Press release

How to Start an Isoborneol Flakes Production Plant - Investment & Process Details

Comprehensive Guide to Setting Up an Isoborneol Flakes Production PlantIMARC Group's Isoborneol Flakes Production Plant Analysis Report 2025 provides users with a complete roadmap to successfully set up an isoborneol flakes production facility.

The report offers detailed insights into industry trends, plant setup guidance, machinery and technology requirements, raw material and utility needs, infrastructure planning, manpower allocation, packaging solutions, and transportation logistics. It also provides an in-depth financial evaluation including capital investment, project funding, operating expenses, fixed and variable costs, income and expenditure projections, expected ROI, net present value (NPV), and profit and loss analysis.

Designed for entrepreneurs, investors, and industry stakeholders, this report serves as a comprehensive resource for financial planning, investment decision-making, and efficient production management in the isoborneol flakes sector.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/isoborneol-flakes-manufacturing-plant-project-report/requestsample

What is Isoborneol Flakes?

Isoborneol flakes are white crystalline organic compounds derived from camphene or camphor through hydrogenation or reduction processes. Known for their strong camphor-like odor, they are widely used in the production of fragrances, flavors, pharmaceuticals, and intermediates for chemical synthesis. Isoborneol's excellent chemical stability and aromatic properties make it a preferred ingredient in cosmetics, daily-use products, and fine chemicals manufacturing.

What's the Process of Isoborneol Flakes Manufacturing/Production?

The production of isoborneol flakes typically involves the chemical reduction of camphor or oxidation of borneol, using reducing agents like sodium borohydride or catalytic hydrogenation. The process includes reaction, distillation, crystallization, and drying to produce pure, solid isoborneol flakes. Proper temperature control and purification are critical to ensure product consistency and purity, which determine the compound's suitability for pharmaceutical and fragrance applications.

Key Insights for Isoborneol Flakes Production Plant Setup:

Detailed Process Flow: Unit Operations and Quality Standards:

• Unit Operations: Reaction, cooling, crystallization, separation, drying, and packaging.

• Quality Assurance: Conformance to purity standards (≥98%), odor stability, and melting point consistency.

• Technical Tests: GC-MS analysis, IR spectroscopy, and moisture content testing.

• Raw Material Requirements: Camphor, hydrogen, reducing agents, solvents, and stabilizers.

An isoborneol flakes production facility typically follows multiple reaction and purification stages to achieve high yield and product purity. Strict quality control ensures compliance with pharmaceutical-grade and industrial-grade standards for safety and performance.

Land, Location, and Site Development:

• Selection Criteria: Near chemical manufacturing zones with strong logistics and utility access.

• Site Development: Includes drainage systems, reactor foundations, and chemical storage safety setups.

• Environmental Impact: Must meet local environmental and effluent treatment standards.

• Land Requirement and Costs: Generally 1,000-3,000 square meters depending on capacity.

A strategically located plant reduces supply chain costs and ensures smoother raw material procurement.

Plant Layout: Importance and Influencing Factors:

• Designated Zones: Separate areas for reaction, crystallization, and packing.

• Layout Factors: Workflow efficiency, safety compliance, and space optimization.

• Operational Benefits: Reduced handling losses, better safety, and higher throughput.

An efficient layout enables streamlined operations and easy scalability for future production expansion.

Plant Machinery: Requirements and Costs:

• Essential Equipment: Reactors, condensers, crystallizers, centrifuges, dryers, filtration units, and packaging machines.

• Cost Considerations: Varies based on automation level and capacity.

• Supplier Support: Machinery installation, maintenance, and performance testing assistance available.

Reliable equipment enhances production consistency, safety, and reduces operational downtime.

Raw Materials: Procurement and Costs:

• Feedstock Options: Camphor, borneol, or turpentine oil derivatives.

• Procurement Strategy: Source from certified chemical suppliers with stable pricing contracts.

• Cost Factors: Influenced by raw material purity, transportation, and seasonal fluctuations.

Ensuring consistent feedstock supply is crucial for minimizing production disruptions.

Packaging: Requirements and Suppliers:

• Packaging Materials: Polyethylene-lined drums or HDPE bags.

• Procurement Needs: Must ensure moisture resistance and chemical stability.

• Cost and Compliance: Packaging must comply with transport and export regulations.

Packaging integrity is vital for maintaining product quality and preventing contamination during shipment.

Other Requirements and Costs:

• Transportation: Efficient logistics for raw material and finished product distribution.

• Utilities: Reliable power, steam, and water supply.

• Energy and Water: Systems for process cooling, heating, and recycling.

• Human Resources: Skilled chemists, process engineers, and operators.

Operational efficiency depends heavily on trained manpower and reliable utilities.

Project Economics: Costs and Profitability:

• Capital Investment: Covers land, infrastructure, and machinery procurement.

• Operating Costs: Includes raw materials, labor, energy, and maintenance.

• Revenue and Margins: Depend on product grade, yield, and market price stability.

Proper cost optimization and pricing strategy ensure steady profitability.

Financial Analysis: Investment Returns and Risk Assessment:

• Performance Metrics: ROI, IRR, and payback period analysis.

• Return on Investment: Evaluates short- and long-term profitability.

• Risk Factors: Raw material price volatility, regulatory shifts, and competition.

A thorough feasibility and sensitivity analysis helps mitigate investment risks.

Other Analysis Covered: Market Trends and Strategic Insights:

• Market Trends: Rising demand from fragrance and pharmaceutical sectors.

• Segmentation: Divided by purity grade, end-use, and region.

• Regulatory Environment: Governed by REACH and EPA compliance.

• Case Studies: Highlights of successful small- and medium-scale producers.

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=9141&flag=C

Conclusion:

Establishing an isoborneol flakes production plant requires a structured approach covering site selection, chemical process optimization, machinery procurement, and financial evaluation. With the increasing global demand for aromatic chemicals and eco-friendly production methods, this industry presents significant opportunities for investors seeking high-return chemical manufacturing ventures.

Frequently Asked Questions (FAQs) about Isoborneol Flakes Production Plant Setup:

1. What are the unit operations involved in an isoborneol flakes production plant?

2. What is the total land area required for setting up an isoborneol flakes manufacturing unit?

3. What are the machinery and equipment requirements for establishing an isoborneol flakes plant?

4. What are the raw materials and utilities needed for isoborneol flakes production?

5. What are the capital and operating costs involved in setting up an isoborneol flakes production facility?

6. And more

Services:

• Market Entry and Opportunity Assessment

• Competitive Intelligence and Benchmarking

• Procurement Research

• Pricing and Cost Research

• Sourcing Partner Identification

• Distribution Partner Identification

• Contract Manufacturer Identification

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally.

Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Start an Isoborneol Flakes Production Plant - Investment & Process Details here

News-ID: 4258695 • Views: …

More Releases from IMARC Group

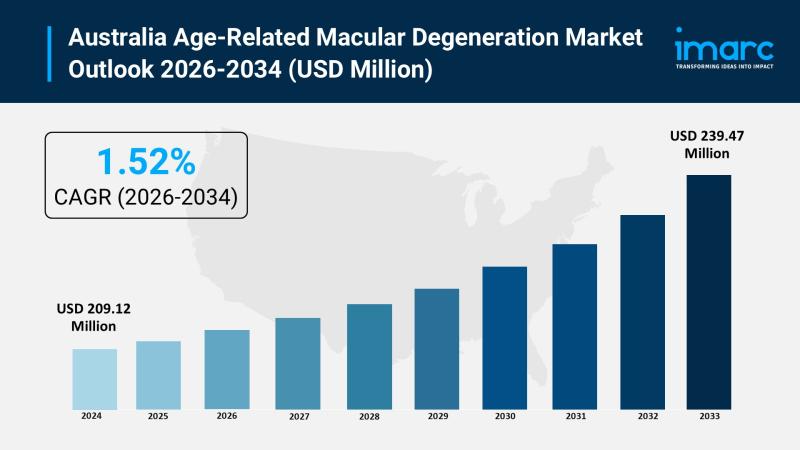

Australia Age-Related Macular Degeneration Market | Worth USD 239.47 Million 202 …

Market Overview

The Australia age-related macular degeneration market reached USD 209.12 Million in 2025 and is projected to grow to USD 239.47 Million by 2034. The forecast period spans from 2026 to 2034 with an anticipated CAGR of 1.52%. Key growth drivers include Australia's rapidly aging population, enhanced government reimbursement policies, and advancements in artificial intelligence enabling early diagnosis and disease monitoring. These factors collectively boost treatment accessibility and expand the…

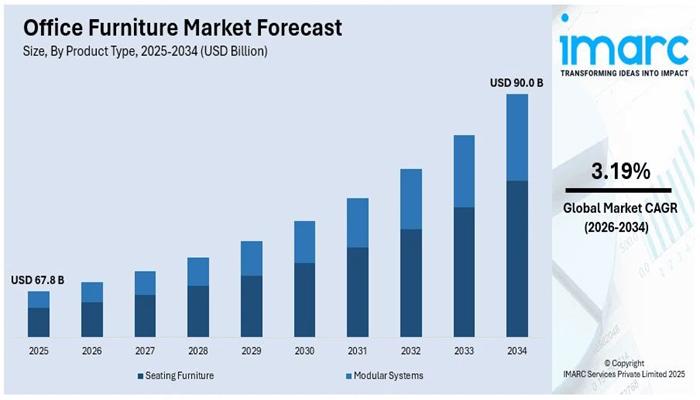

Global Office Furniture Market to Grow at 3.19% from 2026-2034, Driven by Growin …

Market Overview

The global office furniture market was valued at USD 67.8 Billion in 2025 and is projected to reach USD 90.0 Billion by 2034, exhibiting a CAGR of 3.19% over the forecast period 2026-2034. Market growth is attributed to corporate expansions, rising demand for ergonomic furniture, and the greater number of coworking spaces. Presently, Asia Pacific dominates the market with a share of more than 36%.

Study Assumption Years

• Base Year: 2024

• Historical…

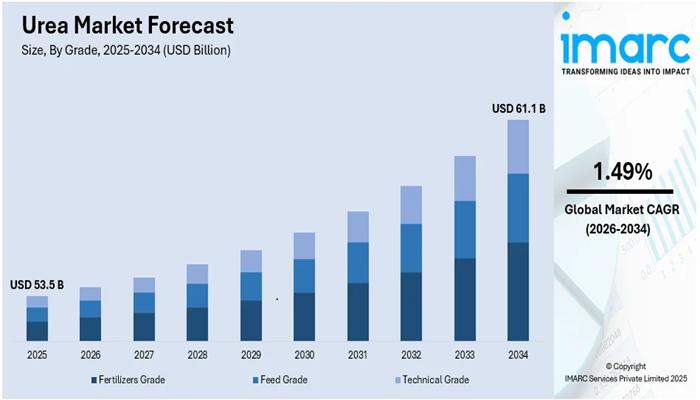

Global Urea Market Size to Surpass USD 61.1 Billion by 2034, Asia-Pacific holdin …

Market Overview

The global urea market was valued at USD 53.5 Billion in 2025 and is projected to reach USD 61.1 Billion by 2034, growing at a CAGR of 1.49% during the forecast period of 2026-2034. Asia Pacific is forecasted to control the market with a market share of more than 45. 2% in 2025 as a result of the high population density that is driving food demand, widespread agricultural activities,…

Global Aluminum Extrusion Market Report 2025: Size Projected USD 185.2 Billion, …

Market Overview

The global aluminum extrusion market was valued at USD 97.4 Billion in 2024 and is expected to reach USD 185.2 Billion by 2033, growing at a CAGR of 7.4% during the forecast period of 2025-2033. Asia-Pacific held the largest market share of over 74.0% in 2024, driven by factors such as sustainable architecture, availability of raw materials, lower manufacturing costs, and extensive use of aluminum extrusions in construction and…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…