Press release

Phosphor Bronze Sheets Manufacturing Plant Project Details, Requirements, Cost and Economics 2025

The phosphor bronze industry has become one of the fastest-growing segments in the non-ferrous metals sector, supported by increasing demand across global markets. Setting up a phosphor bronze sheets manufacturing plant requires more than just infrastructure; it involves strategic planning, investment, efficient equipment, and strong market awareness. This article presents an overview of phosphor bronze sheets manufacturing plants, covering setup, processing stages, market trends, investment considerations, and operational requirements.What About Phosphor Bronze Sheets?

Phosphor bronze sheets hold a significant position in the global metal products market due to their exceptional properties, durability, and versatility in industrial applications. The alloy is characterized by excellent corrosion resistance, high fatigue strength, superior spring properties, and good electrical conductivity. The growing demand for phosphor bronze sheets in electrical connectors, springs, bearings, marine hardware, musical instruments, and industrial components has driven demand for high-quality products with precise thickness, finish, and mechanical properties. Quality control, consistent alloy composition, and adherence to international standards are becoming increasingly important, as industrial users and regulators emphasize performance reliability and material traceability.

Request a Sample Report: https://www.imarcgroup.com/phosphor-bronze-sheets-manufacturing-plant-project-report/requestsample

What is Driving the Phosphor Bronze Sheets Market?

The phosphor bronze sheets market is primarily driven by rising industrial demand for corrosion-resistant alloys in marine, automotive, and electrical industries, alongside increasing requirements for durable spring materials that emphasize long service life and fatigue resistance. Global manufacturing growth, particularly in electronics, telecommunications, and precision engineering sectors, has boosted consumption of phosphor bronze products. Expanding applications in marine hardware, fasteners, pump components, and valve systems have further facilitated wider utilization across industries. Moreover, the increasing use of phosphor bronze in musical instrument manufacturing, particularly for cymbals and strings, is fueling demand in specialized markets. Industrial modernization, infrastructure development, and rising quality standards in emerging economies also support market expansion. Sustainability initiatives, recycling programs for copper-based alloys, and the development of specialized phosphor bronze grades are influencing purchasing decisions, aligning the industry with evolving preferences for high-performance engineering materials.

Understanding Phosphor Bronze Sheets Manufacturing

• Phosphor bronze sheets manufacturing refers to converting raw copper, tin, and phosphorus into precision-rolled metal sheets with specific properties.

• Manufacturing activities include melting, alloying, casting, hot rolling, cold rolling, annealing, surface treatment, slitting, and packaging.

• Phosphor bronze requires precise alloy composition control; therefore, strict temperature management, rolling parameters, and quality monitoring are vital.

• Efficiency in the process ensures consistent quality, dimensional accuracy, appropriate mechanical properties, and meeting specific industrial application requirements for domestic and export markets.

Key Components of a Business Plan

• Executive Summary: Outlines vision, mission, and business objectives.

• Market Research: Identifies demand patterns, consumer behavior, and competitive players.

• Operational Strategy: Includes plant design, capacity, workflow, and quality assurance measures.

• Marketing and Sales Plan: Defines distribution channels, branding, and positioning in domestic and export markets.

• Financial Planning: Covers projected investments, cost structures, and revenue expectations.

• Risk Assessment: Evaluates potential challenges such as raw material supply, regulatory compliance, and market fluctuations.

Capital Investment Overview

CapEx (Capital Expenditure):

• Land acquisition, plant construction, utilities setup, and equipment purchase.

• One-time costs associated with establishing infrastructure and ensuring manufacturing efficiency.

• Defines long-term productivity and competitiveness.

OpEx (Operating Expenditure):

• Recurring costs including labor, utilities, packaging, storage, and transportation.

• Raw material procurement and regular equipment maintenance.

• Compliance with safety certifications, hygiene practices, and quality control standards.

Buy Report Now: https://www.imarcgroup.com/checkout?id=24054&method=1911

Machinery and Equipment Requirements

Primary Equipment:

• Induction melting furnaces for alloy preparation.

• Continuous casting machines or ingot casting systems.

• Hot rolling mills for initial thickness reduction.

• Cold rolling mills for precise gauge control.

• Annealing furnaces for stress relief and property enhancement.

• Pickling and cleaning lines for surface treatment.

• Slitting machines for width customization.

• Leveling and flattening equipment for dimensional accuracy.

• Shearing and cutting machines for size customization.

• Automated packaging systems for protective wrapping.

Supporting Equipment:

• Material handling cranes and forklifts.

• Spectroscopic analyzers for composition verification.

• Tensile testing machines and hardness testers.

• Edge trimming equipment.

• Coil handling and storage systems.

• Cooling systems and water treatment plants.

• Dust collection and emission control systems.

Operating Costs

• Procurement of raw materials (copper cathodes, tin ingots, phosphorus master alloy).

• Labor salaries, training, and workforce management.

• Utilities such as electricity, natural gas, and water.

• Maintenance and servicing of machinery and equipment.

• Packaging materials including protective films, wooden crates, and steel strapping.

• Transportation and distribution logistics.

• Certification, compliance, and quality assurance activities.

Raw Materials

• Main Raw Materials: Copper cathodes (92-94%), tin ingots (5-8%), and phosphorus in deoxidized form (0.03-0.35%).

• Additional Inputs: Deoxidizing agents, flux materials, and alloying elements for specific grade requirements.

• Packaging Materials: Protective paper, plastic films, wooden pallets, steel strapping, and export-quality crates.

• Supply Considerations: Consistency of quality, reliable sourcing partnerships, LME-grade material procurement, price volatility management, and adherence to international metallurgical standards.

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=24054&flag=C

Frequently Asked Questions (FAQs)

1. What is the first step in setting up a phosphor bronze sheets manufacturing plant?

The process begins with developing a business plan, securing land, obtaining environmental and manufacturing licenses, and identifying reliable suppliers for copper, tin, and phosphorus materials.

2. Why is alloy composition control considered critical?

Precise alloy composition ensures desired mechanical properties, corrosion resistance, and electrical conductivity, helping meet domestic and international quality standards and customer specifications.

3. Can phosphor bronze sheets manufacturing plants focus only on domestic markets?

Yes, though many plants also target exports, as international markets often demand high-quality phosphor bronze sheets for specialized industrial and engineering applications.

4. How does automation benefit phosphor bronze sheets manufacturing?

Automation improves rolling precision, reduces dimensional variations, lowers dependency on manual labor, enhances product consistency, and ensures accurate thickness control throughout production.

5. Is backward integration into copper refining necessary?

Not mandatory; many manufacturers rely on partnerships with copper refineries, metal traders, and alloy suppliers for consistent raw material supply.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Phosphor Bronze Sheets Manufacturing Plant Project Details, Requirements, Cost and Economics 2025 here

News-ID: 4244196 • Views: …

More Releases from IMARC Group

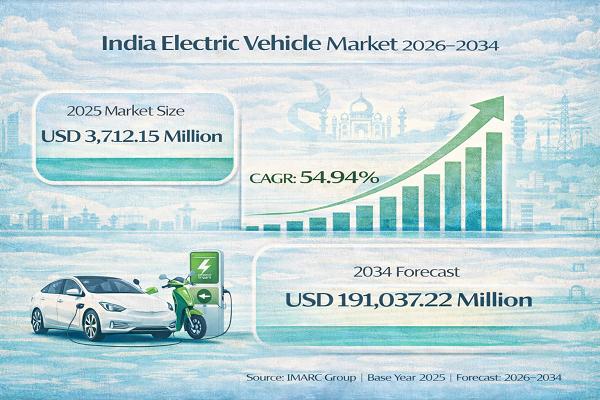

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Phosphor

Evolving Market Trends In The Phosphor Screen Scanners Industry: Advancements In …

Our market reports now include the latest updates on global tariffs, trade impacts, and evolving supply chain dynamics.

What Is the Expected Phosphor Screen Scanners Market Size During the Forecast Period?

The market size of phosphor screen scanners has witnessed a swift expansion in the past few years. The growth forecast indicates an increase from $1.76 billion in 2024 to $1.95 billion in 2025, showing a compound annual growth rate (CAGR) of…

Phosphor for X-ray Market Booming Segments; Investors Seeking Stunning Growth, M …

Los Angeles, (United States) - The Global Phosphor for X-ray Market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Phosphor for X-ray market. For instance, the market dynamics section digs deep into the drivers,…

LED Phosphor Market to See Massive Growth by 2029

The LED Phosphor Market size is expected to grow at an annual average of CAGR 19% during the forecast period (2023-2029). LED phosphor is a photo luminescent material that can absorb the energy of violet and blue light from gallium nitride and other LED chips in order to transform it into visible light. Phosphors are widely deployed in this technology as they greatly determine the LED's stability, efficiency, and light…

Phosphor Screen Market 2020: Trends And Growth Factors Analysis 2028 | Leading P …

An influential Phosphor Screen Market report carries out an evaluation of the growth rate and the market value of Phosphor Screen industry based on market dynamics and growth inducing factors. Thorough market analysis covered in this report by skilled experts gives every bit of knowledge which is imperative to design and align with current market scenarios. This market research report is one-stop archive for in-depth knowledge of market analytics aggregated…

Phosphor Bronze Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Phosphor Bronze Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Phosphor Bronze players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Phosphor Bronze with respect to individual growth…

Silicate LED Phosphor Market Overview by 2025: QY Research

Global Silicate LED Phosphor market report is first of its kind research report that covers the overview, summary, market dynamics, competitive analysis, and leading player’s various strategies to sustain in the global market. This report covers five top regions of the globe and countries within, which shows the status of regional development, consisting of market value, volume, size, and price data. Apart from this, the report also covers detail information…