Press release

High Temperature Coatings Market Size Worth US$4.13 Billion by 2032

The global market for high temperature coatings has experienced strong growth over the past decade, driven by rapid industrialization, increasing infrastructure development, and the growing need for materials that can withstand extreme heat conditions. These coatings are specifically engineered to protect surfaces exposed to elevated temperatures, oxidation, and corrosion. They play an essential role in maintaining structural integrity and performance efficiency in a wide range of industrial applications. As global industries continue to modernize and adopt advanced production technologies, the demand for durable, heat-resistant coatings is projected to rise significantly.High temperature coatings are commonly used in sectors such as automotive, aerospace, petrochemical, power generation, metal processing, and construction. These coatings enhance performance, improve safety, and extend the service life of materials and components exposed to thermal stress. The global market is also witnessing a growing preference for environmentally friendly coatings that combine high performance with low emissions.

Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response: https://www.persistencemarketresearch.com/samples/35438

According to Persistence Market Research, the global high temperature coatings market size is projected to rise from US$3.12 billion in 2025 to US$4.13 billion by 2032. The market is further anticipated to register a compound annual growth rate of 4.1 percent during the forecast period from 2025 to 2032. According to the Persistence Market Research report, market growth is driven by increased product demand across various sectors such as metal processing, cookware and bakeware, building and construction, automotive, aerospace, petrochemical, and industrial machinery.

Market Overview

High temperature coatings are specialized formulations that can withstand temperatures ranging from 150 degrees Celsius to over 1000 degrees Celsius. These coatings are applied to surfaces exposed to high heat in order to prevent oxidation, corrosion, scaling, and degradation. The key objective of these coatings is to maintain surface integrity and performance in extreme thermal environments.

The market is segmented by product type, substrate, technology, and end-use industry. Product types typically include epoxy, silicone, polyester, acrylic, and powder-based coatings. Each type serves specific temperature ranges and application needs. Silicone-based coatings, for example, are widely used due to their excellent thermal stability and protective properties.

Substrates include metal, steel, and aluminum surfaces, as these materials are commonly used in high-temperature environments. Technological advancements have also led to the development of water-based and solvent-based coatings that deliver high heat resistance while maintaining environmental compliance.

Key Growth Drivers

The growing demand for high temperature coatings is underpinned by several fundamental factors that are reshaping industrial requirements and technological standards worldwide.

Expanding Industrial Base

The increase in industrial production across sectors such as manufacturing, automotive, and construction has significantly fueled the demand for heat-resistant coatings. Industrial machinery, furnaces, turbines, and processing equipment operate under extreme heat and require durable coatings for protection and performance.

Rising Automotive Production

The automotive sector remains a primary consumer of high temperature coatings. These coatings are applied to exhaust systems, engine components, and braking systems to enhance heat resistance and longevity. With the expansion of the electric vehicle market, there is also a growing need for coatings that can protect high-performance components exposed to varying thermal conditions.

Infrastructure Development

Large-scale infrastructure projects across emerging economies have spurred demand for heat-resistant coatings in construction and metal processing. The increasing use of steel structures, pipelines, and equipment in energy and building sectors requires high durability coatings that can withstand temperature fluctuations.

Technological Advancements

Continuous innovations in coating formulations, including the introduction of nanotechnology and advanced silicone resins, have improved the performance, adhesion, and durability of high temperature coatings. These innovations allow coatings to maintain functionality in more extreme environments and extend the lifespan of industrial assets.

Regulatory and Environmental Compliance

Global regulations targeting industrial emissions and environmental sustainability are encouraging manufacturers to develop eco-friendly coatings. The trend toward low-VOC (volatile organic compound) coatings and waterborne formulations is increasing, driving the adoption of advanced, environmentally responsible heat-resistant products.

Dive deeper into the market data: https://www.persistencemarketresearch.com/market-research/high-temperature-coatings-market.asp

Market Segmentation

The high temperature coatings market is categorized based on product type, technology, application, and end-use industry.

By Product Type

• Epoxy Coatings: Offer excellent adhesion and chemical resistance, ideal for protective applications in industrial equipment.

• Silicone Coatings: Widely used for their superior thermal stability and corrosion protection.

• Polyester and Acrylic Coatings: Used for moderate temperature applications requiring aesthetic appeal and surface protection.

• Powder Coatings: Known for their eco-friendly characteristics and superior performance at high temperatures.

By Technology

• Water-Based Coatings: Increasingly adopted due to environmental advantages, including low emissions and compliance with strict regulations.

• Solvent-Based Coatings: Provide high durability and chemical resistance for applications that demand superior protection.

• Powder Coatings: Preferred for their durability and ability to provide uniform coverage without using solvents.

By End-Use Industry

• Metal Processing: Utilizes heat-resistant coatings to protect equipment such as furnaces, heat exchangers, and pipes.

• Automotive: Uses coatings in exhaust manifolds, brake systems, and engine components for enhanced heat performance.

• Aerospace: Requires high-performance coatings to protect aircraft parts exposed to extreme temperatures.

• Building and Construction: Applies coatings on structural steel and architectural components for fire resistance and protection.

• Petrochemical and Industrial Machinery: Relies on coatings to prevent corrosion and damage caused by heat and chemical exposure.

Regional Insights

The global high temperature coatings market demonstrates significant regional diversity in terms of production, consumption, and technological innovation.

North America

North America remains a prominent market due to advanced industrial infrastructure and strong presence of key manufacturers. The region's focus on sustainability and innovation has driven the adoption of eco-friendly coating technologies. Industries such as aerospace and automotive in the United States are among the leading consumers of high temperature coatings.

Europe

Europe is another major market, supported by stringent environmental regulations and growing demand for heat-resistant coatings in construction, automotive, and energy sectors. The region's emphasis on sustainable materials and circular economy principles continues to promote research and development in heat-resistant technologies.

Asia Pacific

Asia Pacific represents the fastest-growing regional market. Rapid industrialization, urbanization, and infrastructure investments in countries such as China, India, Japan, and South Korea are fueling the demand for high temperature coatings. The expansion of manufacturing sectors, combined with favorable government policies promoting industrial growth, makes this region a key contributor to global market revenues.

Latin America and Middle East & Africa

These regions are emerging as important markets, driven by growing industrial activity and development in petrochemical and construction sectors. Increasing investments in oil and gas infrastructure and metal processing plants are expected to boost regional demand for heat-resistant coatings.

Competitive Landscape

The high temperature coatings market is moderately consolidated with several leading global and regional players competing through product innovation, mergers, and acquisitions. Companies are focusing on enhancing product performance, expanding production capacities, and developing sustainable coating technologies.

Key players in the market include Akzo Nobel N.V., PPG Industries, The Sherwin-Williams Company, Axalta Coating Systems, Hempel A/S, Jotun Group, Aremco Products Inc., Chemco International Ltd., Carboline Company, and Belzona International Ltd. These companies are investing in research and development to create next-generation coatings capable of delivering superior thermal performance, corrosion protection, and environmental compliance.

In addition, strategic partnerships between coating manufacturers and end-use industries are strengthening supply chains and ensuring long-term business growth. Expansion into emerging markets and development of customized formulations tailored to specific industrial applications remain central to competitive strategies.

Request for Customization of the Research Report: https://www.persistencemarketresearch.com/request-customization/35438

Challenges and Opportunities

While the high temperature coatings market presents numerous growth opportunities, certain challenges may restrain its expansion. Fluctuations in raw material prices, particularly for resins and specialty chemicals, can impact production costs. The complexity of manufacturing heat-resistant coatings that meet both performance and environmental standards also requires substantial investment in research and quality control.

Despite these challenges, the market outlook remains positive. Growing awareness about energy efficiency, safety, and sustainability in industrial processes is expected to drive further demand. The development of bio-based coatings and advancements in nanotechnology offer new growth avenues for manufacturers seeking to differentiate their products.

Future Outlook

Looking ahead, the global high temperature coatings market is poised for steady and sustained growth through 2032. The increasing emphasis on eco-friendly products, combined with the demand for materials that can operate under extreme conditions, will continue to shape the future of this market. Technological innovation will play a central role in enabling manufacturers to meet performance standards while minimizing environmental impact.

Emerging trends such as smart coatings capable of self-healing or providing thermal monitoring capabilities are expected to redefine industry standards. Additionally, the integration of advanced materials into coating formulations will enhance their thermal stability, corrosion resistance, and service life.

Conclusion

The global high temperature coatings market is set for consistent growth driven by the expansion of industrial infrastructure, increasing demand from key end-use sectors, and technological advancements in coating formulations. As industries strive to enhance efficiency and durability while meeting environmental goals, the role of high temperature coatings becomes even more critical.

Read More Related Reports:

Electrical Steel Market: https://www.persistencemarketresearch.com/market-research/electrical-steel-market.asp

Pdc Drill Bits Market: https://www.persistencemarketresearch.com/market-research/pdc-drill-bits-market.asp

Compostable Pouch Market: https://www.persistencemarketresearch.com/market-research/compostable-pouch-market.asp

Contact Us:

Persistence Market Research

Second Floor, 150 Fleet Street,

London, EC4A 2DQ, United Kingdom

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release High Temperature Coatings Market Size Worth US$4.13 Billion by 2032 here

News-ID: 4242822 • Views: …

More Releases from Persistence Market Research

Event Tourism Market Set for Exponential Growth through 2032 - PMR Research

The global Event Tourism Market is poised for remarkable expansion, driven by sustained demand for live experiences, increased business travel, hybrid event adoption, and a rebound in international tourism. According to industry projections, the market is expected to grow from an estimated US$1,538.3 billion in 2025 to US$2,631.5 billion by 2032, registering a CAGR of 7.3% over the forecast period.

This robust growth underscores the evolution of event tourism into one…

Residential Lighting Fixtures Market Set for Robust Growth Through 2032

The global residential lighting fixtures market is poised for strong expansion over the coming decade, underpinned by shifting consumer preferences toward energy efficient, smart, and design centric lighting solutions. According to a comprehensive market analysis by Persistence Market Research, the market was valued at US$ 20.4 billion in 2025 and is projected to reach US$ 32.2 billion by 2032, growing at a CAGR of 5.9 % from 2025 to 2032.

➤…

Active Modified Atmospheric Packaging Market to Reach US$ 37.9 Billion by 2033 - …

The active modified atmospheric packaging market is gaining strong traction as food manufacturers retailers and logistics providers focus on extending product shelf life while maintaining freshness quality and safety. Active modified atmospheric packaging integrates gas flushing scavengers and moisture regulators to actively control the internal atmosphere of a package thereby slowing microbial growth oxidation and spoilage. Unlike passive packaging this advanced technology continuously interacts with the packaged product creating an…

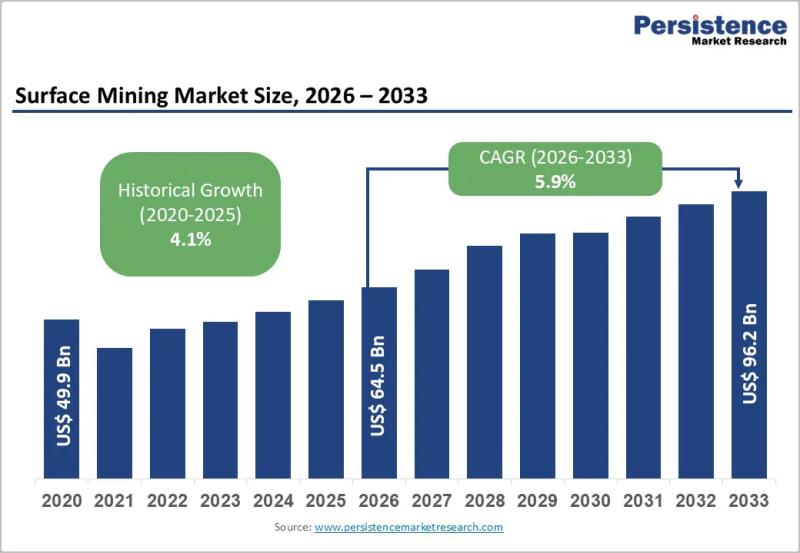

Surface Mining Market Size to Reach US$ 96.2 Billion by 2033 - Persistence Marke …

The surface mining market plays a critical role in the global extraction industry, enabling efficient recovery of minerals, metals, and fossil fuels located near the earth's surface. Surface mining techniques such as open pit mining, strip mining, mountaintop removal, and quarrying are widely used for coal, iron ore, copper, bauxite, and other industrial minerals. Compared to underground mining, surface mining offers higher production rates, lower operational risks, and improved cost…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…