Press release

How to Launch a Cotton Bags Manufacturing Plant: Detailed Process Flow, Project Details, Requirements and Costs Involved

Comprehensive Guide to Setting Up a Cotton Bags Manufacturing Plant:IMARC Group's Cotton Bags Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue provides a complete roadmap for successfully establishing a cotton bags manufacturing plant.

The report covers market trends, plant setup guidance, detailed machinery and technology requirements, raw material and utility needs, infrastructure planning, manpower requirements, packaging solutions, and transportation logistics. It also includes an extensive analysis of project economics, detailing capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI, net present value (NPV), and profit and loss account assessments. Developed for investors, entrepreneurs, and industry stakeholders, the report enables informed decision-making through robust financial analysis and strategic operational insights.

How are cotton bags manufactured?

Cotton bags are manufactured through a series of well-defined steps that transform raw cotton into durable, eco-friendly products. First, cotton fibers are cleaned, spun into yarn, and woven into fabric. The fabric is then bleached, dyed, or printed with designs as required. After processing, the cloth is cut into different sizes and stitched into bags using industrial sewing machines.

Handles or drawstrings are added, and quality checks ensure durability and strength. Some manufacturers use screen printing or embroidery for branding. The final products are ironed, packed, and distributed to wholesalers, retailers, or directly to eco-conscious consumers.

See the Data First: Download Your Sample Report: https://www.imarcgroup.com/cotton-bags-manufacturing-plant-project-report/requestsample

Is making cotton bags profitable?

Making cotton bags can be profitable, especially with rising environmental awareness and restrictions on plastic usage. Demand for reusable and sustainable products is growing across global markets.

Profitability depends on factors like raw material costs, labor efficiency, and production scale. Small-scale manufacturers can earn decent margins by selling customized or branded bags, while large-scale operations benefit from bulk orders and exports. Though initial setup costs for machinery and skilled labor may be high, long-term returns are promising.

With smart marketing and quality assurance, cotton bag manufacturing can become a sustainable and profitable business venture in the eco-friendly industry.

Key Insights for Cotton bags manufacturing plant Setup-

Detailed Process Flow: Unit Operations and Quality Standards:

• Unit Operations: The production process includes fabric sourcing, cutting, stitching, printing, finishing, inspection, and packaging.

• Quality Assurance: Adherence to textile quality standards ensures durability, color fastness, and seam strength.

• Technical Tests: Tests include tensile strength, shrinkage, washability, and print adhesion.

• Raw Material Requirements: Core raw materials include woven cotton fabric, cotton yarn, thread, dyes, handles, and packaging materials.

Land, Location, and Site Development:

• Selection Criteria: The ideal site should offer access to textile markets, skilled labor, and reliable transportation facilities.

• Site Development: The plant should include dedicated zones for cutting, stitching, printing, storage, and administrative operations.

• Environmental Impact: Cotton bag manufacturing has minimal environmental impact; waste fabric can be recycled or repurposed.

• Land Requirement and Costs: Land and infrastructure costs depend on production capacity and location, forming a significant part of capital investments.

Plant Layout: Importance and Influencing Factors

• Designated Zones: Separate sections for raw material storage, cutting, stitching, printing, and packing ensure smooth workflow.

• Layout Factors: Layout planning focuses on worker efficiency, material movement, and compliance with safety standards.

• Operational Benefits: A well-designed layout minimizes handling time, reduces wastage, and supports scalable operations, lowering long-term operating expenses.

Plant Machinery: Requirements and Costs:

• Essential Equipment: Key machinery includes cutting tables, industrial sewing machines, overlock machines, screen or digital printers, heat press units, and finishing tools.

• Cost Considerations: Machinery cost varies based on production capacity, automation level, and printing technology.

• Supplier Support: Reliable suppliers offer equipment installation, operator training, and maintenance services to reduce direct and indirect costs.

Raw Materials: Procurement and Costs:

• Feedstock Options: Cotton fabric is the primary raw material, with variations such as canvas, muslin, or organic cotton depending on the target market.

• Procurement Strategy: Long-term partnerships with textile mills ensure consistent quality and pricing stability.

• Cost Factors: Raw material prices, fabric quality, and logistics directly impact project economics and overall operating expense.

Packaging: Requirements and Suppliers:

• Packaging Materials: Bags are packed in recyclable cartons or paper sleeves to maintain eco-friendly branding.

• Procurement Needs: Packaging materials must ensure safe transportation and preserve bag quality.

• Cost and Compliance: Packaging cost is influenced by material quality, printing, and volume, affecting income and expenditure projections.

Other Requirements and Costs:

• Transportation: Efficient logistics systems are essential for distributing finished products to domestic and export markets.

• Utilities: The plant requires power for machinery, lighting, air circulation, and water for washing or dyeing.

• Energy and Water: Energy-efficient machinery and water recycling systems can reduce recurring operating expenses.

• Human Resources: Skilled tailors, cutters, quality controllers, and print technicians are vital to ensure consistent product quality and timely output.

Request a Customized Project Report for Your Capacity: https://www.imarcgroup.com/request?type=report&id=30726&flag=C

Project Economics: Costs and Profitability:

• Capital Investment: Initial capital investments include land, construction, machinery, utilities, and working capital.

• Operating Costs: Recurring operating expenses include fabric procurement, labor, utilities, maintenance, and logistics.

• Revenue and Margins: Revenue streams come from retail, promotional, and export sales. Well-structured income and expenditure projections and a comprehensive profit and loss account enable margin optimization and profitability forecasting.

Financial Analysis: Investment Returns and Risk Assessment:

• Performance Metrics: Key metrics include expected ROI, net present value (NPV), internal rate of return (IRR), and payback period.

• Return on Investment: Improved operational efficiency, cost control, and product diversification enhance expected ROI.

• Risk Factors: Raw material price fluctuations, market competition, and policy changes affecting textile exports pose risks; sound financial analysis and contingency planning mitigate these challenges.

Other Analysis Covered: Market Trends and Strategic Insights:

• Market Trends: Rising environmental awareness and bans on single-use plastics are driving strong demand for reusable cotton bags.

• Segmentation: Market segments include tote bags, drawstring bags, promotional bags, and customized printed bags.

• Regulatory Environment: Compliance with textile labeling, export certification, and eco-standards is essential.

• Case Studies: Successful ventures demonstrate the benefits of automation, branding, and participation in government sustainability programs.

Get Instant Access Now: https://www.imarcgroup.com/checkout?id=30726&method=1911

Conclusion:

Establishing a cotton bags manufacturing plant offers a sustainable and profitable business opportunity amid the global transition toward eco-friendly products. Proper management of project economics, sound capital investments, and comprehensive financial analysis-including fixed costs vs. variable costs, direct and indirect costs, expected ROI, and net present value (NPV)-ensures business resilience and scalability. With growing consumer preference for reusable materials and supportive environmental regulations, cotton bag manufacturing presents strong prospects for long-term profitability and market expansion.

• Plant Location: Selection of optimal location for the plant.

• Plant Capacity: Customization based on desired production capacity.

• Machinery: Choice between automatic, semi-automatic, or manual machinery.

• List of Machinery Providers: Identification of suitable machinery suppliers.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Launch a Cotton Bags Manufacturing Plant: Detailed Process Flow, Project Details, Requirements and Costs Involved here

News-ID: 4254771 • Views: …

More Releases from IMARC Group

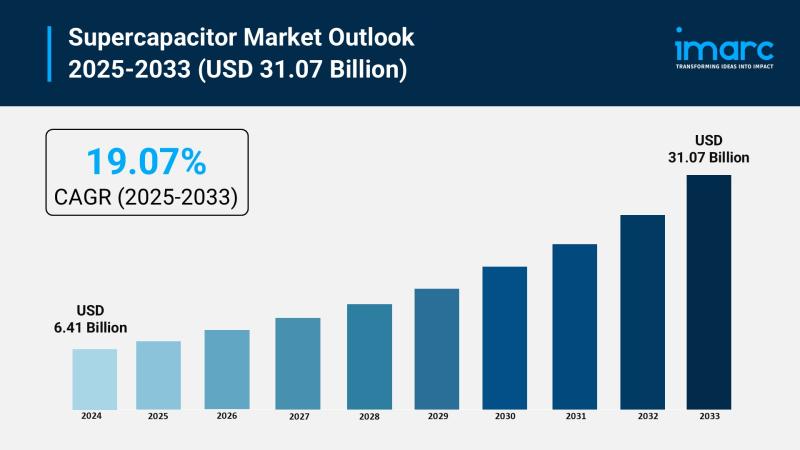

Supercapacitor Market Size to Reach $31.07B by 2033: Trends & Opportunities

Market Overview:

The supercapacitor market is experiencing rapid growth, driven by electrification of automotive systems, renewable energy and grid stabilization, and expansion of industrial automation and robotics. According to IMARC Group's latest research publication, "Supercapacitor Market Size, Share, Trends and Forecast by Product Type, Module Type, Material Type, End Use Industry, and Region, 2025-2033", the global supercapacitor market size was valued at USD 6.41 Billion in 2024. Looking forward, IMARC Group…

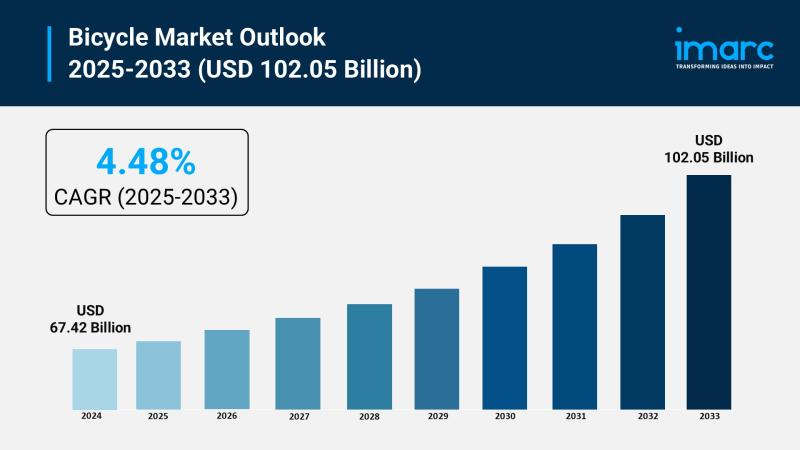

Bicycle Market Size to Surpass $102.05B by 2033: Growth & Insights

Market Overview:

The bicycle market is experiencing rapid growth, driven by global expansion of cycling infrastructure, rising health consciousness and preventative wellness, and technological advancements in e-bike propulsion. According to IMARC Group's latest research publication, "Bicycle Market Size, Share, Trends and Forecast by Type, Technology, Price, Distribution Channel, End User, and Region, 2025-2033", The global bicycle market size was valued at USD 67.42 Billion in 2024. Looking forward, IMARC Group estimates…

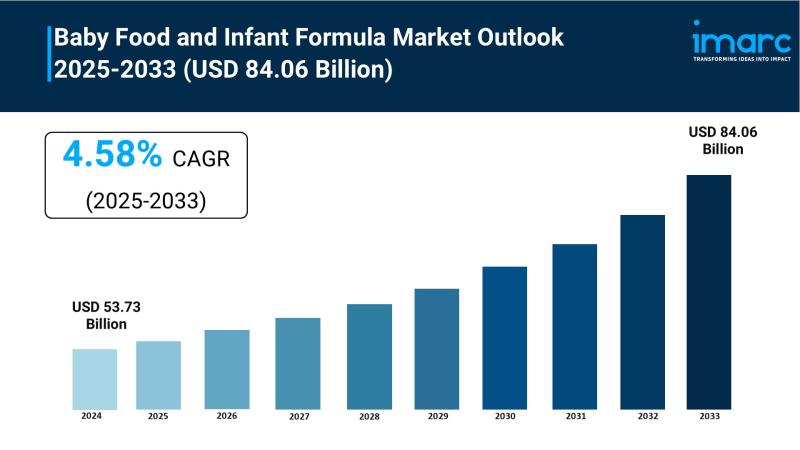

Baby Food and Infant Formula Market to Reach USD 84.06 Billion by 2033, Growing …

Market Overview:

The Baby Food and Infant Formula Market is experiencing steady expansion, driven by Increasing Awareness of Nutritional Needs for Infants, Rising Number of Working Women, and Technological Advancements and Product Innovation. According to IMARC Group's latest research publication, "Baby Food and Infant Formula Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global baby food and infant formula market size reached USD 53.73 Billion in 2024.…

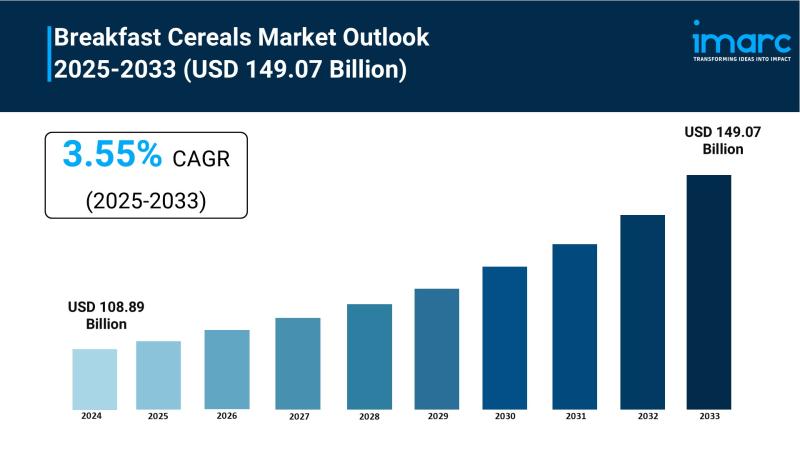

Breakfast Cereals Market to Reach USD 149.07 Billion by 2033, Growing at a CAGR …

Market Overview:

The Breakfast Cereals Market is experiencing rapid growth, driven by Health and Wellness Awareness, Busy Lifestyles and On-the-Go Demand and Rising Disposable Incomes and Global Market Expansion . According to IMARC Group's latest research publication, "Breakfast Cereals Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global breakfast cereals market size was valued at USD 108.89 Billion in 2024. Looking forward, IMARC Group estimates…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…