Press release

From Cocoa Bean to High-End Confectionery - LST Provides End-to-End Solutions to Transform Global Chocolate Manufacturing

The global chocolate industry is undergoing a delicious yet demanding transformation. Once defined by high-volume, standardized products, the market is rapidly pivoting toward premiumization, health consciousness, and artisanal quality. Consumers worldwide are no longer satisfied with simple sweetness; they demand complex flavours, unique textures, and products aligned with modern wellness trends, such as high cocoa content, low sugar, and functional ingredients.This shift presents a significant challenge to food manufacturers: how to produce a wide, volatile range of sophisticated products at industrial scale while simultaneously maximizing efficiency and maintaining razor-thin profit margins. The answer lies not in traditional batch processing, but in the strategic adoption of end-to-end automation and Industry 4.0 integration, spearheaded by specialized equipment providers like Chengdu LST Science And Technology Co., Ltd. (LST Machine).

This analysis delves into the prevailing trends shaping the global chocolate market and highlights how LST Machine has positioned itself as the critical partner for food manufacturers aiming to achieve sustainable profitability and technological leadership.

Image: https://www.abnewswire.com/upload/2025/10/16f173f40dc77e42c4d5205a1f746c4e.jpg

Part I: The Global Chocolate Manufacturing Landscape & The Automation Imperative

The global chocolate market continues its robust expansion, propelled by rising disposable incomes in emerging economies and a sustained consumer desire for high-quality indulgences in established markets. This demand profile is forcing manufacturers to rethink their production lines entirely. The complexity of modern recipes-from intricate flavour profiles to precise tempering requirements for specialized coatings-makes the transition to automated equipment an economic and quality imperative.

Automation in chocolate manufacturing is no longer a luxury; it is the single most critical factor in maximizing Return on Investment (ROI) and securing a competitive edge. This investment generates immediate and long-term financial returns across three main areas: Operational Efficiency, Consistency and Quality Control, and Agility in Product Diversification.

The Core ROI Drivers of Industrial Automation1. Operational Efficiency and Labor Optimization

In manual or semi-automated environments, labour costs are a major factor, and production speeds are inherently constrained. Modern automated lines, which feature continuous systems for tempering, moulding, and cooling, can operate around the clock with minimal direct supervision.

*

Throughput Maximization: High-speed, continuous equipment dramatically increases output volume, enabling manufacturers to efficiently meet surging seasonal demand or successfully penetrate new high-volume markets.

*

Reduced Labor Cost: Automation minimizes the need for continuous manual intervention. This allows skilled personnel to be reallocated from repetitive production tasks to more valuable roles, such as advanced quality control, maintenance oversight, and vital new recipe development, optimizing the labour force and reducing operational expenditure.

2. Consistency, Quality Control, and Waste Reduction

Chocolate manufacturing is a process demanding scientific precision, especially during the critical tempering stage. Tempering dictates the chocolate's final physical properties-its appealing gloss, the satisfying 'snap' upon breaking, and its shelf life. Variance at this stage leads directly to product rejection and significant material waste.

*

Absolute Precision: Automated tempering machines, controlled by sophisticated sensors and advanced PLC (Programmable Logic Controller) systems, ensure that the exact crystal structure required is achieved consistently, batch after batch. This eliminates the quality variance that is common in manual operations.

*

Minimizing Human Error: Automated systems virtually eliminate production errors, leading to a substantial reduction in expensive rework and material waste. This direct impact on the cost of goods sold is a major factor in boosting net margins.

*

Regulatory Compliance: The modern, all-stainless-steel construction of high-end equipment is designed for easier cleaning and sterilization, meeting stringent global food safety standards (such as HACCP and GMP). This mitigates the financial and reputational risk associated with costly product recalls and regulatory penalties.

3. Agility and Product Diversification

The contemporary consumer market is defined by fluid trends, requiring manufacturers to rapidly adjust their product offerings. Legacy equipment often necessitates lengthy and costly downtime for configuration changes, making market responsiveness difficult.

*

Quick Changeover: Advanced automated moulding and depositing lines are engineered for fast recipe changes and quick mould swaps. This flexibility allows a single production line to handle multiple Stock Keeping Units (SKUs)-from simple, high-volume bars to complex filled chocolates, decorated confectionery, or specialty items like cereal bars. This adaptability is the key to capturing high-margin niche market segments and maximizing revenue opportunities during peak seasonal periods.

The contemporary chocolate industry thus requires a partner capable of delivering integrated, high-precision machinery that spans the entire value chain-a role LST Machine has embraced as its core mission.

Part II: LST Machine - Maximizing Value Through End-to-End Solutions

Established in 2009, Chengdu LST Science And Technology Co., Ltd. (LST Machine) has strategically focused on providing comprehensive "overall solutions" for mid-to-high-end chocolate food manufacturing. Their core competitive advantages directly address the modern manufacturer's need for efficiency, reliability, and versatility, positioning them to drive measurable ROI for their partners.

1. The Core Advantage: Integrated System Design

LST's primary value proposition is its ability to supply a complete, integrated production ecosystem, ensuring seamless operation from raw cocoa processing to final packaging. This holistic approach eliminates the complexity and potential compatibility issues associated with sourcing fragmented, specialized components from multiple vendors. LST's comprehensive product portfolio covers every essential stage:

*

Initial Processing: Includes robust chocolate feeding systems, high-precision ball mills for ultra-fine refining, and advanced conching equipment to develop rich, consistent flavour profiles.

*

Core Manufacturing: Features industry-leading, continuous tempering machines, versatile automatic moulding and depositing lines, and specialized coating/enrobing machines.

*

Finishing and Packaging: Covers specialized decorating machines, controlled-environment cooling tunnels, and fully automated, high-speed packaging lines.

By offering this single-source solution, LST simplifies the capital investment process, streamlines maintenance protocols, and significantly accelerates setup time-all factors that reduce hidden costs and time-to-market for new products. The company's commitment to robust construction, utilizing all-stainless-steel materials and securing globally recognized CE certification, guarantees the durability and longevity of the equipment.

2. Technological Innovation and Application Scenarios

LST's focus on high automation is non-negotiable, with their equipment employing advanced PLC and intuitive touch screen interfaces. This technology provides operators with precise, real-time control and parameter adjustment, which is essential for successfully managing the complexity and variability of diverse chocolate recipes.

The equipment finds application across a broad spectrum of production scales and complexities:

Application Scenario

LST Products Utilized

Core ROI Benefit

Industrial Volume Production

High-capacity Ball Mills, Automatic Moulding Lines, Continuous Tempering Machines.

Maximized throughput and absolute consistency in quality with minimal human intervention.

Mid-Size & Craft Chocolate Makers

Versatile Tempering Machines, Automatic Oat Chocolate Production Lines.

Ability to scale production quickly without sacrificing artisanal quality; rapid diversification into niche products (e.g., nut clusters, cereal bars).

Specialty & Seasonal Products

Coating/Enrobing Machines, Decorating Machines.

High flexibility and quick changeovers for intricate designs and specialty coatings, allowing manufacturers to capture high-margin, seasonal sales peaks.

For example, the flexibility of LST's automated lines allows a manufacturer to pivot seamlessly from producing standard chocolate bars to highly complex products, such as fully automatic oat chocolate or gourmet cereal bars, without requiring significant additional capital expenditure on entirely new lines. This agility is vital for adapting to rapidly shifting consumer trends.

3. Global Commitment and Partnership

For capital equipment, ROI is deeply dependent on equipment uptime and longevity. LST supports its international customer base by maintaining a comprehensive global after-sales support system, with machinery deployed across major markets in Europe, Asia, the Americas, Africa, and Oceania. This global service network is crucial for minimizing potential production downtime and protecting the significant initial investment, directly contributing to long-term profitability.

While specific, detailed client case studies may be protected under commercial agreements, LST effectively demonstrates the reliability and performance of its solutions through its "Our Projects" sections. These visual proofs, combined with high industry ratings, serve as strong evidence of the company's commitment to delivering reliable, timely, and high-quality equipment-the foundational components for trust in high-value B2B partnerships.

Conclusion

The future of chocolate manufacturing is characterized by highly automated, consistent, and agile production. For food manufacturers looking to increase ROI in a premiumizing and health-conscious market, the strategic investment in integrated, high-quality equipment is paramount.

LST Machine's commitment to providing versatile, end-to-end chocolate solutions-from foundational milling and refining to final intricate decorations and packaging-positions them not just as a supplier, but as an essential strategic partner. By enabling superior consistency, minimizing waste, and offering the technological flexibility to pivot across diverse product lines, LST's equipment transforms operational cost centers into powerful profit drivers, helping the global industry transition seamlessly from the cocoa bean to high-end confectionery.

To explore how integrated chocolate automation can streamline your production and significantly enhance your bottom line, visit their official website: https://www.google.com/url?sa=E&source=gmail&q=https://www.lstchocolatemachine.com/

Media Contact

Company Name: Chengdu LST Science and Technology Co., Ltd

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=focus-from-cocoa-bean-to-highend-confectionerylst-provides-endtoend-solutions-to-transform-global-chocolate-manufacturing]

Phone: 0086 15528001618

Country: China

Website: http://www.lstchocolatemachine.com

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release From Cocoa Bean to High-End Confectionery - LST Provides End-to-End Solutions to Transform Global Chocolate Manufacturing here

News-ID: 4243425 • Views: …

More Releases from ABNewswire

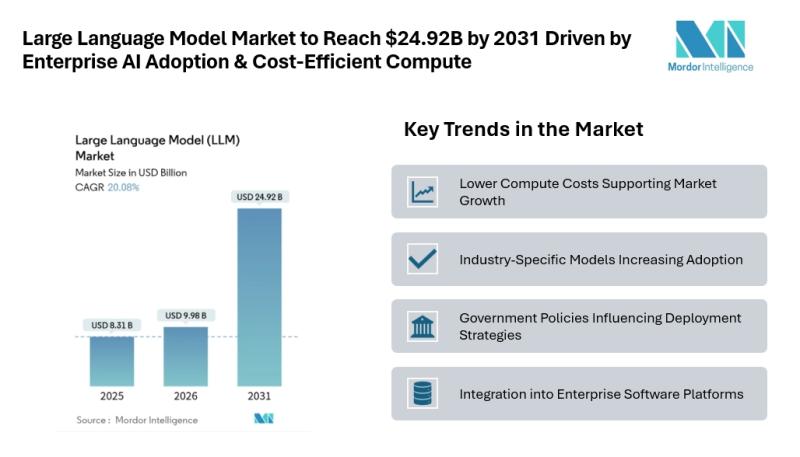

Large Language Model Market to Reach $24.92B by 2031 Driven by Enterprise AI Ado …

Mordor Intelligence has published a new report on the large language model market, offering a comprehensive analysis of trends, growth drivers, and future projections.

Large Language Model Market Outlook

According to Mordor Intelligence, the LLM market size [https://www.mordorintelligence.com/industry-reports/large-language-model-llm-market?utm_source=abnewswire] was valued at USD 8.31 billion in 2025 and is estimated to grow to USD 9.98 billion in 2026, reaching USD 24.92 billion by 2031 at a CAGR of 20.08% during the forecast period.…

Self Employed Tax Software UK: Why Freelancers and Sole Traders Are Switching to …

With Many individuals are seeking software that simplifies tax filing while ensuring full compliance with HMRC requirements. Manual spreadsheets and paper-based calculations are being replaced by real-time, automated systems that give users visibility over their tax position throughout the year. Among the platforms gaining traction is Pie, a UK-based digital tax app built specifically to support self-employed individuals with modern income needs.

LONDON, United Kingdom - February 19, 2026 - Demand…

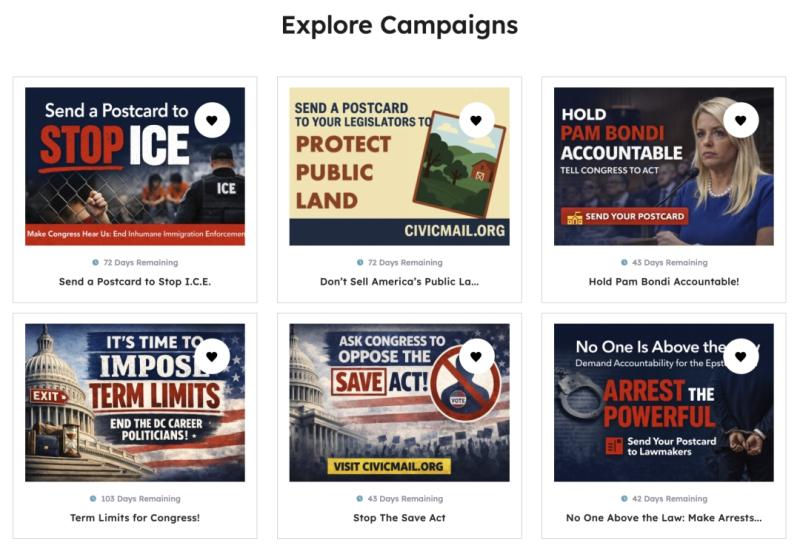

CivicMail.org Reinvents Postcard Campaigns for Grassroots Advocacy

CivicMail.org aims to bring civic engagement back to basics through the power of pen, paper, and postage.

Image: https://www.abnewswire.com/upload/2026/02/2addd1e9e0381d7e2262e1edbb064123.jpg

CivicMail.org [https://civicmail.org/] has announced its launch to help Americans send real, physical postcards to their elected officials with just a few clicks, delivering personalized messages directly to the desks of decision-makers at the local, state, and federal levels.

Research shows [https://www.concordia.ca/news/stories/2021/09/24/personalized-messages-are-more-likely-to-get-a-response-from-politicians-new-research-finds.html] that physical mail carries more weight with elected officials than petitions, emails, or…

New Children's Story: The Story of Sharin' Bear

A Heartfelt Message Of Courage, Kindness, And The True Meaning Of Giving

A pleasant new story for children, The Story of Sharin' Bear by Sharon Woods , introduces families to a lovable little cub whose journey of bravery and compassion changes him into a representation of sharing for children globally.

Entrenched in adventure, innocence, and emotional growth, this uplifting tale offers an unforgettable reminder that even the smallest acts of kindness can…

More Releases for LST

Leading Manufacturer LST: Innovative Chocolate Machine Lines for Versatile Confe …

CHENGDU, CHINA - In the dynamic world of confectionery, where precision, innovation, and versatility are paramount, one name stands out as a beacon of excellence: Chengdu LST Science & Technology Co., Ltd. [https://www.lstchocolatemachine.com/](LST Machine). Established in 2009, LST has rapidly ascended to become a leading manufacturer, offering an unparalleled suite of advanced chocolate machinery that empowers confectioners worldwide to transform their creative visions into delectable realities. This press release delves…

Leading Manufacturer LST: Innovative Chocolate Machine Lines for Versatile Confe …

CHENGDU, CHINA - In the dynamic world of confectionery, where precision, innovation, and versatility are paramount, one name stands out as a beacon of excellence: Chengdu LST Science & Technology Co., Ltd. (LST Machine) (https://www.lstchocolatemachine.com/). Established in 2009, LST has rapidly ascended to become a leading manufacturer, offering an unparalleled suite of advanced chocolate machinery that empowers confectioners worldwide to transform their creative visions into delectable realities. This press release…

LST Machine's Versatile Depositors Redefine Global Confectionery Production

The Versatility Mandate: Why Multi-Functional Equipment is the Future of Chocolate Manufacturing

The global chocolate and confectionery machinery market is undergoing a rapid transformation, driven by consumer demand for novelty, personalization, and higher quality. Manufacturers are no longer content with producing a single line of products; success now hinges on the ability to swiftly pivot, innovate, and master diverse product categories-all while maintaining operational efficiency and cost-effectiveness. This new operating environment…

LST Machine's Versatile Depositors Redefine Global Confectionery Production

The Versatility Mandate: Why Multi-Functional Equipment is the Future of Chocolate Manufacturing

The global chocolate and confectionery machinery market is undergoing a rapid transformation, driven by consumer demand for novelty, personalization, and higher quality. Manufacturers are no longer content with producing a single line of products; success now hinges on the ability to swiftly pivot, innovate, and master diverse product categories-all while maintaining operational efficiency and cost-effectiveness. This new operating environment…

LST Machine Unveils Cutting-Edge Chocolate Tempering Innovations for Global Conf …

November 6, 2025 - Chengdu, China - In a move poised to reshape the confectionery manufacturing landscape, Chengdu LST Technology Co., Ltd. (LST Machine) (https://www.lstchocolatemachine.com/)has introduced groundbreaking advancements in chocolate tempering technology. These innovations promise unprecedented precision, efficiency, and versatility for chocolate producers worldwide, addressing the evolving demands of an industry projected to reach $250 billion by 2030.

The Booming Confectionery Equipment Sector: Trends Driving Innovation

The global chocolate and confectionery machinery…

LST Equipment: Multi-Functional Design Breaks Production Barriers

The Sweet Future: Global Trends Driving the Chocolate Machinery Market

The global chocolate industry is undergoing a profound transformation, moving beyond traditional mass production toward customization, health consciousness, and ethical sourcing. This shift is placing unprecedented pressure and opportunity on the machinery sector that equips this multi-billion-dollar market. For manufacturers like Chengdu LST Science and Technology Co., Ltd. (LST Machine), understanding and meeting these dynamic needs is key to maintaining market…