Press release

Top Companies in the Metal Injection Molding Market: Benchmarking Performance & Future Value Creation

The Metal Injection Molding (MIM) Market is gaining prominence as industries increasingly demand high-precision metal components with complex geometries and cost-efficient production methods. From automotive to medical devices, consumer electronics to aerospace, MIM technology is transforming how metal parts are designed, produced, and integrated into advanced systems. As global manufacturers prioritize lightweighting, miniaturization, and material efficiency, the MIM market is emerging as a critical enabler of next-generation industrial innovation.Get deeper insights into competitive positioning and strategic benchmarking: Download our sample Metal Injection Molding Market report here → https://www.researchnester.com/sample-request-4916

Top Companies & Their Strategies

Indo-MIM Pvt. Ltd.

Headquartered in India, Indo-MIM Pvt. Ltd. is widely recognized as one of the largest MIM manufacturers globally. The company's strength lies in vertical integration-from metal powder production to finished part manufacturing-ensuring quality control and cost efficiency. Indo-MIM serves diversified industries such as automotive, aerospace, and healthcare. Its state-of-the-art facilities in India and the U.S., coupled with a strong focus on R&D and sustainability, enable it to maintain a global competitive edge.

ARC Group Worldwide

ARC Group Worldwide, based in the United States, has built its market position through additive manufacturing integration and MIM process optimization. The company focuses on precision-engineered components for defense, medical, and consumer electronics sectors. Its hybrid approach, combining MIM with 3D metal printing, allows for greater design flexibility and faster prototyping, addressing the growing demand for customized metal components.

CN Innovations (CNI)

Hong Kong-based CN Innovations specializes in MIM solutions for consumer electronics and automotive components. The company leverages strategic partnerships with Asian OEMs and strong supply chain integration in China and Southeast Asia. CNI's manufacturing agility and automation-driven efficiency have enabled it to capture substantial market share in the high-volume electronics sector, where precision and scalability are critical.

Dynacast International

Dynacast International, part of Form Technologies, offers a diverse portfolio encompassing MIM, die casting, and precision machining. Its competitive strength is multi-process manufacturing, which allows clients to choose the optimal production method for each component. Dynacast's extensive global footprint-covering over 20 countries-provides a strategic advantage in serving multinational clients while minimizing logistics and lead times.

Explore detailed profiles of top players and new entrants in this space - access your free sample report → https://www.researchnester.com/sample-request-4916

OptiMIM (a division of ARC Group)

OptiMIM, a division under ARC Group, focuses specifically on miniature and high-density MIM parts. Its expertise lies in developing micro-MIM components for medical and electronics applications. OptiMIM's precision engineering and proprietary sintering technology help achieve tight tolerances and consistent quality, making it a preferred supplier for surgical instruments and electronic connectors.

MIM-Technik GmbH

Germany's MIM-Technik GmbH emphasizes customized MIM part production for European clients across automotive, industrial, and consumer segments. Its strengths include material innovation and close collaboration with end-users to tailor alloy compositions. MIM-Technik's focus on sustainability and reduced material waste aligns with Europe's green manufacturing objectives, supporting its expansion within the region.

Smith Metal Products

U.S.-based Smith Metal Products has established itself as a trusted manufacturer for medical and aerospace components. The company's strength lies in its engineering-driven approach, offering extensive design assistance and prototyping services. Smith Metal Products continues to expand its capabilities in biocompatible materials and stainless steel alloys, which are vital for surgical tools and implantable devices.

Parmatech Corporation

A subsidiary of ATW Companies, Parmatech Corporation has been one of the pioneers in the MIM industry, known for its innovation in complex part geometries and tight tolerance components. The company's collaboration with Stanford Research Institute (SRI) has driven advancements in binder systems and feedstock materials, enhancing MIM's performance and environmental footprint. Parmatech's strong reputation in the medical device and firearm sectors underscores its expertise in critical, safety-sensitive applications.

View our Metal Injection Molding Market Report Overview here: https://www.researchnester.com/reports/metal-injection-molding-market/4916

SWOT Analysis of Leading Companies

Strengths

Leading MIM companies boast deep technical expertise in powder metallurgy, automation, and material science. Their diversified industry exposure-spanning automotive, medical, and electronics-reduces dependency on any single vertical. The use of advanced feedstocks and hybrid manufacturing techniques (combining MIM with additive manufacturing) enhances flexibility, product complexity, and design precision. Additionally, global distribution networks and localized manufacturing facilities provide these companies with strong logistical and regional advantages.

Weaknesses

While MIM technology offers superior precision and cost advantages for small-to-medium-sized components, it faces limitations in large-part manufacturing. High initial tooling costs and complex debinding processes can deter smaller manufacturers or low-volume projects. Moreover, feedstock availability and cost fluctuations-especially for specialty alloys-pose production challenges. Some companies also face regional regulatory hurdles, particularly concerning the environmental aspects of binder removal and sintering emissions.

Opportunities

The rising demand for miniaturized, lightweight, and durable components in electric vehicles (EVs), 5G infrastructure, and wearable medical devices is opening new growth avenues for MIM manufacturers. Advances in metal powders and binder systems, coupled with integration with additive manufacturing, are creating room for product innovation. Strategic collaborations between MIM producers and OEMs in automotive and medical sectors are enabling co-development of next-generation components. The Asia-Pacific region, with its strong manufacturing base and expanding consumer electronics industry, presents lucrative expansion opportunities.

Threats

The MIM industry faces competitive threats from alternative manufacturing technologies such as CNC machining, metal 3D printing, and die casting. Rapid technological advancements could shorten the lifecycle of MIM advantages in some applications. Additionally, supply chain disruptions and geopolitical factors affecting raw material availability-particularly stainless steel and titanium powders-pose ongoing risks. Intellectual property (IP) challenges, particularly in markets with weaker IP enforcement, may also hinder technology-driven differentiation.

Access a complete SWOT breakdown with company-specific scorecards: Claim your sample report → https://www.researchnester.com/sample-request-4916

Investment Opportunities & Market Trends

Integration of Additive Manufacturing and MIM

A defining trend in the MIM industry is the integration of additive manufacturing to improve prototyping, design validation, and tooling. Companies like ARC Group Worldwide and Parmatech are leveraging 3D printing to accelerate new part development cycles. This hybrid approach allows manufacturers to reduce time-to-market while maintaining the high-volume efficiency of MIM for production runs. Investors are increasingly funding ventures that combine both technologies to create adaptive, on-demand manufacturing ecosystems.

Growth of Medical and Dental Applications

The medical sector represents one of the most promising investment avenues for MIM technology. MIM's ability to produce biocompatible, corrosion-resistant, and complex components aligns perfectly with the demands of surgical instruments, dental implants, and orthopedic devices. Companies like OptiMIM and Smith Metal Products are expanding their medical-grade facilities to meet stringent FDA and ISO standards. This segment is also attracting private equity and venture capital investment, given the long-term growth in healthcare infrastructure.

Automotive Lightweighting and Electrification

The global shift toward electric and hybrid vehicles is fueling demand for lightweight, precision metal parts. MIM's capability to create high-strength, lightweight components makes it ideal for EV powertrains, sensors, and actuator systems. Automotive leaders are forming strategic sourcing partnerships with MIM suppliers to optimize performance and cost. Europe and Asia, driven by stricter emission norms, are becoming key regions for MIM investment in automotive applications.

Sustainability and Green Manufacturing Initiatives

Environmental sustainability is now a top priority across the manufacturing sector. MIM processes inherently produce less material waste compared to traditional machining, aligning with circular economy goals. Companies like MIM-Technik and Indo-MIM are adopting closed-loop production systems and recyclable binder technologies to enhance environmental compliance. Governments supporting green manufacturing policies-particularly in the EU and North America-are incentivizing cleaner production technologies, creating further investment momentum.

Strategic Mergers and Acquisitions

The MIM market has seen an uptick in M&A activity as large industrial firms seek to strengthen their advanced manufacturing portfolios. Form Technologies' consolidation of Dynacast and OptiMIM is a notable example, enabling operational synergies across metal processing methods. Similarly, partnerships between MIM producers and material science companies are driving innovation in feedstock composition and performance. These consolidations improve scalability, enhance technology access, and increase market resilience.

Stay ahead of investment moves in the Metal Injection Molding Market- view our analyst-verified insights → https://www.researchnester.com/sample-request-4916

Related News-

https://www.linkedin.com/pulse/how-xenon-gas-transforming-industries-future-applications-q9d9f

https://www.linkedin.com/pulse/why-neurovascular-guidewires-market-center-healthcare-kj0gf

Contact Data

AJ Daniel

Corporate Sales, USA

Research Nester

77 Water Street 8th Floor, New York, 10005

Email: info@researchnester.com

USA Phone: +1 646 586 9123

Europe Phone: +44 203 608 5919

About Research Nester

Research Nester is a one-stop service provider with a client base in more than 50 countries, leading in strategic market research and consulting with an unbiased and unparalleled approach towards helping global industrial players, conglomerates and executives for their future investment while avoiding forthcoming uncertainties. With an out-of-the-box mindset to produce statistical and analytical market research reports, we provide strategic consulting so that our clients can make wise business decisions with clarity while strategizing and planning for their forthcoming needs and succeed in achieving their future endeavors. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Top Companies in the Metal Injection Molding Market: Benchmarking Performance & Future Value Creation here

News-ID: 4240847 • Views: …

More Releases from Research Nester Pvt Ltd

Lutein and Zeaxanthin Market - Key Players, Capability Assessment & M&A Indicato …

The lutein and zeaxanthin market has expanded steadily as demand for eye-health supplements, functional foods, and preventive nutrition increases across global consumer segments. Lutein and zeaxanthin, two essential carotenoids concentrated in the retina, are widely recognized for their protective roles against oxidative stress, age-related macular degeneration (AMD), blue-light exposure, and general visual fatigue. Their adoption has accelerated with the rise of digital lifestyles, an aging population, and growing clinical evidence…

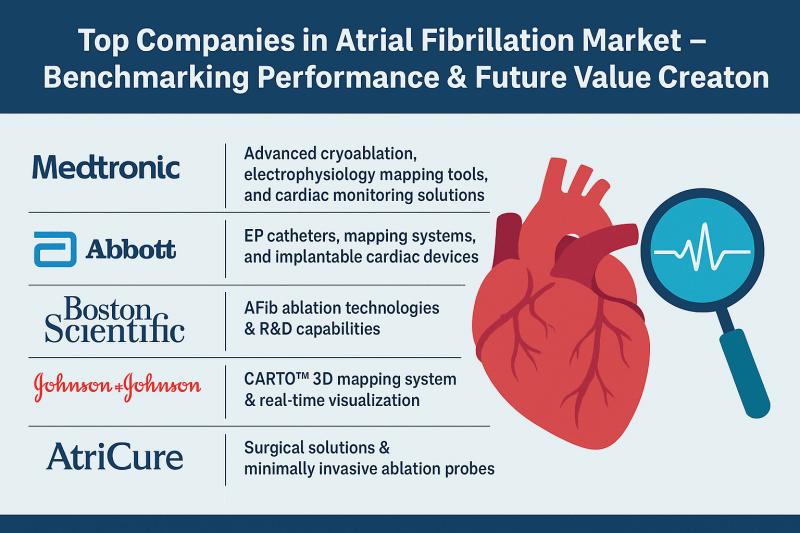

Top Companies in Atrial Fibrillation Market - Benchmarking Performance & Future …

The atrial fibrillation market is undergoing a period of rapid transformation as diagnostic technologies, catheter-based therapies, and antiarrhythmic solutions continue to advance. Atrial fibrillation (AFib) is one of the most prevalent cardiac arrhythmias globally, prompting significant demand for improved detection, early intervention, and minimally invasive treatment. The shift toward advanced ablation systems, AI-enabled diagnostics, wearable monitoring, and next-generation electro-mapping tools has strengthened competition across the market. Companies are expanding their…

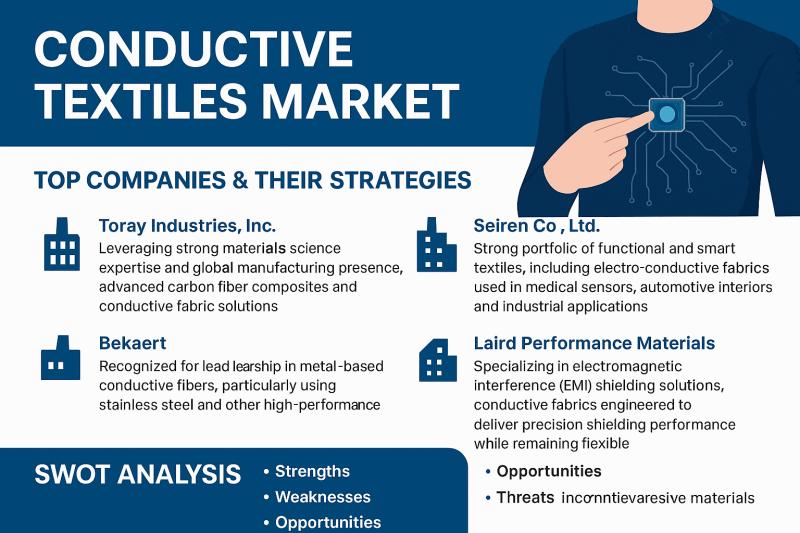

Conductive Textiles Market - Top Companies, SWOT Deep Dive & Capital Flow Trends

The conductive textiles market is undergoing a rapid transformation as wearable electronics, smart apparel, and advanced sensor-integrated fabrics move from niche applications to mainstream adoption. Conductive textiles-engineered using conductive polymers, metal-coated fibers, or intrinsically conductive yarns-have become integral to next-generation healthcare wearables, military gear, automotive interiors, and consumer smart devices. As industries push for lighter, flexible, and more energy-efficient electronic systems, conductive materials embedded within fabrics are emerging as a…

Global Osteosynthesis Devices Market: Top Companies, Market Share Rankings & Inv …

The osteosynthesis devices market continues to evolve as orthopedic care moves toward minimally invasive procedures, biologically compatible materials, and technology-enabled implants. These devices-ranging from plates and screws to intramedullary nails and fixation systems-are essential for treating fractures, deformities, and complex bone injuries. Companies operating in this space are adopting strategies centered around product innovation, clinical efficacy, and expansion into fast-growing regions. As trauma care volumes rise in both developed and…

More Releases for MIM

Metal Powder Injection Molding (MIM) Market Size, Key Market Insights, Opportuni …

LOS ANGELES, United States: The report is a brilliant presentation of a highly detailed, comprehensive, and accurate research study on the global Metal Powder Injection Molding (MIM) market. The research study explores some of the important aspects of the global Metal Powder Injection Molding (MIM) market and shows how different factors such as price, competition, market dynamics, regional expansion, gross margin, and consumption are impacting market growth. The report includes…

Metal Injection Molding (MIM) Market: A Comprehensive Overview

Metal Injection Molding (MIM) is revolutionizing the manufacturing industry by combining the benefits of plastic injection molding with the unique properties of metals. This process allows for the production of complex, high-precision metal parts that are both cost-effective and efficient. As industries increasingly demand high-quality, intricately designed metal components, the MIM market has witnessed significant growth.

Browse More About This Research Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-market

Overview

Metal Injection Molding is a manufacturing technique…

Metal Injection Moulding (MIM) Technology Market Size in 2023 To 2029 | OPTIMIM, …

This report provides an in-depth analysis of the global market's competitive landscape, focusing on key players operating in the Metal Injection Moulding (MIM) Technology industry. It offers a comprehensive overview of their performance, highlighting important details such as market value, status, and revenue. By examining these factors, stakeholders gain valuable insights into the competitive advantages of the market. The report delves into the strategies and performance of major competitors, presenting…

AMTMIM Shifting Production to New MIM Plant in Jiangsu

Some of the old plant's business was transferred from Dongguan, in 2017, AMTMIM established a new MIM plant in Jiangsu, China.

The new MIM plant in Jiangsu, China, started up last September. AMTMIM recently said it designed the operation to serve the region's automotive, consumer electronics, and telecommunications manufacturers. AMTMIM manages its own 20,000 square meters modern manufacturing facility, though to date it operates ten injection molding machines, eight vacuum sintering…

Metal Injection Molding Parts (MIM Parts) Market is Projected to Gain Significan …

The Metal Injection Molding Parts (MIM Parts) Market research report Forcast 2023-2030 provides in-depth information on market trends, market capacity, industry size, growth factors, share, innovations, competitive environment, business problems, and more. This report's historical data confirms demand growth on a global, national, and regional scale. The studies on the global industry cover everything from comprehensive research to market size and forecasting to dynamics, growth factors, prospects, and hazards, as…

Metal Injection Molding Parts (MIM Parts) Market Size 2022 By Top Key Players - …

A three-dimensional CAD model is used as the basis for the metal injection moulding (MIM) manufacturing process, which produces parts using metal powder and a binder. In a hopper, the binder and metal powder are mixed, and the resulting material is then injected into a mould. The part is expelled from the mould after the mould has been heated until the binder has dried. When standard machining or casting would…