Press release

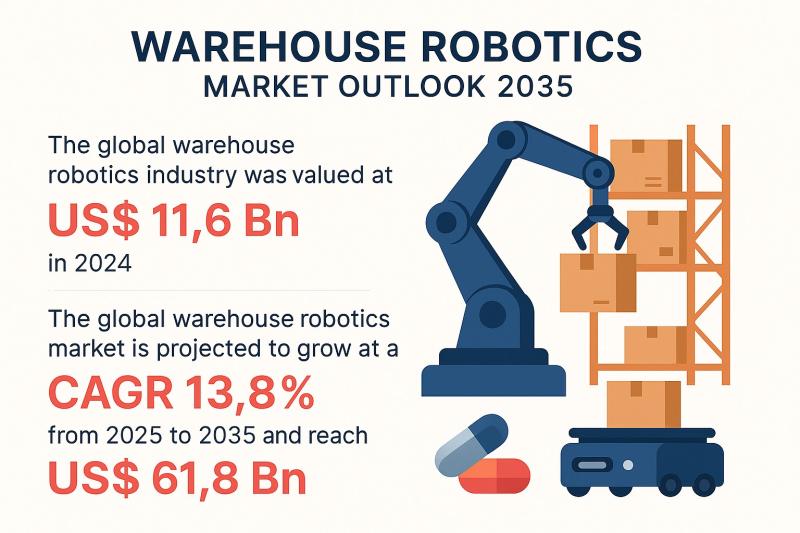

Warehouse Robotics Market Size to Surpass USD 61.8 Billion by 2035 | Growth Fueled by AI, Vision Systems, and Contactless Automation Across Global E-Commerce and Supply Chains

The global warehouse robotics market (https://www.transparencymarketresearch.com/warehouse-robotics-market.html) is entering a transformative decade, fueled by the accelerating adoption of automation technologies across logistics, retail, and manufacturing sectors. Valued at US$ 11.6 billion in 2024, the market is projected to grow at a CAGR of 13.8% between 2025 and 2035, reaching a staggering US$ 61.8 billion by 2035.This remarkable growth is driven by rising e-commerce activities, labor shortages, advancements in artificial intelligence (AI), machine vision, and the growing need for contactless operations. Warehouse robotics is no longer a futuristic concept; it has become an essential part of the modern supply chain, helping businesses enhance speed, precision, and efficiency while cutting operational costs.

Discover Market Opportunities - Request Your Sample Copy No: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=42617

Analysts' Viewpoint: AI and E-Commerce Redefining Warehouse Operations

The rapid rise of e-commerce has been a defining factor in the evolution of warehouse robotics. Customers today demand faster deliveries, real-time tracking, and error-free order fulfillment. Businesses, in turn, are under immense pressure to manage shorter lead times, maintain accuracy, and optimize their fulfillment processes.

Labor shortages have also accelerated automation adoption. Many warehousing tasks, such as picking, sorting, and palletizing, are repetitive, physically demanding, or difficult to fill with human workers. Robots are increasingly replacing or augmenting human labor in these areas, working continuously with minimal error.

Technological innovation has made robotics more capable than ever. With the integration of AI, machine learning (ML), IoT, and smart sensors, robots can now learn from experience, make autonomous adjustments, and communicate seamlessly with warehouse management systems. These capabilities make them intelligent, scalable, and essential components of next-generation warehouses.

Furthermore, the Robotics-as-a-Service (RaaS) model is expanding, allowing companies to adopt robotics with minimal upfront investment. The rise of collaborative robots (cobots), designed to safely work alongside humans, adds another layer of flexibility. Cobots are being deployed in warehouses where adaptability and safety are critical, allowing hybrid work environments where humans and machines collaborate to optimize productivity.

Introduction: The Automation Revolution in Warehousing

The warehouse robotics industry focuses on designing, developing, and implementing automated systems that streamline material handling, storage, and logistics operations. These robots are transforming how warehouses function-making them faster, more accurate, and safer.

Warehouse robotics enhances efficiency and reduces the dependency on manual labor. Robots are now performing complex tasks such as order picking, sorting, packing, palletizing, and even inventory scanning. They help reduce operational costs, eliminate human error, and ensure uninterrupted workflows.

Different types of robots are used across warehouse operations. Autonomous Mobile Robots (AMRs) navigate freely using sensors and mapping technologies. Automated Guided Vehicles (AGVs) follow pre-defined routes to move goods. Robotic arms handle picking and placing of items, while gantry robots are used for heavy lifting and stacking. In addition, drones are emerging as a vital tool for inventory management, offering real-time data from aerial perspectives.

Each robot type plays a specific role depending on the warehouse's scale and complexity. From e-commerce to automotive and pharmaceuticals, warehouse robots are becoming indispensable to industries with high-speed, high-volume logistics needs.

Market Drivers

The growth of the warehouse robotics market is influenced by several key drivers, notably advancements in AI and machine vision, and the rising demand for contactless operations.

Advancements in AI and Machine Vision

Artificial intelligence and machine vision are among the most transformative technologies driving warehouse automation. Robots equipped with these technologies can recognize, analyze, and respond to their environment in real time. Machine vision enables robots to understand spatial surroundings, identify objects, and perform quality checks autonomously.

AI-driven algorithms allow robots to learn continuously, improving their efficiency and accuracy over time. For instance, robots can detect and handle irregularly shaped or non-uniform items, dynamically adapting to complex workflows. This level of intelligence enhances throughput, reduces errors, and increases safety in warehouse operations.

As supply chains become more complex, AI and vision technologies will continue to be crucial in enabling adaptive, high-speed robotic systems that can manage diverse tasks without constant human intervention.

Rising Demand for Contactless Operations

The COVID-19 pandemic accelerated the global shift toward contactless and automated operations. Labor-intensive supply chains faced massive disruptions, highlighting the risks of over-reliance on human workers in critical logistics functions.

Businesses began investing in automation to reduce physical contact during picking, sorting, and packaging. Even after the pandemic, the demand for contactless operations remains strong, as companies continue to seek solutions that ensure business continuity, safety, and resilience.

By deploying autonomous robots, companies can maintain uninterrupted operations even under challenging circumstances. Workers can focus on higher-level supervisory roles, leaving repetitive tasks to machines. This trend is expected to drive sustained demand for warehouse robotics in the coming decade.

Explore Strategies & Trends - Request Full Report Access - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=42617

Market Segmentation

By Type

The warehouse robotics market includes several robot types such as Autonomous Mobile Robots (AMRs), Automated Guided Vehicles (AGVs), Unmanned Aerial Vehicles (UAVs), Collaborative Robots (Cobots), Automated Storage and Retrieval Systems (AS/RS), and robotic arms.

Among these, AMRs dominate the market, thanks to their flexibility and scalability. Unlike AGVs, which require fixed infrastructure, AMRs navigate freely using sensors and mapping algorithms. They can adapt to layout changes, avoid obstacles, and optimize their routes autonomously.

AMRs are ideal for warehouses that need to manage dynamic workflows, such as e-commerce fulfillment centers. The growing demand for same-day or next-day delivery is further accelerating the adoption of AMRs globally.

By Function

Warehouse robots perform various functions such as loading and unloading, palletizing and depalletizing, sorting, packaging, transportation, and storage or delivery. Each function addresses a specific challenge in warehouse management.

Automated palletizing systems, for example, handle heavy loads efficiently, while sorting and packaging robots increase speed and reduce human error in fulfillment operations. As demand for faster and more reliable order fulfillment rises, multi-functional robots capable of performing multiple tasks will gain prominence.

By Component

The market is broadly divided into hardware and software components. Hardware includes sensors, controllers, actuators, and robotic arms, while software includes control systems, warehouse management platforms, and AI-based decision engines.

The integration of software intelligence with advanced hardware enables robots to perform tasks autonomously and adapt to changing conditions in real time. As AI and cloud-based analytics continue to evolve, the software segment is expected to witness significant growth, making robots more intelligent and data-driven.

By Payload

Warehouse robots come in different payload capacities ranging from light-duty robots (1-7 kg) used in e-commerce and electronics warehouses to heavy-duty robots capable of handling loads exceeding 1000 kg, often used in the automotive or metal industries.

This flexibility allows companies to deploy tailored solutions depending on their product type, volume, and handling requirements. The ability to scale robotics according to payload demands enhances the efficiency and adaptability of warehouse operations.

By End-User Industry

The adoption of warehouse robotics spans multiple industries. The e-commerce sector leads the way, driven by the need for rapid order fulfillment and precise inventory management. Automotive manufacturers use robots to transport parts and support just-in-time manufacturing. Food and beverage companies rely on robots for packaging and cold storage automation.

In the pharmaceutical industry, robotics ensures sterility and accuracy in handling delicate medical products. Electronics manufacturers utilize robots for handling small, sensitive components, while metals and machinery industries benefit from robotic systems for heavy lifting and assembly line logistics.

As digital transformation continues, every industry involved in high-volume logistics is expected to embrace warehouse robotics to maintain competitiveness and efficiency.

Regional Outlook

North America currently dominates the global warehouse robotics market. The region's leadership is primarily driven by the expansion of e-commerce giants such as Amazon, GreyOrange, and Berkshire Grey, which have heavily invested in warehouse automation.

Labor shortages across the U.S. and Canada, coupled with increasing consumer expectations for faster delivery times, have accelerated the deployment of robotics in fulfillment centers. Furthermore, strong government support for innovation and a well-developed R&D ecosystem continue to drive advancements in the region.

Europe follows closely, with countries like Germany, the U.K., and France at the forefront of adopting robotics in logistics and manufacturing. The Asia Pacific region is witnessing rapid growth as well, fueled by industrialization, rising e-commerce penetration, and government initiatives promoting automation in countries like China, Japan, and India.

Competitive Landscape

The warehouse robotics market features a mix of established industrial automation giants and emerging technology companies. These players are investing in research and development to build intelligent, adaptive, and cost-effective robotic systems capable of meeting diverse warehousing demands.

Key market participants include FANUC Corporation, ABB Ltd., Daifuku Co., Ltd., Honeywell International Inc., KUKA AG, Zebra Technologies Corporation, Omron Corporation, KNAPP AG, Toyota Material Handling, YASKAWA Electric Corporation, KION Group AG, GreyOrange, JBT Corporation, Amazon.com, Inc., and Ambi Robotics.

These companies are focusing on integrating AI-driven systems, simulation technologies, and advanced sensing capabilities to enhance robot performance. Many are also exploring modular designs and human-robot collaboration features to make automation more flexible and scalable.

Recent Developments

In June 2025, Amazon reached a major milestone by deploying its one millionth robot and launching a new generative AI foundation model named DeepFleet. DeepFleet leverages AWS cloud tools, real-time data, and historical performance analytics to optimize robotic motion inside Amazon's fulfillment centers. The system is designed to enhance delivery speed and reduce costs by improving coordination among thousands of robots simultaneously.

In January 2025, Ambi Robotics introduced AmbiStack, an AI-powered palletizing system that can autonomously stack both uniform and irregular packages. AmbiStack uses machine vision, reinforcement learning, and an overhead four-axis gantry robot equipped with a multi-zone vacuum gripper. The system enhances throughput by enabling the simultaneous handling of multiple packages and can be configured for truck unloading or pallet building in retail and logistics settings.

These developments reflect a clear market shift toward AI-driven, self-learning robotics systems that can adapt to complex logistics environments and deliver higher operational efficiency.

Market Snapshot and Forecast

By 2035, the warehouse robotics market is expected to reach US$ 61.8 billion, growing from US$ 11.6 billion in 2024 at a CAGR of 13.8%. Historical data from 2020 to 2023 indicates a steady rise in automation investments, which will continue as companies seek to address supply chain disruptions and efficiency bottlenecks.

The market outlook includes detailed segmentation by robot type, function, component, payload, end-user, and region. The report also highlights the competition landscape, providing insights into company strategies, technological innovations, and future product launches.

Buy Full Report Now: https://www.transparencymarketresearch.com/checkout.php?rep_id=42617<ype=S

Future Outlook: Toward Fully Autonomous, Intelligent Warehouses

The future of the warehouse robotics market lies in intelligent, interconnected automation ecosystems. The convergence of AI, IoT, 5G, and cloud computing will enable seamless communication between robots, warehouse management systems, and digital twins.

Emerging innovations such as autonomous fleet orchestration, AI-based route optimization, and self-learning predictive maintenance will transform warehouses into intelligent environments that can self-optimize operations in real time.

By 2035, most large warehouses are expected to be fully automated, with minimal human intervention. Robots will not only execute physical tasks but will also make data-driven decisions that enhance efficiency, accuracy, and safety. The adoption of Robotics-as-a-Service will make this technology accessible to small and medium enterprises, democratizing automation across industries.

Conclusion

The warehouse robotics market is at the heart of the global shift toward intelligent, automated logistics. The synergy of AI, machine vision, and automation technologies is transforming warehouses into dynamic, high-performance hubs capable of meeting the demands of the digital economy.

By 2035, with a projected valuation of US$ 61.8 billion, warehouse robotics will redefine supply chain efficiency, productivity, and resilience. Companies that embrace this transformation will gain a decisive competitive edge, shaping the future of logistics and manufacturing worldwide.

The coming decade will mark a new era-where human intelligence and robotic precision work together to power the global economy.

Explore Latest Research Reports by Transparency Market Research:

DCB and AMB Substrate Market: https://www.transparencymarketresearch.com/dcb-and-amb-substrate-market.html

AI in Aviation Market: https://www.transparencymarketresearch.com/ai-in-aviation-market.html

Grid-scale Battery Market: https://www.transparencymarketresearch.com/grid-scale-battery-market.html

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Warehouse Robotics Market Size to Surpass USD 61.8 Billion by 2035 | Growth Fueled by AI, Vision Systems, and Contactless Automation Across Global E-Commerce and Supply Chains here

News-ID: 4253539 • Views: …

More Releases from Transparency Market Research

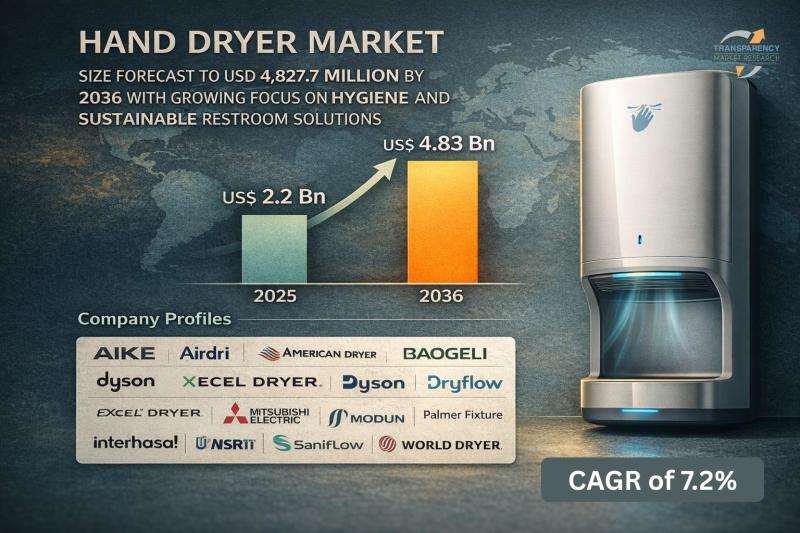

Hand Dryer Market Size Forecast to USD 4.83 Billion by 2036 with Growing Focus o …

Hand Dryer Market Outlook 2036

The global hand dryer market was valued at US$ 2.23 Billion in 2025 and is projected to reach US$ 4.83 Billion by 2036, expanding at a steady CAGR of 7.2% from 2026 to 2036. Market growth is driven by increasing emphasis on hygiene and sanitation, rising adoption in commercial infrastructure, and growing preference for eco-friendly and cost-effective hand drying solutions.

👉 Get sample market research report copy…

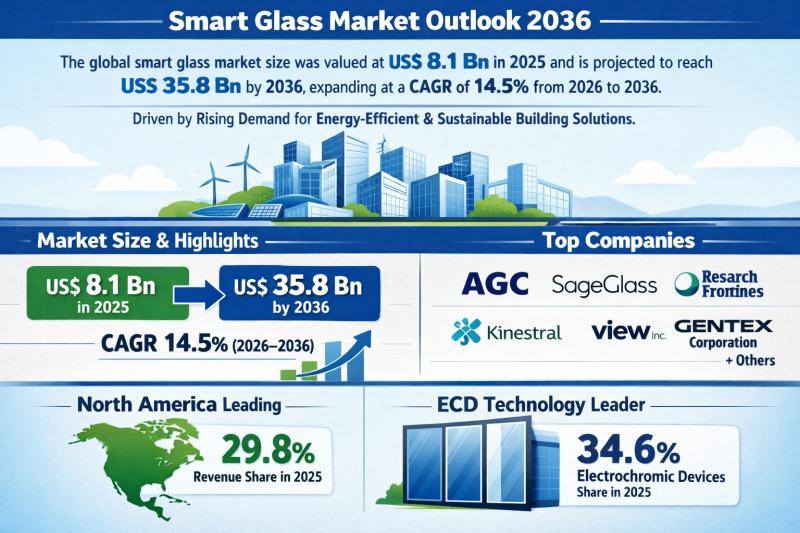

Smart Glass Market Outlook 2036: Projected to Reach USD 35.8 Billion at 14.5% CA …

The global smart glass market was valued at US$ 8.1 Bn in 2025 and is projected to surge to US$ 35.8 Bn by 2036, expanding at a robust CAGR of 14.5% from 2026 to 2036. This nearly 4.4x growth over eleven years underscores the accelerating demand for intelligent glazing solutions across commercial, residential, automotive, and infrastructure sectors.

North America emerged as the leading regional market in 2025, accounting for 29.8% of…

Smoking Cessation and Nicotine De-Addiction Market to Reach USD 46.4 Bn by 2036, …

The global smoking cessation and nicotine de-addiction market is witnessing strong and sustained growth, fueled by intensifying public health initiatives and rising awareness about the long-term consequences of tobacco use. Valued at USD 15.5 Bn in 2025, the market is projected to expand at a robust CAGR of 10.5% from 2026 to 2036, reaching USD 46.4 Bn by 2036.

Smoking cessation solutions encompass a wide range of products and services designed…

3D Imaging Market to be Worth USD 266 Bn by 2036 - By Component Type / By End-Us …

The global 3D imaging market is witnessing exponential growth, reflecting strong demand across healthcare, manufacturing, media, and industrial sectors. Valued at US$ 50 billion in 2025, the market is projected to reach US$ 266 billion by 2036, expanding at a robust CAGR of 18.2% from 2026 to 2036.

Get a concise overview of key insights from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=2743

This impressive trajectory highlights the rapid integration of advanced imaging…

More Releases for Warehouse

Cargo Insurance Explained: Warehouse-to-Warehouse vs. Carrier Liability

A Comprehensive Analysis of Cargo Insurance: From the Fundamental Difference Between "Warehouse-to-Warehouse" and "Carrier Liability" to Setting the Most Cost-Effective Deductible

When a batch of electronic products departs from a Southeast Asian factory warehouse, transits by sea and land to a distribution warehouse in Europe, and is damaged by rain in the transit yard, the cargo owner often faces a dilemma: should they claim compensation from the carrier or file a…

How to Process Inter Warehouse & Intra Warehouse Transfers in Odoo 18

Managing inventory efficiently is a cornerstone of any successful business. Whether you're dealing with multiple warehouses or a single location, Odoo 18 offers robust tools to streamline your operations. One of the most critical aspects of inventory management is handling inter-warehouse and intra-warehouse transfers. In this article, we'll dive deep into how you can process these transfers seamlessly in Odoo 18. Plus, we'll explore how Odoo integration with WMS Warehouse…

Warehouse Management

Warehouse Management

Introduction:

In today's fast-paced business landscape, efficient warehouse management is crucial for small businesses to stay competitive and streamline their operations. A well-organized and optimized warehouse can lead to increased productivity, reduced costs, and improved customer satisfaction. In this blog post, we will explore some valuable tips and strategies to help small businesses streamline their warehouse management and achieve success.

For more information- https://krystal-group.com/blog/warehouse-management/

1. Optimize Layout and Space Utilization:

One of…

Streamlining Warehouse Operations: Choosing the Right Warehouse Management Syste …

The global market offers numerous Warehouse Management System ( https://businessprocessxperts.com/lean-warehouse-management-consulting/ ) software options, including renowned solutions such as SAP WM, Oracle WMS, Infor WMS, Odoo Inventory, Zoho Inventory, Manhattan WMS, and Microsoft Dynamics 365 Supply Chain Management. With a wide range of choices available, selecting the best-fit WMS for your business can be a daunting task. However, by considering a few essential prerequisites, you can navigate through the options and…

BPX Warehouse Specialists Redefining Warehouse Operations with Cutting-Edge Auto …

In the fast-paced world of modern logistics, warehouses play a pivotal role in ensuring efficient supply chain management. To stay ahead in the competitive landscape, businesses are turning to automation as a game-changer. Recognizing the transformative power of automation, BPX Warehouse Specialists, renowned experts in warehouse optimization, have unveiled a comprehensive suite of automation solutions that are revolutionizing the industry.

With years of experience and a deep understanding of warehouse operations,…

BPX Warehouse Specialists: Your Trusted Partner in Warehouse Setup and Optimizat …

The efficient setup of a warehouse is the foundation for smooth operations and seamless supply chain management. Recognizing the criticality of this process, BPX Warehouse Specialists, renowned experts in warehouse setup and optimization, have unveiled a comprehensive suite of services designed to help businesses establish and optimize their warehouse operations.

Setting up a warehouse involves careful planning ( https://businessprocessxperts.com/lean-warehouse-management-consulting/ ), meticulous layout design, standardized processes, and the right technology solutions. With…