https://qfliving.com/listing/pavilion-sands-apartment/], a newly launched two-bedroom coastal apartment located close to the seafront and near the mouth of the River Yare.

The addition strengthens QF Living's offering for leisure guests,…

More Releases for DTF

SAILLAGE Showcases its DTF Products at Global Exhibitions

SAILLAGE: A Global Participant in DTF Industry Exhibitions

As a forward-looking enterprise dedicated to the innovation and promotion of Direct-to-Film (DTF) printing technology, SAILLAGE has been actively participating in major global exhibitions since 2025, bringing its high-quality DTF products(https://www.saillage.com/dtf-film-series/) and professional solutions to industry peers and partners around the world. Through continuous participation in international and domestic industry events, SAILLAGE has not only demonstrated its strong R&D strength and product competitiveness…

Can You Recommend Top Reliable DTF Film Manufacturers

Introduction: Why the Right DTF Film Manufacturer Matters

When global textile printing, customization, and garment enterprises seek high-quality DTF (Direct to Film) film(https://www.saillage.com/dtf-film-series/), price is no longer the sole deciding factor. Modern buyers prioritize ink adhesion, transfer durability, material compatibility, and consistent batch-to-batch performance. Amid China's booming DTF film market, Shanghai Saillage International Trade Co., Ltd. has stood out as a trustworthy partner for global clients pursuing stable, high-performance DTF film…

DTF printerusa Unveils Comprehensive Guide: DTF Printing vs. Traditional Printin …

The printing industry has witnessed numerous technological advances, but few have been as transformative as Direct-to-Film (DTF) printing. To understand the true value proposition of DTF printer [https://dtfprinterusa.com/collections/dtf-printers-and-dryers] technology, it's essential to compare it comprehensively with traditional printing methods across various performance metrics, cost factors, and practical considerations.

Screen printing has long been the gold standard for high-volume apparel decoration, offering excellent durability and cost-effectiveness for large runs. However, DTF printing…

DTF CENTER Expands Market Reach with Premium DTF Transfers and Gang Sheets

Los Angeles, CA - DTF CENTER, a leading U.S. provider of Direct-to-Film (DTF) transfers and gang sheets, today announced its expanding role in the fast-growing custom apparel printing industry. With demand for personalized, durable, and cost-effective printing solutions on the rise, DTF CENTER is empowering businesses and entrepreneurs nationwide to scale their operations with professional-grade printing technology.

Driving Innovation in Apparel Printing

The apparel printing industry has undergone a rapid transformation, fueled…

DTF printing: exploring the application of DTF powder shaking thermal transfer f …

Direct-to-film (DTF) printing has become a revolutionary technology in the field of textile printing, with bright colors, delicate patterns and versatility that are difficult to match with traditional methods. One of the key components of DTF printing is the DTF powder shake thermal transfer film, which plays a vital role in the transfer process. This article will explore the application of DTF powder shake thermal transfer film and its main…

Why DTF Printing is Revolutionizing the Industry: Best DTF Printers, Inks, and F …

Whether you're looking to upgrade your printing process or start a new custom apparel business, Direct-to-film offers a future-proof solution.

Garment printing has developed into an industry with the evolution of new technologies, especially Direct-to-Film or (DTF). DTF printing is a versatile, durable, and cost-effective solution for custom apparel and textile designing. DTG Pro assures high-quality results with enhanced color vibrancy and long-lasting durability on all fabrics, including cotton, polyester, and…