Press release

Lathe Machine Chucks Market, The Backbone of Precision Engineering and Toolroom Advancements

The Lathe Machine Chucks Market plays a critical role in the global manufacturing and machining industry, serving as the backbone of metalworking, tooling, and precision engineering. A lathe chuck is an essential workholding device used to clamp and hold the workpiece during machining, ensuring accuracy, consistency, and stability throughout production. As industries increasingly demand tighter tolerances and higher productivity, the market for advanced lathe chucks has witnessed a significant surge in technological innovations and automation integration.Get a Sample PDF Brochure of the Report: https://www.persistencemarketresearch.com/samples/24775

The market growth is primarily fueled by the rising adoption of CNC (Computer Numerical Control) lathes, automation in metalworking, and the need for precision machining in automotive, aerospace, and energy sectors. Among various types, power chucks dominate the market due to their ability to provide higher clamping force and automation compatibility. Regionally, Asia-Pacific leads the global market, supported by rapid industrialization, expanding manufacturing infrastructure, and the presence of major machine tool producers in China, Japan, and India.

Key Highlights from the Report

• Rising automation in manufacturing drives the adoption of CNC-compatible power chucks.

• Asia-Pacific remains the leading region with over 40% market share due to strong industrial growth.

• Expanding applications in automotive, aerospace, and heavy machinery sectors fuel global demand.

• Technological integration, such as smart sensors and self-centering chucks, enhances precision.

• Sustainable manufacturing trends are promoting the development of energy-efficient lathe components.

Market Segmentation

The lathe machine chucks market can be segmented based on type, jaw configuration, lathe type, end-user industry, and region. Each segment contributes uniquely to the overall market growth and technological evolution.

By Type

The market is segmented into manual chucks, power chucks, and hydraulic chucks. Power chucks dominate the global market due to their superior efficiency, reduced setup time, and suitability for automated machining processes. These are widely used in CNC lathes for heavy-duty industrial applications. Manual chucks, on the other hand, remain popular in small workshops and maintenance operations, particularly in developing countries where cost sensitivity is high. Hydraulic chucks are emerging as a premium segment due to their ability to deliver consistent gripping force and minimal vibration during high-speed machining.

By Jaw Configuration

Based on jaw configuration, the market includes 2-jaw, 3-jaw, 4-jaw, and 6-jaw chucks. The 3-jaw chuck segment holds the largest market share, primarily because it offers self-centering capability ideal for round or hexagonal workpieces. 4-jaw independent chucks are preferred for irregularly shaped components that require individual adjustment. Meanwhile, 6-jaw chucks are gaining traction in precision industries like aerospace and electronics due to their ability to reduce deformation and provide superior clamping accuracy.

By Lathe Type

Lathe machine chucks are used across engine lathes, CNC lathes, turret lathes, and special-purpose lathes. The CNC lathe segment leads this category, driven by the rapid transition toward automated manufacturing and Industry 4.0 adoption. Engine lathes continue to find demand in traditional manufacturing setups and educational institutions for basic machining operations.

By End-User Industry

The key end-user industries include automotive, aerospace, construction, oil & gas, energy, shipbuilding, and general machinery manufacturing. Among these, the automotive sector dominates due to the high demand for precision components such as shafts, gear blanks, and brake discs. The aerospace industry follows closely, as the sector requires tight-tolerance parts machined from exotic materials. Additionally, energy and oil & gas industries rely on heavy-duty chucks for machining pipes, valves, and turbine components.

Read More In Detail: https://www.persistencemarketresearch.com/market-research/lathe-machine-chucks-market.asp

Regional Insights

The geographical landscape of the lathe machine chucks market reflects distinct industrial dynamics across major regions: Asia-Pacific, North America, Europe, Latin America, and the Middle East & Africa.

Asia-Pacific (APAC)

The Asia-Pacific region dominates the global market with over 40% share. This growth is propelled by large-scale manufacturing in China, Japan, India, and South Korea. China remains the world's largest producer and consumer of machine tools, contributing significantly to market expansion. The growing demand for automotive components, metal parts, and industrial equipment fuels continuous adoption of advanced lathe chucks. Moreover, government initiatives supporting local manufacturing and automation-such as "Made in China 2025" and "Make in India"-are further boosting demand.

North America

North America ranks as the second-largest market, supported by advanced manufacturing ecosystems in the United States and Canada. The region's focus on CNC automation, aerospace precision machining, and energy-efficient solutions drives the adoption of modern lathe chucks. The integration of IoT (Internet of Things) in machine tools is becoming common, allowing operators to monitor clamping performance and predictive maintenance in real-time.

Europe

Europe's market growth is underpinned by its well-established automotive, machinery, and aerospace industries. Germany, Italy, and the UK lead the region, with many manufacturers emphasizing sustainability, digital manufacturing, and automation. The European Union's "Green Manufacturing" initiatives are encouraging machine tool producers to design environmentally friendly chucks that minimize energy consumption while maximizing efficiency.

Latin America and MEA

Emerging regions such as Latin America and the Middle East & Africa (MEA) are gradually adopting machining technologies due to industrial diversification. Brazil and Mexico are key contributors to Latin America's growth, while Turkey, South Africa, and Saudi Arabia show increasing interest in localized manufacturing. Rising foreign investments in these regions' industrial sectors are likely to create new opportunities for lathe chuck manufacturers.

Market Drivers

The lathe machine chucks market is primarily driven by the rising demand for precision machining, especially in industries that require high-quality surface finishes and complex geometries. The shift from conventional manufacturing to smart and automated production systems is another major growth driver. As manufacturers embrace Industry 4.0, machine tools are becoming smarter, incorporating digital controls, automation, and predictive analytics to improve efficiency and reduce downtime.

The growing adoption of CNC and robotic machining systems has significantly increased the need for power chucks with quick-change jaws and self-centering mechanisms. Moreover, the automotive and aerospace sectors are pushing the limits of material science-using high-strength alloys and composites-which require specialized chucks capable of maintaining rigidity under extreme conditions. Government policies encouraging industrial modernization and technological innovation are further accelerating market development.

Market Restraints

Despite steady growth, the lathe machine chucks market faces several challenges. One of the primary restraints is the high cost of advanced and automated chucks, which limits their adoption among small and medium-sized enterprises (SMEs). The price sensitivity in developing markets discourages investment in high-precision, automated systems.

Another restraint is the lack of skilled operators capable of handling and maintaining sophisticated CNC and power chucks. In addition, fluctuations in raw material prices, especially steel and alloy components, impact production costs and profitability. Environmental regulations related to machining waste and lubrication fluids also add to the operational complexity for manufacturers.

Do You Have Any Query Or Specific Requirement? Request Customization of Report: https://www.persistencemarketresearch.com/request-customization/24775

Market Opportunities

The future outlook for the lathe machine chucks market presents several opportunities, primarily driven by technological innovation and digital transformation. The integration of IoT-enabled sensors for real-time monitoring and predictive maintenance is revolutionizing workholding systems. Smart chucks that can automatically adjust gripping force based on material hardness or part geometry are expected to gain rapid traction.

Additionally, there is growing demand for customized and modular chucks tailored to specific applications in aerospace, defense, and energy sectors. Manufacturers are increasingly focusing on lightweight and high-strength materials to improve energy efficiency and machine performance. The rise of additive manufacturing and hybrid machining is another key area creating new use cases for adaptive workholding solutions.

Sustainability also represents a major opportunity. The push toward eco-friendly machining-reducing waste, vibration, and power consumption-is prompting the development of energy-efficient chucks that align with global green manufacturing standards. Emerging economies, where industrialization is expanding rapidly, present vast untapped potential for both domestic and international market players.

Company Insights

The lathe machine chucks market is moderately consolidated, with a mix of global leaders and regional manufacturers competing through technological innovation, product quality, and customer service.

• SMW Autoblok

• SCHUNK GmbH & Co. KG

• Kitagawa Europe Ltd.

• Forkardt Inc.

• Bison-Bial S.A.

• Pratt Burnerd International Ltd.

• RÖHM GmbH

• Howa Machinery Ltd.

• Samchully Workholding Inc.

• TDG Clamping Solutions

Recent Developments:

SCHUNK GmbH & Co. KG launched a new line of intelligent lathe chucks integrated with sensor systems for automated pressure control, enabling smart manufacturing in CNC operations.

SMW Autoblok introduced an energy-efficient power chuck series designed to reduce air consumption and improve grip force consistency, aligning with sustainable manufacturing initiatives.

Related Reports:

https://www.persistencemarketresearch.com/market-research/electromagnetic-flow-meters-market.asp

https://www.persistencemarketresearch.com/market-research/coating-machines-market.asp

https://www.persistencemarketresearch.com/market-research/conveyors-in-food-market.asp

https://www.persistencemarketresearch.com/market-research/overhead-conveyors-market.asp

https://www.persistencemarketresearch.com/market-research/bag-heat-sealing-equipment-market.asp

Persistence Market Research

Second Floor, 150 Fleet Street, London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lathe Machine Chucks Market, The Backbone of Precision Engineering and Toolroom Advancements here

News-ID: 4243902 • Views: …

More Releases from Persistence Market Research

Event Tourism Market Set for Exponential Growth through 2032 - PMR Research

The global Event Tourism Market is poised for remarkable expansion, driven by sustained demand for live experiences, increased business travel, hybrid event adoption, and a rebound in international tourism. According to industry projections, the market is expected to grow from an estimated US$1,538.3 billion in 2025 to US$2,631.5 billion by 2032, registering a CAGR of 7.3% over the forecast period.

This robust growth underscores the evolution of event tourism into one…

Residential Lighting Fixtures Market Set for Robust Growth Through 2032

The global residential lighting fixtures market is poised for strong expansion over the coming decade, underpinned by shifting consumer preferences toward energy efficient, smart, and design centric lighting solutions. According to a comprehensive market analysis by Persistence Market Research, the market was valued at US$ 20.4 billion in 2025 and is projected to reach US$ 32.2 billion by 2032, growing at a CAGR of 5.9 % from 2025 to 2032.

➤…

Active Modified Atmospheric Packaging Market to Reach US$ 37.9 Billion by 2033 - …

The active modified atmospheric packaging market is gaining strong traction as food manufacturers retailers and logistics providers focus on extending product shelf life while maintaining freshness quality and safety. Active modified atmospheric packaging integrates gas flushing scavengers and moisture regulators to actively control the internal atmosphere of a package thereby slowing microbial growth oxidation and spoilage. Unlike passive packaging this advanced technology continuously interacts with the packaged product creating an…

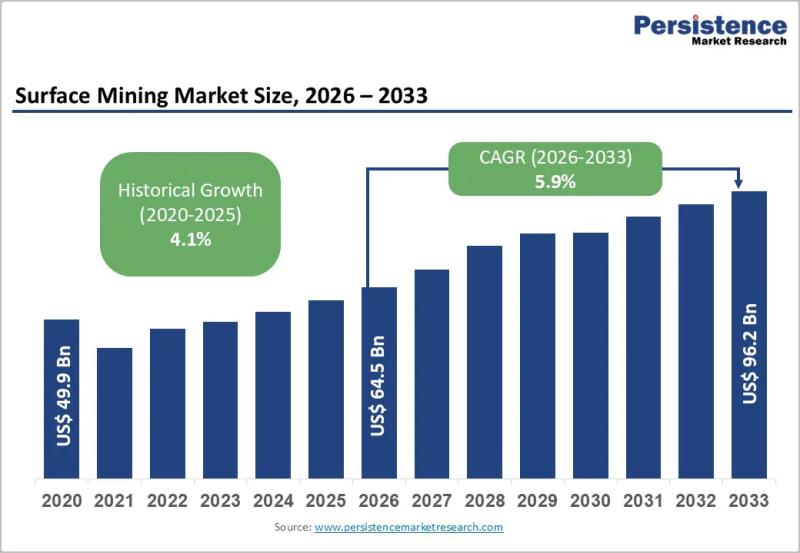

Surface Mining Market Size to Reach US$ 96.2 Billion by 2033 - Persistence Marke …

The surface mining market plays a critical role in the global extraction industry, enabling efficient recovery of minerals, metals, and fossil fuels located near the earth's surface. Surface mining techniques such as open pit mining, strip mining, mountaintop removal, and quarrying are widely used for coal, iron ore, copper, bauxite, and other industrial minerals. Compared to underground mining, surface mining offers higher production rates, lower operational risks, and improved cost…

More Releases for CNC

XTJ CNC Elevates Custom CNC Machining for Highly Precise Industrial Applications

Carmel, IN 46032, United States, 28th Jan 2026 - XTJ CNC, a prominent provider of custom CNC machining servicesa prominent provider of custom CNC machining services, has announced significant advancements in its capabilities to better serve industries requiring high-precision components. With a focus on custom CNC machining, the company is reinforcing its reputation as a trusted partner in the aerospace, automotive, and electronics sectors. These advancements reflect XTJ CNC's commitment…

Benefits of CNC Machining for Custom Robotic Projects - Tuofa CNC Machining

Robotics is evolving quickly, and higher-performance robots demand stronger mechanical consistency. As DOF increases, joint stacks and mounting interfaces must align accurately to preserve smooth, repeatable motion. CNC machining delivers custom parts with controlled dimensions and reliable quality, reducing fit issues during assembly. It also shortens prototype cycles and supports small-batch production, helping robotics teams convert designs into dependable hardware.

Robotics is getting smarter and smarter. Better perception, smarter control loops,…

CNC Controller Market Report 2024 - CNC Controller Market Trends, Opportunities …

"The Business Research Company recently released a comprehensive report on the Global CNC Controller Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

CNC Controller Global Market to Generate $3.84 Billion By 2028, Registering at a …

"The new report published by The Business Research Company, titled CNC Controller Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the cnc controller market size has grown strongly in recent years. It will grow from $2.82 billion…

Silver CNC Now Offers CNC Rotary Tables for CNC Machining Centers

Silver CNC is now offering a new line of CNC rotary tables that are perfect for use with CNC machining centers. The rotary tables are available in three different sizes, and each one is made from high-quality cast iron to ensure durability and precision. With a built-in indexing system, the rotary tables make it easy to position your workpiece exactly where you need it. Plus, they're backed by a full…

Trending 2020: CNC Machine (CNC Machine Tools) Market Booming Worldwide

Prophecy Market Insights recently presented CNC Machine (CNC Machine Tools) market report which provides reliable and sincere insights related to the various segments and sub-segments of the market. The market study throws light on the various factors that are projected to impact the overall dynamics of the CNC Machine (CNC Machine Tools) market over the forecast period (2019-2029).

The CNC Machine (CNC Machine Tools) research study contains 100+ market data Tables,…