Press release

Titanium Nitride Coating Market Set to Reach USD 3.3 Billion by 2035, Driven by Precision Manufacturing in APAC, Advanced Engineering in Europe, Sustainable Tooling in the USA, and Industrial Investments in Saudi Arabia

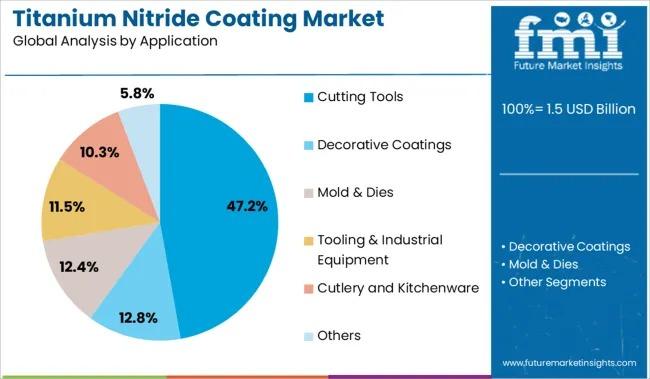

The global Titanium Nitride (TiN) Coating Market, valued at USD 1.5 billion in 2025, is projected to reach USD 3.3 billion by 2035, expanding at a compound annual growth rate (CAGR) of 7.8%, according to the latest industry analysis. The growth reflects rising adoption of surface enhancement technologies across high-performance industries seeking durability, precision, and sustainability in manufacturing.TiN coatings-celebrated for their exceptional hardness, wear resistance, and corrosion protection-have become indispensable in the automotive, aerospace, medical, and metalworking sectors. Their ability to extend component lifespan and reduce downtime positions TiN as a critical enabler of next-generation manufacturing efficiency.

Review the full report to examine in-depth market dynamics, strategic developments, and growth opportunities across key regions! Request Sample Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-22607

Key Market Drivers: Durability Meets Efficiency

The TiN coating market's momentum is fueled by the growing emphasis on high-precision manufacturing, environmental compliance, and production cost optimization. Physical Vapor Deposition (PVD) technology remains the industry standard due to its energy efficiency, coating uniformity, and low environmental footprint.

- Physical Vapor Deposition (PVD) accounts for 53.7% of total revenue in 2025, retaining leadership through 2035. Its versatility in coating complex geometries and superior adhesion drives widespread use in tool manufacturing and component finishing.

- Cutting tools represent the largest application segment, contributing 47.2% of market revenue in 2025, driven by the rising demand for precision machining in automotive, aerospace, and industrial tooling.

- Automotive applications lead end-use demand, accounting for 34.9% of revenue, as automakers increasingly use TiN coatings to improve component longevity, minimize friction, and enhance corrosion resistance.

Regional Market Insights

Asia-Pacific (APAC): The Epicenter of High-Performance Coating Expansion

The Asia-Pacific region commands the fastest growth, spearheaded by China (CAGR 10.5%) and India (CAGR 9.8%), accounting for nearly half of global volume expansion by 2035.

- China dominates the regional landscape with extensive investment in plasma-assisted deposition and vacuum sputtering technologies. Major hubs such as Suzhou and Shenzhen are scaling capacity to meet surging demand from the semiconductor, optics, and automotive sectors.

PVD expansion enables improved coating thickness and adhesion uniformity.

National R&D initiatives foster applications in aerospace and medical components.

- India, emerging as a competitive coatings hub, benefits from rapid tooling modernization, defense-sector localization, and growing use of multi-layer TiN-TiCN hybrid coatings for high-friction applications.

Indigenous PVD facilities support automotive and medical OEMs.

Medical device manufacturers adopt TiN for its biocompatibility and corrosion resistance.

Across APAC, the integration of TiN-coated tooling into high-speed machining lines underpins the region's leadership in precision manufacturing and sustainable production technologies.

Europe: Engineering Excellence and Advanced Surface Technologies

Europe remains a cornerstone of the TiN coating ecosystem, driven by Germany, France, and the United Kingdom, where innovation and regulatory frameworks converge to promote sustainable manufacturing.

- Germany (CAGR 9.0%) anchors the region with heavy investment in thin-film deposition systems for aerospace, defense, and precision machining. Companies such as Oerlikon Balzers and CemeCon AG are pioneering multilayer TiN coatings engineered for extreme thermal stability.

Aerospace manufacturers integrate TiN for improved fatigue resistance.

Automation and robotics sectors favor TiN-coated components to reduce maintenance cycles.

- France (CAGR 8.2%) demonstrates strong demand from defense contractors and industrial manufacturers, increasingly substituting traditional plating with environmentally friendly PVD coatings.

TiN is gaining prominence in luxury goods and watchmaking due to its gold-like finish and abrasion resistance.

United Kingdom (CAGR 7.4%) shows steady growth across medical, dental, and industrial machinery applications.

TiN coatings are now common in orthopedic implants and surgical tools, where antimicrobial and hypoallergenic performance is crucial.

Universities collaborate with defense manufacturers on nano-structured coatings for next-generation lightweight alloys.

Europe's focus on circular manufacturing, reduced waste, and high-precision tooling continues to reinforce its position as a technological innovator in surface engineering.

Acquire the complete report to access detailed projections, country-level insights, company share assessments, and technology outlooks! Buy Full Report: https://www.futuremarketinsights.com/checkout/22607

United States: Sustainable Tooling and Functional Coating Innovation

The U.S. market is projected to grow at a 6.6% CAGR through 2035, supported by re-industrialization initiatives and sustainability mandates across advanced manufacturing sectors.

- Adoption of PVD and CVD systems in machining and aerospace facilities is improving tool longevity and reducing total lifecycle costs.

- The aerospace and defense industries increasingly rely on TiN coatings for engine components and high-stress fasteners.

- The medical device sector is emerging as a secondary growth pillar, with TiN's biocompatibility ensuring its use in surgical instruments and implants.

The rise of Industry 4.0 tooling automation, combined with high demand for wear-resistant surfaces, is solidifying the U.S. as a leader in high-value functional coatings.

Saudi Arabia: Strategic Investments Under Vision 2030

Under the Saudi Vision 2030 initiative, the Kingdom is building an industrial ecosystem that incorporates surface engineering and coating technologies to advance aerospace, defense, and renewable energy manufacturing.

Government-backed collaborations with global coating specialists are introducing localized PVD and CVD deposition capabilities for aerospace tooling, oilfield equipment, and precision components. TiN coatings are being prioritized for high-temperature and corrosion-resistant applications, aligning with the country's broader materials innovation and sustainability goals.

Saudi Arabia's industrial diversification strategy positions it as the Middle East's emerging TiN coating hub, linking raw material supply, research, and applied manufacturing.

Competitive Landscape: Consolidation and Technology Leadership

The titanium nitride coating market is moderately consolidated, with Oerlikon Balzers holding an estimated 26.5% global market share. The company's proprietary PVD technologies and extensive service network underscore its dominance.

Tier 2 and 3 suppliers-including voestalpine eifeler Group, NISSIN ELECTRIC Co., Ltd., Wallwork Heat Treatment Ltd, ACREE Technologies Inc., and SurfTech Inc.-leverage regional specialization and customized formulations to serve diversified end-use sectors.

Recent industry developments include:

- Eco-friendly PVD and CVD systems introduced by Oerlikon Balzers and IHI Ionbond AG, reducing process emissions while improving coating adhesion and thickness control.

- Precision multilayer deposition advancements supporting aerospace and medical implants with enhanced fatigue strength and biocompatibility.

- Automation-integrated coating systems designed for predictive maintenance and consistent production quality in high-throughput environments.

This convergence of technology innovation and sustainability compliance is reshaping competitive dynamics and pushing coating performance standards higher.

Outlook: The Future of Engineered Surfaces

The titanium nitride coating market is transitioning from a specialized industrial solution to a mainstream productivity enabler across global manufacturing. With CAGR 7.8%, the sector's expansion through 2035 will be anchored by:

- Rapid industrialization and tooling modernization in APAC,

- Engineering excellence and regulatory strength in Europe,

- Sustainable re-industrialization in the USA, and

- Strategic industrial transformation in Saudi Arabia.

As industries converge on durability, efficiency, and environmental stewardship, titanium nitride coatings stand at the intersection of innovation and resilience-a benchmark for the next generation of advanced materials and surface technologies.

Browse Complete Report: https://www.futuremarketinsights.com/reports/titanium-nitride-coating-market

Exploring Insights Across Emerging Global Markets:

Zeolite for Detergents Market: https://www.futuremarketinsights.com/reports/zeolite-for-detergents-market

Zinc Chloride Market: https://www.futuremarketinsights.com/reports/zinc-chloride-market

Polysilicon Market: https://www.futuremarketinsights.com/reports/polysilicon-market

Metalworking Fluids Market: https://www.futuremarketinsights.com/reports/metal-working-fluids-market

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Titanium Nitride Coating Market Set to Reach USD 3.3 Billion by 2035, Driven by Precision Manufacturing in APAC, Advanced Engineering in Europe, Sustainable Tooling in the USA, and Industrial Investments in Saudi Arabia here

News-ID: 4262126 • Views: …

More Releases from Future Market Insights

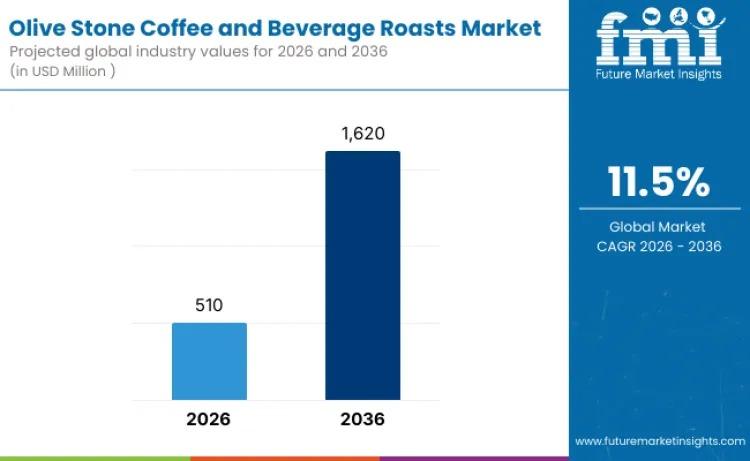

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

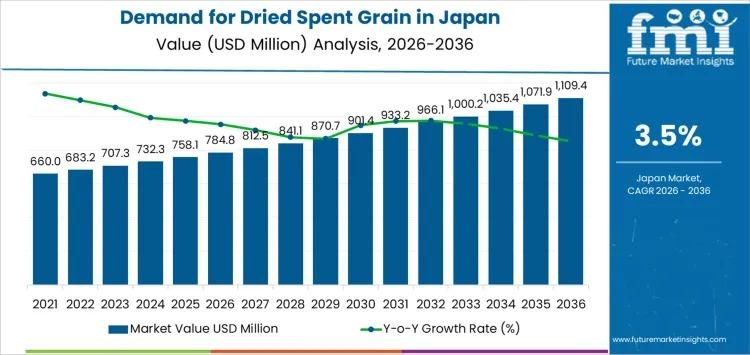

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

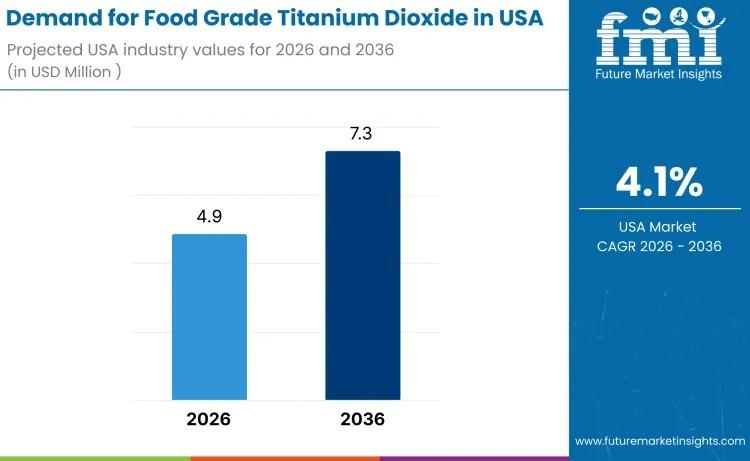

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

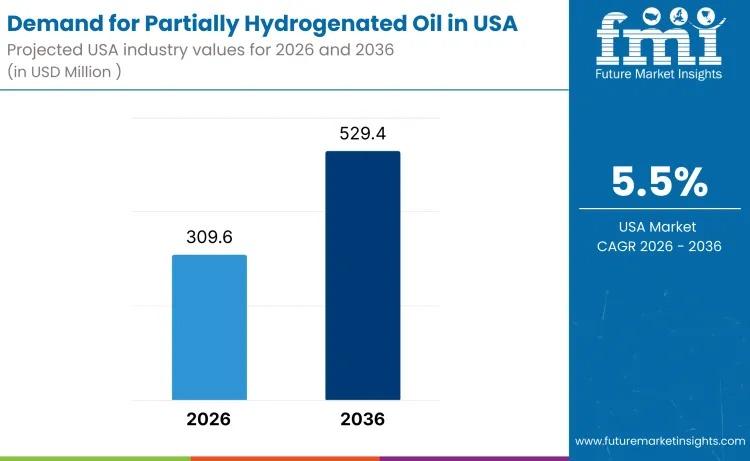

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for TiN

eTattoos Market Growth | Trends, Demand & Key Players 2024-2032 | Google LLC, Ti …

Global eTattoos Market Size, Status, and forecast for the 2025-2032. The research provides accurate economic, global, and country-level predictions and analyses. It provides a comprehensive perspective of the competitive market as well as an in-depth supply chain analysis to assist businesses in identifying major changes in industry practices. The market report also examines the current state of the eTattoos Market industry, as well as predicted future growth, technological advancements, investment…

Tin Selenide

Global Info Research announces the release of the report "Global Tin Selenide Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company…

Digital Tattoo Market to Witness Growth Acceleration | Fortune Tattoo, Tin-Tin T …

Digital tattoo is to a temporary tattoo that is outfitted with electronics, such as sensors or a near field communication (NFC) chip. A digital tattoo also refers to the permanent nature of a person's actions and communications online, also known as a digital footprint.

The Comprehensive study on Digital Tattoo includes historical data as well as share, size, and projection information for the major players, geographies, applications, and product categories for…

Global Indium Tin Oxide Market, Global Indium Tin Oxide Industry, Covid-19 Impac …

Indium tin oxide (ITO) involves of tin oxide and indium oxide prevail in solid form and on the weight basis indium oxide contains 10% tin oxide and 90% indium oxide. It is a transparent directing oxide member. Several indium tin oxide applications comprise heat reflective coatings, touch panels, electroluminescent display photovoltaic, gas sensors, LCD displays, electrochromic, field emission displays, plasma displays, and energy-effectual window.

According to the report analysis, ‘Global…

Global Tin Foil Market, Global Tin Foil Industry, Market Revenue, Tin Foil Bakin …

Tin foil is a versatile material, which is used in various packaging applications such as wrappers, household foil, pouches, blister packs, and lids. It is recyclable and therefore represents a beneficial opportunity for manufacturers as increasing recovery & collection rates for product mean less production cost along with improved profitability. It possess significant characteristics including better thermal & electrical conductivity, non-absorptive to grease, water, light, and oil, superior formability, and…

Global Tin(II) Methanesulfonate Market Top Player 2019 - Dow, TIB Chemicals, Hub …

Market Research store investigators figure the most recent report on “Tin(II) Methanesulfonate Market Will reaches at CAGR with Significant Growth”, according to their latest report. The Tin(II) Methanesulfonate Market report covers the overall and all-inclusive analysis of the Tin(II) Methanesulfonate Market with all its factors that have an impact on market growth. This report is anchored on the thorough qualitative and quantitative assessment of the global Tin(II) Methanesulfonate Market. The…