Press release

HPMC Capsule Manufacturing Plant Report 2025: Business Plan, Requirements and Cost Involved

HPMC (Hydroxypropyl Methylcellulose) capsules are plant-based, vegetarian alternatives to traditional gelatin capsules. Made from cellulose derived from wood or cotton, these capsules are free from animal-derived ingredients, making them suitable for vegans and individuals with dietary restrictions. HPMC capsules are widely used in the pharmaceutical and nutraceutical industries for encapsulating herbal supplements, vitamins, and other dietary formulations. They offer advantages such as improved stability, resistance to moisture, and compatibility with a wide range of active ingredients.Establishing an HPMC capsule manufacturing facility involves procuring raw materials like HPMC powder, water, and colorants. The process includes preparing the HPMC solution, dipping mold pins into the solution to form capsule bodies and caps, drying, and joining the two parts. The plant requires specialized equipment such as dipping tanks, drying ovens, and capsule joining machines. Compliance with Good Manufacturing Practices (GMP) and obtaining necessary certifications are essential for ensuring product quality and regulatory adherence.

Request for a Sample Report: https://www.imarcgroup.com/hpmc-capsule-manufacturing-plant-project-report/requestsample

IMARC Group's report, titled "HPMC Capsule Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a HPMC capsule manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

This comprehensive business plan outlines every critical step involved in setting up a HPMC capsule manufacturing plant successful unit - from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as HPMC capsule manufacturing plant setup, cost breakdown, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

HPMC Capsule Industry Outlook 2025:

The HPMC capsule market is experiencing steady growth due to rising consumer demand for vegetarian and gelatin-free capsules. Increasing preference for plant-based products, technological advancements in capsule manufacturing, and expanding applications in pharmaceuticals and nutraceuticals are key drivers. Growing awareness of clean-label products and health-conscious consumption further strengthens market potential, creating opportunities for new manufacturers and investors in the industry.

Key Insights for HPMC Capsule Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=14415&flag=C

Key Cost Components of Setting Up a HPMC Capsule Plant:

• Raw Material Costs: HPMC powder, water, colorants, and other excipients required for capsule production.

• Machinery & Equipment: Dipping tanks, drying ovens, capsule joining machines, polishing equipment, and quality inspection systems.

• Infrastructure & Utilities: Land or factory lease/purchase, plant construction, HVAC systems, water treatment units, and electricity supply.

• Technology & Software: Automation systems, process control software, and laboratory information management systems (LIMS).

• Labor Costs: Skilled technicians, machine operators, quality control personnel, and supervisory staff.

• Packaging & Labeling: Bottles, blister packs, cartons, labels, and sealing materials.

• Quality Control & Testing: Laboratory instruments for testing moisture content, capsule uniformity, dissolution, and contamination.

• Maintenance & Safety: Routine maintenance of machinery, waste management systems, and safety equipment for employees.

• Regulatory Compliance & Certification: GMP compliance, ISO certifications, and other regulatory approvals.

• Administrative & Overhead Expenses: Licensing, insurance, marketing, and general management costs.

Economic Trends Influencing HPMC Capsule Plant Setup Costs 2025:

• Raw Material Price Volatility: Fluctuations in the prices of HPMC, glycerin, and other excipients can impact overall production costs.

• Energy Costs: Rising electricity prices and the demand for renewable power sources increase operational expenses.

• Supply Chain Disruptions: Logistics challenges and material shortages affect procurement and lead times.

• Inflationary Pressures: Higher construction, labor, and equipment costs raise capital requirements.

• Technological Advancements: Adoption of automation and digitalization requires higher initial investment but reduces long-term operational costs.

• Regulatory Compliance Costs: Adhering to stringent quality and safety standards necessitates investment in compliance measures and certifications.

• Labor Market Dynamics: Availability and cost of skilled labor influence operational efficiency and wage expenses.

• Market Demand Fluctuations: Changes in consumer demand for vegetarian and vegan products affect production volumes and economies of scale.

• Currency Exchange Rates: Fluctuations in exchange rates impact the cost of imported raw materials and equipment.

• Environmental Sustainability Initiatives: Investments in eco-friendly manufacturing practices and waste management may increase costs but offer long-term benefits.

Challenges and Considerations for Investors in HPMC Capsule Plant Projects:

• High Initial Capital Investment: Significant funds required for machinery, automation systems, and plant infrastructure.

• Raw Material Dependence: Reliable supply of HPMC, glycerin, and excipients is crucial for uninterrupted production.

• Skilled Workforce Requirement: Need for trained technicians, operators, and quality control personnel.

• Regulatory Compliance: Adhering to GMP, ISO, and other pharmaceutical standards is mandatory.

• Quality Control Requirements: Ensuring consistent capsule size, moisture content, and dissolution rates requires strict monitoring.

• Technological Expertise: Advanced manufacturing and automation technologies are essential for efficiency and precision.

• Energy and Utility Costs: High electricity and water consumption for solution preparation, dipping, drying, and polishing.

• Market Competition: Growing number of domestic and international HPMC capsule manufacturers increases competitive pressure.

• Supply Chain Management: Efficient sourcing of raw materials and distribution of finished capsules is critical.

• Sustainability Expectations: Increasing demand for eco-friendly and clean-label production processes may require additional investment.

Buy Now:

https://www.imarcgroup.com/checkout?id=14415&method=1911

Conclusion:

Investing in an HPMC capsule manufacturing plant offers strong growth potential due to rising demand for vegetarian and gelatin-free capsules in pharmaceuticals and nutraceuticals. However, investors must carefully address challenges such as high capital investment, regulatory compliance, raw material sourcing, and skilled labor requirements. By leveraging modern technology, ensuring strict quality control, and adopting sustainable practices, HPMC capsule plants can achieve operational efficiency, meet market demand, and deliver long-term profitability.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release HPMC Capsule Manufacturing Plant Report 2025: Business Plan, Requirements and Cost Involved here

News-ID: 4227473 • Views: …

More Releases from IMARC Group

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

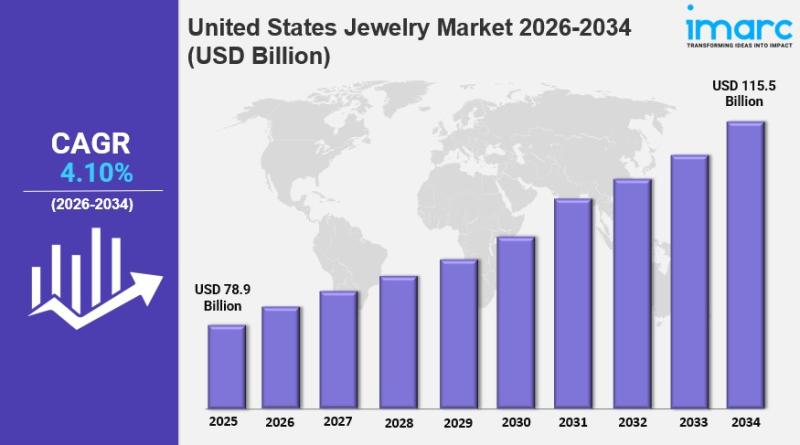

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

Saudi Arabia Pilates & Yoga Studios Market Size to Surpass USD 3.6 Billion by 20 …

Saudi Arabia Pilates & Yoga Studios Market Overview

Market Size in 2024: USD 1.6 Billion

Market Forecast in 2033: USD 3.6 Billion

Market Growth Rate 2025-2033: 8.20%

According to IMARC Group's latest research publication, "Saudi Arabia Pilates & Yoga Studios Market Size, Share, Trends and Forecast by Activity Type, Application, and Region, 2025-2033", the Saudi Arabia pilates & yoga studios market size reached USD 1.6 Billion in 2024. Looking forward, IMARC Group expects the…

More Releases for HPMC

The Rising Tide: HPMC Capsule Market Overview

In recent years, the pharmaceutical, nutraceutical, and supplement industries have seen a clear shift toward plant based, non animal derived dosage forms. Among these, hydroxypropyl methyl cellulose (HPMC) capsules have emerged as a leading non gelatin alternative, largely driven by growing consumer preferences for vegetarian/vegan products, stricter regulatory trends, and technical advantages of HPMC over traditional gelatin shells.

According to a market report by The Insight Partners, the global HPMC Capsule…

Hard HPMC Capsules Market: A Comprehensive Overview

The global Hard HPMC Capsules market was valued atapproximately USD 1.234 billion and is projected to reach USD 1.795 billion by 2030, reflecting a compound annual growth rate (CAGR) of 5.7% during the forecast period.

Hard HPMC Capsules Market Overview

Hard HPMC capsules, derived from plant-based cellulose, serve as an alternative to traditional gelatin capsules, catering to the growing demand for vegetarian and vegan pharmaceutical and nutraceutical products. The market's…

HPMC Capsules Market Size, Share, Growth 2031

HPMC Capsules Market Size was estimated at USD 563.4 million in 2021 and is projected to reach USD 940.8 million by 2028, exhibiting a CAGR of 7.6% during the forecast period.

The HPMC Capsules Market 2024 Report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It offers…

Hpmc Capsules Market Size, Future Trends

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲: HPMC Capsules Market is growing at a moderate pace with substantial growth rates over the last few years and is estimated that the market will grow significantly in the forecasted period i.e. 2020 to 2027.

Market Overview for Hpmc Capsules Market

Hpmc Capsules Market OverviewThe Hpmc capsules market has witnessed substantial growth in recent years, driven by their increasing adoption in pharmaceutical and nutraceutical industries. Hpmc capsules, made from…

Hydroxypropyl Methyl Cellulose (HPMC) Market 2023 | Detailed Report

The Hydroxypropyl Methyl Cellulose (HPMC) report compiles the market information depending upon market development and growth factors, optimizing the growth path. In addition, it highlights the strategies and market share of the leading vendors in the particular market. The report follows a robust research methodology model that helps to make informed decisions. It obtains both qualitative and quantitative market information supported by primary research.

The Hydroxypropyl Methyl Cellulose (HPMC) research report…

Latest Trends in HPMC Capsules Market 2020-2025

GLOBAL INFO RESEARCH�has recently published a research report titled, [Global HPMC Capsules Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2025] assessing various factors impacting its trajectory. Analysts have used primary and secondary research methodologies to determine the path of the market. The data includes historic and forecast values for a well-rounded understanding. The global HPMC Capsules�market is expected to augment in the forecast period owing to various…