Press release

Wafer Fab Materials Market to Reach USD 77.5 Billion by 2034

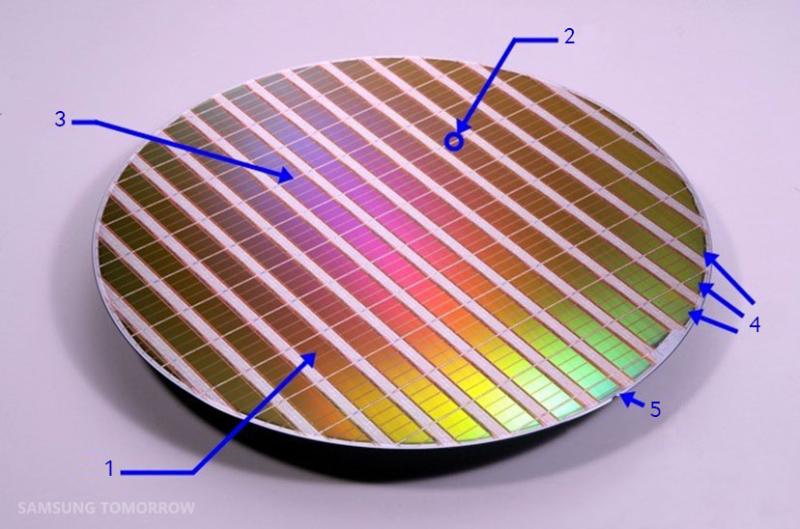

IntroductionThe global Wafer Fab Materials Market is witnessing robust expansion, powered by the semiconductor industry's transition toward smaller process nodes, high-performance computing (HPC), and electric vehicle (EV) electronics. As the backbone of integrated circuit (IC) fabrication, wafer fab materials-comprising silicon wafers, photomasks, photoresists, CMP slurries, and gases-enable the creation of advanced chips that drive everything from smartphones and servers to autonomous vehicles and artificial intelligence (AI) systems.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/75436

According to Exactitude Consultancy, the Wafer Fab Materials Market was valued at USD 45.2 billion in 2024 and is projected to reach USD 77.5 billion by 2034, growing at a CAGR of 5.6% during the forecast period. The surge is driven by the global semiconductor supply chain expansion, escalating demand for logic and memory chips, and ongoing investments in foundry capacity across Asia-Pacific, North America, and Europe.

Market Overview

Wafer fabrication (wafer fab) materials are indispensable for the microfabrication process, where multiple steps-such as oxidation, etching, deposition, and lithography-transform raw silicon wafers into finished semiconductor chips. The recent wave of AI-driven applications, 5G rollouts, and EV adoption has intensified global demand for high-purity and precision-engineered materials that ensure device reliability and miniaturization.

Key Market Highlights:

• Market Size (2024): USD 45.2 billion

• Forecast (2034): USD 77.5 billion

• CAGR (2025-2034): 5.6%

• Key Drivers: Semiconductor boom, AI chip demand, and government-backed localization policies.

• Key Challenges: Supply chain volatility, high R&D costs, and environmental regulations.

• Top Players: Shin-Etsu Chemical Co. Ltd., Dow Inc., BASF SE, Sumco Corporation, and JSR Corporation.

As global foundries race to achieve process nodes below 3nm and integrate heterogeneous packaging, the quality, precision, and purity of wafer fab materials are becoming central to semiconductor performance and yield optimization.

Segmentation Analysis

By Material Type:

• Silicon Wafers

• Photomasks

• Photoresists

• CMP Slurries & Pads

• Wet Chemicals

• Gases (Specialty & Bulk)

• Sputtering Targets

• Others (SOI Substrates, Epitaxial Wafers)

By Application:

• Logic ICs

• Memory (DRAM, NAND Flash)

• Analog ICs

• Discrete Devices

• MEMS & Sensors

• Power Devices

By End Use Industry:

• Consumer Electronics

• Automotive Electronics

• Telecommunications

• Industrial Automation

• Healthcare Devices

By Process Type:

• Front-End-of-Line (FEOL) Materials

• Back-End-of-Line (BEOL) Materials

Segmentation Summary:

The silicon wafers segment dominates the market, accounting for over 30% of total revenue, as demand surges for 300mm and 200mm wafers across logic and memory fabs. Photoresists and CMP materials are witnessing rapid adoption due to the proliferation of extreme ultraviolet (EUV) lithography in sub-7nm process nodes.

In terms of applications, logic and memory ICs collectively represent more than 65% of global demand. With rising chip content in automobiles, renewable energy systems, and connected devices, wafer fab materials are increasingly being optimized for power efficiency, high-k dielectric integration, and advanced metallization schemes.

Explore Full Report here: https://exactitudeconsultancy.com/reports/75436/wafer-fab-materials-market

Regional Analysis

North America:

North America remains a strategic hub for semiconductor innovation, with the U.S. leading investments through the CHIPS and Science Act (2022), which earmarked over USD 52 billion to boost domestic chip manufacturing. Foundries such as Intel, TSMC Arizona, and Micron Technology are driving significant demand for wafer materials including high-purity gases, photomasks, and CMP slurries. The region's growing focus on defense-grade semiconductors and AI computing chips further reinforces long-term market stability.

Europe:

Europe's wafer fab materials market is expanding under the EU Chips Act, which aims to double Europe's semiconductor share to 20% of global production by 2030. Key nations like Germany, the Netherlands, and France are home to advanced equipment and material suppliers supporting fabs from STMicroelectronics, GlobalFoundries, and Infineon Technologies. Sustainability initiatives are promoting low-emission chemicals and circular wafer recycling programs across the continent.

Asia-Pacific:

Asia-Pacific dominates the global market, accounting for nearly 65% of total wafer fab material consumption. Taiwan, South Korea, Japan, and China are key players, hosting semiconductor giants such as TSMC, Samsung Electronics, SK Hynix, and SMIC.

• Taiwan remains the largest buyer of photomasks, CMP pads, and photoresists, driven by its leadership in advanced logic foundries.

• South Korea leads in memory chip production, propelling demand for deposition and etching materials.

• Japan maintains global leadership in specialty gases, wafers, and photoresist supply, with companies like JSR, Sumco, and Shin-Etsu forming the backbone of global material sourcing.

• China continues to expand domestic wafer manufacturing capabilities under its Made in China 2025 and National Integrated Circuit Industry Development Program.

Middle East & Africa:

Though a smaller market, MEA is witnessing early semiconductor investments, particularly in Israel and the UAE, aimed at developing microelectronics and cleanroom facilities for regional tech applications.

Latin America:

Countries like Brazil and Mexico are gradually entering the semiconductor supply chain through automotive electronics and assembly operations, indirectly increasing demand for wafer-level components and materials.

Regional Summary:

Asia-Pacific dominates global wafer fab material production and consumption, while North America and Europe are leading innovation and policy-driven localization efforts. This regional interdependence will define the semiconductor value chain over the next decade.

Market Dynamics

Key Growth Drivers

1. Semiconductor Expansion and Localization Policies:

Governments in the U.S., EU, China, and India are heavily investing in domestic semiconductor ecosystems to ensure supply chain resilience, driving parallel growth in wafer fab materials manufacturing.

2. AI and High-Performance Computing (HPC):

The AI revolution-spanning data centers, generative AI, and autonomous systems-requires high-density logic and GPU chips, which depend on ultra-pure photolithography and deposition materials.

3. Electric Vehicle (EV) and Power Semiconductor Demand:

The rapid electrification of transportation is boosting production of SiC (Silicon Carbide) and GaN (Gallium Nitride) wafers for power electronics, requiring specialized etching gases and high-thermal-capacity substrates.

4. Technological Advancements in Lithography:

The shift from DUV to EUV lithography has transformed material needs, requiring chemically amplified resists and defect-free photomasks to achieve finer circuit patterning.

5. Rising Integration of MEMS and Sensors:

Growth in IoT, wearable devices, and industrial automation has expanded the demand for wafer materials used in MEMS, biosensors, and microfluidic components.

Key Challenges

• High Manufacturing Cost and Capital Intensity:

Advanced material production requires strict purity control and cleanroom environments, raising entry barriers for new suppliers.

• Environmental and Regulatory Constraints:

Chemicals used in wafer fabrication-such as perfluorocarbons and sulfur hexafluoride-pose emission challenges, prompting stricter sustainability requirements.

• Supply Chain Vulnerabilities:

The semiconductor materials market remains exposed to geopolitical risks and logistical disruptions, particularly across Asia-Pacific's concentrated supplier network.

• Rapid Technology Obsolescence:

Frequent process upgrades in semiconductor fabs require continuous material innovation, increasing R&D and compliance costs for suppliers.

Latest Market Trends

1. Shift Toward Compound Semiconductors (SiC & GaN):

Demand for SiC and GaN materials is rising rapidly in EV powertrains, 5G infrastructure, and renewable energy, supporting higher thermal and voltage tolerances.

2. Sustainability and Green Manufacturing:

Material suppliers are investing in low-GWP etching gases, chemical recycling, and eco-friendly CMP slurries to meet ESG goals.

3. AI-Integrated Process Optimization:

Foundries are adopting AI algorithms to monitor material deposition and defect control in real-time, reducing waste and improving wafer yield.

4. Collaborative Ecosystem Development:

Strategic alliances between wafer material suppliers and semiconductor fabs (e.g., Dow-TSMC, BASF-Intel) are expediting next-gen material qualification cycles.

5. Localized Supply Chains:

The post-pandemic semiconductor shortages have led to regional diversification of wafer material sourcing, encouraging capacity additions in North America and Europe.

Get Your Exclusive Offer with up to 10% Discount : https://exactitudeconsultancy.com/checkout/?currency=USD&type=single_user_license&report_id=75436

Competitive Landscape

Leading Companies:

• Shin-Etsu Chemical Co. Ltd.

• SUMCO Corporation

• JSR Corporation

• Tokyo Ohka Kogyo Co. Ltd. (TOK)

• Dow Inc.

• BASF SE

• Linde plc

• Air Liquide SA

• Merck KGaA

• DuPont de Nemours Inc.

Competitive Summary

The global wafer fab materials market is highly consolidated, dominated by Japanese, U.S., and European firms specializing in high-purity chemicals and wafers. Top companies focus on expanding regional manufacturing footprints, particularly near major foundries, to ensure consistent material supply and regulatory compliance.

Recent Developments:

• 2024: Shin-Etsu Chemical expanded its 300mm silicon wafer production facility in Japan to meet rising demand from AI and automotive chipmakers.

• 2023: JSR Corporation developed a new-generation EUV photoresist with enhanced resolution for sub-3nm nodes.

• 2023: BASF SE launched sustainable CMP slurries with reduced carbon footprint for advanced logic fabrication.

• 2022: Dow introduced chemical-mechanical planarization pads compatible with advanced logic and memory manufacturing.

• 2021: Air Liquide invested USD 700 million to build high-purity gas facilities near TSMC fabs in Taiwan and South Korea.

These innovations reflect an industry-wide shift toward eco-friendly materials, AI-enabled precision manufacturing, and strategic localization of semiconductor supply chains.

Future Outlook

The next decade will mark a semiconductor supercycle, where AI, EVs, and quantum computing will demand increasingly sophisticated wafer materials. The Wafer Fab Materials Market will continue to evolve through innovations in EUV photoresists, advanced CMP formulations, and high-purity precursor gases.

Emerging markets such as India and Southeast Asia are expected to become important nodes in the global semiconductor value chain, attracting investment in wafer material production and R&D centers. Moreover, compound semiconductor technologies (SiC, GaN) will witness exponential growth as automotive and renewable energy industries seek higher efficiency and durability.

By 2034, digital twins, AI-based quality control, and closed-loop chemical recycling will define the future of sustainable wafer material production. The integration of environmental stewardship with high-precision engineering will be the key differentiator for next-generation suppliers.

Conclusion

The Wafer Fab Materials Market is entering a transformative decade, underpinned by semiconductor innovation, electrification, and global digitalization. As chip complexity increases, so does the need for ultra-pure, sustainable, and precision-engineered materials that form the foundation of tomorrow's technology.

According to Exactitude Consultancy, the market will expand from USD 45.2 billion in 2024 to USD 77.5 billion by 2034, at a steady CAGR of 5.6%. The convergence of AI, EVs, and green manufacturing will redefine wafer material strategies, ensuring the industry's pivotal role in shaping the future of intelligent, connected, and sustainable technologies.

This report is also available in the following languages : Japanese (ウェーハファブ材料市場), Korean (웨이퍼 팹 소재 시장), Chinese (晶圆制造材料市场), French (Marché des matériaux pour la fabrication de plaquettes), German (Markt für Wafer-Fertigungsmaterialien), and Italian (Mercato dei materiali per la fabbricazione di wafer), etc.

Request for a sample of this research report at (Use Corporate Mail ID for Quick Response) @ https://exactitudeconsultancy.com/reports/75436/wafer-fab-materials-market#request-a-sample

Our More Reports:

Wafer Fabrication Equipment Market

https://exactitudeconsultancy.com/reports/75770/wafer-fabrication-equipment-market

Integrated Gas Supply System for Semiconductor Market

https://exactitudeconsultancy.com/reports/70432/integrated-gas-supply-system-for-semiconductor-market

Status of the Wafer Fab Equipment Market

https://exactitudeconsultancy.com/reports/74214/status-of-the-wafer-fab-equipment-market

Semiconductor Grade Carbon Fiber Soft Felts Market

https://exactitudeconsultancy.com/reports/74978/semiconductor-grade-carbon-fiber-soft-felts-market

About Us

Exactitude Consultancy is a market research & consulting services firm which helps its client to address their most pressing strategic and business challenges. Our market research helps clients to address critical business challenges and also helps make optimized business decisions with our fact-based research insights, market intelligence, and accurate data.

https://bulletin.exactitudeconsultancy.com/

https://www.thehealthanalytics.com/

https://www.analytica.global/

https://www.marketintelligencedata.com/

https://www.marketinsightsreports.com/

https://exactitudeconsultancy.com/

Connect Us:

Irfan Tamboli

PHONE NUMBER +1 (704) 266-3234

EMAIL ADDRESS: sales@exactitudeconsultancy.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Wafer Fab Materials Market to Reach USD 77.5 Billion by 2034 here

News-ID: 4254399 • Views: …

More Releases from Exactitude Consultancy

Cold Planer Market Sees Consistent Growth Supported by Global Road Rehabilitatio …

The global cold planer market is experiencing steady growth as governments and private contractors increase spending on road rehabilitation, resurfacing, and infrastructure modernization. Cold planers, also known as milling machines, are widely used to remove damaged asphalt and concrete surfaces efficiently, supporting sustainable road construction practices.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/68250

Key Market Highlights

• Increasing focus on road maintenance and resurfacing projects

• Growing demand for efficient and precision milling…

Credit Management Software Market Accelerates as Organizations Focus on Risk Mit …

The global credit management software market is witnessing robust growth as organizations across industries adopt digital solutions to manage credit risk, improve receivables performance, and strengthen financial controls. Credit management software enables businesses to automate credit scoring, monitor customer creditworthiness, and streamline collections processes.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/68248

Key Market Highlights

• Growing adoption of automated credit risk assessment tools

• Increasing focus on working capital and cash flow management

• Integration…

Session Border Controller Market Expands Rapidly as Enterprises and Telecom Oper …

The global session border controller (SBC) market is experiencing strong growth as telecom operators and enterprises increasingly deploy SBC solutions to secure, manage, and optimize real-time IP communications. SBCs play a critical role in protecting voice over IP (VoIP), unified communications (UC), and multimedia sessions from cyber threats while ensuring interoperability and quality of service.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/68246

Key Market Highlights

• Growing adoption of VoIP and…

Biofuel Market Including E-Methane and Sustainable Aviation Fuel Gains Strong Tr …

The global biofuel market, encompassing e-methane, sustainable aviation fuel (SAF), and other advanced biofuels, is witnessing robust growth as governments and industries intensify efforts to reduce carbon emissions and transition toward cleaner energy sources. These fuels play a critical role in achieving net-zero targets while enabling decarbonization of hard-to-abate sectors such as aviation, shipping, and heavy transportation.

Download Full PDF Sample Copy of Market Report @ https://exactitudeconsultancy.com/request-sample/68244

Key Market Highlights

• Rapid growth of…

More Releases for Wafer

Semiconductor Silicon Wafer Market Is Going to Boom |• Silicon Wafer • Globa …

Worldwide Market Reports has released a new in-depth research study on the "Semiconductor Silicon Wafer Market," highlighting strong growth potential in the coming years. The report delivers a structured and data-driven analysis of the market landscape, combining robust research methodology, market sizing, validated data modeling, and insights sourced from reliable primary and secondary channels.

The study thoroughly examines key market aspects, including growth drivers, restraints, challenges, emerging opportunities, technological advancements, innovation…

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market Size, Trends & F …

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market Size

The global Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market is projected to grow from US$ 1227 million in 2024 to US$ 1672.7 million by 2030, at a Compound Annual Growth Rate (CAGR) of 5.3% during the forecast period.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-38F13137/Global_Semiconductor_Wafer_Electrostatic_Chucks_for_300mm_Wafer_Market_Research_Report_2023?utm_source=openpr&utm_medium=referral

The US & Canada market for Semiconductor Wafer Electrostatic Chucks for 300mm Wafer is estimated to increase from $ million in…

Wafer Hybrid Bonding Equipment Market Share Driven by Wafer-to-Wafer Technology …

Wafer Hybrid Bonding Equipment Market Size

The global market for Wafer Hybrid Bonding Equipment was valued at US$ 164 million in the year 2024 and is projected to reach a revised size of US$ 756 million by 2031, growing at a CAGR of 24.7% during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-31W14822/Global_Wafer_Hybrid_Bonding_Equipment_Market_Insights_Forecast_to_2029

The Wafer Hybrid Bonding Equipment market is experiencing accelerated growth, driven by increasing demand for advanced semiconductor packaging technologies that enable higher…

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market

Semiconductor Wafer Electrostatic Chucks for 300mm Wafer Market

The global Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market was valued at US$ 1165 million in 2023 and is anticipated to reach US$ 1672.7 million by 2030, witnessing a CAGR of 5.3% during the forecast period 2024-2030.

View Sample Report

https://reports.valuates.com/request/sample/QYRE-Auto-38F13137/Global_Semiconductor_Wafer_Electrostatic_Chucks_for_300mm_Wafer_Market_Research_Report_2023

Report Scope

The Semiconductor Wafer Electrostatic Chucks for 300mm Wafer market size, estimations, and forecasts are provided in terms of output/shipments (Units) and revenue…

Automatic Mounter Wafer Equipment Market Report 2018: Segmentation by Type (100 …

Global Automatic Mounter Wafer Equipment market research report provides company profile for Lintec Corporation, Nitto Denko, Tokyo Electron, Technovision, Takatori, Ultron Systems, DISCO Corp., Syagrus Systems, Advanced Dicing Technologies, Longhill Industries and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…

EMEA Solar Wafer Cutting Fluid PEG Market For Semiconductor, Solar Wafer, Crysta …

Latest industry research report on: EMEA (Europe, Middle East and Africa) Solar Wafer Cutting Fluid PEG Market : Industry Size, Share, Research, Reviews, Analysis, Strategies, Demand, Growth, Segmentation, Parameters, Forecasts

Request For Sample Report @ https://www.marketresearchreports.biz/sample/sample/1194694

Geographically, this report split EMEA into Europe, the Middle East and Africa, With sales (K MT), revenue (Million USD), market share and growth rate of Solar Wafer Cutting Fluid PEG for these regions, from 2012 to…