Press release

Automotive Sonic Welding Equipment Market to Reach USD 356 Million by 2031 Top 20 Company Globally

The global automotive sonic welding equipment industry represents a vital segment of advanced manufacturing technologies used to join thermoplastic components within automotive production lines. Sonic (ultrasonic) welding uses high-frequency acoustic vibrations typically between 20 kHz and 40 kHz to fuse parts without the need for adhesives, screws, or other fasteners. The result is a clean, fast, and reliable bond suitable for components such as instrument panels, interior trims, lighting housings, door panels, sensor casings, and battery module covers. The method has become an essential part of modern vehicle assembly, particularly in the age of electrification and lightweighting, where precise and non-destructive joining methods are crucial to both performance and cost efficiency.In 2024, the global market for automotive sonic welding equipment reached an estimated USD 240 million and projected to reach USD 358 million by 2031 with a CAGR of 5,8%. An average selling price is around USD 8,000 per unit for a typical production-ready sonic welding station. Based on that selling price, the implied global units sold in 2024 total approximately 30,000 units. The typical factory gross margin for a production-quality sonic welding machine is set at 25%, yielding a factory gross profit of USD 2,000 per unit and a cost of goods sold of USD 6,000 per unit. A COGS breakdown is materials/components, direct labor & assembly, manufacturing overhead & test, tooling & amortized jigs, logistics & packaging, and spare/other. A single line full machine production capacity for an established OEM line is estimated at about 100 unit per line per year. Downstream demand for these systems is concentrated in interior & exterior parts followed by electronics & sensors, battery and wire harness.

Latest Trends and Technological Developments

The sector has seen steady product refreshes focused on automation-ready features, multi-probe control, traceability/data capture, and energy efficiency. Dukane announced the iQ Auto-Plus ultrasonic generator with an integrated Multi-Probe Controller aimed at multi-point automotive staking and spot welding in automated door-panel and interior applications (manufacturer news, 2025). Herrmann hosted "Ultrasonic TECH DAYS" on July 23, 2025 to showcase systems for high-speed manufacturing and data-driven process control; the event emphasized automation, process traceability and reduced cycle times for automotive parts (July 2025). Telsonic and other European suppliers reported regional expansion and active deployment projects in Asia in 2024 to 2025, and Rinco unveiled next-generation servo-driven ultrasonic machines with enhanced traceability and energy-saving features early in 2025. These product and market activities illustrate vendor competition around multi-point control, Industry-4.0 connectivity protocols (EtherNet/IP, EtherCAT, Profinet), and higher-frequency / higher-power units optimized for large thermoplastic assemblies.

Asia is the worlds manufacturing backbone for automotive assembly and parts production, and it represents the largest regional demand pool for sonic welding equipment. China, Japan, South Korea, and increasingly India serve both as production hubs for OEMs and as installation markets for high-throughput ultrasonic lines. Suppliers emphasize local service centers, regional tech support, and exhibition presence to win long lead programs with Asian OEMs. The Asia market mix leans more heavily toward automated multi-head installations in EV and interior structural programs, where cycle time and cosmetic quality are critical. Several global vendors including Dukane, Herrmann, Telsonic and Rinco have strengthened regional footprints in 2024 to 2025 to supply Asias large Tier-1 networks and captive OEM plants.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5182009

Automotive Sonic Welding Equipment by Type:

Handheld Sonic Welding Equipment

Automated Sonic Welding Equipment

Bench Top Sonic Welding Equipment

Others

Automotive Sonic Welding Equipment by Material:

Aluminum Alloy Frame Systems

Stainless Steel Construction Units

Composite and Polymer Frame Units

Hybrid Metal Polymer Equipment

Others

Automotive Sonic Welding Equipment by Structure:

Vertical Press Type Systems

Horizontal Systems

Handheld Tool Type Welders

Cell Based Structures

Others

Automotive Sonic Welding Equipment by Application:

Interior and Exterior Parts

Electronics and Sensors

EV Pack Assembly

Wire Harness

Others

Global Top 20 Key Companies in the Automotive Sonic Welding Equipment Market

Dukane Corporation

Emerson

Herrmann Ultrasonics

Rinco ultrasonics

Schunk Group

Sonics & Materials Inc

Sonotronic Nagel GmbH

Telsonic AG

Ultrasonic Engineering Co., Ltd

Shanghai Chenfeng

Sonobond Technologies

Crest Group

Mecasonic

Thermosonix

Nippon Avionics Co.,Ltd

Roop Ultrasonix

MS Ultraschall Technologies GmbH

Weihai Kaer Sonic Power Co., Ltd.

K&M Technologies (Knmtech)

Weber Ultrasonics

Regional Insights

Southeast Asia represents a fast-growing manufacturing corridor as production shifts for cost, market proximity, and supply-chain diversification. Indonesia, Thailand, Malaysia, and Vietnam are notable for assembly expansion, especially for light vehicles and two-wheelers, creating steady demand for medium-duty sonic welding equipment for interiors, bumper/sub-assemblies, and wire-harness joining. Indonesias domestic assembly growth (localization of parts and higher local content requirements) is raising interest in compact multi-probe ultrasonic cells that minimize floor space while increasing throughput. Vendors report an uptake of automation-ready work-cells in ASEAN to meet local OEM quality and cycle-time requirements; country-level demand remains more project-driven and price-sensitive compared to developed Asian markets, favoring modular systems and local service agreements.

Key challenges include competition from alternative joining methods (vibration welding, laser welding, adhesive bonding), the upfront CAPEX sensitivity of price-conscious assembly plants, and supply-chain constraints for high-precision horn tooling and electronic drives. Another recurring challenge is process integration: ultrasonic welding must be tuned to part geometry, polymer grades, and assembly fixturing; inexperienced integrators risk poor first-time yield. After-sales service, spare parts lead times, and local technical support are decisive factors for adoption in Asia and ASEAN, particularly in areas with limited local vendor presence. Finally, rising customer expectations for process traceability and data capture (to meet quality standards and traceability mandates) require suppliers to bundle software and networked control options, which increases solution complexity and sales cycle length.

Vendors should prioritize modular, automation-ready product families with multi-probe control and standardized industrial communication stacks to shorten integration time with OEM PLCs and robots. Offering local test labs, rapid horn/tooling turnaround, and outcome-based service contracts (uptime SLAs) is a competitive differentiator in Asia and Southeast Asia. Buyers should evaluate lifecycle cost (service, tooling, upgrades) not only CAPEX, and insist on process validation support from vendors to accelerate line ramp. Strategic partnerships between local systems integrators and global vendors can reduce deployment risk and optimize TCO for ASEAN projects.

Product Models

The Automotive Sonic Welding Equipment market encompasses several key types of machines that use high-frequency ultrasonic vibrations to join thermoplastic components in vehicles, ensuring precision, durability, and cost efficiency.

Handheld Sonic Welding Equipment, ideal for flexible and small-scale applications. Notable products include:

Ultraweld HH35 Herrmann Ultrasonics: Compact handheld ultrasonic welder offering ergonomic design and precise control for small automotive parts.

iQ Auto Handheld Dukane: Portable unit with digital control system for consistent weld quality in trim and interior applications.

Sonobond SM-1100 Sonobond Ultrasonics: Lightweight ultrasonic hand welder used for bonding automotive wire harnesses.

Rinco Ultrasonic HandyStar Energy Rinco Ultrasonics: Efficient handheld model with easy operation and quick changeover for spot welding.

Telsonic H-20 Hand Welder Telsonic AG: Reliable ultrasonic hand tool offering high repeatability and precision welding.

Automated Sonic Welding Equipment, designed for high-throughput production lines with robotic integration. Examples include:

Branson GSX-E1 Series Emerson: Fully automated welding system with intelligent control for high-volume automotive production.

Dukane iQ Servo Dukane: Servo-driven ultrasonic system for precise, repeatable welds in automated assembly lines.

Herrmann HiQ Line Herrmann Ultrasonics: Modular automated ultrasonic platform with Industry 4.0 connectivity for automotive applications.

Telsonic MAG Series Telsonic AG: Automated multi-head welding solution for large plastic component assemblies.

Rinco Ultrasonic AMP Series Rinco Ultrasonics: Designed for integration into robotic cells, offering consistent weld strength.

Bench Top Sonic Welding Equipment, suitable for mid-volume, high-accuracy manufacturing environments. Notable products include:

Branson 2000X Series Emerson: Versatile bench top ultrasonic welder offering precision control for small and medium parts.

Dukane iQ Series Bench System Dukane: Digital bench unit providing high weld consistency for automotive connectors and clips.

Herrmann HiQ DIALOG Herrmann Ultrasonics: Bench top model with real-time process monitoring for stringent automotive requirements.

Rinco Ultrasonic Standard Series Rinco Ultrasonics: Reliable bench unit suited for prototypes and small-scale production.

Telsonic TSP750 Telsonic AG: Compact bench top press combining strength and precision for interior trim applications.

The automotive sonic welding equipment market is a mature niche within the broader ultrasonic welding space, anchored by strong adoption in automotive OEMs and Tier-1 suppliers. With a 2024 market size near USD 240 million and a mid-single-digit CAGR, expansion is steady and largely tied to vehicle electrification, increased automation, and the need for faster, cleaner assembly methods. Asia (including China, Japan, South Korea, India) and ASEAN (notably Indonesia, Thailand, Vietnam, Malaysia) are pivotal regional growth engines, though adoption patterns differ by project scale and price sensitivity. Vendors that combine automation-ready hardware, robust process engineering services, and strong regional support stand to gain the majority of upcoming programs.

Investor Analysis

What investors should note: the combination of stable mid-single-digit CAGR, high unit price points, and recurring service/tooling revenue creates a predictable revenue profile with attractive aftermarket margins. How the insight helps: investors can prioritize firms with strong regional footprints in Asia/ASEAN, proven multi-probe and Industry-4.0 capabilities, and low customer churn through service contracts. Why it matters: program wins with large OEMs lead to multi-year orders and aftermarket spares/tooling sales; strategic M&A or minority investments in regional integrators can accelerate market penetration at scale in price-sensitive ASEAN markets. In short, a hardware-plus-services business model and localized support are the primary value drivers for investors seeking exposure to this segment.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5182009

5 Reasons to Buy This Report

Detailed, region-focused market sizing and growth outlook for automotive sonic welding (Asia & ASEAN emphasis).

Unit-level economics and margin benchmarks that support capex and valuation models.

Vendor landscape and recent product/technology developments (multi-probe control, automation-ready systems).

Practical buyer and vendor strategic recommendations for deployment in Asia and Indonesia.

Actionable investor analysis highlighting revenue drivers, aftermarket potential, and acquisition/investment priorities.

5 Key Questions Answered

What is the 2024 global market size and the growth trajectory to 2031 for automotive sonic welding equipment?

How many units were sold globally in 2024 and what is the implied per-unit economics?

Which vendors and technologies are leading the automation and multi-point control trends?

What are the regional market dynamics and adoption patterns across Asia and ASEAN?

What operational, supply-chain, and commercial risks should buyers and investors prioritize?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Related Report Recommendation

Global Automotive Sonic Welding Equipment Market Outlook, InDepth Analysis & Forecast to 2031

https://www.qyresearch.com/reports/5182011/automotive-sonic-welding-equipment

Automotive Sonic Welding Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

https://www.qyresearch.com/reports/5182010/automotive-sonic-welding-equipment

Global Automotive Sonic Welding Equipment Market Research Report 2025

https://www.qyresearch.com/reports/5182009/automotive-sonic-welding-equipment

Global Automotive Sonic Welding Equipment Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

https://www.qyresearch.com/reports/5182008/automotive-sonic-welding-equipment

Global Welding Equipment Market Research Report 2025

https://www.qyresearch.com/reports/3466524/welding-equipment

Global GAS Welding Equipment Market Research Report 2025

https://www.qyresearch.com/reports/4089830/gas-welding-equipment

Global MIG Welding Equipment Market Research Report 2025

https://www.qyresearch.com/reports/3934938/mig-welding-equipment

Global Sonic Welding Market Research Report 2025

https://www.qyresearch.com/reports/3507002/sonic-welding

Global Arc Welding Equipment Market Research Report 2025

https://www.qyresearch.com/reports/3423727/arc-welding-equipment

Global Spot Welding Equipment Market Research Report 2025

https://www.qyresearch.com/reports/4251327/spot-welding-equipment

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automotive Sonic Welding Equipment Market to Reach USD 356 Million by 2031 Top 20 Company Globally here

News-ID: 4227864 • Views: …

More Releases from QY Research

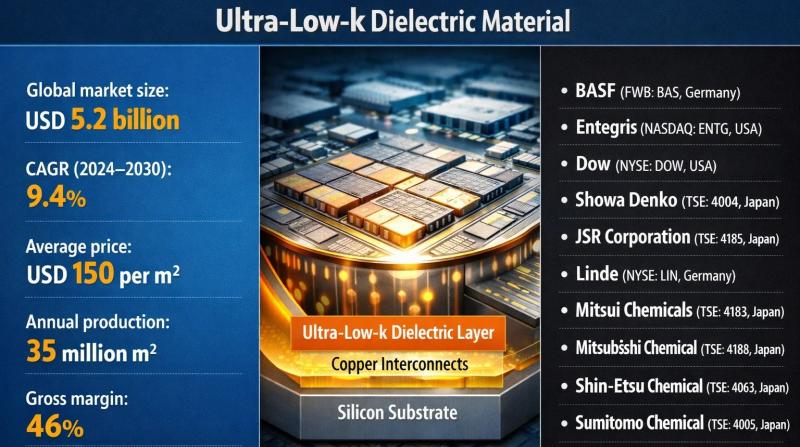

Market Overview - Ultra-low-k Dielectric Material

QY Research has recently published a comprehensive market study on Ultra-low-k Dielectric Material, a critical class of advanced insulating materials engineered to reduce parasitic capacitance and signal delay in advanced semiconductor interconnects. Ultra-low-k dielectrics are essential enablers for sub-7 nm logic nodes, advanced memory, high-performance computing, and AI accelerators, where interconnect RC delay increasingly limits device performance and power efficiency.

The market is transitioning from dense SiO2 and conventional low-k materials…

Global and U.S. Quadruped Mobile Robots Market Report, Published by QY Research.

QY Research has released a comprehensive new market report on Quadruped Mobile Robots, are four-legged robotic systems designed to move and operate in complex, unstructured environments by mimicking the locomotion of animals. They use a combination of advanced sensors, actuators, AI algorithms, and real-time control systems to maintain balance, navigate uneven terrain, climb obstacles, and adapt to dynamic conditions. Because of their high stability and mobility, quadruped robots are widely…

Global and U.S. Industrial Edge Cloud Devices Market Report, Published by QY Res …

QY Research has released a comprehensive new market report on Industrial Edge Cloud Devices, ruggedized computing platforms that bring cloud-native processing, storage, and AI analytics directly to the industrial edge-close to machines, sensors, and control systems. By executing latency-sensitive workloads locally while synchronizing with central or public clouds, these devices enable real-time decision-making, improved reliability, and secure data governance across factories, utilities, energy assets, and transportation infrastructure. As Industry 4.0,…

Top 30 Indonesian Ceramic Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Arwana Citramulia Tbk (ARNA)

PT Cahayaputra Asa Keramik Tbk (CAKK)

PT Intikeramik Alamasri Industri Tbk (IKAI)

PT Keramika Indonesia Assosiasi Tbk (KIAS)

PT Mulia Industrindo Tbk (MLIA)

PT Asahimas Flat Glass Tbk (AMFG) (glass & ceramic-adjacent)

PT Niro Ceramic Nasional Indonesia

PT Eleganza Tile Indonesia

PT Roman Ceramic International

PT Platinum Ceramics Industry

PT Granito (Citra Granito)

PT Diamond Keramik Indonesia

PT Indogress (Inti Keramik Sejahtera)

PT Indopenta Sakti Teguh

PT Sun Power Ceramics

PT Satyaraya Keramindo Indah…

More Releases for Welding

Welding Consumables Market to Witness Unbelievable Growth from 2024 to 2030: Ged …

The latest survey on Welding Consumables Market is conducted to provide hidden gems performance analysis of Welding Consumables to better demonstrate competitive environment. The study is a mix of quantitative market stats and qualitative analytical information to uncover market size revenue breakdown by key business segments and end-use applications. The report bridges the historical data from 2019 to 2023 and forecasted till 2030. The outbreak of the latest scenario in…

EMEA Welding Consumables Market | welding supplies, welding machine, welding equ …

Market Research Reports Search Engine (MRRSE) has been serving as an active source to cater intelligent research report to enlighten both readers and investors. This research study titled “Welding Equipment and Welding Services Market “

The welding industry comprises welding equipment, welding consumables and welding services. Welding consumables account for a significant share of the welding industry compared to welding equipment and welding services. The welding consumables industry has been experiencing…

EMEA Welding Consumables Market | welding supplies, welding machine, welding equ …

Market Research Reports Search Engine (MRRSE) has been serving as an active source to cater intelligent research report to enlighten both readers and investors. This research study titled “Welding Equipment and Welding Services Market “

The welding industry comprises welding equipment, welding consumables and welding services. Welding consumables account for a significant share of the welding industry compared to welding equipment and welding services. The welding consumables industry has been experiencing…

Electric Welding Clamp Market 2018 Shandong Solid Solider, Shandong Juli Welding …

Global Electric Welding Clamp market 2018 by ReportsQuest presents a professional and complete analysis of on the current Industry situation. The Global report includes Electric Welding Clamp Revenue, market Share, industry volume, Trends, Growth aspects. It analyses the important factors of the based on present industry situations, demands, business strategies utilized by Electric Welding Clamp market players and the future prospects from various angles in detail. Industry analysis is a…

Global Welding Equipment Market: Arc welding, Resistant welding, Oxy fuel weldin …

MarketResearchReports.Biz adds “Global Welding Equipment Market 2016 Share, Size, Trends and Forecast to 2021 Market Research Report” reports to its database. This report provides a strategic analysis of the Welding Equipment market and the growth estimates for the forecasted period.

A comprehensive research report created through extensive primary research (inputs from industry experts, companies, stakeholders) and secondary research, the report aims to present the analysis of global welding equipment market on…

Global Welding Consumables Market 2017 - Lincoln Electric, Hyundai Welding, Colf …

Global Welding Consumables Market 2017, presents a professional and in-depth study on the current state of the Welding Consumables market globally, providing basic overview of Welding Consumables market including definitions, classifications, applications and industry chain structure, Welding Consumables Market report provides development policies and plans are discussed as well as manufacturing processes and cost structures. Welding Consumables market size, share and end users are analyzed as well as segment markets…