Press release

The Global Aerospace & Defense Additive Manufacturing Market is projected to reach a market size of USD 18.56 Billion by the end of 2030.

According to the report published by Virtue Market Research The Global Aerospace & Defense Additive Manufacturing Market was valued at USD 5.33 Billion and is projected to reach a market size of USD 18.56 Billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 19.51%.Request Sample Copy of this Report @https://virtuemarketresearch.com/report/aerospace-defense-additive-manufacturing-market/request-sample

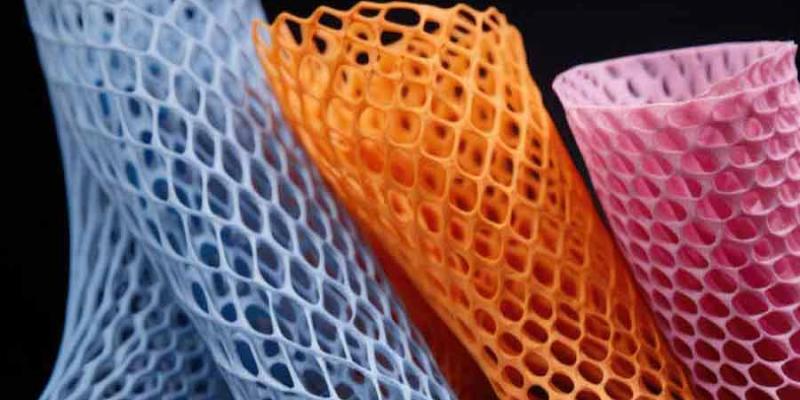

The aerospace and defense additive manufacturing market has been moving forward with a strong push from the need for lighter and stronger parts. One of the most important long-term drivers has been the industry's focus on reducing the overall weight of aircraft and defense equipment. By using additive manufacturing, also called 3D printing, companies can create parts that are both light and durable. Lighter planes and defense systems require less fuel, which saves money and improves efficiency. This factor alone has made additive manufacturing a key part of the industry's future. However, the impact of COVID-19 was a major setback in this path. During the pandemic, supply chains were disrupted, projects were delayed, and many manufacturers faced a shortage of skilled workers. Yet, the crisis also highlighted the importance of having more flexible and faster production methods. Additive manufacturing gave companies the ability to produce parts locally, reducing dependency on distant suppliers, and this lesson is still guiding decisions today.

In the short term, the market is being driven by the urgent need for faster prototyping. Aerospace and defense companies are under constant pressure to test new designs quickly and bring them into real use. Traditional methods of making prototypes often take weeks or even months. Additive manufacturing, in contrast, makes it possible to test a design in days. This advantage gives companies more freedom to experiment and make adjustments faster than before. Speed has become a strong short-term driver, especially when national defense and aerospace missions demand quicker turnarounds.

Alongside this, there is a growing opportunity in the area of spare parts production. Aerospace and defense systems often remain in service for decades, and maintaining them requires a steady supply of spare components. Many of these parts are expensive to keep in stock and difficult to produce on demand using traditional processes. Additive manufacturing provides the chance to create these parts as needed, reducing storage costs and ensuring quicker availability. This approach is especially helpful for military operations, where access to replacement parts in remote or conflict zones can be challenging. With on-site 3D printing capabilities, forces can maintain equipment in the field more effectively, which strengthens operational readiness.

A notable trend across the market is the growing focus on certification and standardization. Aerospace and defense are industries where safety and reliability are non-negotiable. Any new material or process must meet strict rules before it can be widely used. As additive manufacturing technologies expand, more organizations are working together to create global standards for materials, machines, and processes. This trend is important because it builds trust across the industry and encourages wider adoption. Companies are increasingly investing in research and partnerships to develop uniform guidelines that can satisfy regulators while still promoting innovation.

Segmentation Analysis:

By Platform: Aviation, Defense, Space

In the aerospace and defense additive manufacturing market by platform, aviation stands out as the largest segment, while space is projected to be the fastest growing during the forecast period. Aviation has gained this lead because aircraft and UAVs demand lighter, more durable, and complex parts, which can be crafted precisely using additive methods. Airlines and defense air fleets are relying on 3D printing for engine brackets, turbine blades, and UAV components, saving both time and cost while improving fuel efficiency. Meanwhile, the space segment is advancing at a rapid pace as satellites, spacecraft, and rocket producers adopt additive manufacturing for engines and propulsion systems.

The ability to print intricate cooling channels, lightweight satellite frames, and launch vehicle structures without traditional supply chain delays has positioned this area for accelerated growth. Defense platforms, such as combat vehicles, PPE, and weapons, continue to adopt additive processes steadily, but their share remains smaller compared to aviation and space. Additive techniques bring flexibility in producing protective gear, submarine hull parts, and even weapon prototypes. However, the unmatched need for flight efficiency and emerging breakthroughs in space technologies are steering aviation and space into their roles as largest and fastest-growing subsegments.

By Vertical: Printer, Material, Others

In the aerospace and defense additive manufacturing market by vertical, printers form the largest segment, while materials are the fastest growing during the forecast period. Printers dominate because they are the core machines enabling the production of aerospace and defense parts across platforms. Investment in advanced systems such as metal 3D printers and multi-laser platforms is high, driven by aerospace OEMs and defense contractors seeking faster throughput and precision. Manufacturers purchase printers not just for prototyping but also for producing functional, mission-ready parts, which secures their strong position.

Materials, however, are experiencing rapid expansion as the industry demands new powders, polymers, and composites that meet safety, thermal, and mechanical standards. Specialized metal powders such as titanium and nickel alloys, alongside lightweight composites, are unlocking new possibilities in high-performance components. The focus on reducing waste, ensuring consistency, and meeting regulatory standards makes material innovation central to future growth. The "others" category, which includes software and services, plays a supporting role but is yet to surpass the scale of printers or the pace of materials. Together, this dynamic shows the central role of machines today and the vital growth potential of advanced materials tomorrow.

By Application: Engine Components, Space Components, Structural Components, Defense Equipment, Others

In the aerospace and defense additive manufacturing market by application, engine components emerge as the largest segment, while structural components are the fastest growing during the forecast period. Engine components dominate because turbine blades, nozzles, and combustion parts benefit the most from additive manufacturing's ability to handle complex geometries and high-temperature metals.

These components require precision, durability, and lightweight designs, and additive processes meet all three needs more efficiently than traditional casting. Space components are an important category as well, enabling the construction of satellite parts and spacecraft systems, but their share remains smaller compared to engines. Structural components, on the other hand, are set for strong acceleration. The demand for fuselage parts, interior panels, and lightweight frames is increasing as additive manufacturing allows consolidation of multiple parts into single, durable structures. Defense equipment applications like protective gear, vehicle parts, and weapon accessories also continue to adopt 3D printing steadily but at a more limited scale compared to engines and structures. Other applications, such as prototypes and experimental parts, support niche use cases. The balance of proven reliability in engines and rising adoption of structural innovations drives this segmentation forward in distinctive ways.

By Technology: FDM, DMLS, SLA, CLIP, SLS, Others

In the aerospace and defense additive manufacturing market by technology, DMLS (Direct Metal Laser Sintering) holds the largest share, while SLS (Selective Laser Sintering) is the fastest growing during the forecast period. DMLS has become the leading technology because it enables the production of highly detailed, functional metal parts essential for aerospace and defense applications. Complex parts like engine turbines, heat exchangers, and high-strength brackets benefit from its accuracy and ability to work with titanium and nickel alloys. Its adoption by OEMs and defense bodies underscores its importance.

SLS, in contrast, is rapidly advancing as the need for lightweight polymer parts and functional prototypes grows. Its capability to produce strong and durable non-metal components without support structures makes it attractive for aerospace interiors, UAV parts, and defense gear. SLA (Stereolithography) and CLIP (Continuous Liquid Interface Production) remain valuable for high-resolution prototyping but are limited in large-scale functional production. FDM (Fused Deposition Modeling) continues to serve educational and low-cost prototyping needs but lacks the industrial scale of DMLS or SLS. Other emerging technologies provide niche solutions, yet the current landscape reflects DMLS's dominance and SLS's momentum as the technology spectrum evolves.

Read More @https://virtuemarketresearch.com/report/aerospace-defense-additive-manufacturing-market

Regional Analysis:

In the aerospace and defense additive manufacturing market by region, North America stands as the largest segment, while Asia-Pacific is the fastest growing during the forecast period. North America leads because it hosts a strong presence of aerospace OEMs, defense contractors, and space exploration agencies. High investment in R&D, early adoption of advanced additive technologies, and support from both commercial aviation and defense programs drive this dominance. Europe follows closely with its focus on lightweight aircraft design and collaborations in the defense sector.

Asia-Pacific, however, is witnessing rapid acceleration as countries such as China, India, and Japan ramp up aerospace programs and invest in space exploration. The region is actively developing manufacturing hubs, local supply chains, and government-backed initiatives to adopt additive techniques in both civilian and defense domains. South America and the Middle East & Africa are emerging markets, where adoption is growing but still constrained by infrastructure and investment levels. While North America maintains the largest share due to its mature ecosystem, Asia-Pacific's expanding aerospace production and defense modernization efforts position it as the fastest growing in this regional landscape.

Latest Industry Developments:

• Companies are localizing and vertically integrating supply chains: Firms are increasingly building out localized supply chains and bringing more of their value chain in-house. They seek to reduce dependency on foreign suppliers for metal powders, lasers, or printer subcomponents. By making critical parts domestically or regionally, companies slow down effects from tariffs, shipping delays, or trade policy changes. Vertical integration-from designing printers and materials all the way to printing and finishing parts-gives more control over cost, quality, and timing. This helps them offer more consistent lead times and tighter tolerances, which are very important in aerospace and defense sectors.

• Emphasis on repair, maintenance, and overhaul (MRO) using additive methods: A growing trend is leveraging additive manufacturing for repair and overhaul of existing parts rather than just new parts. Companies are developing methods to reprint or restore worn or damaged components using additive techniques, cutting down repair times dramatically. This helps operators reduce downtime, lowers spare-parts inventories, and diminishes the need for full remanufacturing. Using AM in MRO also helps in parts recovery, especially when original suppliers no longer produce certain legacy components. This strategy lets companies expand into aftermarket services and strengthen long-term customer relationships.

• Investment in digitalization and automation combined with advanced material R&D: Another major strategy is to pair improved software, process monitoring, and automated workflows with research into new materials and alloys suited for aerospace and defense use. Companies are using digital twins, in-line sensors, real-time monitoring, and AI-driven process control to improve yields, ensure uniformity, and reduce defects. Simultaneously they are creating or refining materials (metal powders, polymers, composites) that can meet more extreme conditions (temperature, fatigue, corrosion). This combined approach helps reduce costs per part, improves performance, and offers compelling value over traditional manufacturing routes.

customize the Full Report Based on Your Requirements @https://virtuemarketresearch.com/report/aerospace-defense-additive-manufacturing-market/customization

CONTACT US :

Virtue Market Research

Kumar Plaza, #103, SRPF Rd, Ramtekadi, Pune, Maharashtra 411013, India

E-mail: megha@virtuemarketresearch.com

Phone: +1-917 436 1025

ABOUT US :

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Global Aerospace & Defense Additive Manufacturing Market is projected to reach a market size of USD 18.56 Billion by the end of 2030. here

News-ID: 4232152 • Views: …

More Releases from virtue market research

The Global Vodka Seltzer Market is projected to reach a market size of USD 16.22 …

The Vodka Seltzer Market was valued at USD 9.4 billion in 2024 and is projected to reach a market size of USD 16.21 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.1%.

Request Sample @ https://virtuemarketresearch.com/report/vodka-seltzer-market/request-sample

The vodka seltzer market has grown from a niche beverage choice into a mainstream favorite, supported by shifting consumer lifestyles and evolving…

The Global Telehealth Services Market and is projected to reach a market size of …

The Global Telehealth Services Market was valued at USD 126.1 billion and is projected to reach a market size of USD 302.49 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.7%.

Request Sample @ https://virtuemarketresearch.com/report/telehealth-services-market/request-sample

The perennial shift towards patient-centric healthcare has been a pivotal long-term market driver for telehealth services. Over the years, the industry has witnessed…

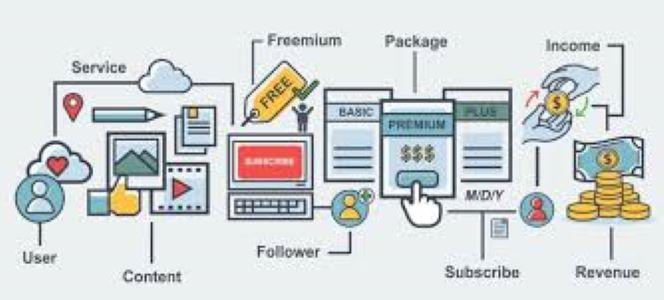

The Subscription Box/Subscription E-Commerce Market is projected to reach a mark …

The Subscription Box/Subscription E-Commerce Market is valued at USD 47.19 billion in 2024 and is projected to reach a market size of USD 97.73 billion by the end of 2030. Over the outlook period of 2025-2030, the market is anticipated to grow at a CAGR of 12.9%.

Request Sample @ https://virtuemarketresearch.com/report/subscription-e-commerce-market/request-sample

The subscription e-commerce market has grown into one of the most dynamic parts of the digital economy. It began as a…

The Global Aramid Fibre Reinforced Polymer Composites Market is projected to rea …

According to the report published by Virtue Market Research in Aramid Fibre Reinforced Polymer Composites Market was valued at USD 5.55 billion and is projected to reach a market size of USD 8.57 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7.5%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/aramid-fibre-reinforced-polymer-composites-market/request-sample

The Aramid Fibre Reinforced Polymer Composites…

More Releases for Defense

Dallas Criminal Defense Attorney Shares Powerful Defense Strategies In Texas

The Medlin Law Firm shares an educational video highlighting powerful defense approaches in Texas criminal cases. A Dallas criminal defense attorney breaks down what may be at stake, why every case needs a personalized defense, and how an attorney can help protect rights.

Dallas, TX - The Medlin Law Firm shares an educational video to help Texans better understand how criminal defense cases are approached in Texas courts. A Dallas criminal…

Virtual Reality in Aerospace & Defense Market Virtual Reality in Aerospace & Def …

The global virtual reality (VR) market in aerospace and defense is estimated to be valued at approximately $8.4 billion in 2024, with expectations to around $20.7 billion by 2034, signifying a robust Compound Annual Growth Rate (CAGR) of 9.5% during the forecast period from 2025 to 2034.

The latest report Virtual Reality in Aerospace & Defense Market Share, Size, Growth, Opportunities, and Forecast 2025-2034 This report offers a new perspective…

Elliott Derzaph, Renowned Self-Defense Instructor, Launches His Latest Book "Wom …

Image: https://www.getnews.info/wp-content/uploads/2024/08/1724155810.png

Self-defense training is about the knowledge of how fighting works and how to survive. Women will learn how to utilize their internal power to develop autonomy, confidence, and empowerment. Real World Techniques were designed to teach practical, real-world defense that can be used in a variety of situations.

Los Angeles, California - August 21, 2024 - Women have traditionally shied away from situations where their self-defense [https://consciousdefense.com/] may be…

Missile Defense System Market is in huge demand | Almaz Antey, Kongsberg Defense …

Global Missile Defense System Market Report from AMA Research highlights deep analysis on market characteristics, sizing, estimates and growth by segmentation, regional breakdowns & country along with competitive landscape, player's market shares, and strategies that are key in the market. The exploration provides a 360° view and insights, highlighting major outcomes of the industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to…

Defense Siren Review 2023 (Defense Siren Must Read!) : Shocking Price About Defe …

In the United States of America, thousands of crimes are reported every day. You name it: mugging, theft, sexual assault, and murder. Some of these crimes are reported in the daily newspaper and on news programs.

After reading and watching the news, it's normal to worry about your family. Anytime, anywhere, you or your family could be attacked while driving. Thus, it's crucial to always remain vigilant. However, being aware is…

Aircraft Communication System Market Global Report 2020 – Rockwell Collins Avi …

Aircraft communication systems use analogue voice and digital data for communication between pilots, members of the crew and passengers during flight. These devices are also used for communication between aircraft. Aircraft communication systems are used to facilitate communications between aircraft and ground units and vice versa.

Get In Depth Sample With Description, Graphs And Charts: https://www.a2zmarketresearch.com/sample?reportId=151555

Aircraft communication system offered by different manufacturers have also been taken into consideration to determine…