Press release

Carbide Tools Market to Reach USD 16.9 Billion by 2035 - Expansion Accelerates in Asia-Pacific, North America, Europe, and EV Manufacturing

The global carbide tools market is poised for robust expansion through 2035, fueled by precision engineering demands, electric vehicle (EV) production, and advancements in high-speed machining. According to Future Market Insights (FMI), the market stands at USD 8.7 billion in 2025 and is forecasted to hit USD 16.9 billion by 2035, growing at a compound annual growth rate (CAGR) of 6.9%.The FMI report, "Carbide Tools Market Size, Trends & Forecast 2025-2035," projects an incremental revenue gain of USD 8.2 billion over the decade, driven by the adoption of wear-resistant, nanostructured coatings and AI-optimized tooling in automotive, aerospace, and renewable energy sectors.

A Decade of Growth Anchored by EV Transition and Smart Machining:

The shift toward lightweight materials in EVs and sustainable manufacturing is redefining carbide tool applications. From 2025 to 2030, the market is expected to add USD 4.1 billion, propelled by aerospace alloy machining and industrial automation. Between 2030 and 2035, FMI anticipates another USD 4.1 billion in growth, supported by hybrid carbide composites, digital twin integration, and closed-loop recycling programs.

Carbide Tools Key Market Insights at a Glance:

- Global Estimate Market Value (2025)- USD 8.7 billion

- Forecast Value (2035)- USD 16.9 billion

- CAGR- 6.9%

- Top Segment- Cutters & Drills (dominant share) Leading Configuration- Machine-based (majority revenue) Fastest-Growing Region- Asia-Pacific (highest regional CAGR)

Asia-Pacific: The Fastest-Growing Carbide Tools Hub:

The Asia-Pacific region leads global momentum, bolstered by automotive giants in China, Japan, India, and South Korea. Infrastructure investments, precision electronics, and government-backed automation initiatives are key accelerators. EV battery assembly and semiconductor micro-machining further amplify demand for ultra-hard carbide drills and mills.

North America and Europe follow with mature aerospace and automotive bases, emphasizing high-strength alloy processing and sustainability-compliant tooling.

Carbide Tools Five Forces Driving Market Expansion:

- EV & Lightweight Materials: Demand for machining high-strength alloys and composites in battery and chassis production.

- Smart Machining Solutions: AI-powered wear monitoring, real-time feed adjustments, and IoT-enabled predictive maintenance.

- Advanced Coatings: Nanostructured DLC and titanium aluminium nitride for enhanced thermal stability and tool longevity.

- Sustainability Initiatives: Carbide recycling programs reducing raw material dependency and environmental impact.

- Automation Surge: CNC integration and Industry 4.0 adoption boosting machine-based carbide tool efficiency.

Carbide Tools Market Segment Overview:

- By Tool Type: Cutters and drills command the largest share, essential for high-speed milling, hole-making, and 3D profiling in aerospace and automotive. Ball end cutters reduce machining time by up to 30%.

- By Configuration: Machine-based tools dominate, driven by CNC automation; hand-based variants grow in custom prototyping.

- By Fabrication: Coated tools lead with superior wear resistance; non-coated options serve cost-sensitive applications.

- By End Use: Transportation (including EV and aerospace) holds the top position, followed by metal fabrication and heavy machinery.

Carbide Tools Market Regional Overview:

- North America: USD growth at 7.0% CAGR average, led by U.S. EV and aerospace investments (USA at 7.2% CAGR).

- Europe: Steady expansion to support EV OEMs and precision engineering (EU at 6.8% CAGR; UK at 6.5%).

- Asia-Pacific: Fastest regional growth from automotive, electronics, and infrastructure (Japan 6.7%;

- South Korea 6.9%). Other Regions: Latin America, Middle East & Africa gain from construction and oil & gas tooling needs.

Carbide Tools Market Competitive Landscape:

- Sandvik AB

- Kennametal Inc.

- Iscar Ltd. (IMC Group)

- Mitsubishi Materials Corporation

- Walter AG (Sandvik Company)

- Guhring KG

- Sumitomo Electric Industries, Ltd.

- YG-1 Co., Ltd.

- Tungaloy Corporation

- Kyocera Corporation

Top players like Sandvik (15-20% share) and Kennametal (12-16%) hold over 40% combined, focusing on AI-optimized coatings, solid carbide innovations, and sustainable sourcing. Emerging digital-first manufacturers are challenging with smart, sensorized solutions.

Carbide Tools Market Outlook: Precision Redefined for a Sustainable Future:

Through 2035, carbide tools will integrate graphene-enhanced materials, self-healing coatings, and cloud-based analytics, transitioning from durable cutters to data-driven productivity engines. As EV production, renewable energy components, and medical device manufacturing scale, leaders blending AI analytics with recycled carbide supply chains will capture the next wave of innovation.

Explore the full market insights and future trends-read the complete Market Report today! : https://www.futuremarketinsights.com/reports/sample/rep-gb-1775

Buy Now Report Here: https://www.futuremarketinsights.com/checkout/1775

Related Reports:

Industrial Linear Accelerator Market

https://www.futuremarketinsights.com/reports/industrial-linear-accelerator-market

United States Plastic-to-fuel Market

https://www.futuremarketinsights.com/reports/us-plastic-to-fuel-market

North America Backflow Preventer Market

https://www.futuremarketinsights.com/reports/north-america-backflow-preventer-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Carbide Tools Market to Reach USD 16.9 Billion by 2035 - Expansion Accelerates in Asia-Pacific, North America, Europe, and EV Manufacturing here

News-ID: 4258010 • Views: …

More Releases from Future Market Insights

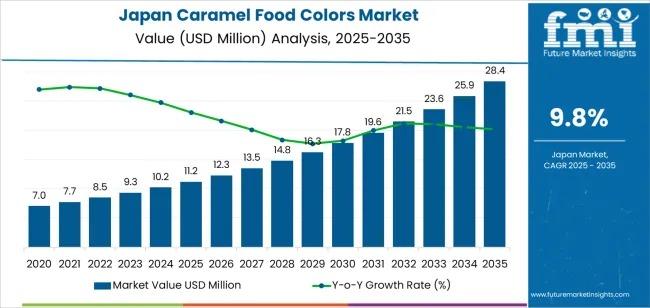

Japan Caramel Food Colors Industry Outlook to 2036: Strategic Insights for R&D, …

The Japanese caramel food colors market is on a steady growth trajectory, with demand projected to rise from USD 11.2 million in 2025 to USD 28.4 million by 2035, registering a CAGR of 9.8%. The initial phase of the forecast period (2025-2030) anticipates a steady increase in demand, reaching approximately USD 17.8 million by 2030, driven by the expanding use of caramel colors across confectionery, dairy, and baked goods.

The market's…

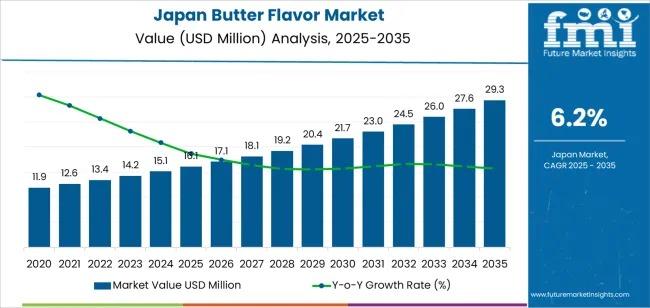

Comprehensive Analysis of the Japan Butter Flavor Market: Technology Evolution, …

The demand for butter flavor in Japan is projected to rise from USD 16.1 million in 2025 to USD 29.4 million by 2035, reflecting a steady compound annual growth rate (CAGR) of 6.2%. This growth is underpinned by increasing adoption across bakery products, confectionery items, and dairy-based preparations, as manufacturers seek to enhance taste experiences and deliver authentic dairy character in a wide range of food offerings.

The Japanese bakery and…

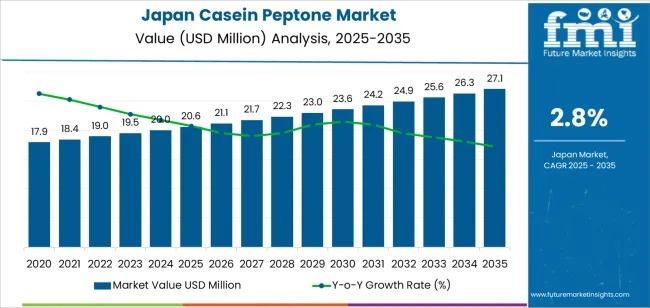

Japan Casein Peptone Market Deep-Dive 2026-2036: Strategic Forecasts, Market Ent …

The demand for casein peptone in Japan is projected to grow steadily, reaching USD 27.1 million by 2035, up from USD 20.6 million in 2025, reflecting a compound annual growth rate (CAGR) of 2.8%. During the early forecast period (2025-2030), demand is expected to rise from USD 20.6 million to approximately USD 23.6 million, supported by its widespread applications in biotechnology, pharmaceuticals, and food industries. Casein peptone continues to play…

Global Boride Powder Market Size, Share & Forecast: High-Growth Segments, Value …

The global boride powder market is valued at USD 19.7 billion in 2025 and is projected to reach USD 32.2 billion by 2035, advancing at a steady 5.0% CAGR over the forecast period. This upward trajectory reflects increasing adoption of boride-based compounds in aerospace technology, high-temperature processing environments, and advanced coating applications, where exceptional thermal stability, corrosion resistance, and mechanical strength are essential for operational performance and product reliability.

Key Market…

More Releases for Carbide

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…